Ceramic separator and lithium ion battery

A ceramic diaphragm and diaphragm technology, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve problems such as low flash point, poor charging and discharging performance of batteries with high current, and potential safety hazards, and achieve high Effects of specific surface area, improvement of cycle life and rate performance, and improvement of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

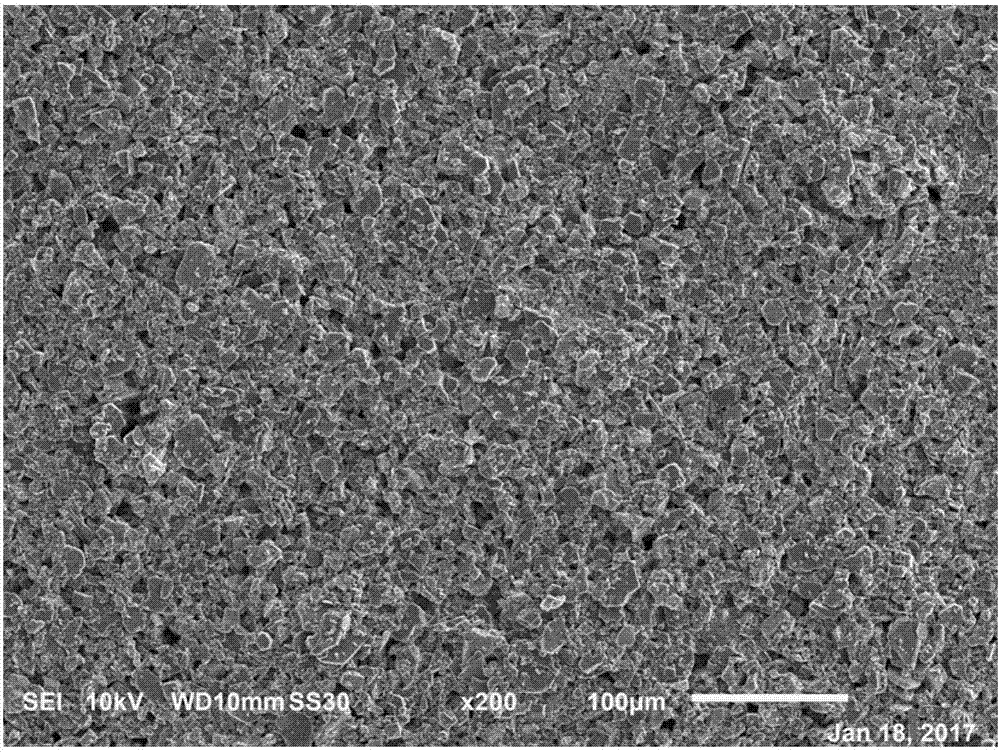

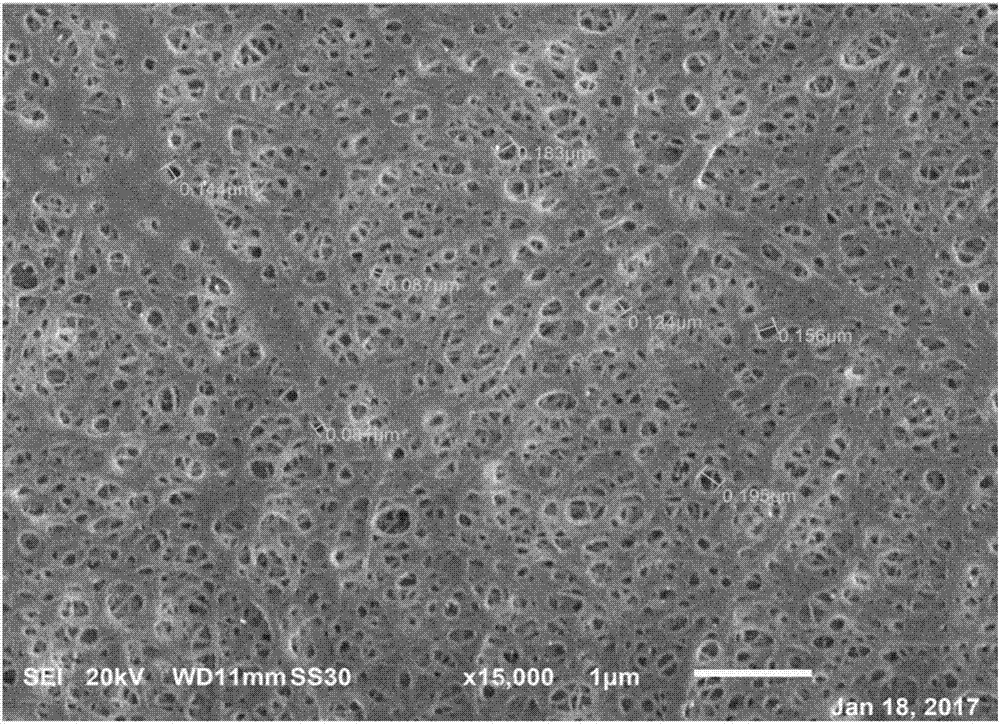

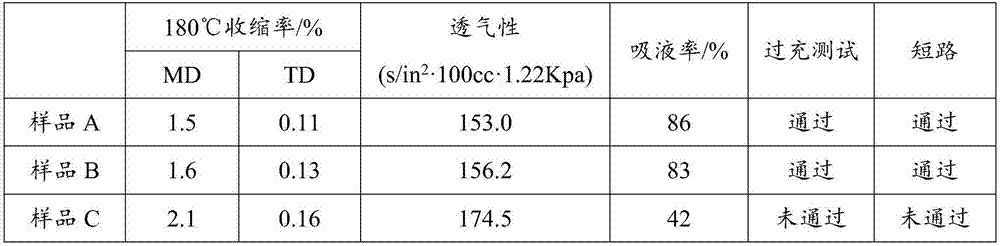

[0026] will have a hollow spherical SiO 2, aluminum hydroxide and polyvinylidene fluoride are added to N-methylpyrrolidone according to the mass ratio of 70:25:5, and a uniform ceramic slurry is formed after ball milling for a period of time. The surface on both sides of a 10 μm polyethylene monolayer film is dried to obtain a ceramic separator with a protective layer thickness of 1 μm, marked as sample A.

Embodiment 2

[0028] will have a hollow tubular SiO 2 , aluminum hydroxide and polyvinylidene fluoride are added to N-methylpyrrolidone according to the mass ratio of 70:25:5, and a uniform ceramic slurry is formed after ball milling for a period of time. The surface on both sides of a 10 μm polyethylene monolayer film is dried to obtain a ceramic separator with a protective layer thickness of 1 μm, marked as sample B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com