A kind of comprehensive recovery method of bismuth matte

A recovery method, the technology of bismuth matte copper, is applied in the improvement of process efficiency, photography technology, instruments and other directions, which can solve the problems of low processing capacity, incomplete oxidation of copper sulfide, large consumption of high-value reagents, etc., so as to increase the content of SO2 , the effect of maintaining temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

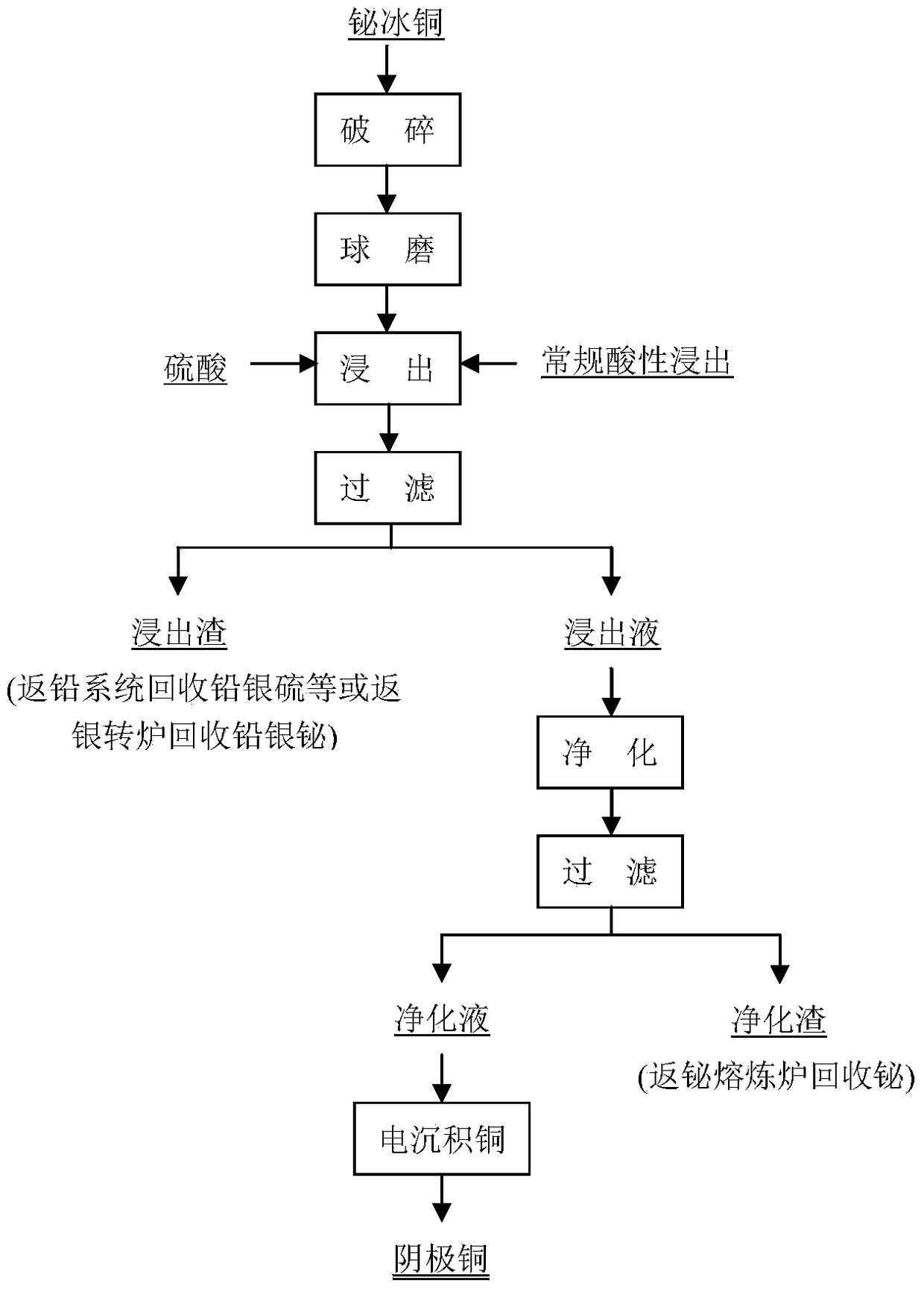

Method used

Image

Examples

preparation example Construction

[0043] In the specific preparation process, preferably, in step A, the particle size of the bismuth matte powder is more than 80% smaller than -80 mesh.

[0044] In step B, the leaching of bismuth matte is carried out in a sulfuric acid system under the condition that an oxidizing atmosphere exists and an activator exists; ℃, the leaching time is 10 to 24 hours, wherein, the oxidizing atmosphere condition refers to adding manganese dioxide or hydrogen peroxide slowly during the leaching process of bismuth matte, or passing oxygen or air into the leaching solution, adding oxidants to reduce production Cost and increase the leaching rate of metals such as copper and iron are prerequisites. The presence of an activator refers to the addition of activator ferric sulfate, ferrous sulfate, ferric nitrate or recycling of activator Fe in the sulfuric acid leaching process. 3+ Either way in the sulfuric acid leaching solution, control the leaching end point, Fe in the leaching solutio...

Embodiment 1

[0052] The present invention is tried out on the production device that handles 500 tons of bismuth matte annually, and its concrete production process is:

[0053] Step A, bismuth matte crushing step: the mass percentage concentration is: Cu 20.15%, Fe5.45%, S12.37%, Pb 19.84%, Sb 0.3%, Ag 1.15%, Bi 3%, As 0.5%, Zn The 0.4% bismuth matte block material is crushed on a crusher, and then ball milled on a ball mill to obtain a bismuth matte powder with a particle size of 80% less than -80 mesh;

[0054] Step B, sulfuric acid leaching step: add the bismuth matte powder obtained in step A into the sulfuric acid mixed solution containing ferric sulfate at a temperature of 90°C (wherein the sulfuric acid mixed solution includes water+ferric sulfate+sulfuric acid), and carry out secondary sulfuric acid For leaching, concentrated sulfuric acid leaching is carried out first, the liquid-solid ratio of the sulfuric acid mixture and bismuth matte is controlled at 2:1, and the concentrated...

Embodiment 2

[0059] The present invention is tried out on the production device that handles 5,000 tons of bismuth matte annually, and its concrete production process is:

[0060] Step A, bismuth matte crushing step: the mass percent concentration is: Cu 30.52%, Fe 6.18%, S17.20%, Pb 20.53%, Sb 0.5%, Ag 2.57%, Bi 4.19%, As 0.73%, Zn 0.62 % of the bismuth matte block material is crushed on the crusher, and then ball milled on the ball mill to obtain a bismuth matte powder with a particle size of 85% less than -80 mesh;

[0061] Step B, sulfuric acid leaching step: adding the bismuth matte powder obtained in step A to a sulfuric acid mixture with a temperature of 94° C. and adding ferric nitrate (wherein the sulfuric acid mixture includes copper electrolysis waste liquid + water + ferric nitrate + sulfuric acid ), carry out sulfuric acid secondary leaching, first carry out concentrated sulfuric acid leaching, the liquid-solid ratio of described sulfuric acid mixed solution and bismuth matte ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com