Flame-retardant glass fiber-reinforced PA6/PA66 alloy material with high CTI value and high GWIT value

A technology of alloy materials and glass fiber, which is applied in the field of flame-retardant glass fiber reinforced alloy materials, can solve the problems of low CTI value and GWIT value, unsuitable electricity environment, etc., achieve high tracking index and improve oxidation resistance , the effect of comprehensive performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

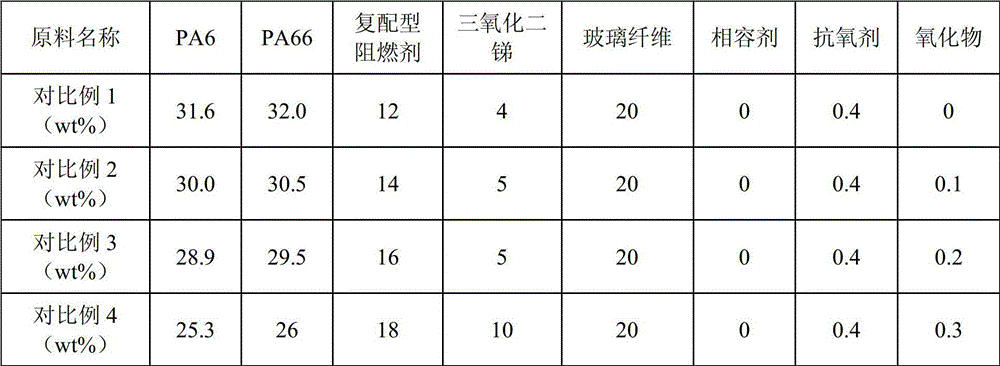

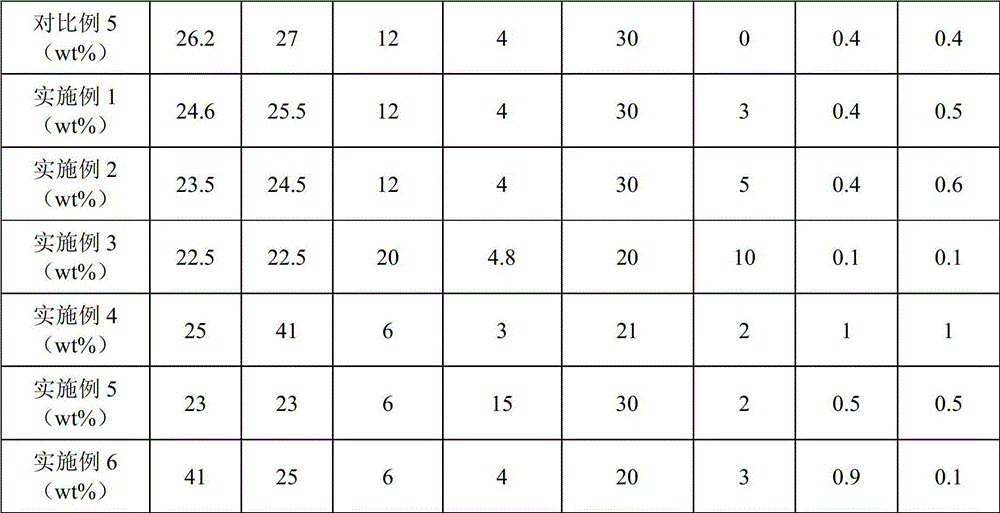

[0036] High CTI value, high GWIT value environment-friendly flame-retardant glass fiber reinforced PA6 / PA66 alloy material, including each component of weight percentage content shown in Table 1; Its preparation method is as follows:

[0037] (1) Weigh the raw materials according to the weight percentage content shown in Table 1, put them in a high-mixer and mix them for 2 to 5 minutes, and discharge; the compound flame retardant masterbatch in Table 1 includes the following components in mass percentage content : BPS: 50%; Magnesium hypophosphite: 25%; Talc powder: 25%;

[0038] (2) Add the above-mentioned mixed raw materials into a twin-screw extruder, extrude and granulate, and obtain the high CTI value, high GWIT value environmental protection flame-retardant glass fiber reinforced PA6 / PA66 alloy material; the twin-screw extruder The parameters such as extrusion temperature and screw revolutions are shown in Table 2.

[0039] The raw material formula of table 1 comparativ...

Embodiment 7

[0044] Embodiment 7, performance test

[0045] Using ASTM standards, performance tests and comparisons were performed on the PA6 / PA66 alloy composition samples prepared in Examples 1-6 and Comparative Examples 1-5. The test performance comparison is shown in Table 3:

[0046] table 3

[0047]

[0048]

[0049] As can be seen from Table 3, compared with Comparative Examples 1, 2, and 3, the sample of the present invention has higher glow wire temperature (GWIT), higher tracking index (CTI), environmental protection, balanced comprehensive performance, and wide Used in low-voltage electronic capacitor housings, load break switches, carbon brush holders, molded case circuit breakers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com