Method for coproduction of high purity aminic acid and acid sodium phosphate by reaction of calcium formate and peroxyphosphoric acid

A technology of calcium dihydrogen phosphate and calcium formate, which is applied in chemical instruments and methods, phosphorus compounds, carboxylate preparation, etc., can solve the problems of high production cost, and achieve the effect of low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

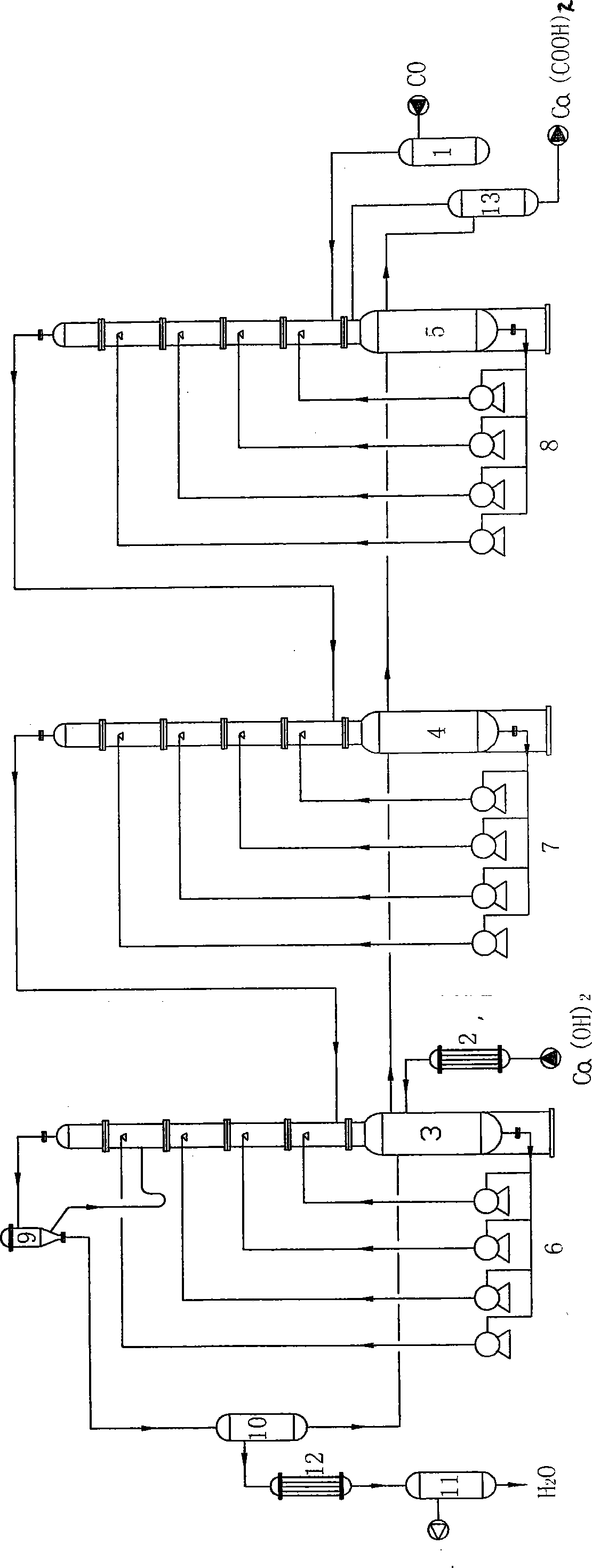

[0031] The present invention relates to a kind of method that calcium formate and superphosphoric acid react and co-produce high-purity formic acid and sodium dihydrogen phosphate, and described method comprises the following process steps:

[0032] Step 1, Calcium Hydroxide Continuous Carbonylation to Produce Calcium Formate

[0033] Such as figure 1 As shown, after purification, CO removal 2 , O 2 Carbon monoxide gas, such as harmful gas, is stabilized to 1.3-2.0Mpa by the surge tank 1, and then enters the three reaction towers 5, and the calcium hydroxide emulsion with a particle size of <50 μm and a weight percentage of 8%-11% passes through the heat exchanger 2 After being preheated to 120°C to 160°C, it enters the first reaction tower 3, and the calcium hydroxide emulsion in the first reaction tower 3 is atomized and sprayed into the first reaction tower 3 by the first circulation pump 6, and is mixed with the calcium hydroxide emulsion from the second reaction tower 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com