Sealing gasket for hydraulic cylinder and preparation method thereof

A technology for gaskets and hydraulic cylinders, applied in the field of gaskets and their preparation, can solve the problems of hydraulic devices not working properly, unsatisfactory sealing performance, aging cracks, etc., and achieve the effects of not being easy to expand, improving oil resistance, and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

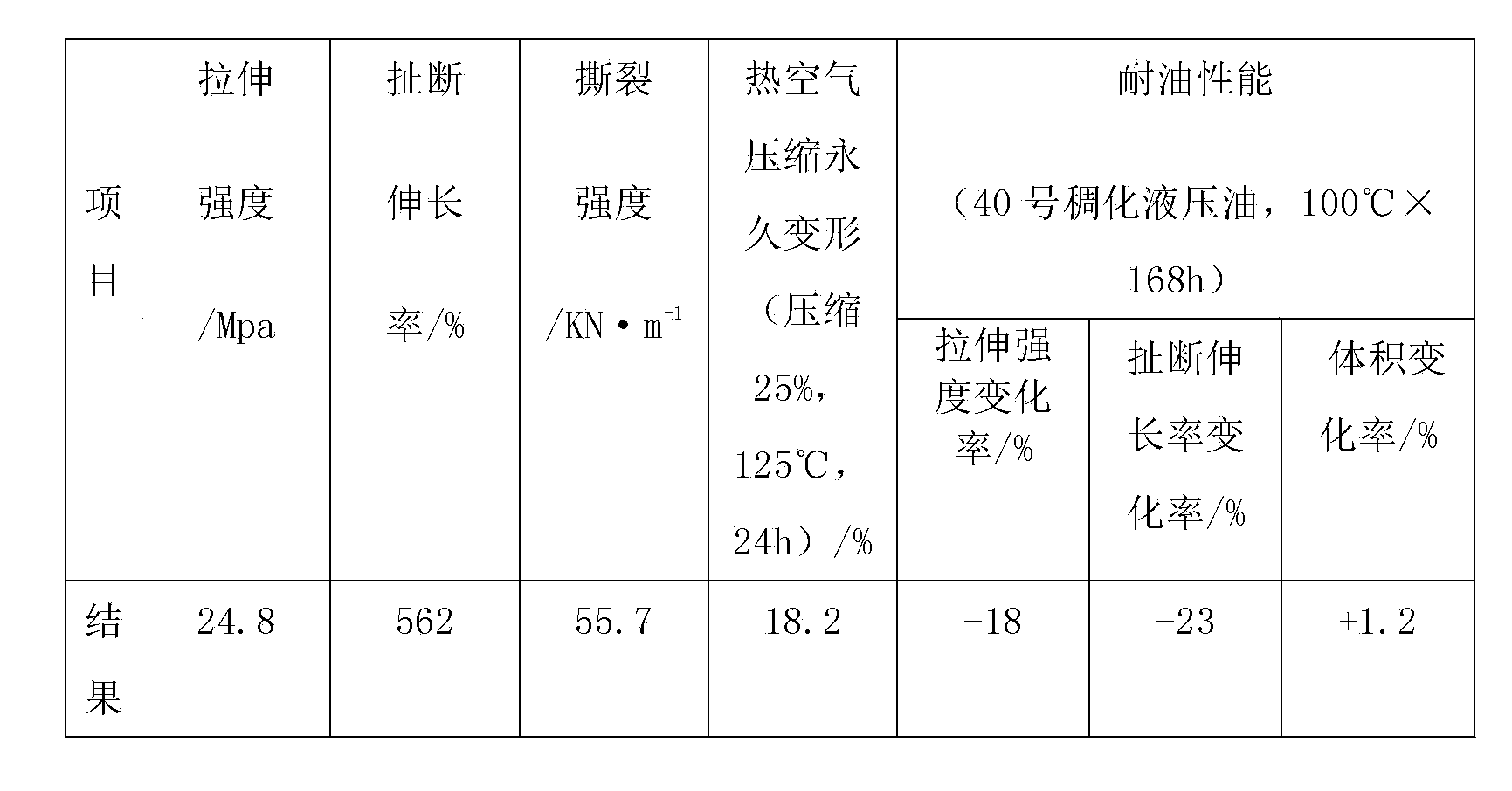

Examples

Embodiment Construction

[0013] A sealing gasket for a hydraulic cylinder, made of the following raw materials by weight (kg): nitrile rubber (CR322) 64, chlorohydrin rubber (H45) 165, POM 12, polyisobutylene 10, 2,4-dichloroperoxide Benzoyl 2, 2.2'-dibenzothiadisulfide 1.5, dioctyl sebacate 4, n-butyl methacrylate 5, microcrystalline paraffin 6, modified wollastonite 12, nano sepiolite 8, Calcium Sulfate Whiskers 6, Zinc Oxide 2, Magnesium Oxide 1.5, Carbon Black N339 15, Dimethyl Dithioglycolate Isooctyl Tin 1.5, Tetramethylthiuram Disulfide 2, Antiaging Agent OD 2, Antiaging Agent NBC 2 , Antioxidant 1010 2, Antioxidant 168 1.

[0014] The preparation method of described modified wollastonite is as follows:

[0015] a. Take the dried wollastonite and crush it to less than 15 μm, put it into a dispersion kettle, add deionized water three times the amount of wollastonite, and then add 3% sodium polyacrylate, 1.5% tricalcium phosphate, 2 % of cocoic acid monoethanolamide, 1% of rice husk ash, 3% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com