Chlorosulfonated polyethylene rubber/chloroprene rubber gasket and preparation method thereof

A technology of chlorosulfonated polyethylene and neoprene, applied in chemical instruments and methods, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc., can solve unsatisfactory sealing effect, poor wear resistance, and low strength And other problems, to achieve excellent results, good wear resistance, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

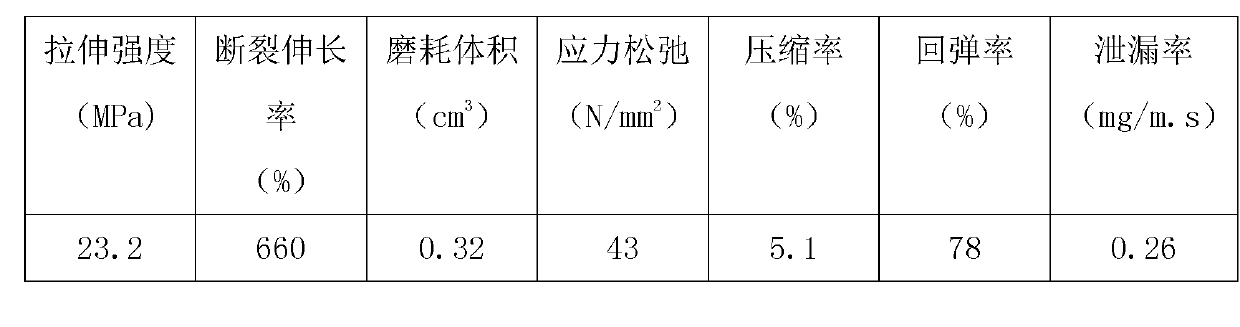

Image

Examples

Embodiment

[0015] A chlorosulfonated polyethylene rubber / chloroprene rubber gasket, which is composed of 140 parts by weight of chlorosulfonated polyethylene rubber CSM2305, 15 parts of neoprene S40V, 10 parts of SG-2 PVC resin, and 3 parts of propylene glycol polyester diacid, 4 parts of n-butyl methacrylate, 2 parts of sodium bicarbonate, 0.8 parts of sulfur, 1.6 parts of calcium stearate, 1.8 parts of isooctyl tin dimethyl dimercaptoacetate, nano Azure 52 parts of stone powder, 44 parts of nano silica, 1.8 parts of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, 1.5 parts of antioxidant 1035, 3 parts of 3-aminopropyltrimethoxysilane, Dicumyl peroxide DCP 1 part, accelerator CZ 1.5 parts, accelerator CBS 1 part, accelerator Na-22 0.15 parts, antioxidant ODA 1.5 parts, antioxidant RD 1.5 parts, modified tree ash 2 parts.

[0016] Wherein, the modified tree ash is prepared by the following method: first soak the tree ash with 12% hydrogen peroxide for 3 hours, then wash it with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com