Continuous casting mold flux for low-carbon steel, and preparation method thereof

A continuous casting mold slag and low-carbon steel technology, which is applied in the field of auxiliary materials for steelmaking and continuous casting, can solve problems such as unstable use process, large fluctuations in slag performance, and imperfect technology, so as to facilitate the separation of steel slag and reduce slag curling , Reduce the effect of slag inclusion defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

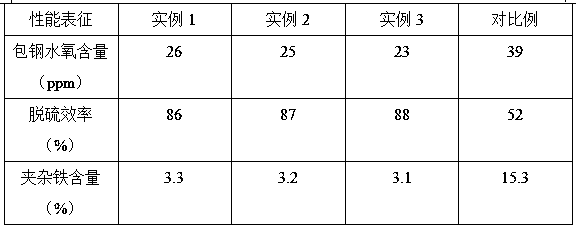

Examples

Embodiment Construction

[0019] According to the matrix composition CaO28.5~32.5%, SiO 2 32.0~36.5%, Al 2 o 3 5.0~15.0%, MgO2.5~3.0%, MnO2.0~7.5%, Fe 2 o 3 1.2~2.5%, Na 2 O4.5~7.0%, Li 2 O2.5 ~ 4.5%, F5.5 ~ 8.5% to configure raw materials, mix the raw materials for the matrix and granulate them, and place them in a water-cooled furnace wall electric furnace without lining at a temperature higher than the melting temperature of the mold slag 150 ~ 300 ° C Melt evenly in the medium to obtain pre-melted slag; import the pre-melted slag into a normal temperature water pool to cool and solidify, filter to obtain slag, dry the slag to a water content of 0.1-2.0%, put it into a grinder, and pass it through a 200-mesh sieve. Then add a reducing agent with a mass of 1.5-3.0% of the total material, and continue grinding for 1-2 hours to obtain a mixture; put the mixture into a ball mill, then add deionized water with a mass of 1.0-1.2 times the mass of the mixture, and use 200-300r / min ball milling for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com