One-component solvent-free polyurethane adhesive and preparation method thereof and raw material composition

A technology of solvent-free polyurethane and raw material composition, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of long gel time, poor initial adhesion, high viscosity, etc., and achieve production High efficiency, convenient use and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

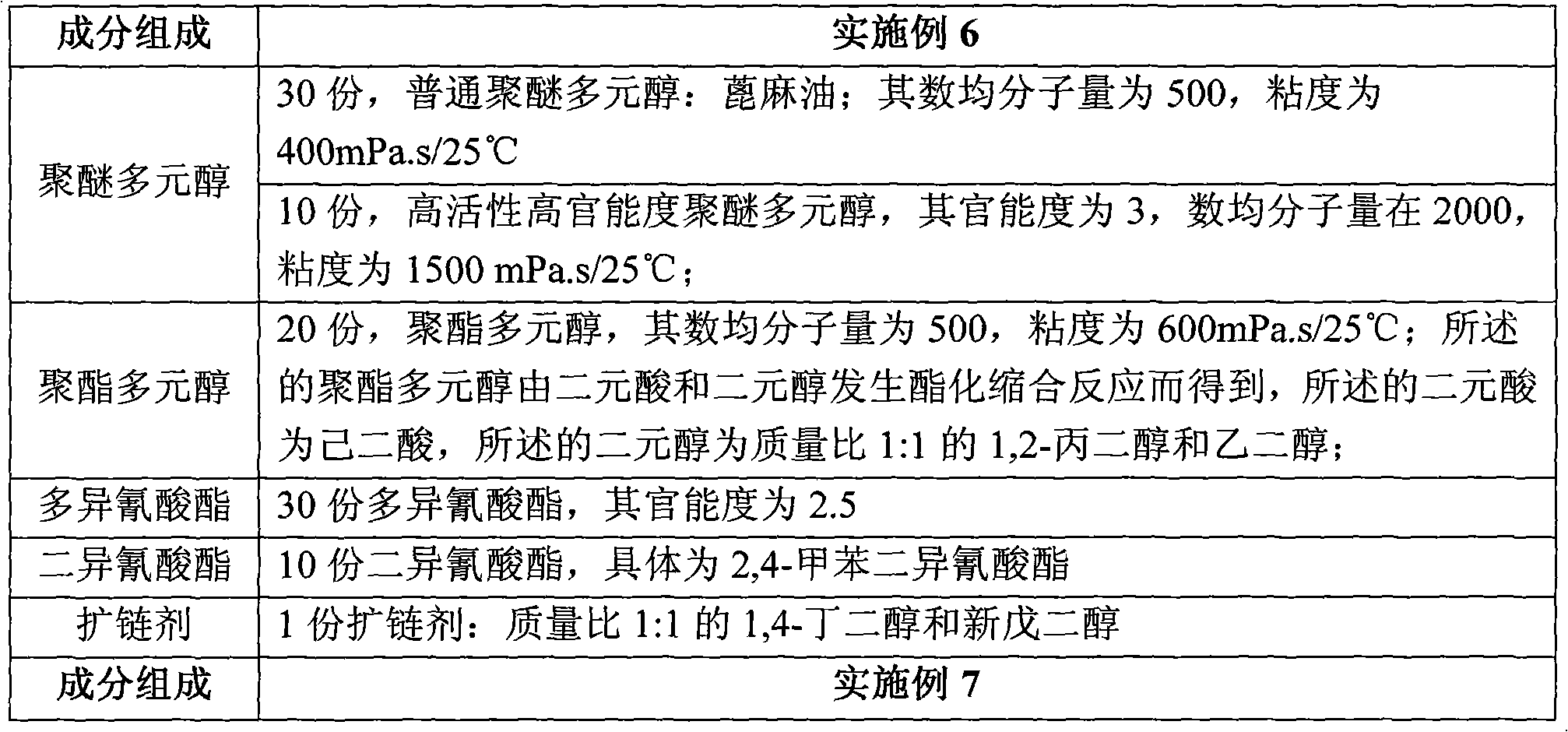

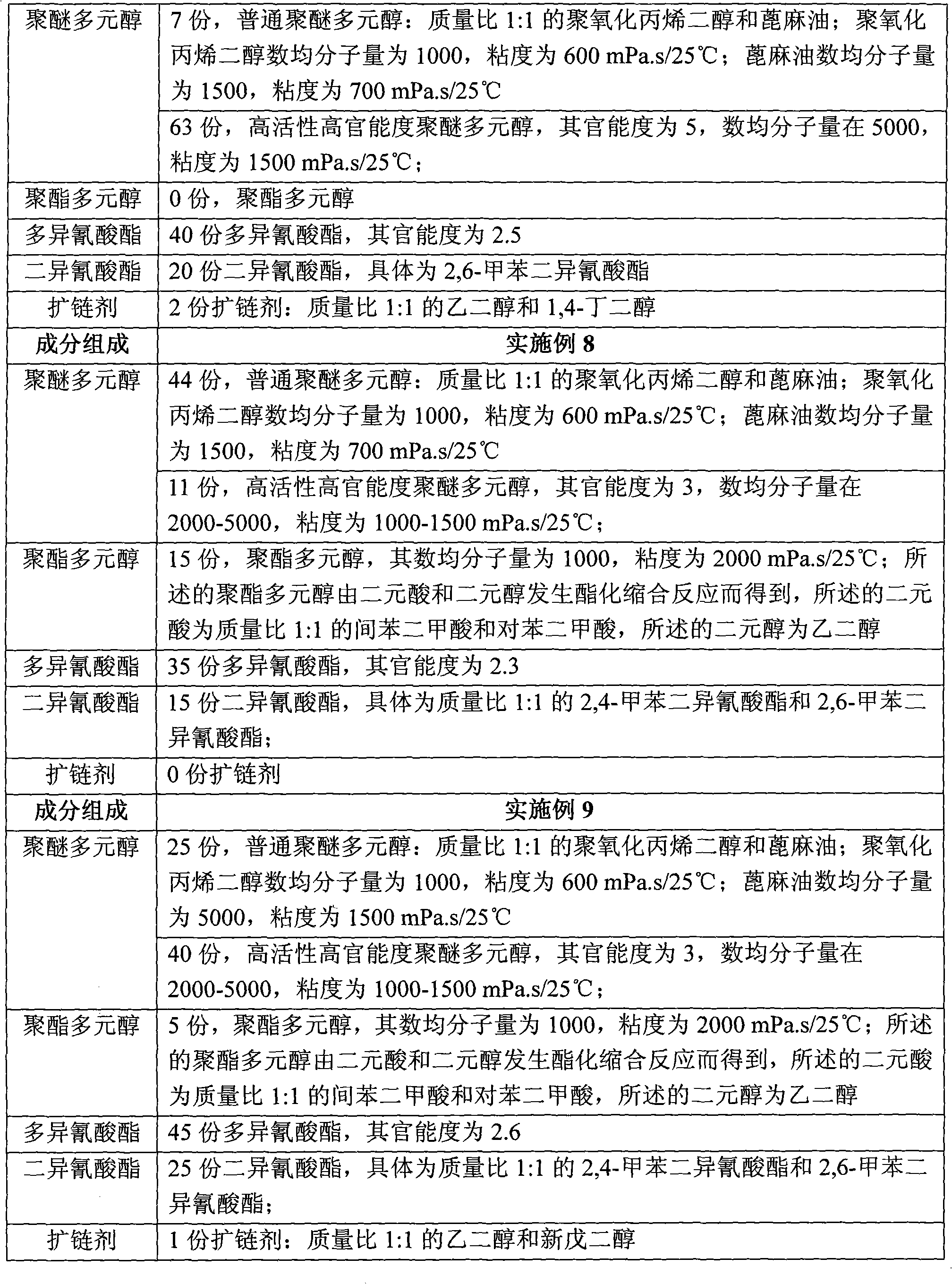

Embodiment 1

[0026] A raw material composition of a one-component solvent-free polyurethane adhesive, which contains components in the following proportions: highly active and high-functionality polyether polyol MPO: polyoxypropylene diol 220: polyester polyol PE1: expanded The mass ratio of chain agent ethylene glycol: polyisocyanate VKS: diisocyanate 44C: diisocyanate M-50 is 30:30:5:1:40:10:10.

[0027] Among them, the high-activity high-functionality polyether polyol MPO has a functionality of 4, a number-average molecular weight of 4,000, and a viscosity of 1,000 mPa.s / 25°C; the number-average molecular weight of polyoxypropylene glycol 220 is 2,000, and a viscosity of 800 mPa. s / 25℃; Polyester polyol PE1 is obtained by the condensation reaction of adipic acid, isophthalic acid, 1,2-propylene glycol, and 1,4-butanediol. Its number-average molecular weight is 1000 and its viscosity is 1600mPa.s / 25°C; polyisocyanate VKS functionality is 2.7, NCO content is 32%; diisocyanate 44C is diph...

Embodiment 2

[0032] A raw material composition of a one-component solvent-free polyurethane adhesive, which contains components in the following proportions: highly reactive high-functionality polyether polyol MPO: polyoxypropylene triol 330N: chain extender ethylene glycol: The mass ratio of polyisocyanate 9258C: diisocyanate 44C: toluene diisocyanate TDI is 40:15:2:50:5:10.

[0033] Among them, polyoxypropylene triol 330N is hydroxyethyl polyoxypropylene triol, its number average molecular weight is 5000, viscosity is 1200mPa.s / 25°C; polyisocyanate 9258C functionality is 2.3, NCO content is 31.5%; the rest With embodiment 1.

[0034] The raw material composition of the one-component solvent-free polyurethane adhesive of this embodiment is a multi-component suit form in which each component is independent or each component is divided into several groups, wherein, isocyanate and polyether polyol and / or polyester polyol are not coexist in the same component.

[0035] The specific preparat...

Embodiment 3

[0038] A raw material composition of a one-component solvent-free polyurethane adhesive, which contains components in the following proportions: highly reactive high-functionality polyether polyol MPO: polyoxypropylene diol 220: polyester polyol PE1: poly The mass ratio of isocyanate VKS: diisocyanate 44C: diisocyanate M-50 is 50:10:20:30:10:20. Above-mentioned each component composition is with preceding embodiment.

[0039] The raw material composition of the one-component solvent-free polyurethane adhesive of this embodiment is a multi-component suit form in which each component is independent or each component is divided into several groups, wherein, isocyanate and polyether polyol and / or polyester polyol are not coexist in the same component.

[0040] The specific preparation method of the one-component solvent-free polyurethane adhesive in this example is the same as that in Example 1. The NCO content of the obtained product was tested to be 15.5±1%, and the viscosity w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com