High-CTI-value high-flame-retardant composite film and preparation method thereof

A composite film and high flame retardant technology, which is applied in the field of high CTI value and high flame retardant composite film and its preparation, can solve the problems of insignificant improvement of CTI value, affecting the impact strength and heat resistance of PC resin, high CTI value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

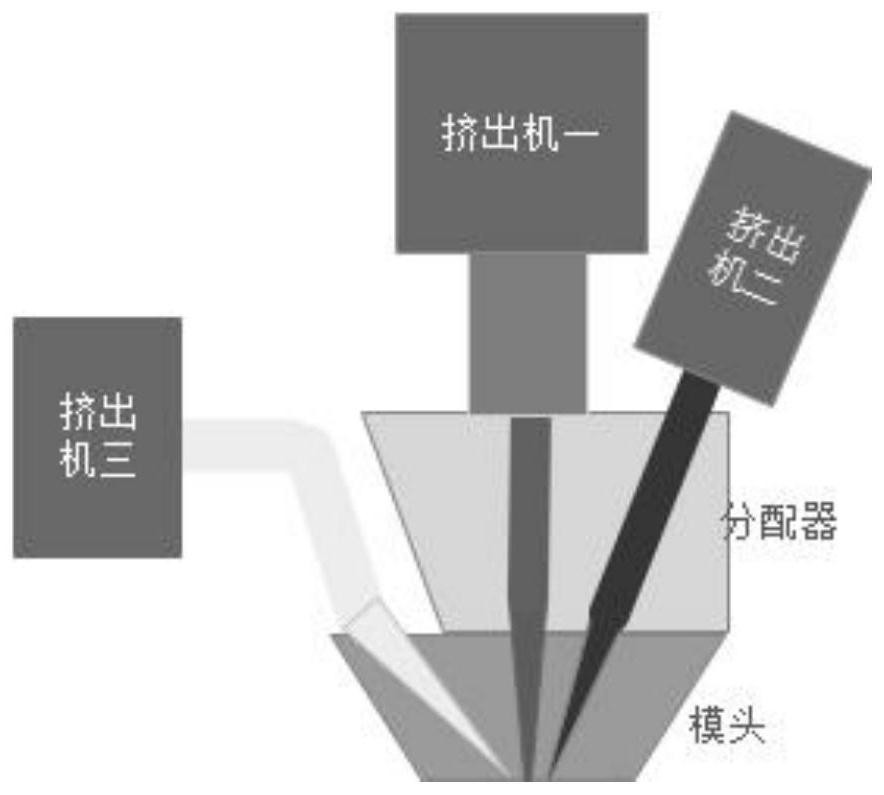

[0015] The present invention is described below in conjunction with accompanying drawing.

[0016] as attached figure 1 As shown, a high CTI value and high flame retardant composite film according to the present invention comprises a modified PC material layer and two modified PPO material layers, the modified PC material layer is used as the substrate layer, and the two modified PPO material layers are The layers are respectively co-extruded and compounded on the upper surface and the lower surface of the modified PC material layer to form a three-layer co-extruded composite film; the modified PC material layer accounts for 80-90% of the total layer thickness of the three-layer co-extruded composite film, and the upper and lower The layer thickness of the modified PPO material of the two layers accounts for 5-10% of the total layer thickness of the three-layer co-extruded composite film respectively.

[0017] Among them, the PPO material is a material suitable for extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com