Polymer lithium ion secondary battery and isolating membrane thereof

A secondary battery, lithium ion technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve the problem of affecting the cycle performance of lithium ion secondary batteries, increasing the irreversible capacity loss of battery cycles, Battery combustion and other problems, to avoid irreversible capacity loss or failure to work properly, good mechanical tensile strength, good cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

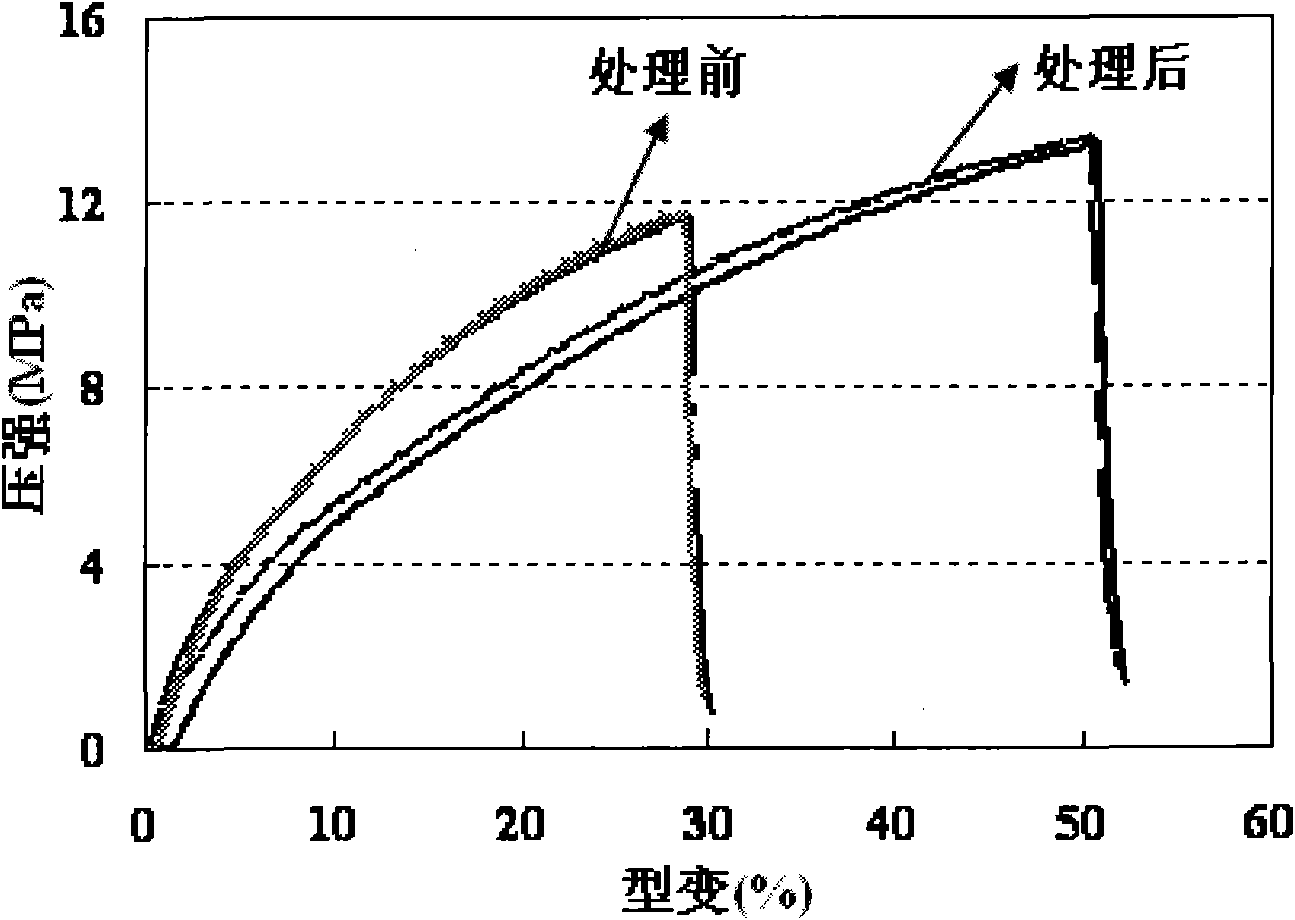

[0025] Preparation of isolation membrane: Take the untreated porous substrate multilayer composite polyethylene and polypropylene microporous membrane (isolation membrane before treatment) as a control.

[0026] Preparation of polymer lithium-ion secondary battery: the cathode sheet containing lithium cobalt oxide as the cathode active material, the above separator, and the anode sheet containing artificial graphite as the anode active material are wound into a battery core, and the separator is separated from the adjacent cathode, Between the anode sheets, the cathode is led out by aluminum tab spot welding, and the anode is drawn out by nickel tab spot welding; then, the battery cell is mixed with lithium salt lithium hexafluorophosphate and non-aqueous solvent ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate The composed electrolyte is packaged in a packaging case to make a polymer lithium ion secondary battery. Example 1

Embodiment 1

[0027] Preparation of the isolation film: Dissolve the polymer poly(methyl methacrylate-vinyl acetate) in acetone solvent at 25 °C to obtain a solution with a solid content of 2%; then, the solution is processed by printing on the porous The substrate is multilayered with polyethylene and polypropylene microporous membranes on one surface to obtain a single-sided treated polymer barrier membrane.

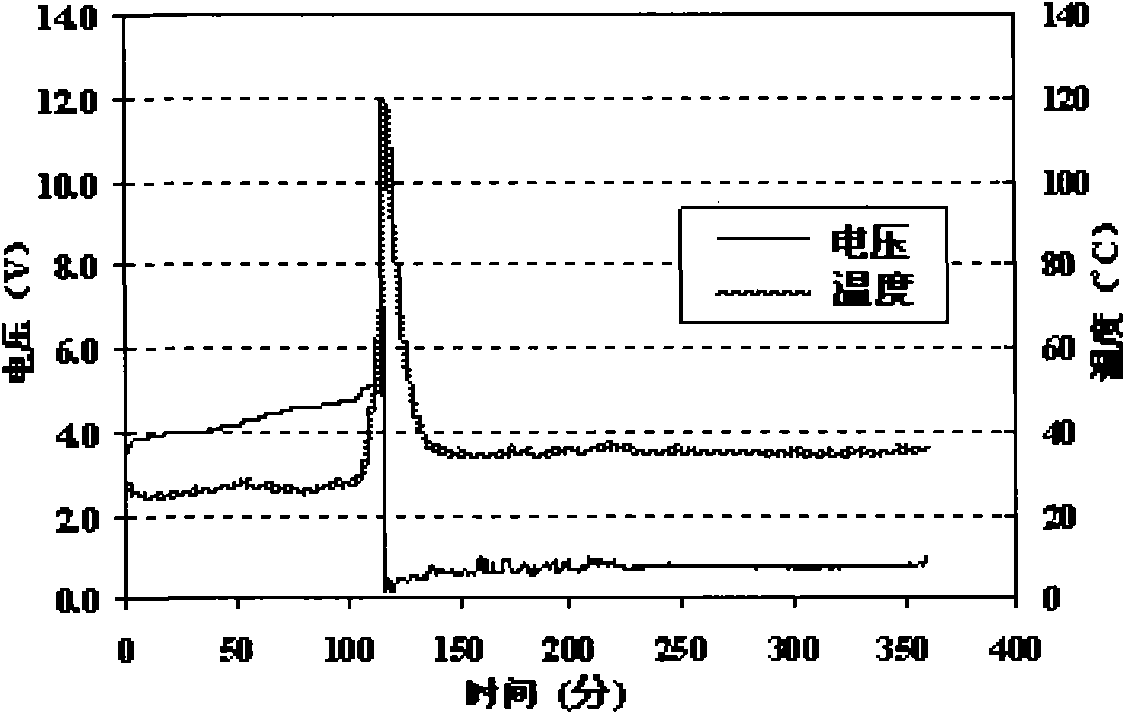

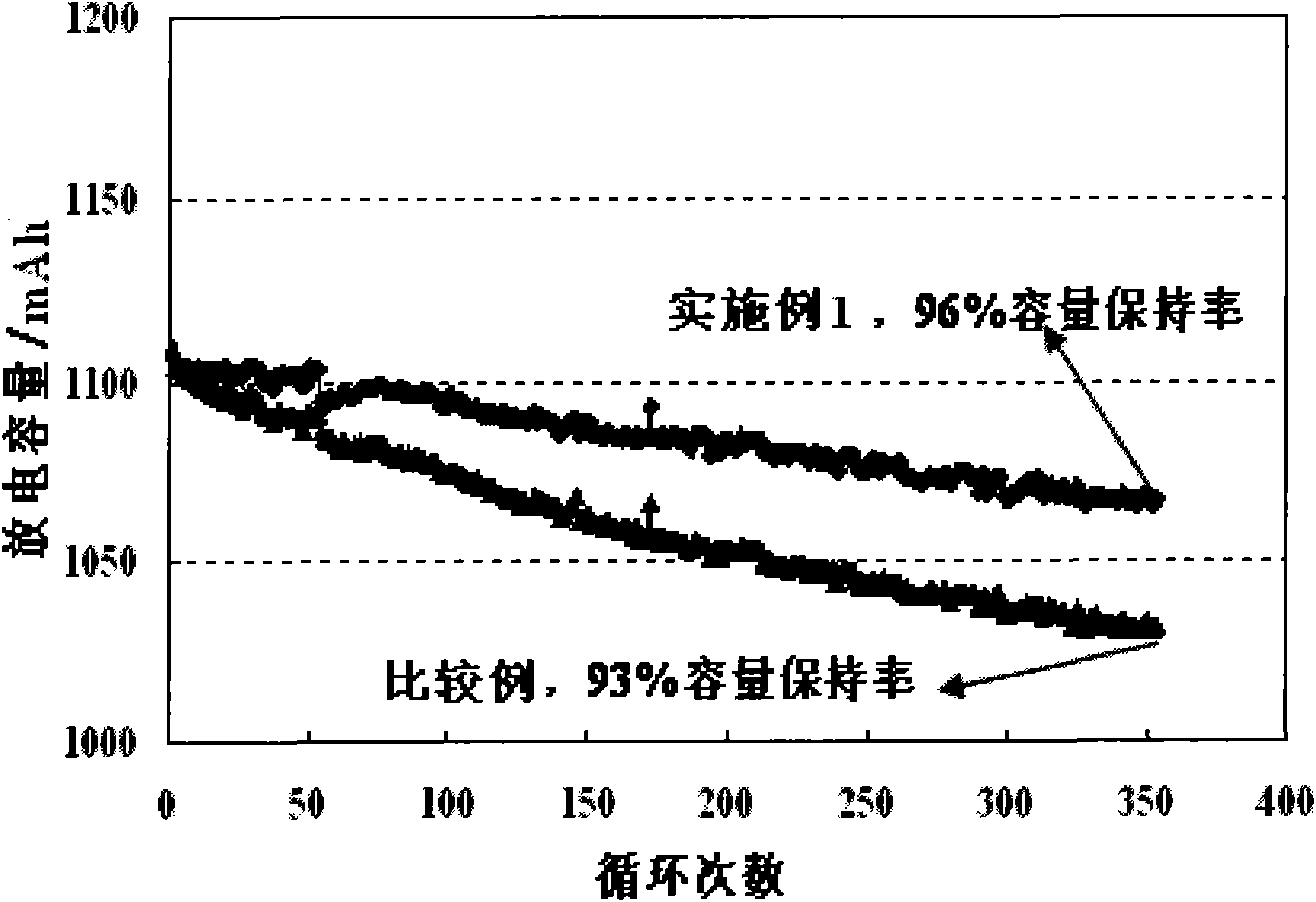

[0028] Preparation of polymer lithium ion secondary battery: the cathode sheet containing the cathode active material lithium cobaltate, the single-side treated polymer separator prepared according to the above method, and the anode sheet containing the anode active material artificial graphite are wound into an electric battery. The core, the separator is spaced between the adjacent cathode and anode sheets, the single-sided processed polymer separator is in direct contact with the anode sheet, the cathode is led out by spot welding of aluminum tabs, and the anode is drawn out by sp...

Embodiment 2

[0032] Preparation of isolation membrane: Dissolve the polymer poly(methyl methacrylate-acrylonitrile) in acetone solvent at 35 °C to obtain a solution with a solid content of 3%; then, the solution is treated by coating method on the porous On one surface of the substrate a polypropylene microporous membrane, a single-side treated polymer barrier membrane is obtained.

[0033] Preparation of a polymer lithium ion secondary battery: the cathode sheet containing the cathode active material nickel cobalt lithium manganese oxide, the single-sided treated polymer separator prepared according to the above method, and the anode containing the anode active material mesophase carbon microspheres The sheet is wound into a cell, the separator is spaced between the adjacent cathode and anode sheets, the single-sided treated polymer separator is in direct contact with the anode sheet, the cathode is led out by spot welding of aluminum tabs, and the anode is led out by nickel tabs. Then, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com