Halogen-free flame-retardant polycarbonate/styrene base resin composition and preparation method thereof

A technology of styrene-based resin and flame retardant polycarbonate, applied in the field of polymer composition and its preparation, can solve the problems of high GWIT requirements, application limitations of electronic and electrical components, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

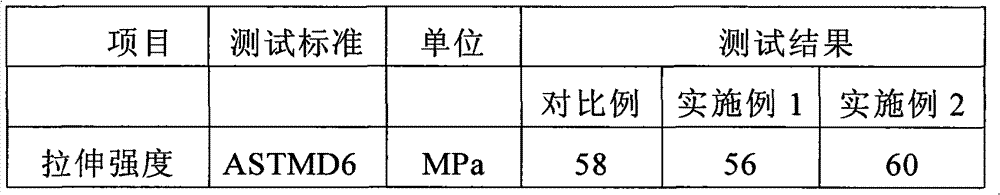

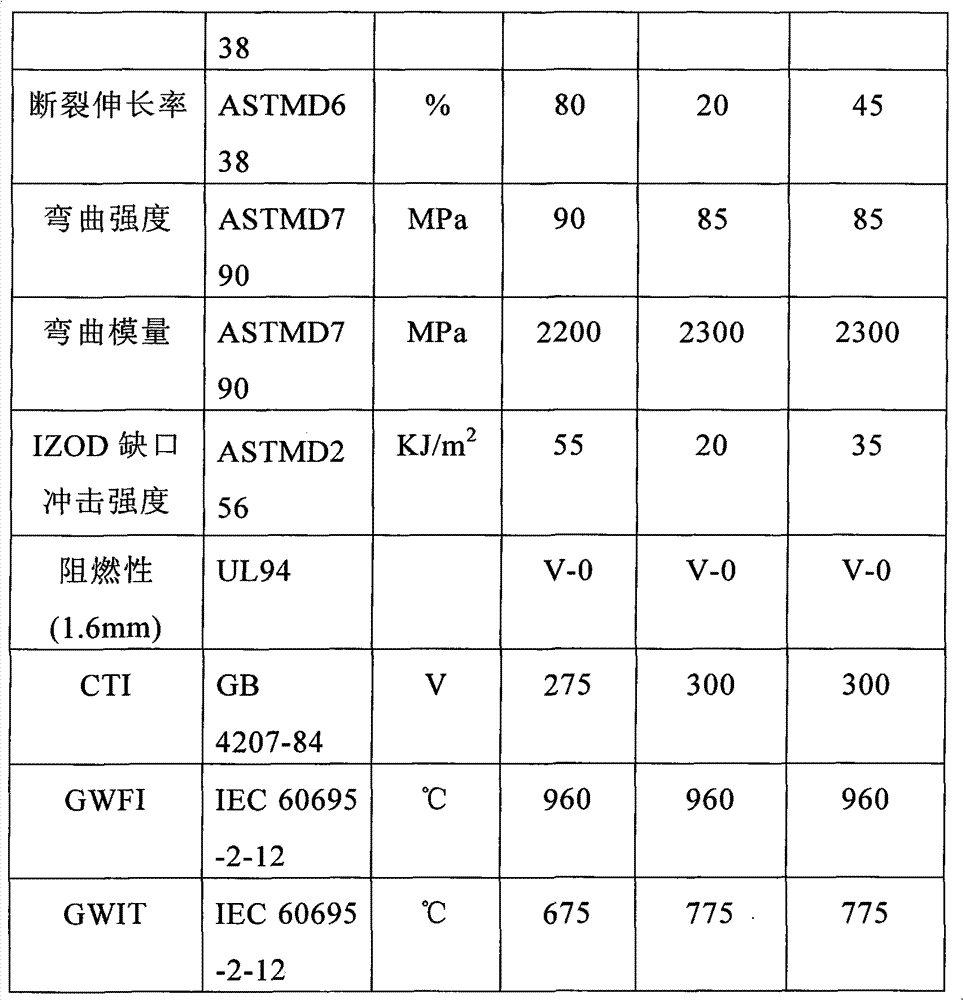

Examples

Embodiment 1-2

[0039] A preparation method of a halogen-free flame-retardant polycarbonate / styrene-based resin composition, the method comprising the following steps:

[0040] (1) The following raw materials are used: PC: produced by Bayer Company of Germany, grade 2805; ABS: produced by Taiwan Chimei Company, grade 757K; methyl methacrylate-styrene-butadiene copolymer (MBS); BDP: Zhejiang Wansheng Bisphenol A bis(diphenyl phosphate) produced by chemical industry; magnesium hydroxide; silicone resin; melamine as flame retardant; antioxidant 1076; antioxidant 168; silicone oil is used as lubricant. The content of each component is shown in Table 1.

[0041] (2) Put polycarbonate as the base material, styrene-based resin, toughening agent compatibilizer, metal inorganic matter, silicone, antioxidant and other additives in a high mixer and mix for 2-3 minutes to obtain a mixture Then, the mixed material is introduced into a twin-screw extruder, the temperature is controlled at 230-250°C, the c...

Embodiment 3

[0053] A preparation method of a halogen-free flame-retardant polycarbonate / styrene-based resin composition, the method comprising the following steps:

[0054] (1) Prepare raw materials according to the following components and contents: 65kg bisphenol A polycarbonate, 25kg styrene-based resin, 2kg toughening compatibilizer, 1kg iron oxide, 5kg organic silicon, 7kg compound flame retardant, 0.1 kg antioxidant 1076, 1.5kg antioxidant 168. Among them, the styrene-based resin is a copolymer of styrene and vinyl monomer; the toughening compatibilizer is methyl methacrylate-styrene-butadiene copolymer; the silicone is dimethyl silicone oil; the compound flame retardant The agent is a compound of monophosphate ester and dicyandiamide in a weight ratio of 3:4.

[0055] (2) Put bisphenol A polycarbonate, styrene-based resin, toughener compatibilizer, iron oxide, organic silicon, antioxidant 1076 and antioxidant 168 in a high mixer and mix for 2 minutes to obtain a mixture Then, the...

Embodiment 4

[0057] A preparation method of a halogen-free flame-retardant polycarbonate / styrene-based resin composition, the method comprising the following steps:

[0058](1) Prepare raw materials according to the following components and contents: 90kg bisphenol A polycarbonate, 0.01kg styrene-based resin, 10kg toughening compatibilizer, 4kg zinc borate, 6kg zinc oxide, 0.5kg silicone, 15kg compound With flame retardant, 1kg antioxidant 1076, 0.1kg antioxidant 168, 1.5kg lubricant fatty acid amide, 0.5kg ultramarine blue toner. Wherein the styrene-based resin is a copolymer of styrene derivatives and vinyl monomers; the toughening compatibilizer is styrene-maleic anhydride copolymer (SMA) and ethylene-octene copolymer grafted maleic anhydride by weight The ratio is a mixture of 1:4; the silicone is ultra-high molecular weight linear polydimethylsiloxane; the compound flame retardant is bisphenol A bis(diphenyl phosphate) and bisphosphonate in a weight ratio of 2 : Compounding of 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com