Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

A technology for animal and vegetable oils and aviation fuels, which is applied in the fields of biofuels, air transportation, biological raw materials, etc., can solve the technical and economic performance of the catalytic hydrogenation of oils and fats needs to be improved, the cost of raw materials and hydrogen production is high, and by-products are difficult to efficiently utilize, etc. problems, to achieve the effect of improving the overall technical and economic performance, reducing operating costs, and avoiding poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

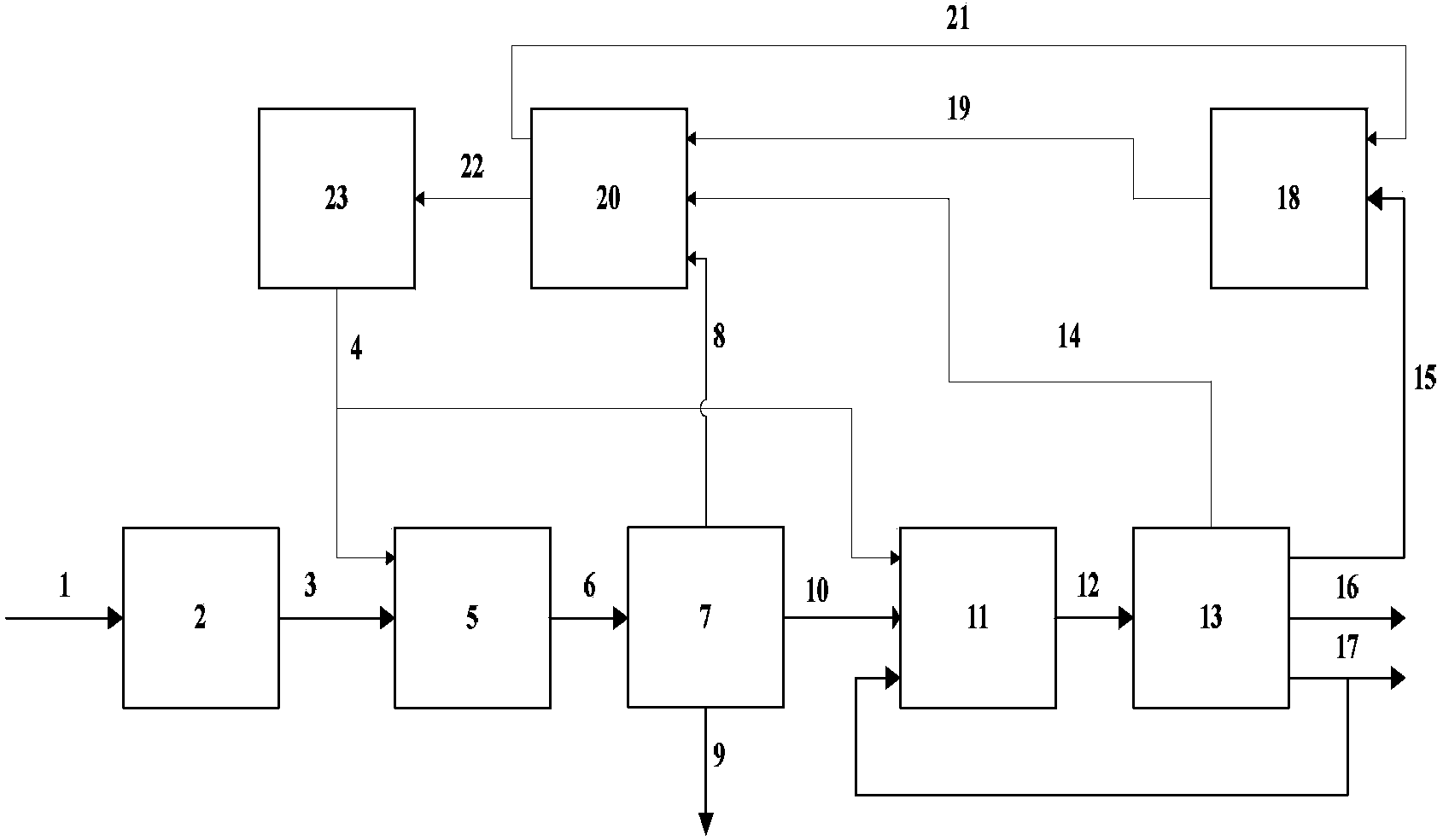

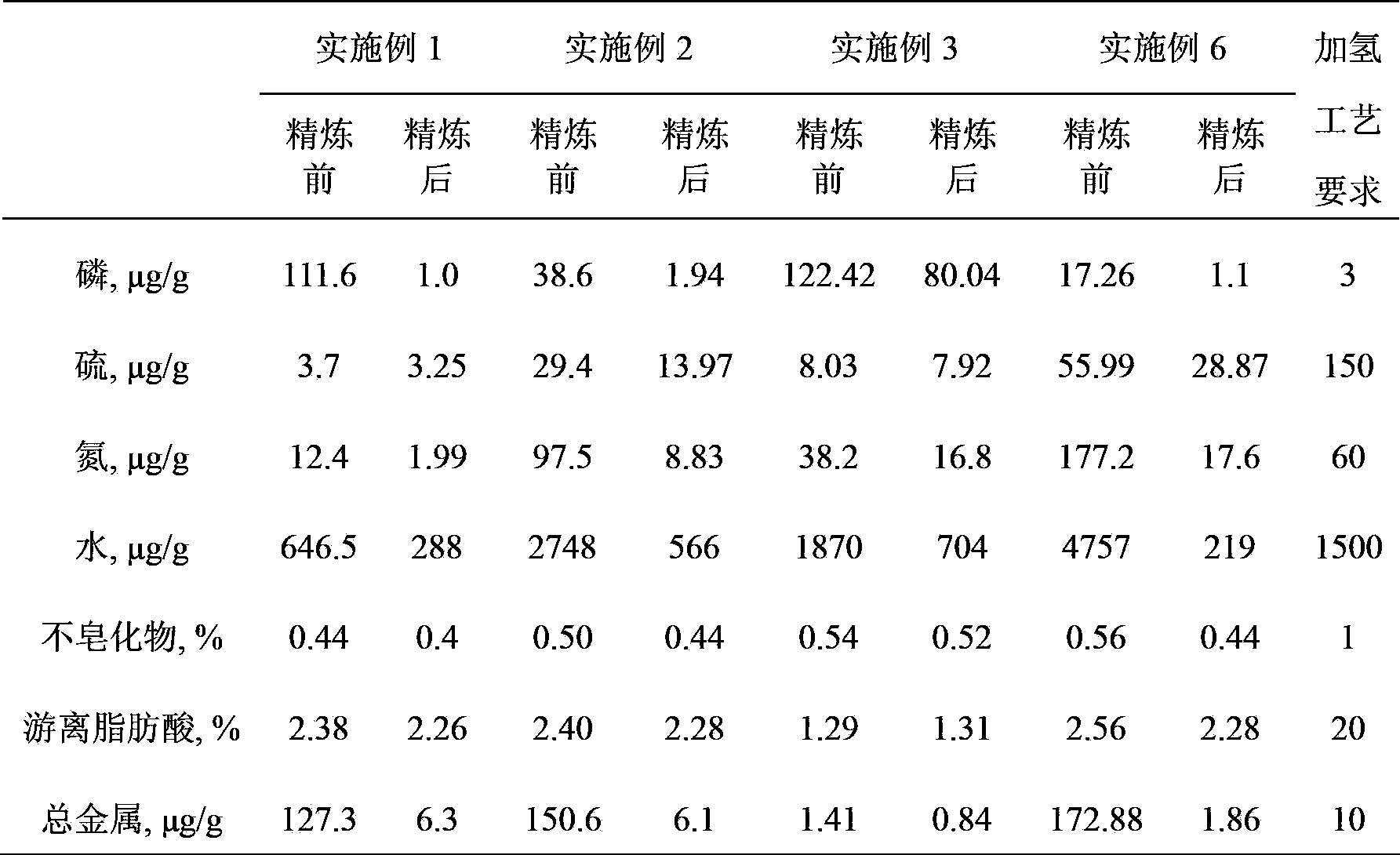

[0032] use figure 1 In the shown process flow, jatropha oil is used as raw material, and aviation fuel distillate is used as the main target product. Firstly, refining treatment was carried out, the dosage of conversion-complexing agent was 1.2%, the reaction time was 60 minutes, the dosage of adsorbent was 1%, and the reaction time was 30 minutes. The impurity content before and after refining treatment is shown in Table 1. Hydrogenation and deoxidation are performed simultaneously in a fixed-bed reactor using sulfided NiMo / γ-Al 2 o 3 Supported catalyst, reaction temperature 380°C, reaction pressure 5.0MPa, volume space velocity 1.0h -1 , The volume ratio of hydrogen to oil is 500:1. The analysis of the stream before and after the reaction shows that the deoxygenation rate reaches 100%, the yield of liquid phase products reaches 81.3%, and the content of saturated linear alkanes reaches 96.5%. Isomerization and cracking are simultaneously completed in a fixed-bed reactor, ...

Embodiment 2

[0034] use figure 1 In the process flow shown, jatropha oil and gutter oil are mixed at a volume ratio of 1:1 as raw material, and aviation fuel distillate is used as the main target product. Firstly, refining treatment was carried out, the dosage of conversion-complexing agent was 1.5%, the reaction time was 60 minutes, the dosage of adsorbent was 2%, and the reaction time was 30 minutes. The impurity content before and after refining treatment is shown in Table 1. Subsequent steps and process conditions were the same as in Example 1, and the composition and concentration of reactants and products in each section were analyzed. After calculation, the aviation fuel fraction yield of the whole process system is 51.5%, and the isomerization rate is 87.1%. The actual measurement results show that the freezing point of aviation fuel is -51°C and the flash point is 43°C, and all indicators meet the requirements of the "No. 3 Jet Fuel" (GB6537-2006) standard.

Embodiment 3

[0036] use figure 1 In the shown process, the millennium tung oil is used as the raw material, and the aviation fuel distillate is used as the main target product. Firstly, refining treatment was carried out, the dosage of conversion-complexing agent was 1.5%, the reaction time was 60 minutes, the dosage of adsorbent was 2%, and the reaction time was 30 minutes. The impurity content before and after refining treatment is shown in Table 1. Except for hydrogenation and deoxidation treatment, subsequent steps and process conditions are the same as in Example 1. Hydrogenation and deoxygenation are completed step by step in two fixed-bed reactors connected in series. The former uses nickel-based catalysts, 200°C, 0.3MPa reaction conditions, and the latter uses NiMo / γ-Al 2 o 3 Supported catalyst, 380°C, 5.0MPa reaction conditions. After calculation, the aviation fuel fraction yield of the whole process system is 51.9%, and the isomerization rate is 86.5%. The actual measurement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com