Method for preparing polymer microporous foaming material by supercritical mould foaming

A microcellular foaming material and polymer technology, which is applied in the field of preparing polymer microcellular foaming materials by using supercritical fluid technology, can solve the problems of small cell density, low bubble nucleation rate, limited weight reduction effect, etc. The effect of high pore density, high cell nucleation rate, and shortened molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

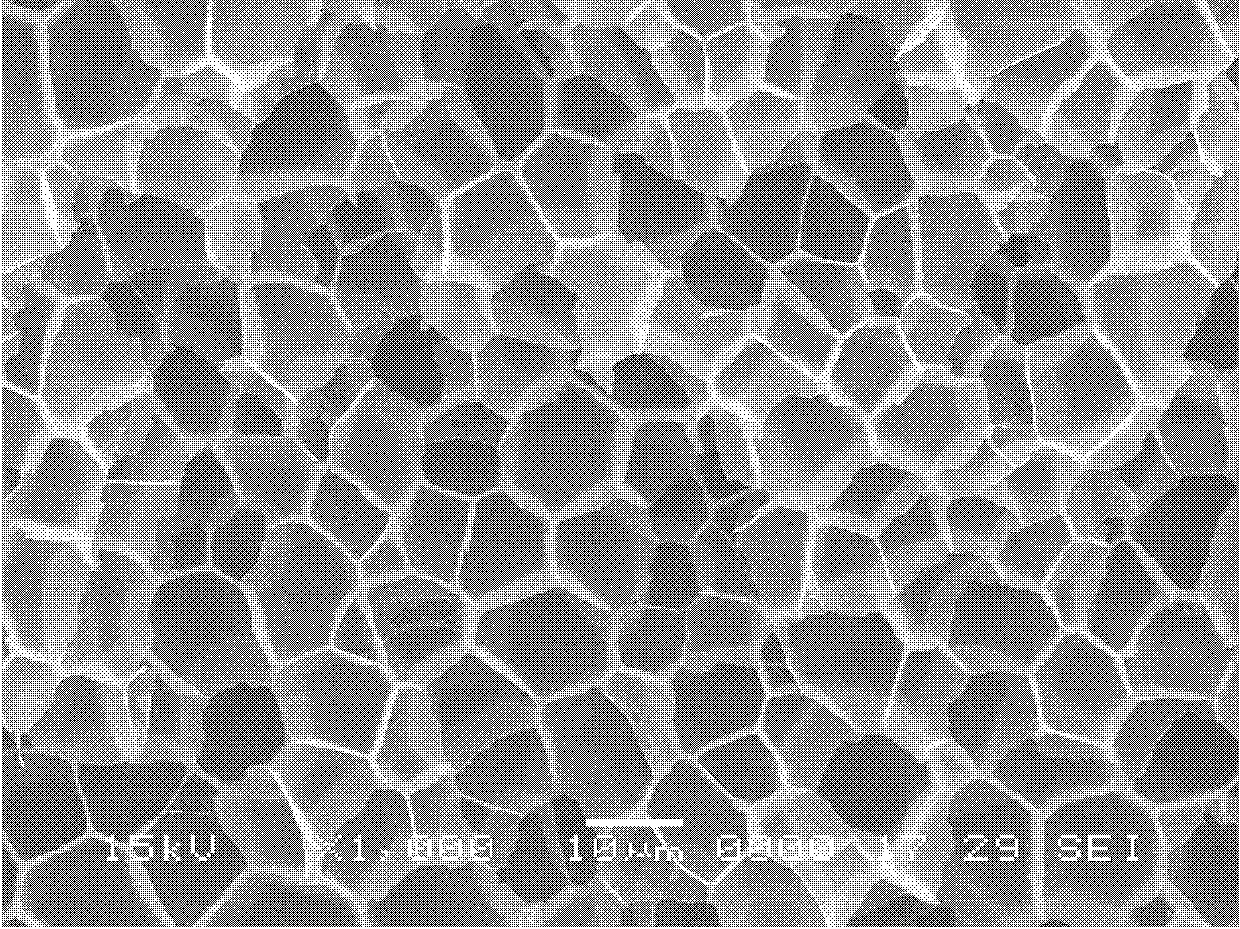

Embodiment 1

[0032] Polylactic acid particles with a number-average molecular weight of 100,000 and a melting point of 120°C were kneaded by a twin-screw extruder, molded through a die, cooled and cut to make a polylactic acid plate to be expanded with a size of 20cm×20cm×1cm. The mold installed between the molding presses is heated up to 115° C., the polylactic acid plate is put into it, the molding presses are closed, and the molds are sealed. Feed 30MPa supercritical nitrogen into the mold, so that the supercritical nitrogen diffuses into the polylactic acid matrix under the conditions of 115°C and 30MPa. After 60 minutes of saturation, the diffusion equilibrium is reached, and the pressure in the mold is reduced to 10MPa through the pressure relief valve, and then the mold is opened to release the pressure and foam, the foam plate pops up, cools and shapes, and the polylactic acid microcellular foamed plate is obtained.

[0033] Based on 100 parts by weight of the polymer, after the di...

Embodiment 2

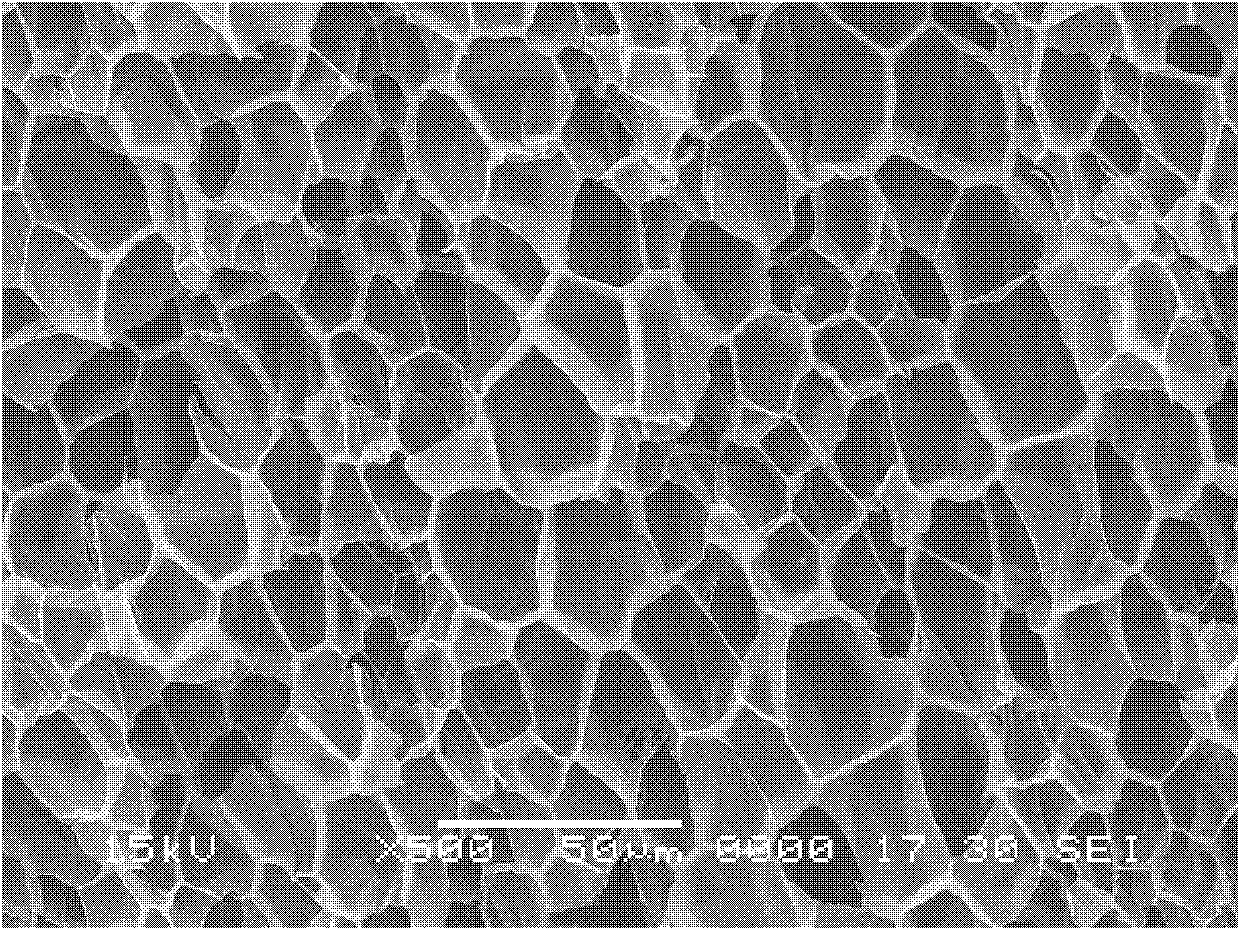

[0036] 200 g of polypropylene particles with a number average molecular weight of 200,000, a melting point of 160° C., and an average particle diameter of 4 mm were put into a mold of a molding machine, and the temperature of the mold was raised to 150° C. The molding machine closes the mold, the mold is sealed, and 10MPa supercritical carbon dioxide is introduced into the mold, so that the supercritical carbon dioxide diffuses into the polypropylene matrix under the conditions of 150°C and 10MPa. After 20 minutes of saturation, the diffusion equilibrium is reached, and the pressure in the mold is released to 2MPa through the pressure relief valve, and then the mold is opened to release the pressure and foam, and the obtained polypropylene microcellular foamed beads are collected.

[0037]Based on 100 parts by weight of the polymer, after the diffusion equilibrium is reached, the content of the supercritical fluid dissolved in the polymer is 11.5 parts.

[0038] The average pa...

Embodiment 3

[0040] Polystyrene particles with a number-average molecular weight of 400,000 and a glass transition temperature of 92°C are kneaded by a twin-screw extruder, shaped by a round-hole die, cooled and cut to make a diameter of 3 mm, each segment length A total of 200g of 20cm polystyrene rods to be expanded. The mold installed between the molding presses is heated up to 105° C., polystyrene rods are put into it, the molding presses are closed, and the molds are sealed. Feed 20MPa supercritical carbon dioxide into the mold to make the supercritical carbon dioxide diffuse into the polystyrene matrix at 105°C and 20MPa. After 15 minutes of saturation, the diffusion equilibrium is reached, the mold is opened to release the pressure and foamed, and the obtained polystyrene microcellular foamed rods are collected.

[0041] Based on 100 parts by weight of the polymer, after the diffusion equilibrium is reached, the content of supercritical fluid dissolved in the polymer is 17.3 parts....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com