Preparation method of novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion

A water-based acrylic acid and biological matrix technology, applied in the coating and other directions, can solve the problems of application field and raw material cost limitation, complicated and complicated process, etc., and achieve the effects of widely adjustable film forming temperature and hardness, renewable raw materials and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

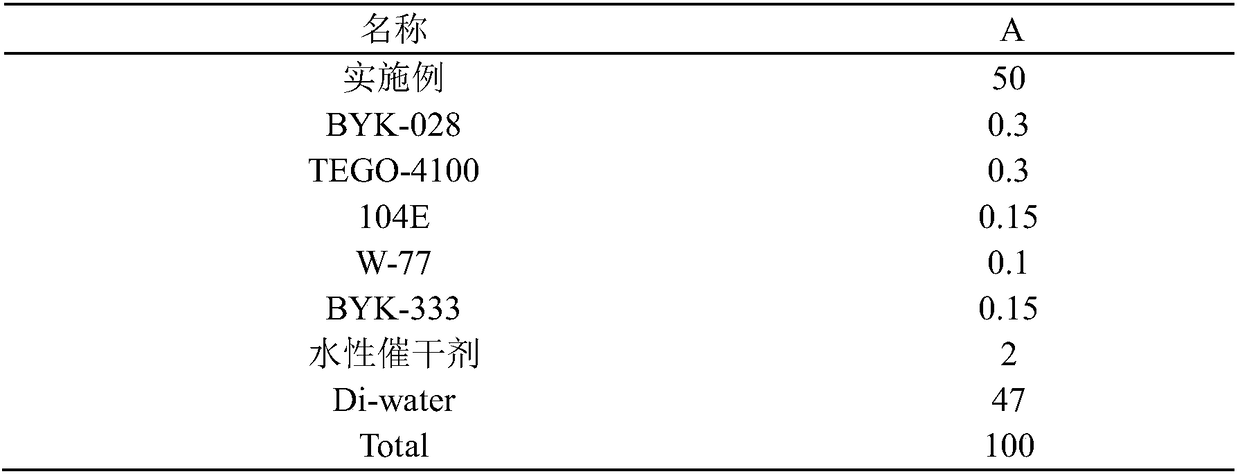

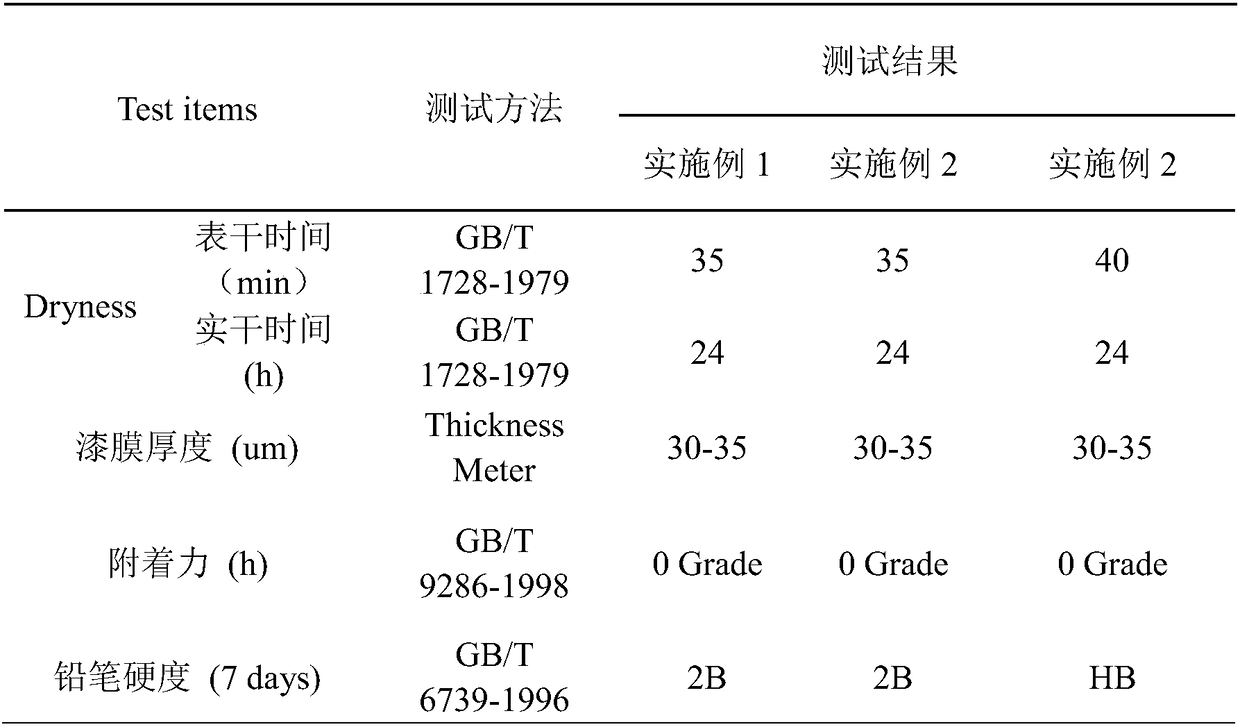

Examples

Embodiment 1

[0036] Add 60 parts of dehydrated castor oil, 3 parts of neopentyl glycol, 1.4 parts of diethylene glycol, 6 parts of trimethylolpropane, 8 parts of pentaerythritol, rapidly increase the temperature to 160°C, slowly increase the temperature from 160°C to 200°C, at 200 Incubate until the acid value is less than 5, obtain the required intermediate, cool down to 160 ℃, add 4 parts of adipic acid, 4 parts of maleic anhydride, 7 parts of terephthalic acid, 4 parts of isophthalic acid-5-sulfonic acid Sodium, 4 parts of trimellitic anhydride, heated to 180 ° C, refluxed for 1 hour, then cooled to 160 ° C, added 6 parts of xylene for dehydration reaction, and then heated to 220 ° C at a speed of 10 ° C / min, and in this Incubate at the temperature and measure the acid value until the acid value reaches 77 mg KOH / g. The reflux solvent was removed by vacuuming again, and then the temperature was lowered to 85° C., 11.5 parts of N,N-dimethylethanolamine were added, and 106.5 parts of deio...

Embodiment 2

[0039] Add 20 parts of dehydrated castor oil, 25 parts of soybean oil, 20 parts of tall oil, 2 parts of glycerol, 4 parts of neopentyl glycol, 4 parts of trimethylolpropane, 4.5 parts of pentaerythritol, rapidly heated to 140 ° C, and then Slowly heat up from 140°C to 210°C, keep the temperature at 210°C until the acid value is less than 5 to obtain the desired intermediate, cool down to 140°C, add 3.5 parts of adipic acid, 4.5 parts of maleic anhydride, 3 parts of terephthalic acid , 6 parts of isophthalic acid-5-sodium sulfonate, 3.5 parts of trimellitic anhydride, heated to 180°C, refluxed for 1 hour, then cooled to 120°C, added 6 parts of xylene for dehydration reaction, and then heated to 10°C / The temperature was increased to 220 °C at a speed of min, and the temperature was maintained at this temperature, and the acid value was measured until the acid value reached 103 mg KOH / g. The reflux solvent was removed by vacuuming again, and then the temperature was lowered to 8...

Embodiment 3

[0042] Add 25 parts of dehydrated castor oil, 20 parts of rosin acid, 13 parts of tall oil, 14 parts of Perstorp P1000, 8 parts of pentaerythritol, quickly heat up to 150°C, then slowly heat up from 150°C to 200°C, and keep at 200°C until the acid value less than 5, obtain the required intermediate, cool down to 150 ℃, add 3 parts of phthalic anhydride, 3 parts of maleic anhydride, 5 parts of isophthalic acid-5-sodium sulfonate, 9 parts of trimellitic anhydride, Heat up to 180°C, reflux for 1 hour, then cool down to 150°C, add 6 parts of xylene for dehydration reaction, then heat up to 230°C at a speed of 10°C / min, and keep warm at this temperature, measure the acid value, until the acid value is The price reaches 100mg KOH / g. The reflux solvent was removed by vacuuming again, and then the temperature was lowered to 80° C., 12 parts of ammonia water were added, and 116.9 parts of deionized water were added to obtain a 35% solid content aqueous solution.

[0043] Cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com