Comprehensive recovery method for valuable metal in copper-cadmium slag

A valuable metal and recovery method technology, applied in the improvement of process efficiency, photography technology, instruments and other directions, can solve the problems of increasing extraction and separation technology, incomplete separation, low recovery rate, etc., to strengthen the acid leaching process and shorten the leaching process. time, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

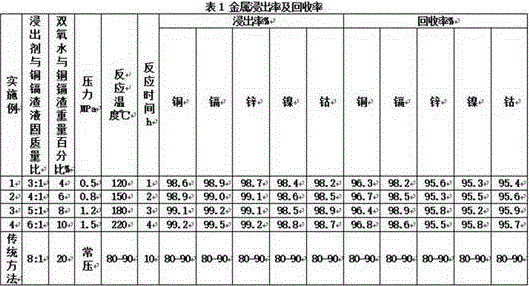

Embodiment 1

[0060] (1) After mixing the copper and cadmium slag with sulfuric acid solution, add it to the reaction kettle, control the temperature at 120℃, add the oxidant hydrogen peroxide, adjust the pressure to 0.5MPa, react for 1h and discharge, and separate the solid and liquid to obtain Cu, Zn, Cd , Ni, Co, Fe acid leaching solution, the leaching rate of the acid leaching solution Cu, Zn, Cd, Ni, Co all reach more than 98%; the concentration of the sulfuric acid solution is 200g / L; the added amount of hydrogen peroxide 4% of the weight of the copper-cadmium slag; the liquid-solid mass ratio of the copper-cadmium slag and the sulfuric acid solution is 3:1;

[0061] (2) The Cu, Zn, Cd, Ni, Co, Fe acid leaching solution obtained in step (1) is subjected to copper extraction and separation and recovery, and copper extraction agent is used to extract and separate copper under certain extraction conditions to obtain copper extraction liquid And copper-containing organic phase; the copper-co...

Embodiment 2

[0067] (1) After mixing the copper and cadmium slag with sulfuric acid solution, add it to the reactor, control the temperature at 150℃, add the oxidant hydrogen peroxide, adjust the pressure to 0.8MPa, react for 2h, discharge, and separate the solid and liquid to obtain Cu, Zn, Cd , Ni, Co, Fe acid leaching solution, the leaching rate of the acid leaching solution Cu, Zn, Cd, Ni, Co all reach more than 98%; the concentration of the sulfuric acid solution is 150g / L; the added amount of hydrogen peroxide It is 6% of the weight of the copper cadmium slag; the liquid-solid mass ratio of the copper cadmium slag and the sulfuric acid solution is 4:1;

[0068] (2) The Cu, Zn, Cd, Ni, Co, Fe acid leaching solution obtained in step (1) is subjected to copper extraction and separation and recovery, and copper extraction agent is used to extract and separate copper under certain extraction conditions to obtain copper extraction liquid And copper-containing organic phase; the copper-contain...

Embodiment 3

[0074] (1) After mixing the copper and cadmium slag with sulfuric acid solution, add it to the reaction kettle, control the temperature at 180℃, add the oxidant hydrogen peroxide, adjust the pressure to 1.2MPa, react for 3h and discharge, after solid-liquid separation, to obtain Cu, Zn, Cd , Ni, Co, Fe acid leaching solution, the leaching rate of the acid leaching solution Cu, Zn, Cd, Ni, Co is above 98%; the concentration of the sulfuric acid solution is 100g / L; the added amount of hydrogen peroxide 8% of the weight of the copper-cadmium slag; the liquid-solid mass ratio of the copper-cadmium slag and the sulfuric acid solution is 5:1;

[0075] (2) The Cu, Zn, Cd, Ni, Co, Fe acid leaching solution obtained in step (1) is subjected to copper extraction and separation and recovery, and copper extraction agent is used to extract and separate copper under certain extraction conditions to obtain copper extraction liquid And copper-containing organic phase; the copper-containing organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com