Polyurethane co-mixed modified polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide, blending modification technology, applied in the field of polyurethane blending modified polyphenylene sulfide composite materials and its preparation, can solve the problems of large dielectric constant, insufficient toughness, insufficient temperature resistance, etc. Small electrical constant, good fluidity, and the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

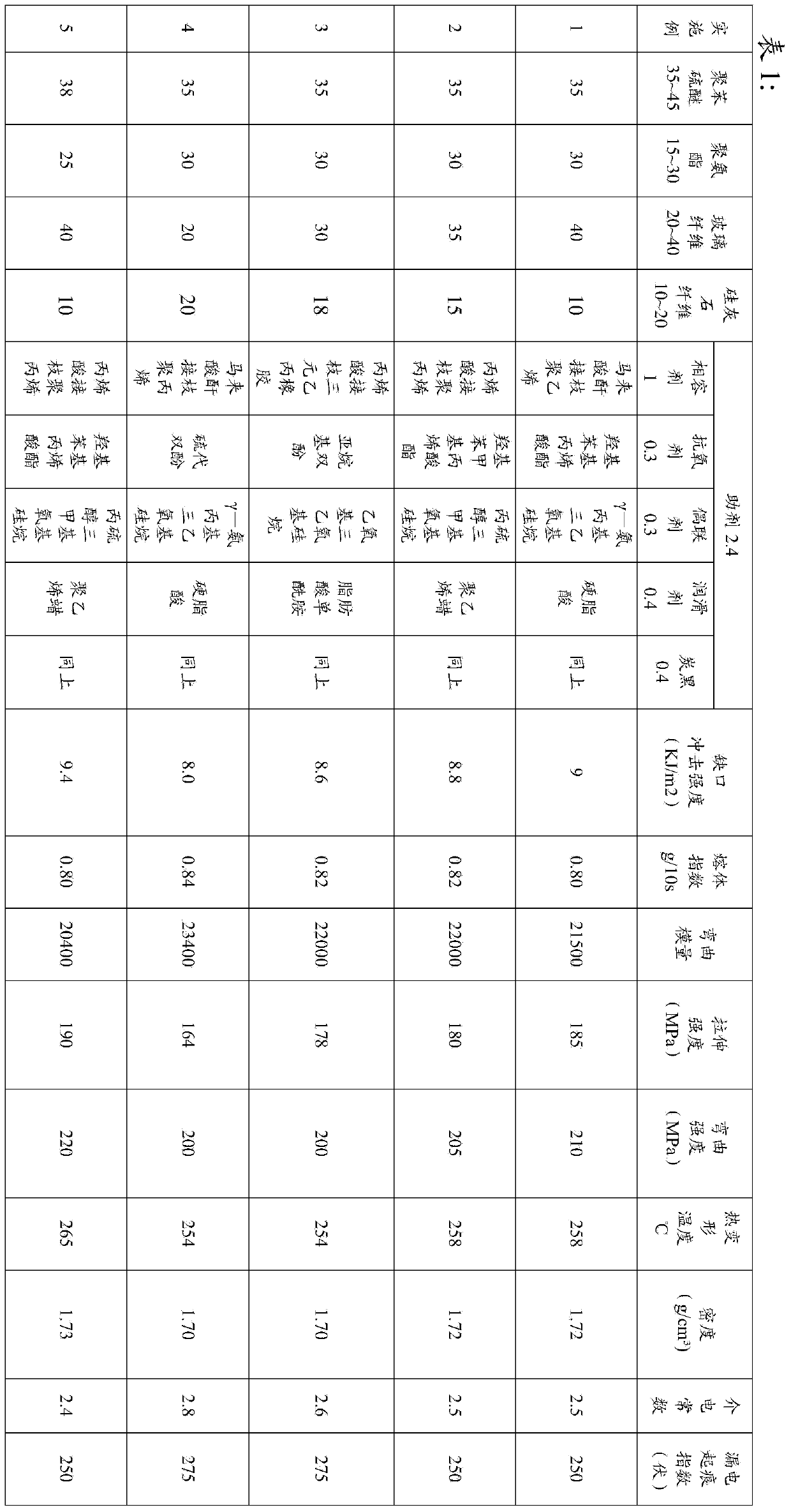

[0021] First, under normal temperature and pressure, polyphenylene sulfide, polyurethane, compatibilizer, antioxidant, coupling agent, lubricant and carbon black are mixed evenly by high-speed stirring. The stirring speed is about 3000 rpm or more. The stirring time About 3 minutes. Then add glass fiber and wollastonite fiber, disperse evenly by stirring at a low speed, the stirring speed is about 200 rpm or less, and obtain a mixture. In this embodiment, in parts by weight, polyphenylene sulfide 35, glass fiber 40, polyurethane 30, wollastonite fiber 10, and additive 2.4. In parts by weight, compatibilizer 1, antioxidant 0.3, coupling agent 0.3, lubricant 0.4, carbon black 0.4.

[0022] Then, the mixed material is added into a twin-screw extruder, and the set process conditions of the twin-screw extruder are a temperature of 300-350° C. and a screw speed of 1100 rpm.

[0023] Finally, a cold water tank is set at the discharge port of the twin-screw extruder, and the extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com