A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa46 alloy material and preparation method thereof

An alloy material and environmental protection technology, applied in the field of alloy materials, can solve problems such as high CTI value, and achieve the effect of balanced comprehensive performance and high tracking index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

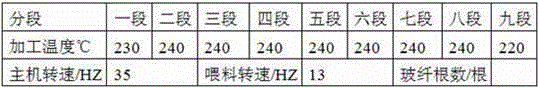

[0040] Weigh raw materials according to weight ratio: PP 25%, PA46 25.1%, compound flame retardant 12%, antimony trioxide 4%, glass fiber 30%, compatibilizer 3%, antioxidant 0.4%, oxidation 0.5% compound; put it into a high mixer and mix for 2-5 minutes, discharge the material, and then use a twin-screw extruder to extrude and granulate. Refer to Table 1 for the machine parameters.

Embodiment 2

[0042] Weigh raw materials by weight: PP 25%, PA46 23%, compound flame retardant 12%, antimony trioxide 4%, glass fiber 30%, compatibilizer 5%, antioxidant 0.4%, oxidation 0.6%; put it into a high mixer and mix for 2-5 minutes, discharge, and then extrude and granulate with a twin-screw extruder. Refer to Table 1 for the machine parameters.

[0043] It should be noted that the composite flame retardant described in Comparative Examples 1-5 and Examples 1-2 is composed of three components mixed, and its mass percentage is brominated polystyrene (BPS): 50% , magnesium hypophosphite: 25%, talcum powder: 25%. The glass fiber is an alkali-free glass fiber whose surface is treated with a silane coupling agent. The compatibilizer is commercially available maleic anhydride grafted PP.

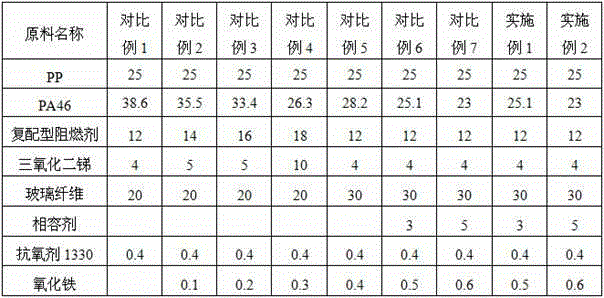

[0044] Raw material formula (wt%) of table 2 comparative example 1-7 and embodiment 1-2

[0045]

Embodiment 3

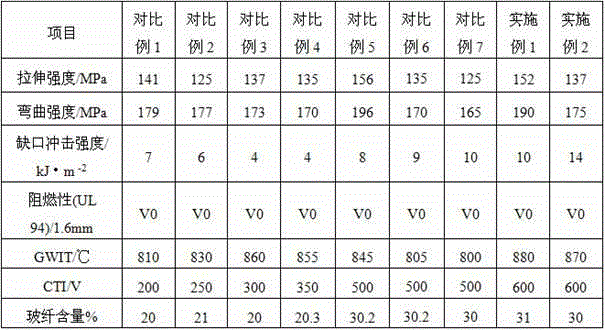

[0046] Embodiment 3 performance test

[0047] According to the samples prepared in Comparative Examples 1-7 and Examples 1-2, the performance test comparison was carried out, using the ASTM standard, and the test performance comparison is shown in the table below.

[0048] Table 3 Comparative Examples 1-7 and Example 1-2 Sample Performance Test Comparison

[0049]

[0050] It can be seen from the above table that the present invention adopts a new flame retardant compound system. Compared with the traditional flame retardant system, the new compound system can increase the glow wire temperature of the material when the percentage of flame retardant is the same. 50 to 100°C, able to pass through 850°C glow wire. As the content of the new compound flame retardant increases, the glow wire temperature of the product also gradually increases. At the same time, the addition of glass fiber also significantly improves the glow wire of the material, the addition of a compatibiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com