Leftward and rightward double-bending type numerical-controlled pipe bending machine

A pipe bending machine and pipe bending technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems affecting the quality of pipe bending, unstable pipe bending devices, and inability to configure swing arm clamping mechanisms, etc., to achieve Improve the quality, improve the efficiency of pipe bending, and ensure the effect of power consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

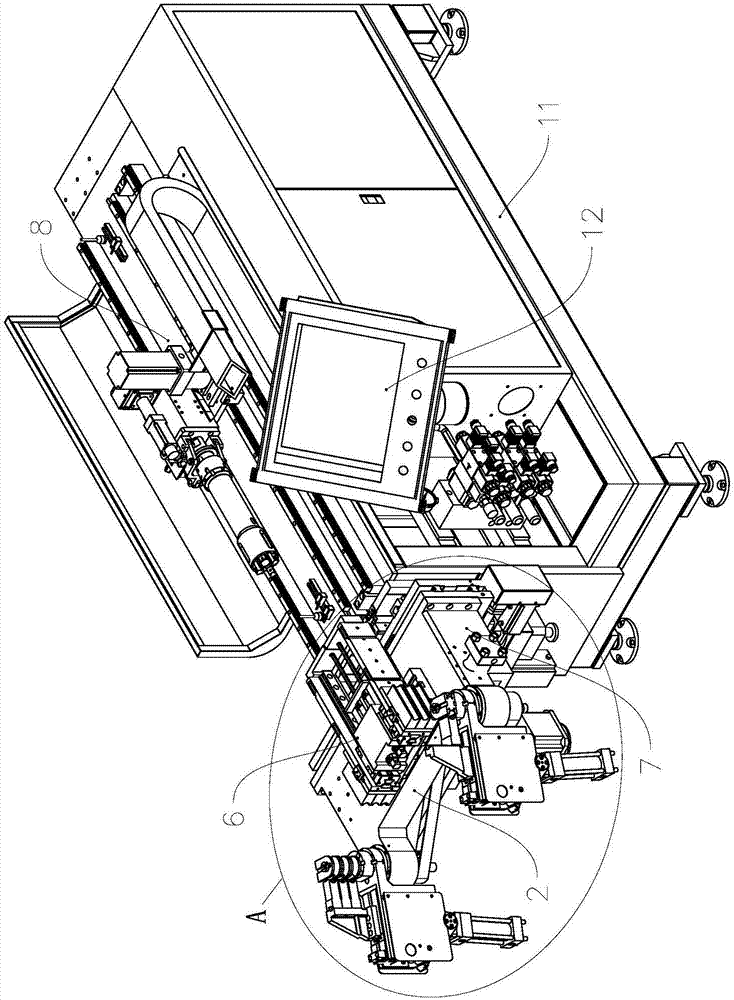

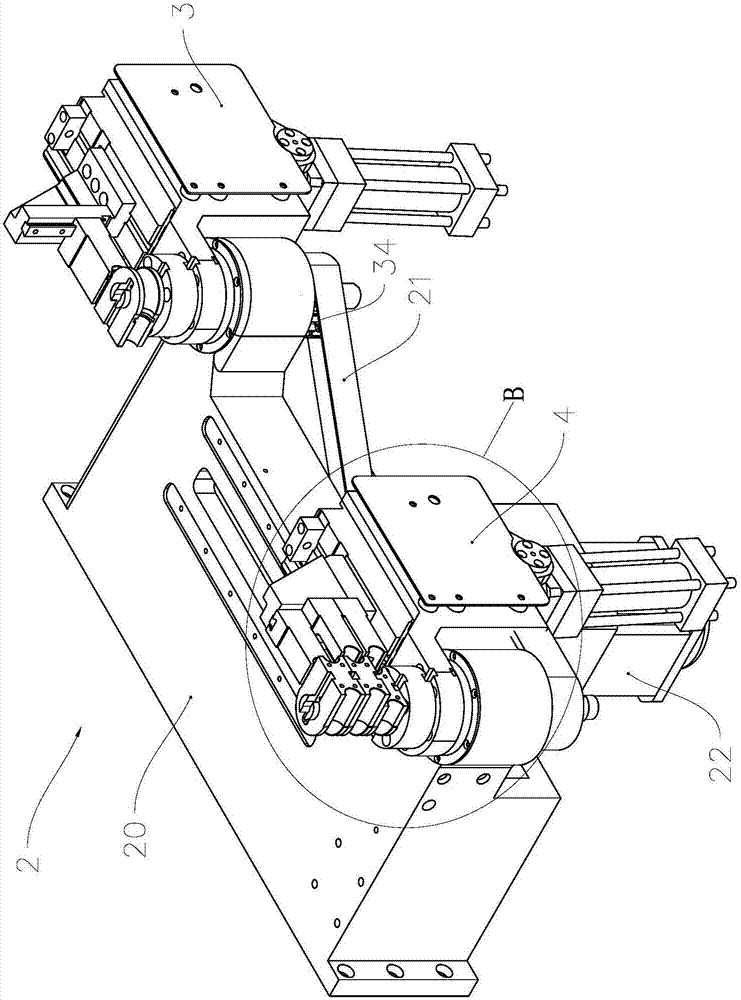

[0031] see figure 1 and figure 2 , the CNC pipe bending machine 1 includes a frame 11, a control unit, and a pipe bending device and a feeding trolley 8 that are installed on the frame 11 and controlled by the control unit; wherein, the pipe bending device includes a machine head 2 and a mold guide unit 6 And die changing unit 7. In the following description of the specific structure, the pipe fitting to be bent is a pipe fitting clamped on the feeding spindle of the feeding trolley 8. In this embodiment, since the feeding spindle is arranged along the horizontal direction, the axial direction of the pipe fitting to be bent is Arranged horizontally.

[0032] In this embodiment, the control unit includes a processor, a memory, and a touch control panel 12. The processor receives input instructions from the operator through the touch control panel 12, and simultaneously controls the pipe bending device and the material feeding by executing a computer program stored in the mem...

Embodiment 2

[0062]As a description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below, that is, only the structure of the clamping mold assembly will be described.

[0063] see Figure 9 and Figure 10 , clamping mold assembly 9 comprises clamping mold base 93, the clamping mold (not shown) that is installed on the mounting surface 930 of clamping mold base 93, the clamping mold adjusting screw 920 that is rotatably installed on the swing arm 92, And be located at the clamping mold driving mechanism between swing arm 92 and clamping mold seat 93. The mold clamping drive mechanism includes a booster rocker 941 , a booster link 942 , a lever 943 and an actuator 95 .

[0064] Actuator 95 is an oil cylinder, and its oil cylinder rod 951 constitutes the mover of actuator 95, and cylinder body 952 constitutes the stator of actuator 95, and cylinder body 952 is hinged on the swing arm 92 by hinge shaft 953, and lever 943 is the booste...

Embodiment 3

[0072] As an explanation of Embodiment 3 of the present invention, only the differences from Embodiment 2 above will be described below.

[0073] see Figure 12 , by hinged more than one guide swing rod 964 on the mounting base to replace the arc-shaped chute in the above-mentioned embodiment 2, that is, hinged to the swing arm through the hinge shaft 965, and the swing end of the guide swing rod 964 passes through the hinge shaft 966 and Clamping base 96 is hinged, guides fork 964 and lever 963 and maintains parallel arrangement in swing process, and the resistance arm equal length of its length and lever 963. That is, the swing track of the swing end of the guiding swing rod 964 constitutes an arc-shaped guide rail for the movement of the mold clamping base 96 relative to the mounting base.

[0074] In order to make the guide swing link 964 form a substantially planar swing surface when swinging, to improve the stability of the clamping mold driving, it can be realized by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com