Composite material of shell micro powder filling bio-based resin and method for preparing same

A bio-based resin, shell micropowder technology, applied in the field of resin modification, can solve problems such as unseen research and reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

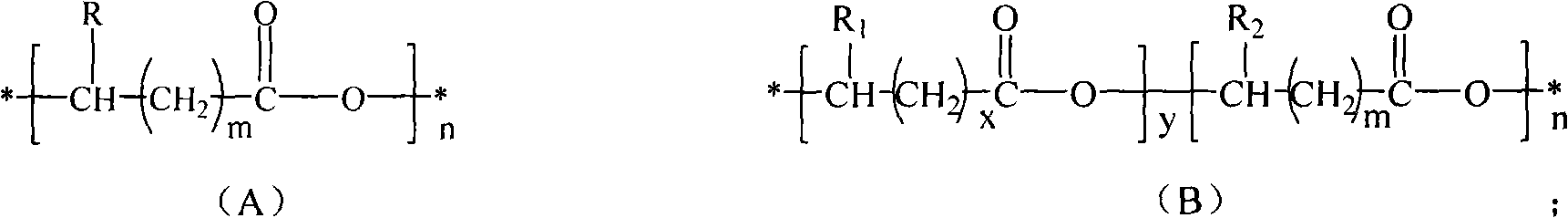

[0073] Wash and dry 20 parts of shell micropowder (parts by mass, the same below), 2.0 parts of chelating titanate coupling agent (NDZ-311w) (diluted into a 1:2 triethylamine solution), B215 antioxidant 0.25 part of agent, 80 parts of polylactic acid (PLA), the Mn=30,000 of this polylactic acid, L content 60%, according to the technical scheme of indirect route, select injection molding machine to add relevant supporting mold to obtain disposable lunch box, flower pot, cutlery and other products. , The granulation process is at a temperature of 180°C to 200°C, and the screw speed is 80rpm; the injection molding process temperature is at 195°C to 205°C.

Embodiment 2

[0075] 30 parts of shell micropowder after washing and drying (mass parts, the same below), 1.2 parts of tolyl diisocyanate (TDI), 0.1 part of dibutyltin dilaurate, 0.25 parts of B561 antioxidant, polyhydroxybutyric acid-valeric acid 70 parts of ester (PHBV), the Mn=50,000 of this PHBV, HV% is 4%, according to the technical scheme of indirect route, selects the sheet forming machine for use, by adjusting the pressure roller pitch (0.6~3mm), obtains the different sheet of thickness The sheet is made into different shapes of disposable lunch boxes, plates, flower pots and other consumable common products under positive or negative pressure conditions while it is hot. The granulation process includes a temperature of 160°C-180°C, a screw speed of 85rpm, a hot-pressing process temperature of 167-180°C, and a pressure of 9-15MPa.

Embodiment 3

[0077] 20 parts (mass parts, the same below) of shell micropowder after cleaning and drying, 0.6 part of lysine triisocyanate (LTI), 0.1 part of dibutyltin dilaurate, 0.2 part of B900 antioxidant, polyhydroxybutyrate ( PHB) 80 parts, the Mn=40,000 of this PHB, by the technical scheme of direct route, select injection molding machine to add supporting flower pot, knife and fork mold to obtain disposable flower pot, knife and fork product. The granulation process is at a temperature of 160°C to 180°C and the screw speed at 90 rpm; the injection molding process temperature is at 165°C to 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com