Half axle gear inner spline carburizing and quenching method and carburizing and quenching equipment

A side gear, carburizing and quenching technology, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of internal spline deformation, internal spline twist, difficult to reach, etc., achieve uniform carburizing and quenching, and prevent distortion , Even cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

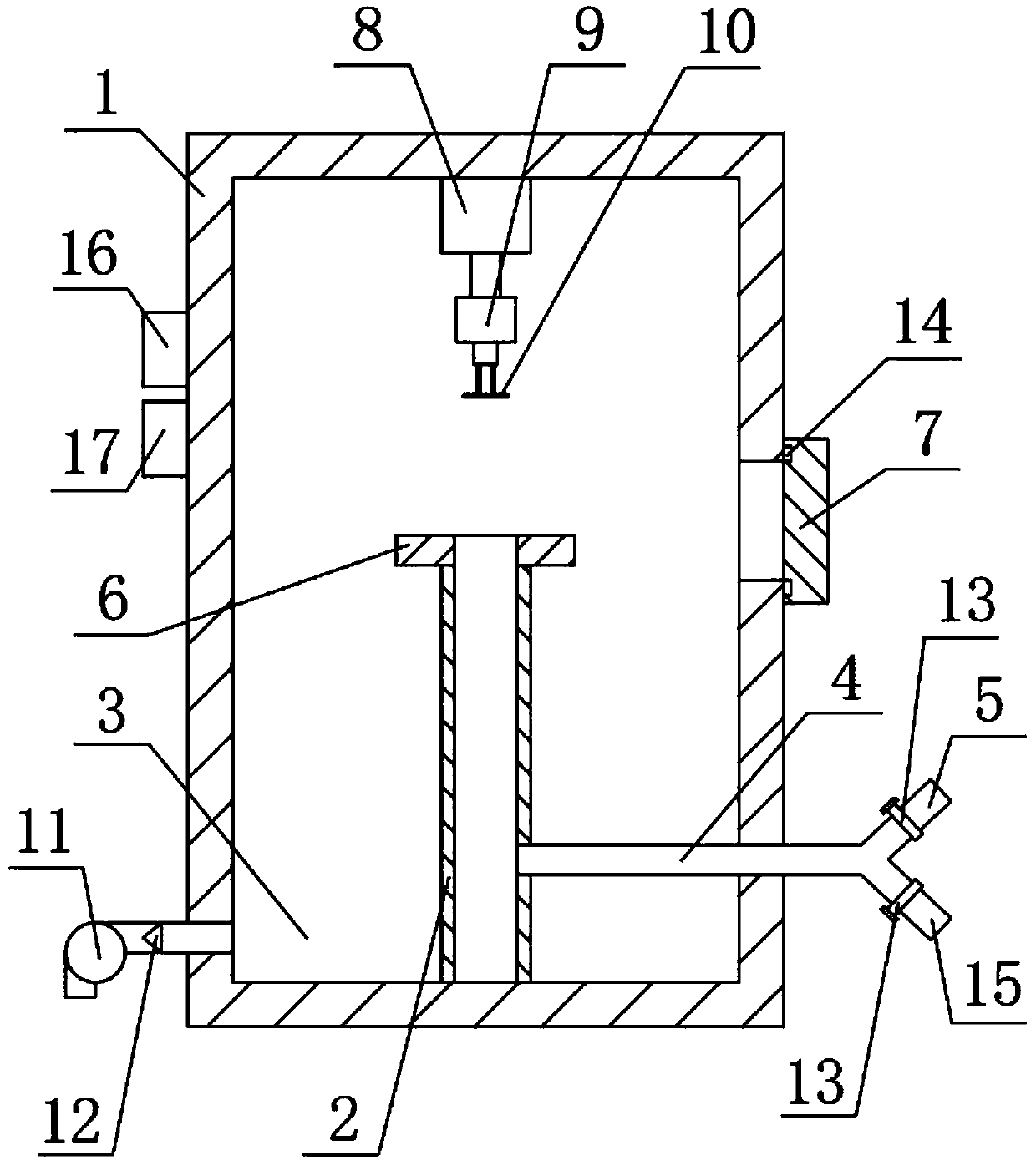

[0022] Example 1. A method for carburizing and quenching an internal spline of a side shaft gear, comprising the following steps:

[0023] a. Connect the compensating sleeve to the half-shaft part of the half-shaft gear to obtain product A; at this time, the thickness of both ends of the half-shaft gear is the same;

[0024] b. Put product A vertically into the top of the hollow column in the quenching furnace, and exhaust the quenching furnace until the pressure in the quenching furnace is 150-2000pa;

[0025] c. Set the resistance heating coil at the position of the inner spline in the middle of the side gear, and then energize the resistance heating coil to heat the inner spline on the side gear to 880-950°C;

[0026] d. Then pass through the hollow placement column from bottom to top with a flow rate of 0.08-0.15m 3 / h of propane, for 220 to 280 minutes, to obtain product D;

[0027] e. Then lower the temperature on the internal spline of the half shaft gear in product ...

Embodiment 2

[0033] Example 2. A method for carburizing and quenching an internal spline of a side gear, comprising a method for carburizing and quenching an internal spline of a side gear, comprising the following steps:

[0034] a. Connect the compensating sleeve to the half-shaft part of the half-shaft gear to obtain product A; at this time, the thickness of both ends of the half-shaft gear is the same;

[0035] b. Put product A vertically into the top of the hollow column in the quenching furnace, and exhaust the quenching furnace until the pressure in the quenching furnace is 1000pa;

[0036] c. Set the resistance heating coil at the position of the inner spline in the middle of the side gear, and then energize the resistance heating coil to heat the inner spline on the side gear to 900°C;

[0037] d. Then pass through the hollow placement column from bottom to top with a flow rate of 0.1m 3 / h of propane, continued 240min, to obtain D product;

[0038] e. Then lower the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com