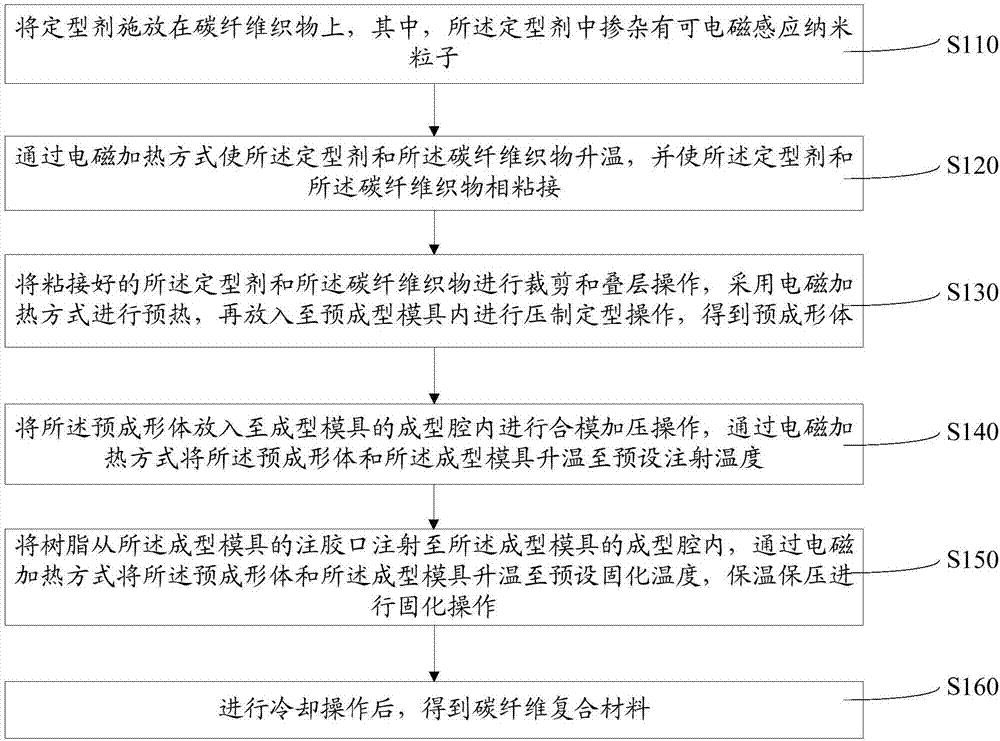

Manufacturing method for carbon fiber composite material

A composite material and manufacturing method technology, applied in the field of materials, can solve the problems of long molding cycle of composite materials, high manufacturing cost of composite materials, slow heating and heating speed, etc., to shorten molding cycle, improve impact toughness, and fast heating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

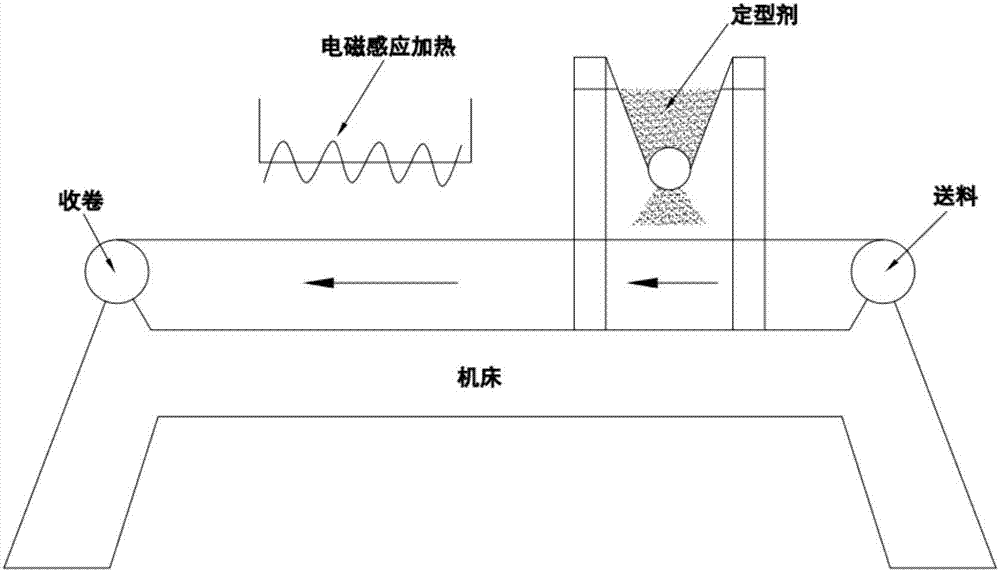

[0052] see figure 2 , the nano-ferrite powder is evenly doped in the epoxy resin-type sizing agent Araldite LT3366, and the sizing agent is applied to the uniaxially woven carbon fiber through the powder coating equipment, and the carbon fiber fabric and the sizing agent are made by the electromagnetic induction effect The nano-ferrite in the powder heats up to partially melt the sizing agent and adheres to the fiber fabric. The temperature can be precisely and uniformly controlled by electromagnetic induction to ensure the adhesion effect of the sizing agent and the carbon fiber fabric. The content of the sizing agent in the carbon fiber fabric is 6%.

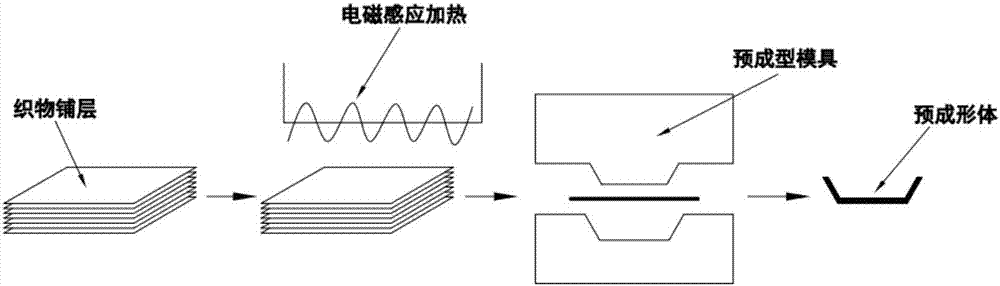

[0053] see image 3 , cut the fabric according to the requirements, superimpose according to 0° / 45° / 90° / -45°, use the electromagnetic induction effect to preheat the superimposed carbon fiber fabric, move it into the preforming mold, pressurize and shape it, and prepare the preformed body .

[0054] see Figure 4 , after c...

Embodiment 2

[0056] The FeAlSi powder with a particle size of 100nm is uniformly doped into the nylon sizing agent, and the sizing agent is applied to the multi-axial carbon fiber fabric through the powder coating equipment, and the temperature of the nano-FeAlSi in the carbon fiber fabric and the sizing agent powder is raised by the electromagnetic induction effect Adhering to the carbon fiber fabric after being partially melted, the content of the sizing agent in the carbon fiber fabric is 4%.

[0057] Superimpose the cut fabrics according to the designed layering method, preheat the superimposed fabrics by electromagnetic induction effect, put them into the preforming mold, pressurize and shape them, and prepare the preformed body.

[0058] After trimming the preformed body according to the size of the forming mold, the mold is opened and moved into the forming mold, the hydraulic press is used to close the mold and pressurize, and the temperature is raised by electromagnetic heating to ...

Embodiment 3

[0060] The carboxyl iron powder with a particle size of 200nm is evenly doped into the phenolic resin sizing agent, and the sizing agent is applied to the carbon fiber twill fabric and unidirectional fabric through the coating equipment, and the electromagnetic induction effect is used to make the carbon fiber fabric and the sizing agent powder inside the nanometer The carboxyl iron powder is heated and partly melted and adhered to the carbon fiber fabric, and the content of the sizing agent in the carbon fiber fabric is 5%.

[0061] Superimpose the cut fabrics according to the designed layering method, lay carbon fiber twill fabric on the outside as the appearance surface, use the electromagnetic induction effect to preheat the superimposed fabrics, put them into the preforming mold, pressurize and shape them, and prepare the preformed body .

[0062] After trimming the preformed body according to the size of the forming mold, the mold is opened and moved into the forming mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com