A kind of preparation method of hexamethylenediamine

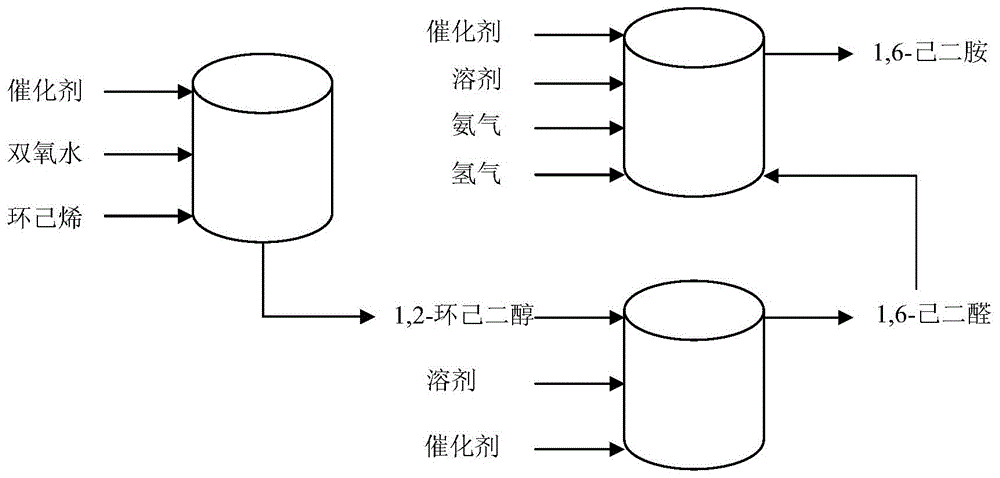

A technology of hexamethylenediamine and cyclohexanediol, which is applied in the field of preparation of hexamethylenediamine, can solve the problems of complex technology, patent technology transfer fees, high one-time construction investment, and large safety risks, and achieve easy-to-obtain reaction media, The production process is green and has obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

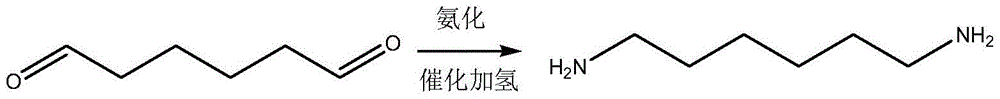

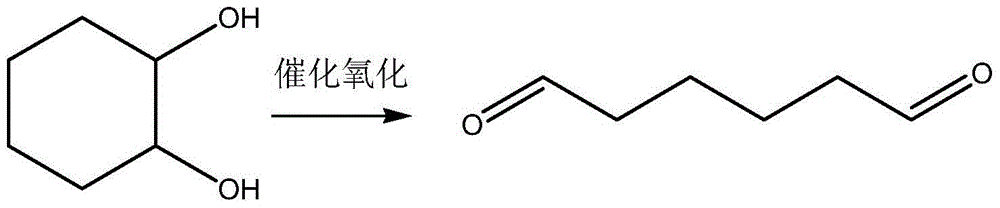

Method used

Image

Examples

Embodiment 1

[0044] Preparation of 1-hexadecyl-3-methylimidazolium decapolytungstate quaternary ammonium salt: Weigh 33.03g of sodium tungstate into a beaker filled with 100mL of water to dissolve, stir magnetically at 60°C, and use 3mol / L hydrochloric acid to adjust its pH value to about 2, then slowly add dropwise a 10mL ethanol solution containing 15.51g of 1-hexadecyl-3-methylimidazolium bromide after heating up to 90°C, and the solution immediately appears white turbid. After the dropwise addition, the reaction was continued at 90°C for 0.5h. After the reaction, the white or light yellow solid was obtained by filtration, washed with water and ethanol, and dried in vacuum.

[0045] Preparation of 1,2-cyclohexanediol: At room temperature, add 1.05g of 1-hexadecyl-3-methylimidazole decapolytungstate quaternary ammonium salt catalyst, 1.05g of phosphoric acid and 20.51g of Cyclohexene was stirred vigorously, and 34.01 g of 30% hydrogen peroxide was slowly added dropwise. At the same time...

Embodiment 2-12

[0051] Except that the corresponding conditions in Example 1 were replaced by the experimental conditions in the following table, the reaction was basically carried out according to the same reaction conditions as in Example 1. The yield data obtained are shown in Table 1.

[0052] Table I

[0053]

[0054] Wherein, in the process of preparing 1,2-cyclohexanediol, catalyst A is the same as that described in the first paragraph of Example 1, using 1-hexadecyl-3-methylimidazolium bromide to prepare 1 -hexadecyl-3-methylimidazole decapolytungstate quaternary ammonium salt; Catalyst B is to replace the 1-hexadecyl-3-methylimidazolium bromide in Example 1 with butyl trimethyl deca Polytungstic acid bromide is prepared as raw material; catalyst C is to replace 1-hexadecyl-3-methylimidazolium bromide in Example 1 with N-hexadecylpyridine decapolytungstate bromide as raw material prepared.

[0055] According to the above examples, it can be seen that the industrialized 1,6-hexan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com