Method and device for selective leaching of valuable elements from slag

A valuable element and selective technology, applied in the direction of improving process efficiency, can solve the problem of low leaching rate of valuable elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

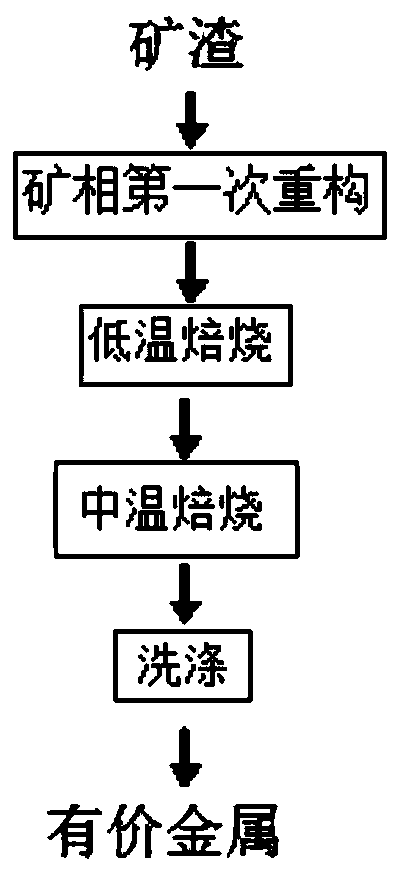

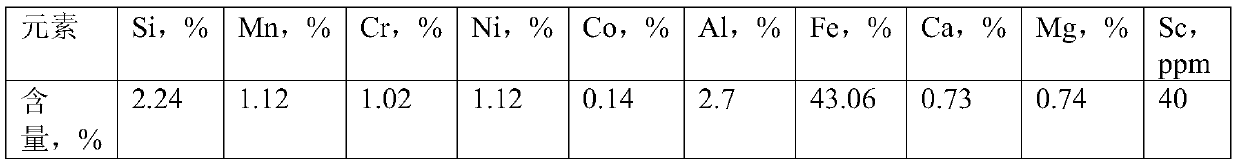

[0070] use as figure 1 The process shown in the process recovers scandium, and mixes the dry laterite ore with the first mineral phase reconstruction agent (sulfuric acid) and water in a ratio of 1g:0.6g:0.5mL to obtain a reconstructed mineral salt.

[0071] With reconstituted mineral acid salt and the second ore phase reconstituted agent (0.1mol / L Na 2 SO 4 solution) at a ratio of 1g:1mL, mix the reconstituted mineral acid salt with the second mineral phase reconstituter, then raise it from room temperature to 500°C at 10°C / min, and keep the temperature constant for 0.5h to carry out the second refactoring process. Then the low-temperature calcined product was raised from 550°C to 730°C, and calcined at 730°C for 2 hours to perform the third reconstruction to obtain a medium-temperature calcined product. After the calcination is completed, it is cooled to below 300°C with the furnace to obtain a medium-temperature calcination product.

[0072] According to the solid-to-li...

Embodiment 2

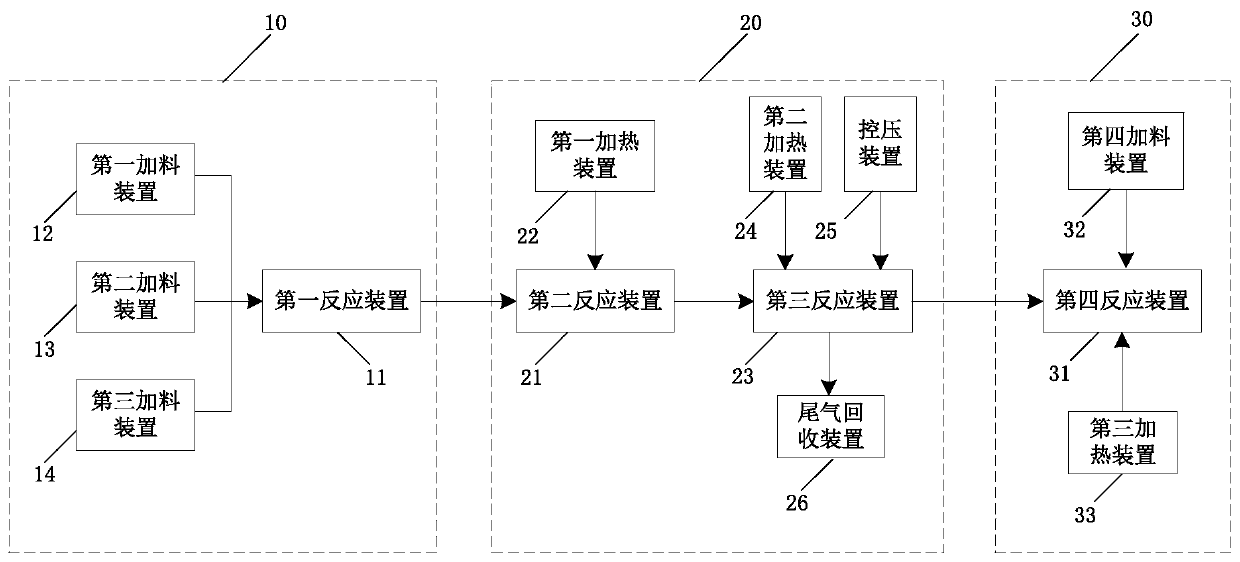

[0074] use as figure 2 The shown technological process recovers scandium element, mixes laterite ore with the second ore phase reconstruction agent in a ratio of 1g:0.4mL to obtain an intermediate product, wherein the second ore phase reconstruction agent is Na 2 SO 4 and KCl in a weight ratio of 1:1, and the concentration is 2mol / L. Add the first mineral phase reconstruction agent to the above intermediate product, and add 0.5mL of the first mineral phase reconstruction agent per gram of laterite to obtain the mineral phase reconstruction product, wherein the first mineral phase reconstruction agent is 18mol / L of sulfuric acid.

[0075] At a heating rate of 5°C / min, it was aged from room temperature to 150°C for 30 minutes, then continued to heat up to 500°C, and fired at 500°C for 1 hour to obtain a low-temperature calcined product. The heating process is mainly to reconstruct the ore phase of laterite ore for the second time.

[0076] The low-temperature roasted produc...

Embodiment 3

[0079] The difference from Example 1 is that the temperature of the medium-temperature roasting process is 400°C.

[0080] The leaching rate of rare earth scandium element is 84wt%, the leaching rate of iron element is 2.20wt%, the leaching rate of chromium element is less than 1wt%, the leaching rate of silicon element is less than 0.5wt%, and the leaching rate of aluminum element is less than 35wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com