Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Glass of antimony" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass of antimony, vitrum antimonii, is a yellow to red, translucent glass created from a preparation of antimony, though historically used as an emetic, the glass was a subject of much interest from alchemists due to its unusual properties. It was created using crude antimony, ground and calcined by a vehement fire, in an earthen crucible, until it no longer fumed, indicating that its sulfur was evaporated. The remaining substance (antimony trioxide) was then vitrified in a wind furnace, and stirred with an iron rod, upon which it became translucent and displayed a ruddy and shining yellow-red color.

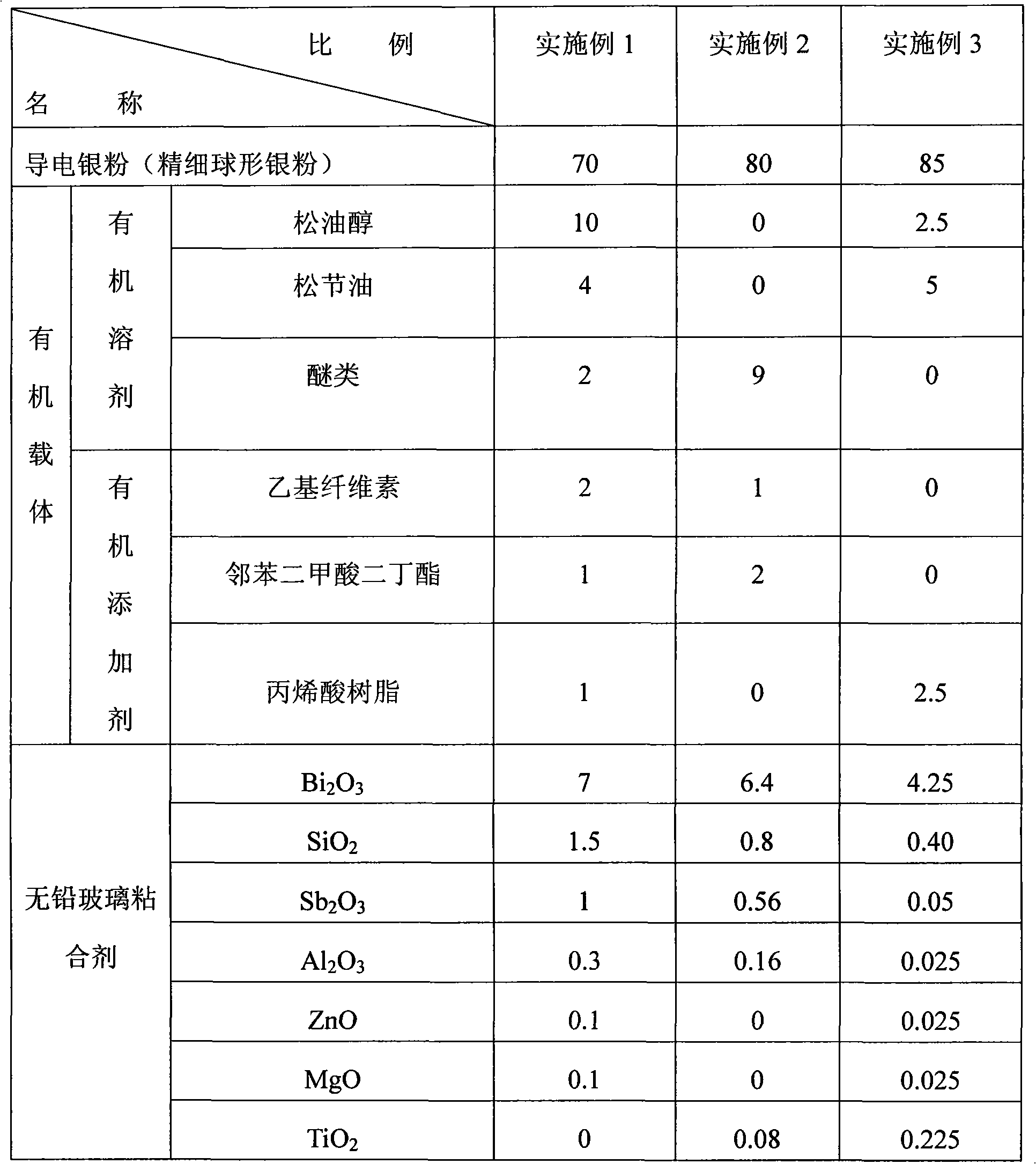

Leadless solar battery silver paste and method for producing the same

InactiveCN101271929AImprove photoelectric conversion efficiencyStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAcrylic resinContact resistance

The invention discloses lead-free solar cell silver serum and a preparation method thereof, which consists of 70-85 percent of conducting silver powder, 5-10 percent of lead-free glass glue and 5.5-25 percent of organic carrier, wherein, the organic carrier consists of organic solvent and organic additive, the organic solvent is any kind of terpineol, terebinth and ethers or their combination; the organic additive is any kind of ethyl cellulose, dibutyl phthalate and acrylic resin or their combination; the particle size of the conducting silver powder is 0.2-2mum; and the lead-free glass glue belongs to bismuth-silicon- antimony glass system. The solar cell silver serum obtained by the method in the invention is lead-free, which complies with requirements of environmental protection, and a conducting electrode with strong adhesive force and low ohm contact resistance can be formed on the surface of the solar cell. The cell has high photoelectric conversion efficiency and is an ideal substituent of the lead silver serum.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

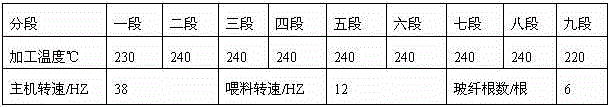

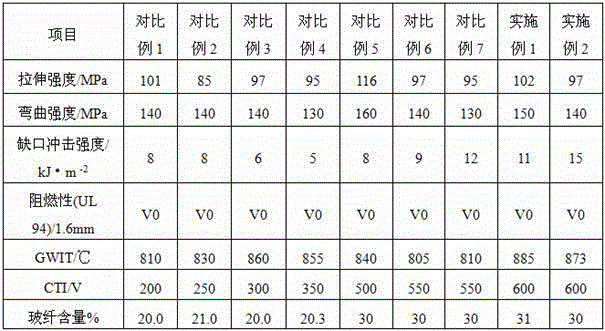

High-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP/PPO (Polypropylene/Polyphenylene Oxide) alloy material and preparation method thereof

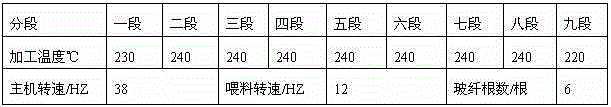

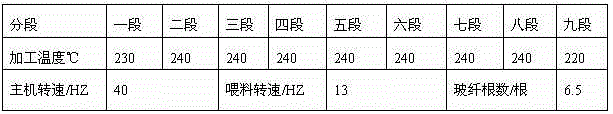

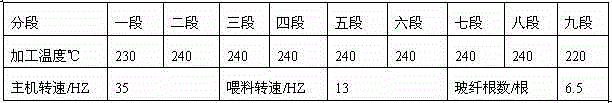

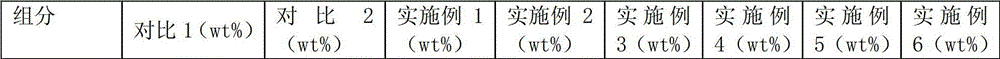

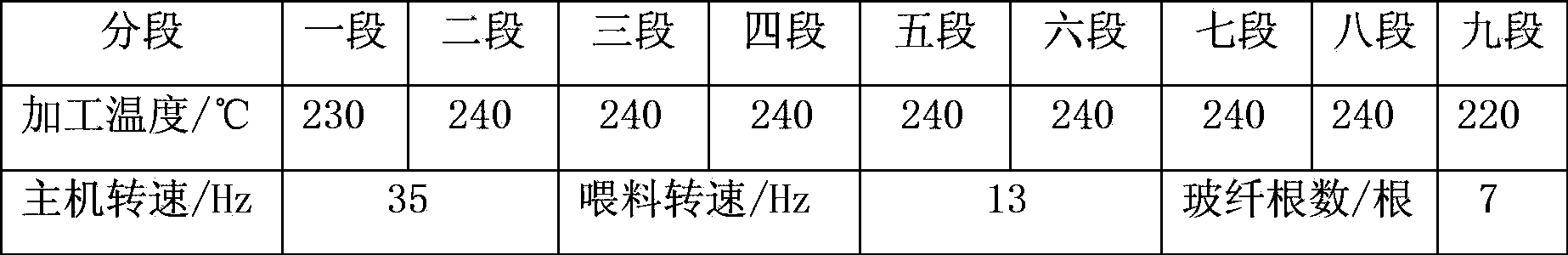

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP / PPO (Polypropylene / Polyphenylene Oxide) alloy material which is prepared from the following raw materials in percentage by weight: 23%-41% of PP, 22%-41% of PPO, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PPO alloy material. The high-CTI value high-GWIT value environmental-friendly flame-retardant glass fiber reinforced PP / PPO alloy material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C by adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; in addiiton, impact property and ageing-resistant property are improved, processing fluidity and smoothness are increased and friction factor is lowered.

Owner:SHANGHAI SUNNY

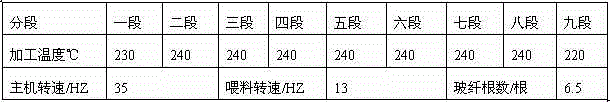

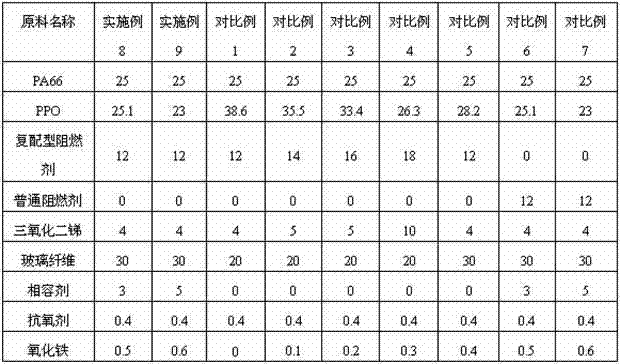

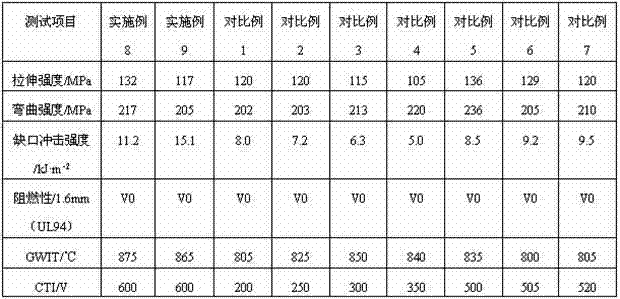

Environment-friendly and flame-retardant glass fiber reinforced PA (polyamide) 66/PPO (polyphenylene oxide) alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

InactiveCN102964829AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly and flame-retardant glass fiber reinforced PA (polyamide) 66 / PPO (polyphenylene oxide) alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material comprises the following raw components in percentage by weight: 23-41% of PA66, 22-41% of PPO, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound flame retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT value and CTI value and good flame retardant effect, is environment-friendly, has balanced overall performances and can be widely applied to such products in the field of electronics as low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

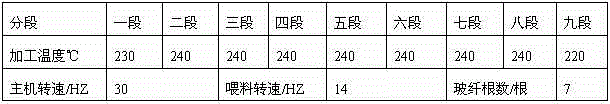

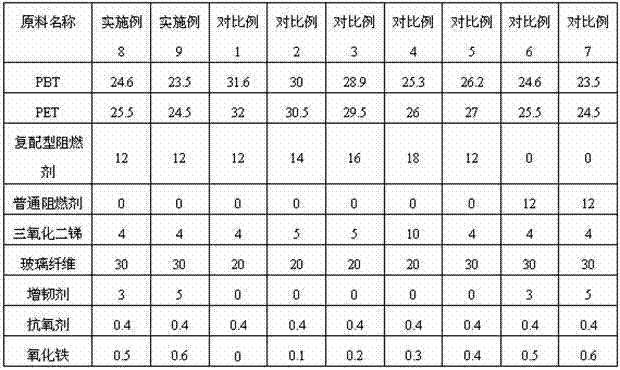

Environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate/ polyethylene terephthalate (PBT/ PET) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952381AHigh GWIT valueImprove impact performancePolymer sciencePolyethylene terephthalate glycol

The invention discloses an environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate / polyethylene terephthalate (PBT / PET) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 22.5-41% of PBT, 22.5-41% of PET, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PBT / PET alloy material with high CTI value and high GWIT value. The alloy material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in alloy material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

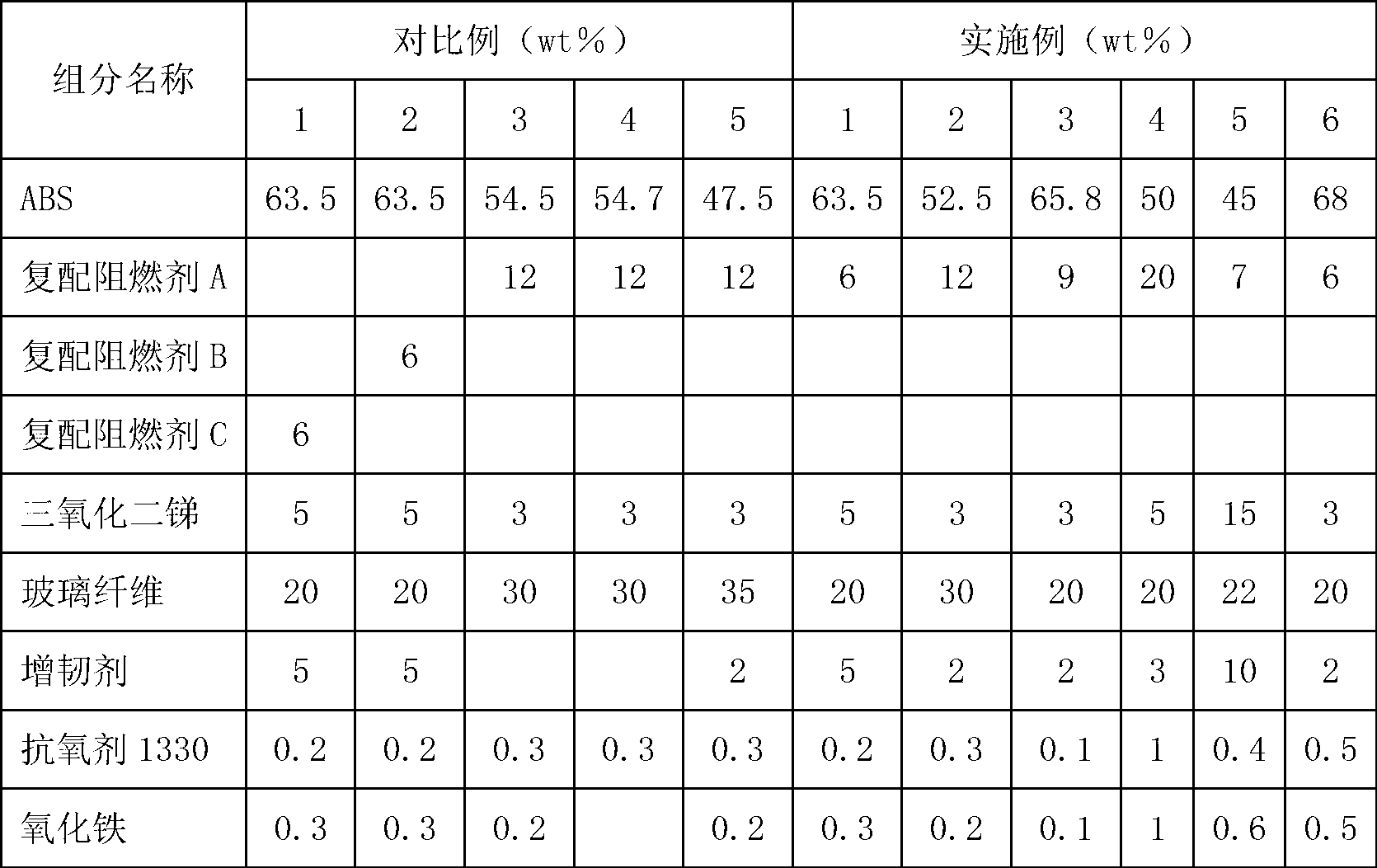

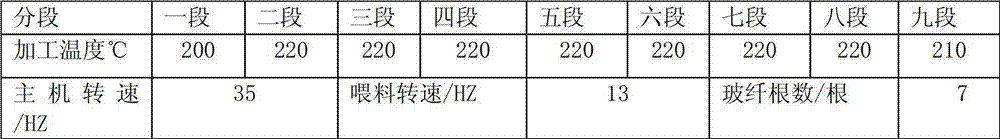

Flame-retardant glass fiber-reinforced ABS material with high CTI value and high GWIT value

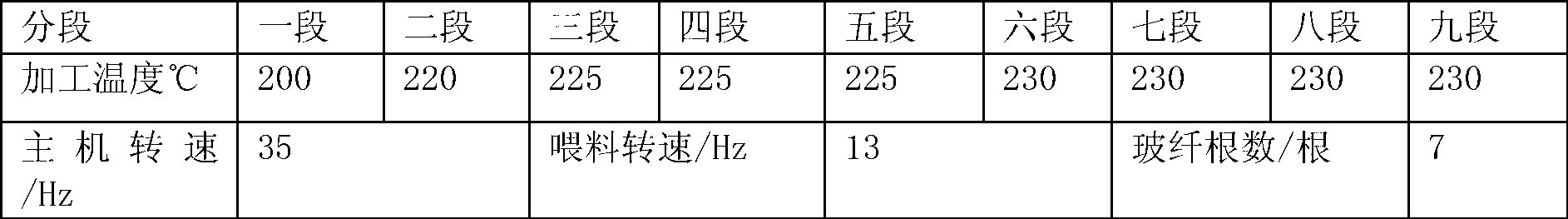

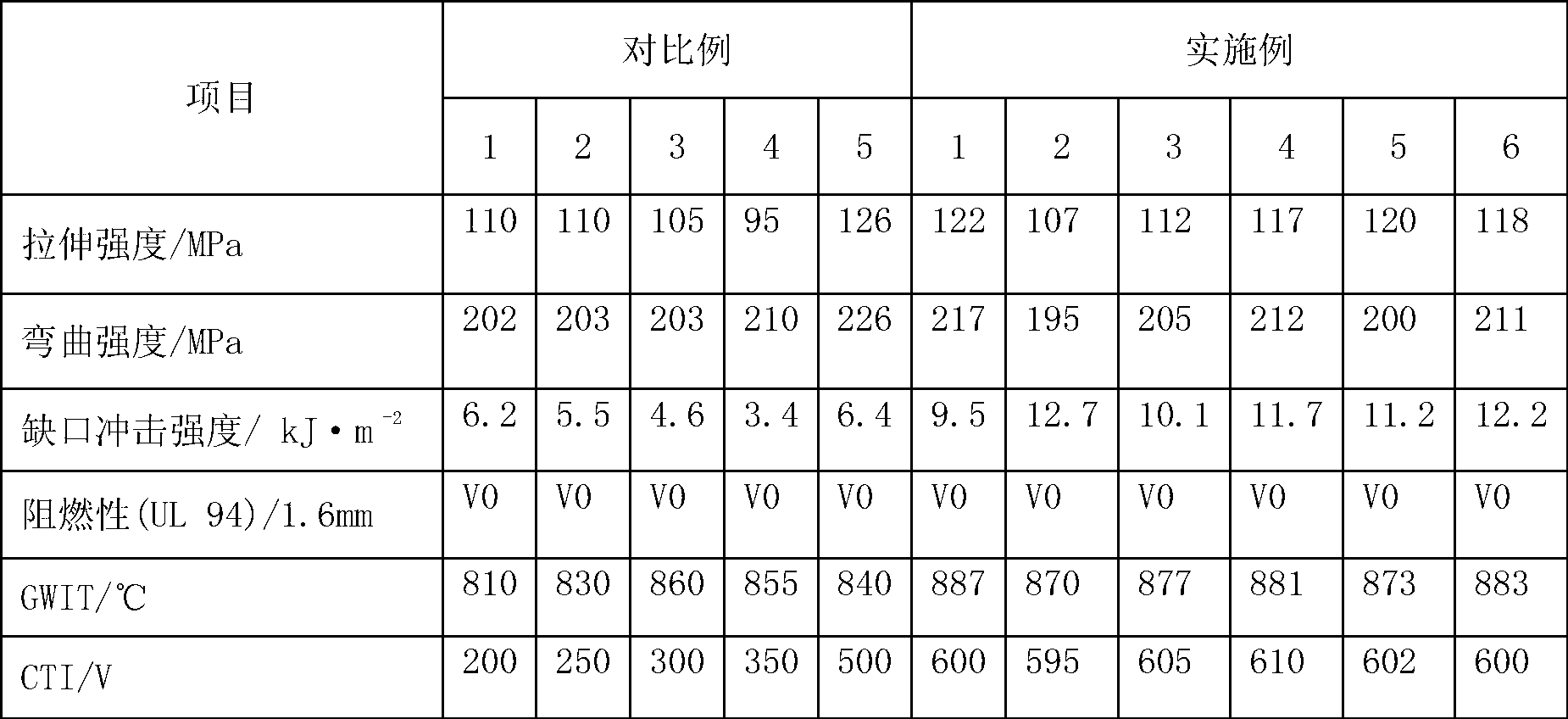

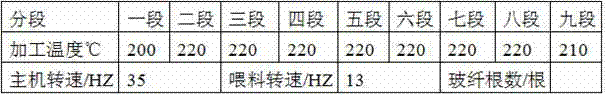

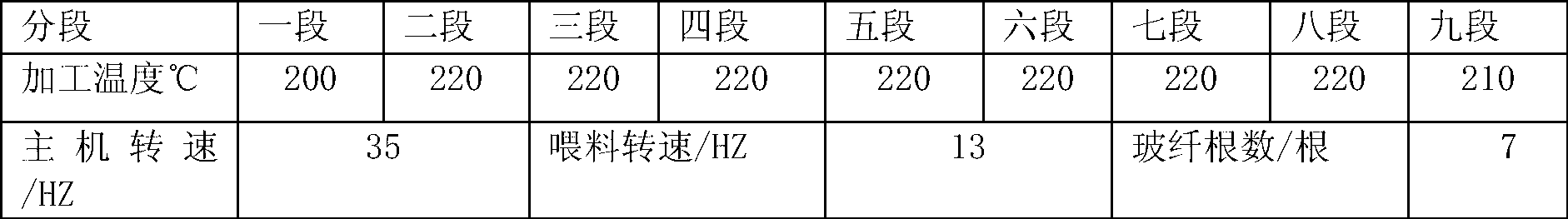

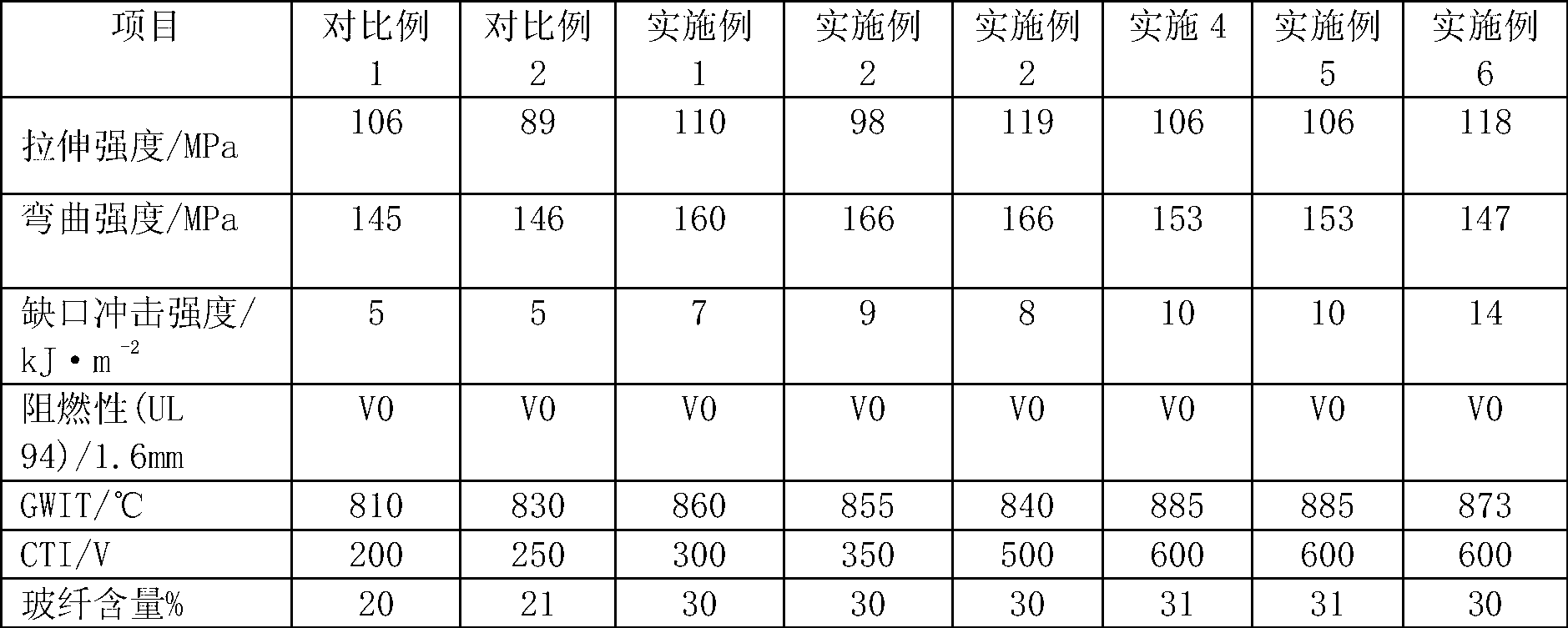

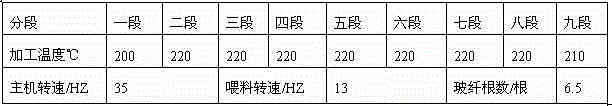

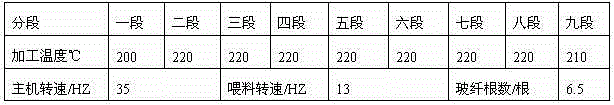

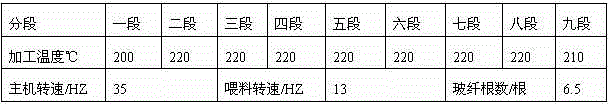

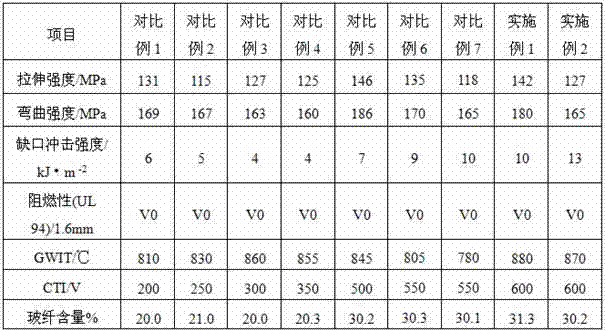

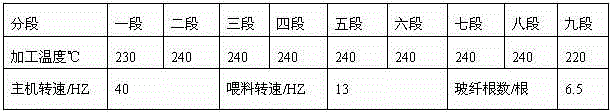

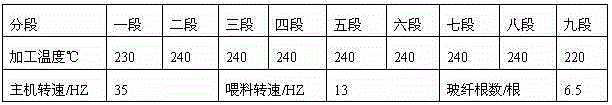

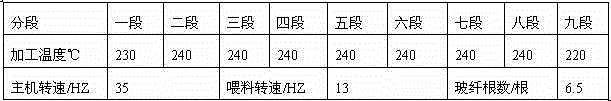

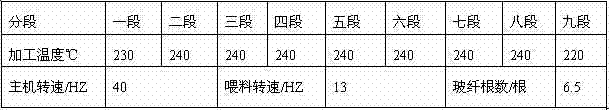

The invention discloses a flame-retardant glass fiber-reinforced ABS material with a high CTI value and a high GWIT value. The ABS material comprises the following components: by weight, 45 to 68% of ABS, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of a metallic oxide. In preparation of the ABS material, all the components are added into a high-speed mixer for mixing for 2 to 5 min, and then discharging and extrusion granulation in a twin-screw extruder are carried out, wherein processing temperature of the twin-screw extruder is 200 to 230 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the ABS material prepared in the invention has the advantages of high glow wire temperature, a high tracking index, environment-friendliness, balanced comprehensive properties and the like through utilization of a novel flame-retardant compounded system in the invention.

Owner:SHANGHAI SUNNY

High-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP (Polypropylene) material and preparation method thereof

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP (Polypropylene) material which is prepared from the following raw materials in percentage by weight: 45%-68.8% of PP, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP material. The high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C by adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; in addition, impact property and ageing-resistant property are improved, processing fluidity and smoothness are enhanced, and friction factor is lowered.

Owner:上海日之升科技有限公司

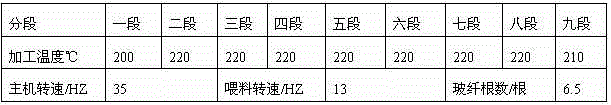

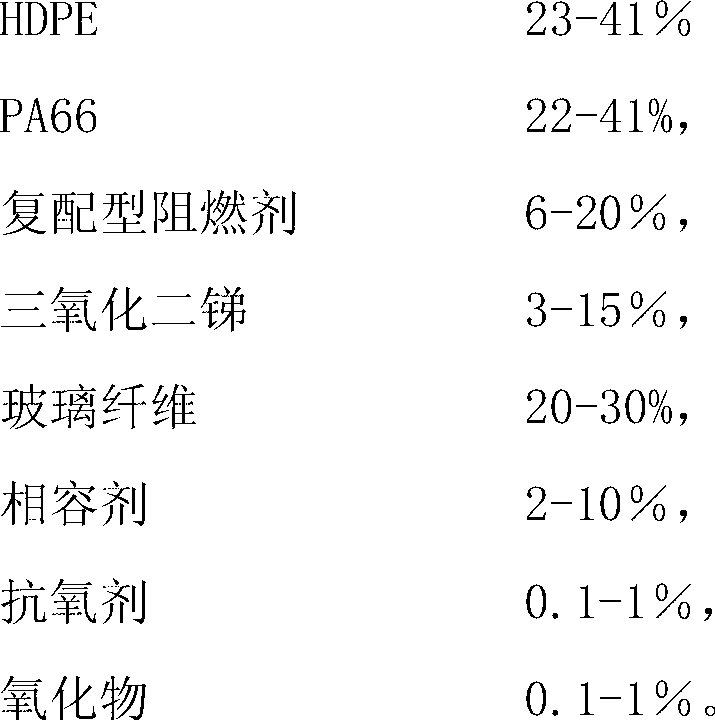

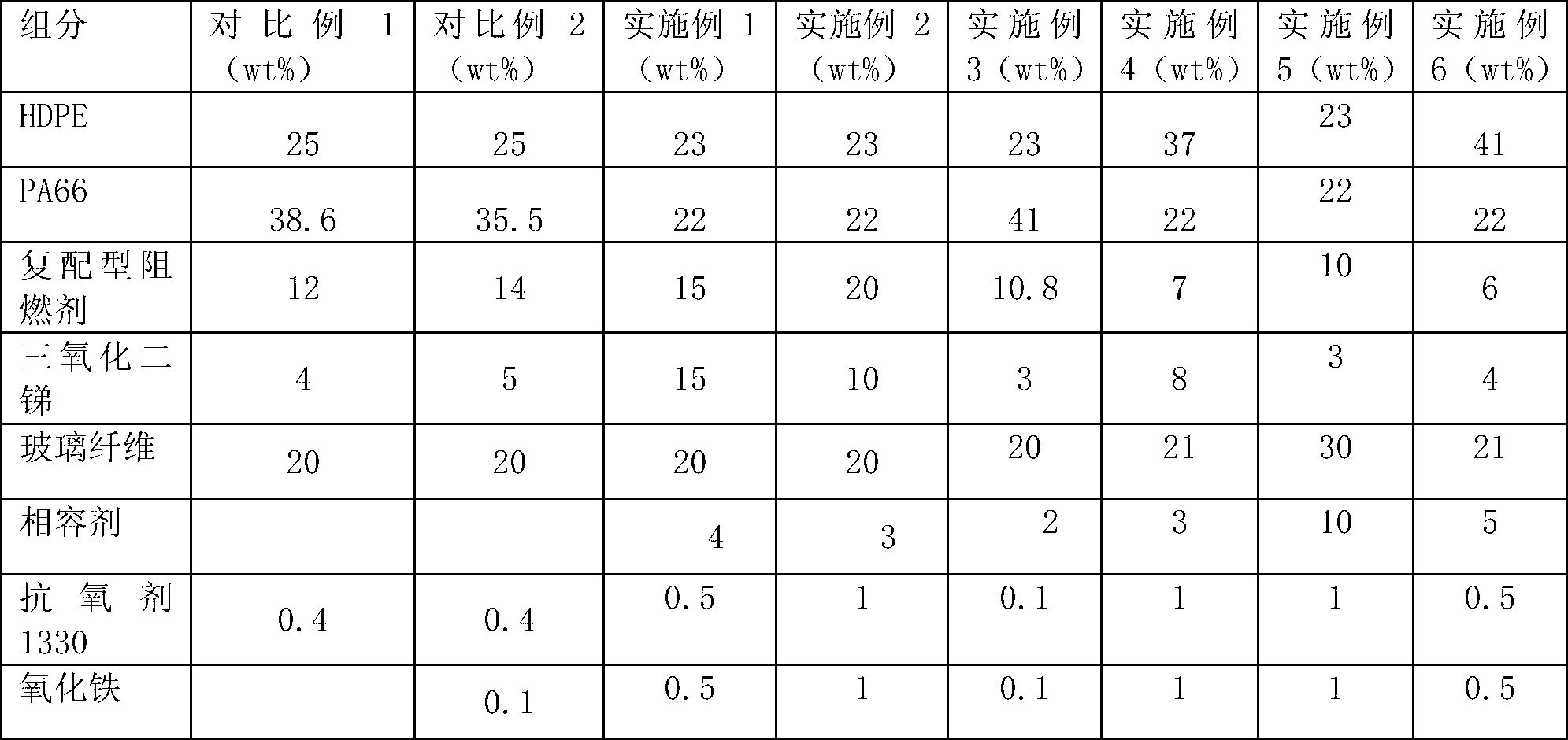

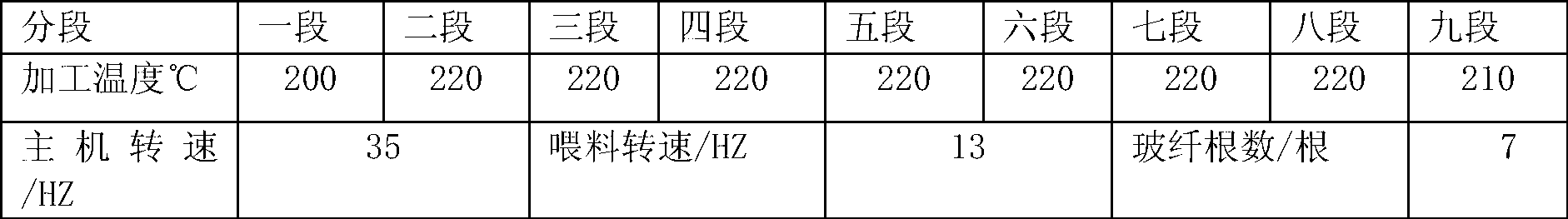

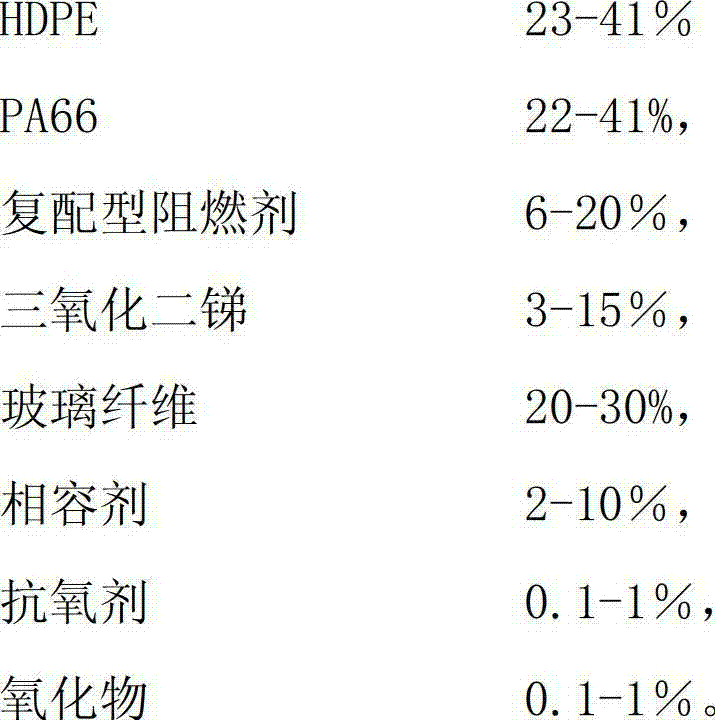

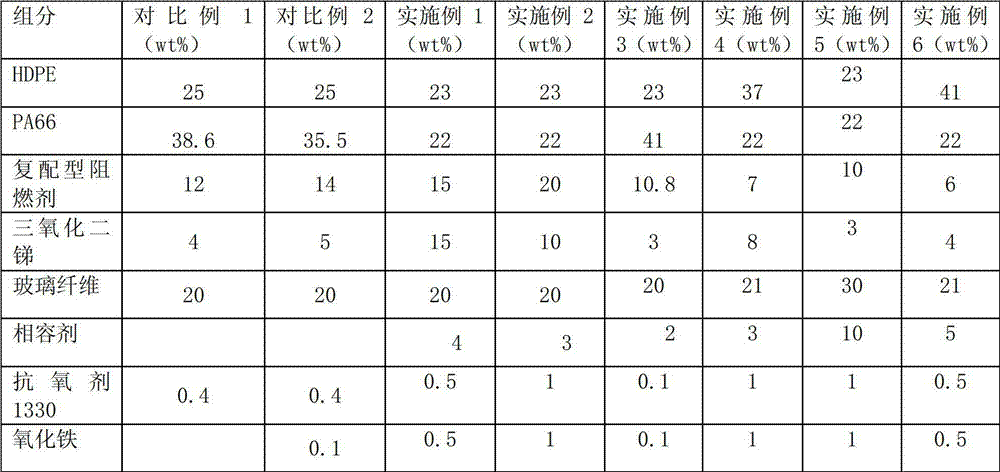

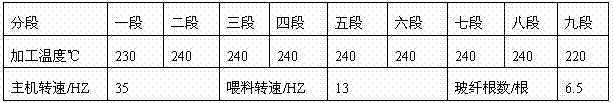

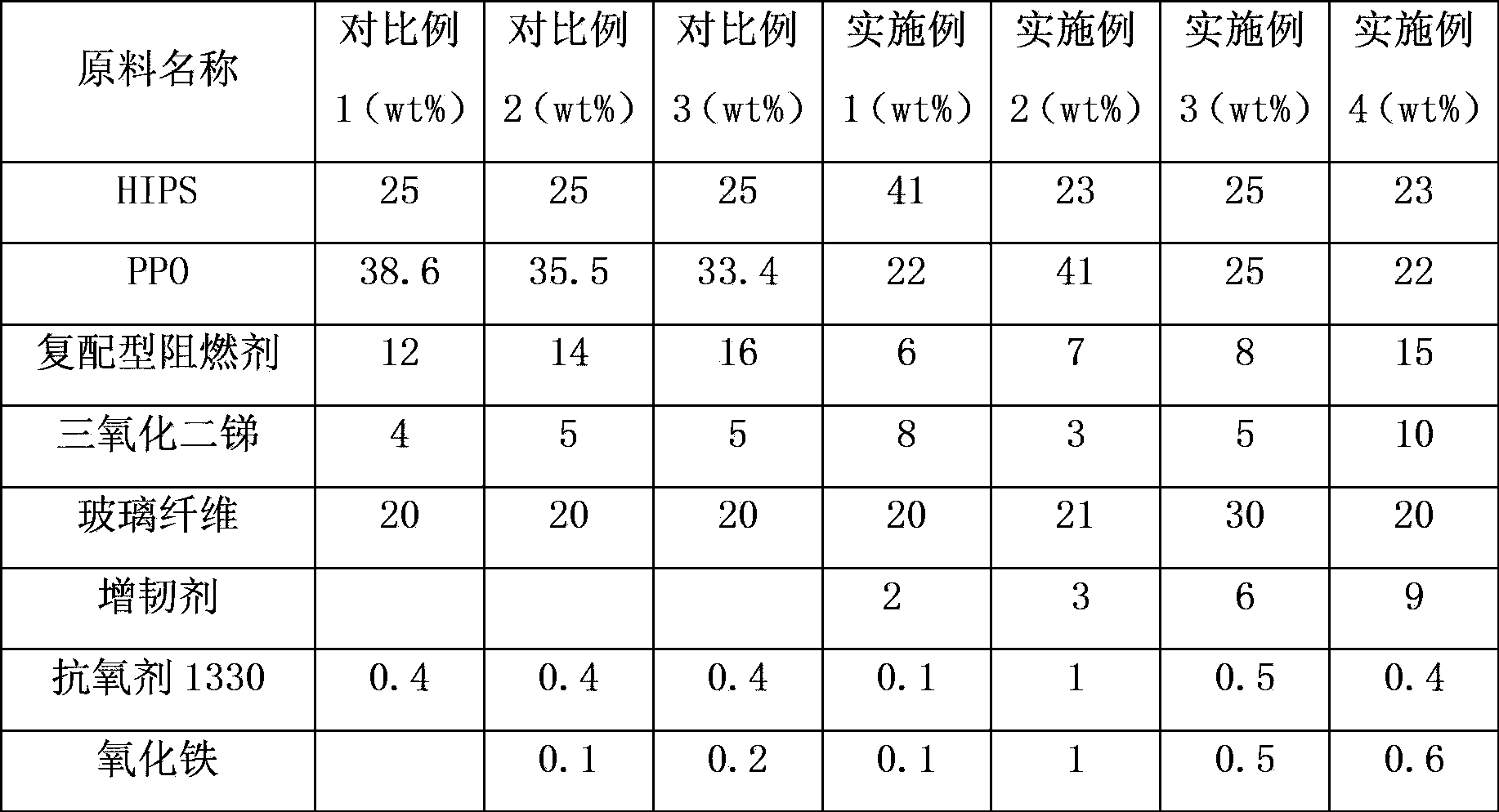

Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

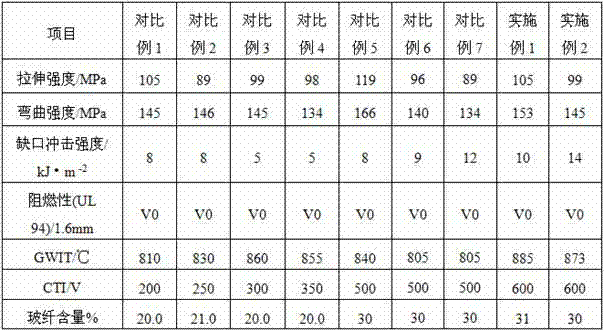

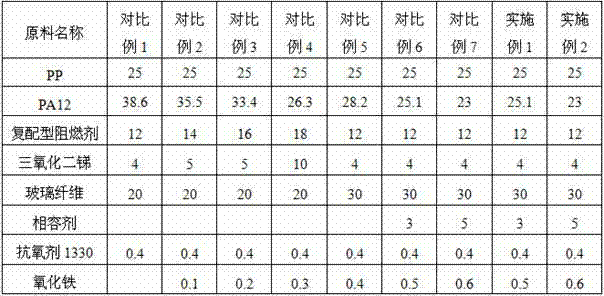

Environment-friendly flame retardant glass fiber reinforced polypropylene/ polyamide12 (PP/ PA12) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

The invention discloses an environment-friendly flame retardant glass fiber reinforced polypropylene / polyamide12 (PP / PA12) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 23-41% of PP, 22-41% of PA12, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PP / PA12 alloy material with high CTI value and high GWIT value. The environment-friendly flame retardant glass fiber reinforced PP / PA12 alloy material with high CTI value and high GWIT value has the advantages of being higher in GWIT and CTI, environment-friendly and balanced in combination properties, thus being widely applied to a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket and a moulded case circuit breaker.

Owner:SHANGHAI SUNNY

Environment-friendly and flame-retardant glass fibre reinforced PP/PA1010 alloy material with high CTI (comparative tracking index) valve and high GWIT (glow wire ignition temperature) value and preparation method thereof

The invention provides an environment-friendly and flame-retardant glass fibre reinforced PP / PA1010 alloy material with a high CTI (comparative tracking index) valve and a high GWIT (glow wire ignition temperature) value, which is prepared from raw materials in percentage by weight: 23-41% of PP (propene polymer), 22-41% of PA1010, 6-20% of a compound flame retardant, 3-15% of antimonous oxide, 20-30% of glass fibres, 2-10% of a compatilizer, 0.1-1% of an antioxidant and 0.1-1% of oxides, wherein the compound flame retardant is composed of substances in the percentage by weight: 50% of BPS (brominated polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention further provides a preparation method for the material aforementioned. The material and the preparation method provided by the invention have the following advantages that with the adoption of a novel flame-retardant compound system, the GWIT value of the material is increased by 50-100 DEG C, and glow wires at 850 DEG C can pass; due to the addition of the glass fibres, the GWIT value of the material is also obviously increased; simultaneously, the impact performance and the ageing resistance of the material are improved, the processing flowability and the smoothness are enhanced, and the friction coefficient is lowered.

Owner:SHANGHAI SUNNY

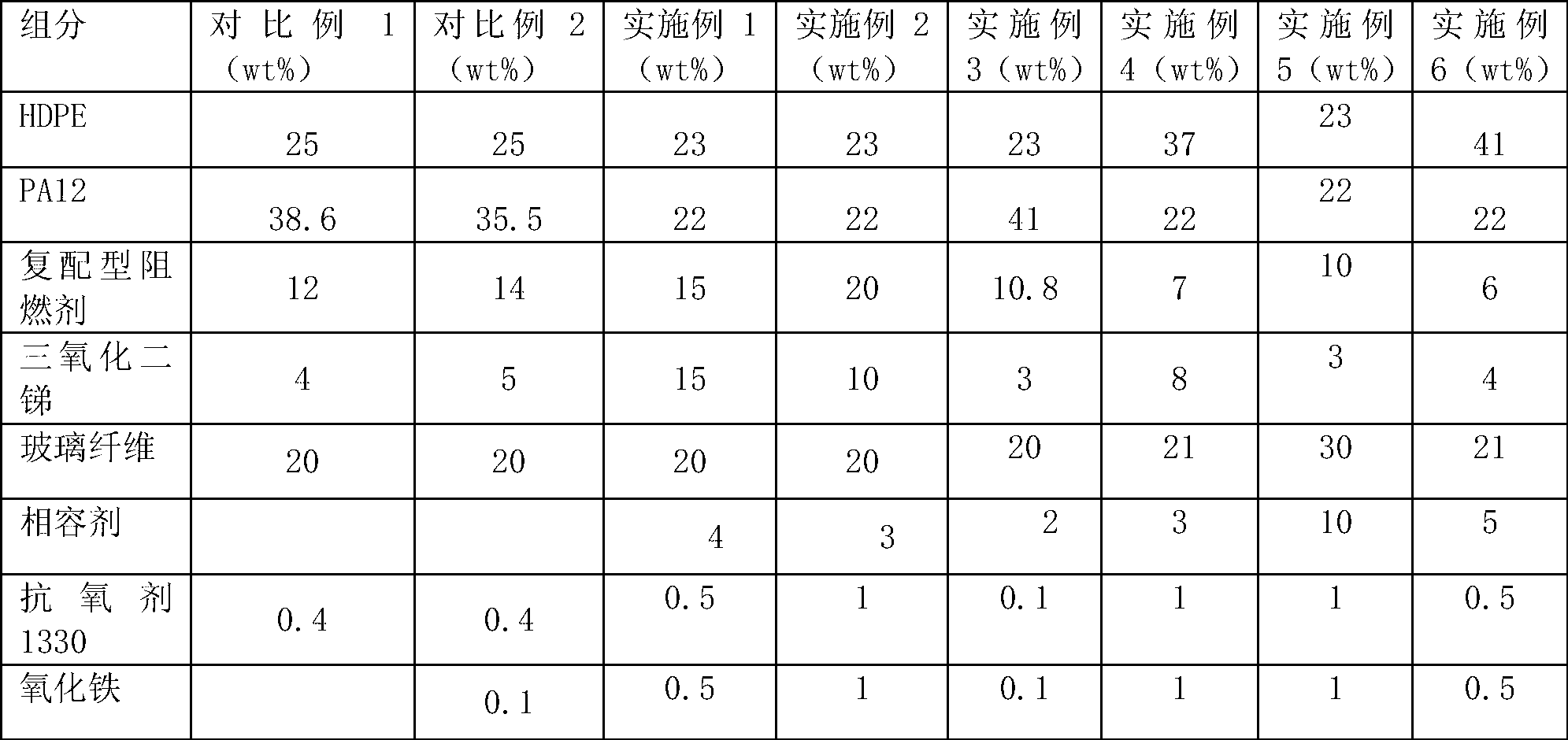

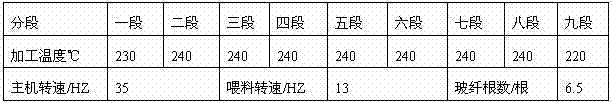

Flame-retardant glass fiber-reinforced HDPE/PA12 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA12 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA12, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

Environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene)/PA (polyamide) 6 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

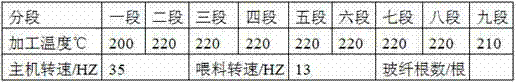

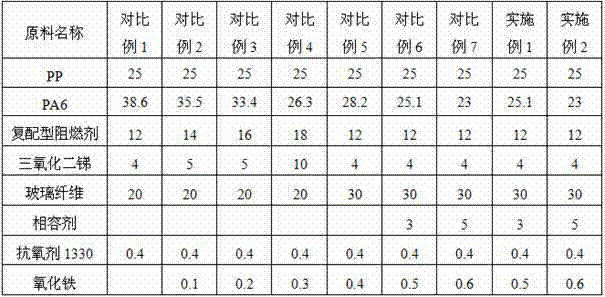

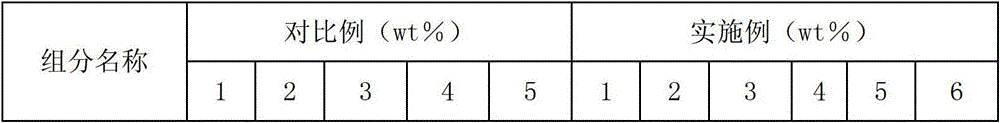

The invention relates to an environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene) / PA (polyamide) 6 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material is prepared from the following raw materials in percentage by weight: 23-41% of PP, 22-41% of PA6, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT and high CTI, is environment-friendly, has balanced overall performances and can be widely applied to low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

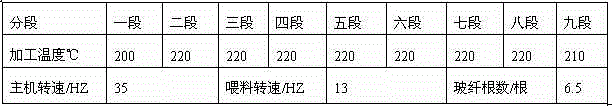

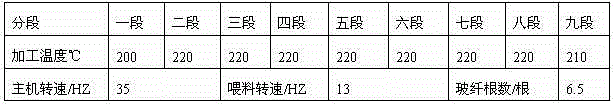

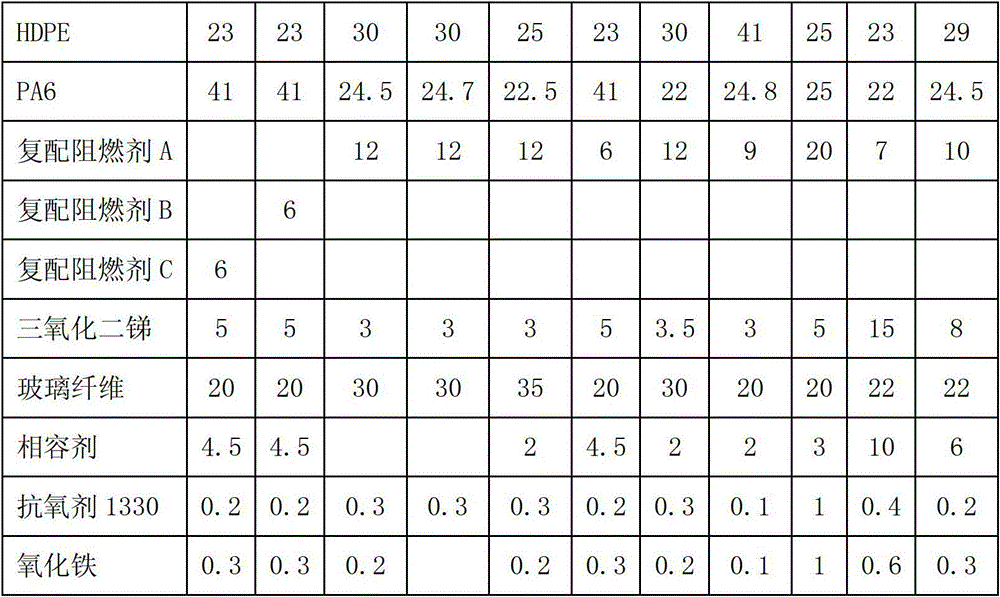

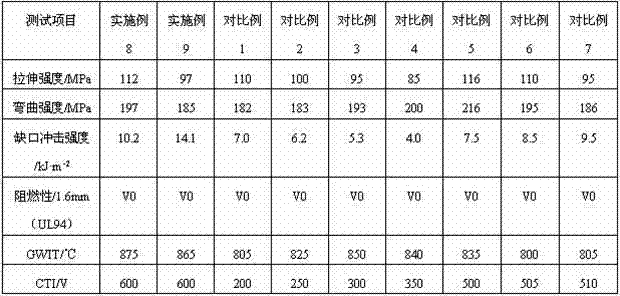

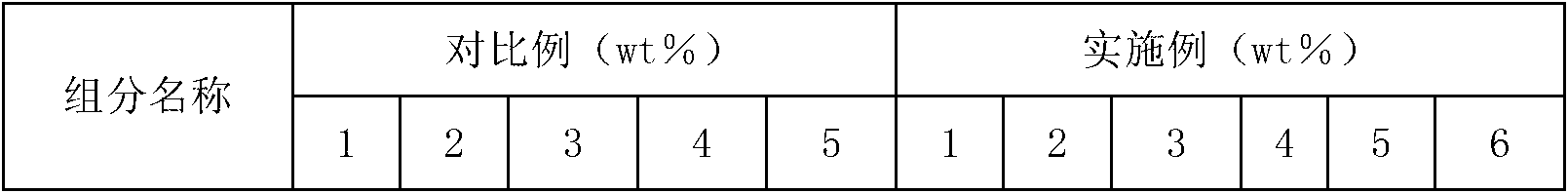

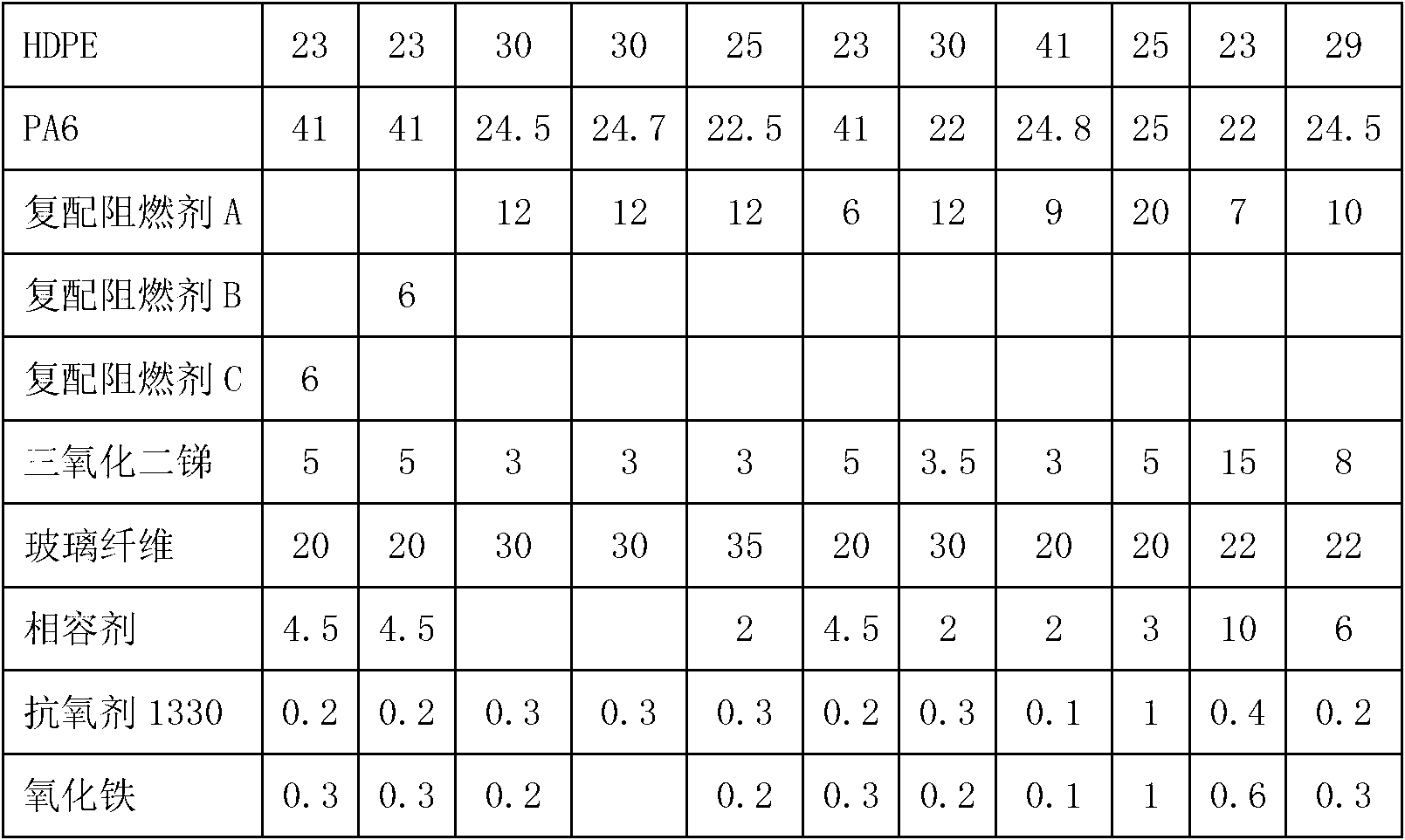

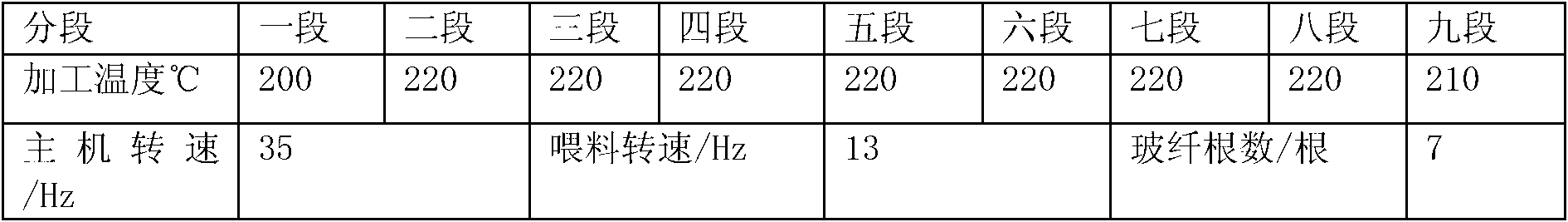

Flame-retardant glass fiber-reinforced HDPE/PA6 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA6 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA6, 6 to 15% of a compound fire retardant, 3 to 10% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 9% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of a metallic oxide. In preparation of the alloy material, all the components are added into a high-speed mixer for mixing for 2 to 5 min, and then discharging and extrusion granulation in a twin-screw extruder are carried out, wherein extrusion temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness, balanced comprehensive properties and the like and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

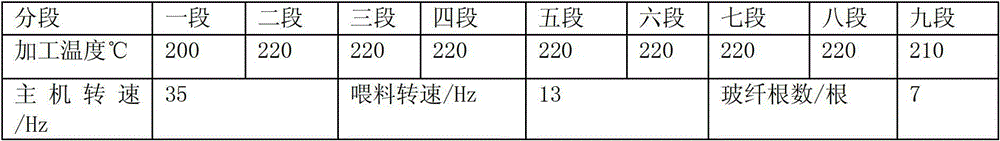

Environment-friendly and flame-retardant glass fiber reinforced PBT (polybutylene terephthalate)/ABS (acrylonitrile butadiene styrene) alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

The invention discloses an environment-friendly and flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) / ABS (acrylonitrile butadiene styrene) alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material comprises the following raw components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound flame retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT value and CTI value and good flame retardant effect, is environment-friendly, has balanced overall performances and can be widely applied to such products in the field of electronics as low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

Flame-retardant glass fiber-reinforced HDPE/PA6 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA6 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA6, 6 to 15% of a compound fire retardant, 3 to 10% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 9% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of a metallic oxide. In preparation of the alloy material, all the components are added into a high-speed mixer for mixing for 2 to 5 min, and then discharging and extrusion granulation in a twin-screw extruder are carried out, wherein extrusion temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness, balanced comprehensive properties and the like and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

A kind of high cti value, high gwit value environment-friendly flame-retardant glass fiber reinforced pp material and preparation method thereof

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP (Polypropylene) material which is prepared from the following raw materials in percentage by weight: 45%-68.8% of PP, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP material. The high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C by adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; in addition, impact property and ageing-resistant property are improved, processing fluidity and smoothness are enhanced, and friction factor is lowered.

Owner:上海日之升科技有限公司

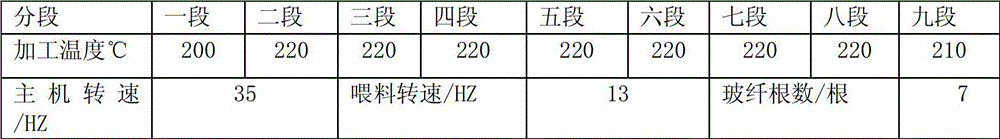

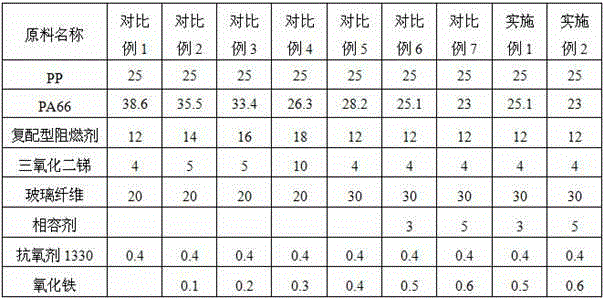

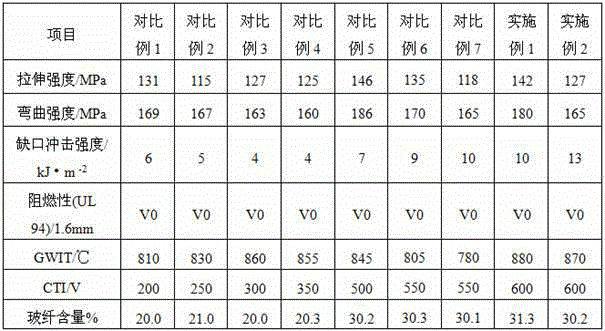

Environment-friendly flame retardant glass fiber reinforced polypropylene/ polyamide66 (PP/ PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

The invention discloses an environment-friendly flame retardant glass fiber reinforced polypropylene / polyamide66 (PP / PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 23-41% of PP, 22-41% of PA66, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value. The environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value has the advantages of being higher in GWIT and CTI, environment-friendly and balanced in combination properties, thus being widely applied to a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket and a moulded case circuit breaker.

Owner:SHANGHAI SUNNY

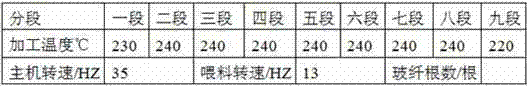

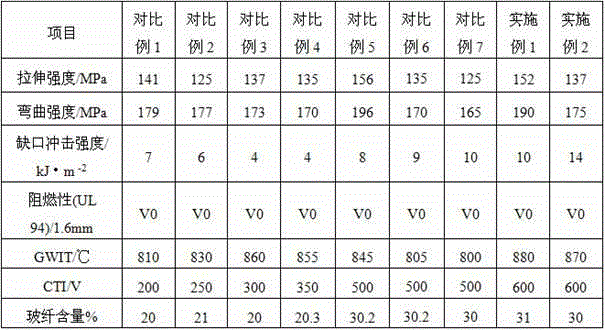

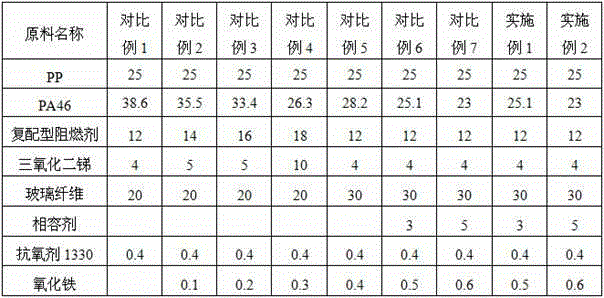

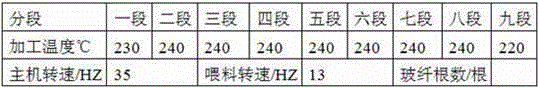

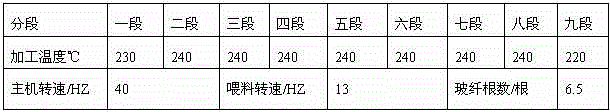

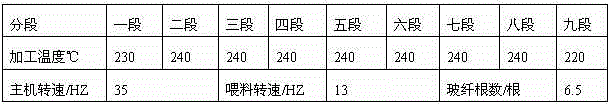

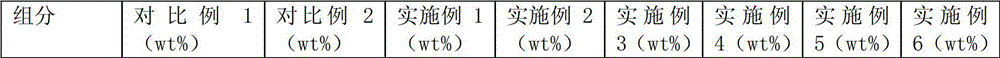

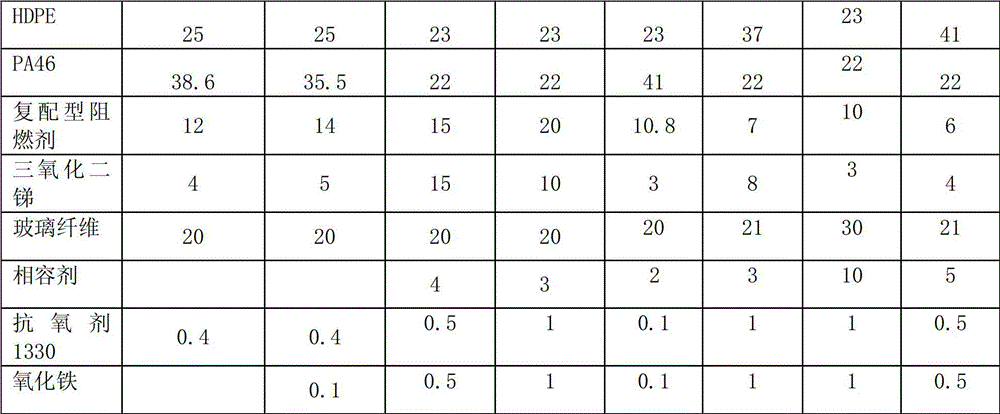

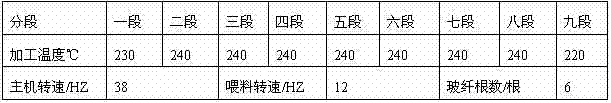

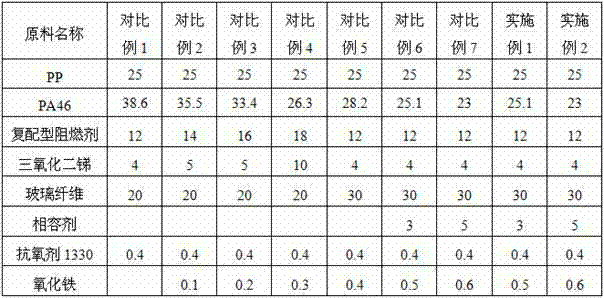

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa46 alloy material and preparation method thereof

Owner:SHANGHAI SUNNY

High-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP/PA612 (Polypropylene/Polyamide 612) alloy material and preparation method thereof

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP / PA612 (Polypropylene / Polyamide 612) alloy material which is prepared from the following raw materials in percentage by weight: 23%-41% of PP, 22%-41% of PA612, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PA612 alloy material. The high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PA612 alloy material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C due to adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; moreover, and impact property and ageing-resistant property are improved, processing fluidity and smoothness are increased and friction factor is lowered.

Owner:SHANGHAI SUNNY

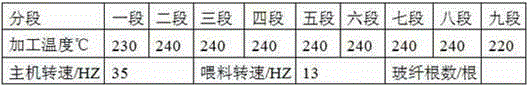

Flame-retardant glass fiber-reinforced HDPE/PA46 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA46 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA46, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

Environment-friendly flame retardant glass fiber reinforced polypropylene/ polyamide66 (PP/ PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

The invention discloses an environment-friendly flame retardant glass fiber reinforced polypropylene / polyamide66 (PP / PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 23-41% of PP, 22-41% of PA66, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value. The environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value has the advantages of being higher in GWIT and CTI, environment-friendly and balanced in combination properties, thus being widely applied to a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket and a moulded case circuit breaker.

Owner:SHANGHAI SUNNY

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa612 alloy material and preparation method thereof

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP / PA612 (Polypropylene / Polyamide 612) alloy material which is prepared from the following raw materials in percentage by weight: 23%-41% of PP, 22%-41% of PA612, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PA612 alloy material. The high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PA612 alloy material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C due to adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; moreover, and impact property and ageing-resistant property are improved, processing fluidity and smoothness are increased and friction factor is lowered.

Owner:SHANGHAI SUNNY

Environment-friendly flame-retardant glass fiber reinforced PP/PA610 (polypropylene/polyamide 610) alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

InactiveCN102936376BHigh GWIT valueImprove impact performancePolymer scienceComparative Tracking Index

The invention provides an environment-friendly flame-retardant glass fiber reinforced PP / PA610 (polypropylene / polyamide 610) alloy material with a high CTI (comparative tracking index) value and a high GWIT (glow-wire ignition temperature) value, which is prepared by following materials by weight percent: 23-41% of PP, 22-41% of PA610, 6-20% of compound type flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxidizing materials, wherein the compound type flame retardant is prepared by the following substances by weight percent: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powders. The invention also provides a preparation method the material. The environment-friendly flame-retardant glass fiber reinforced PP / PA610 alloy material has the advantages that a novel flame-retardant compound system is adopted, so that the GWIT of the material is improved by 50-100 DEG C, the material can pass 850 DEG C glow-wire, the GWIT values of the material is obviously improved due to the addition of glass fibers, meanwhile, the impact performance and the anti-aging performance of the material are improved, the processing mobility and the smoothness are improved, and the friction coefficient is reduced.

Owner:SHANGHAI SUNNY

Environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene)/PA (polyamide) 46 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

The invention relates to an environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene) / PA (polyamide) 46 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material is prepared from the following raw materials in percentage by weight: 23-41% of PP, 22-41% of PA46, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT and high CTI, is environment-friendly, has balanced overall performances and can be widely applied to low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

Environment-friendly and flame-retardant glass fibre reinforced PP/PA1010 alloy material with high CTI (comparative tracking index) valve and high GWIT (glow wire ignition temperature) value and preparation method thereof

The invention provides an environment-friendly and flame-retardant glass fibre reinforced PP / PA1010 alloy material with a high CTI (comparative tracking index) valve and a high GWIT (glow wire ignition temperature) value, which is prepared from raw materials in percentage by weight: 23-41% of PP (propene polymer), 22-41% of PA1010, 6-20% of a compound flame retardant, 3-15% of antimonous oxide, 20-30% of glass fibres, 2-10% of a compatilizer, 0.1-1% of an antioxidant and 0.1-1% of oxides, wherein the compound flame retardant is composed of substances in the percentage by weight: 50% of BPS (brominated polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention further provides a preparation method for the material aforementioned. The material and the preparation method provided by the invention have the following advantages that with the adoption of a novel flame-retardant compound system, the GWIT value of the material is increased by 50-100 DEG C, and glow wires at 850 DEG C can pass; due to the addition of the glass fibres, the GWIT value of the material is also obviously increased; simultaneously, the impact performance and the ageing resistance of the material are improved, the processing flowability and the smoothness are enhanced, and the friction coefficient is lowered.

Owner:SHANGHAI SUNNY

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/ppo alloy material and preparation method thereof

The invention provides a high-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP / PPO (Polypropylene / Polyphenylene Oxide) alloy material which is prepared from the following raw materials in percentage by weight: 23%-41% of PP, 22%-41% of PPO, 6%-20% of compound flame retardant, 3%-15% of antimony trioxide, 20%-30% of glass fibers, 2%-10% of compatilizer, 0.1%-1% of antioxidant and 0.1%-1% of oxide, wherein the compound flame retardant contains the following materials in percentage by weight: 50% of BPS (Brominated Polystyrene), 25% of magnesium hypophosphite and 25% of talcum powder. The invention also provides a preparation method of the high-CTI high-GWIT environmental-friendly flame-retardant glass fiber reinforced PP / PPO alloy material. The high-CTI value high-GWIT value environmental-friendly flame-retardant glass fiber reinforced PP / PPO alloy material provided by the invention has the advantages that the GWIT value is increased by 50-100 DEG C by adoption of a novel flame-retardant compounding system, so that the material can pass 850 DEG C glow-wire test; the GWIT value is also obviously increased through the addition of the glass fibers; in addiiton, impact property and ageing-resistant property are improved, processing fluidity and smoothness are increased and friction factor is lowered.

Owner:SHANGHAI SUNNY

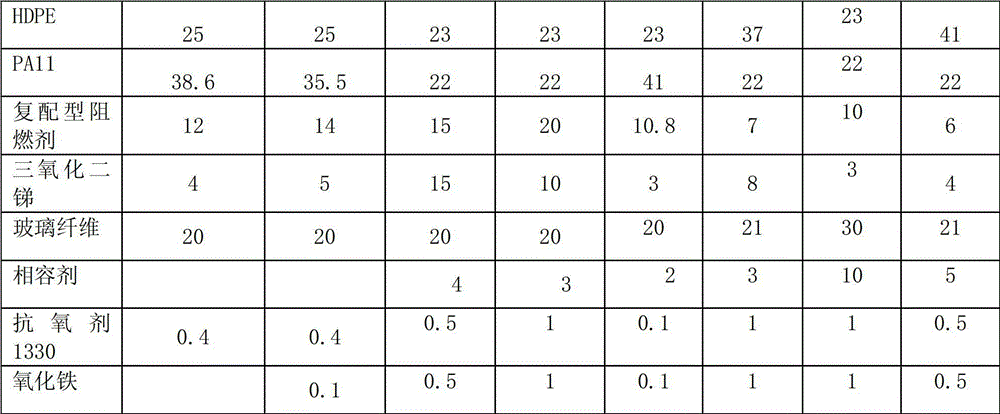

Flame-retardant glass fiber-reinforced HDPE/PA11 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA11 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA11, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

A kind of reduction smelting slag and its application in reduction smelting of crude antimony oxide

The invention relates to reduction smelting slag and application of the reduction smelting slag to reduction smelting of coarse antimony oxide, and belongs to the field of nonferrous metallurgy. The designed reduction smelting slag comprises, by mass, 20-40 parts of SiO2, 20-40 parts of FeO, 5-20 parts of CaO and 5-25 parts of Na2O. During reduction smelting of the coarse antimony oxide, the set reduction smelting slag is supplemented, the temperature ranging from 900 DEG C to 1,200 DEG C is kept for 30-120 min, coarse antimony, glass slag, smoke and flue gas can be generated, the coarse antimony and the slag are independently discharged after settling separation, the smoke is subjected to powder returning treatment, and the flue gas is exhausted after being purified. The design technology has the beneficial effects that the smelting temperature is low, the antimony content of the slag is small, the antimony direct recovery rate is high, and the powder returning amount is small; and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

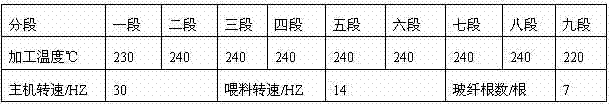

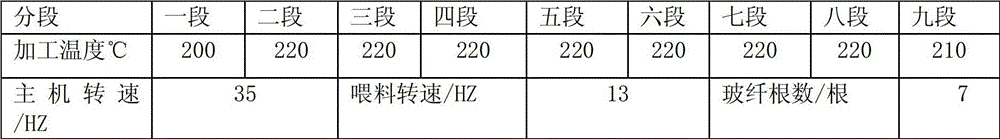

Flame-retardant glass fiber-reinforced HIPS/PPO material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HIPS / PPO material with a high CTI value and a high GWIT value. The alloy material comprises the following components by weight: 23 to 41% of HIPS, 22 to 41% of PPO, 6 to 15% of a compound fire retardant, 3 to 10% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 9% of a toughening agent, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. A preparation method for the material comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. The material provided by the invention has the advantages of a high CTI value, a high GWIT value, environment-friendliness and balanced comprehensive properties and can be used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

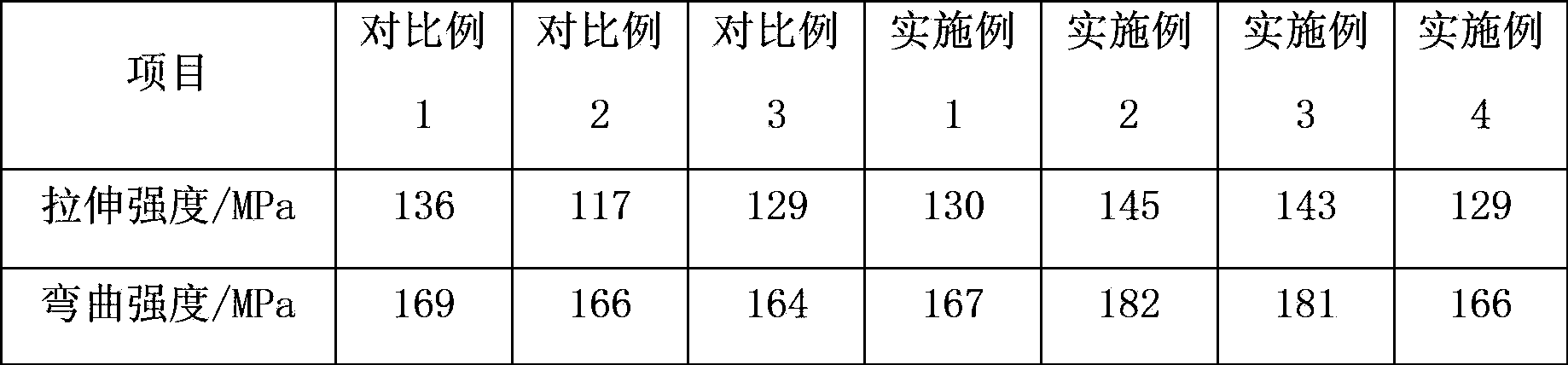

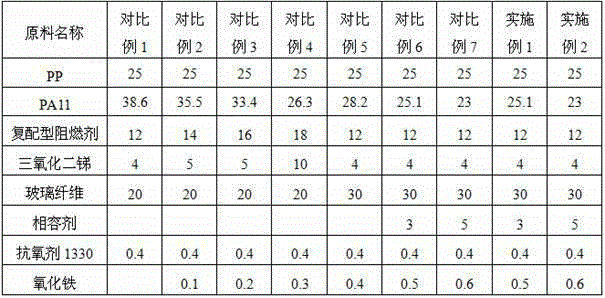

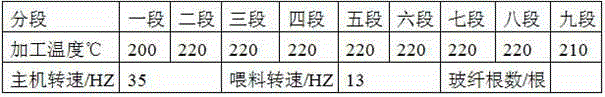

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa11 alloy material and preparation method thereof

The invention relates to an environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene) / PA (polyamide) 11 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material is prepared from the following raw materials in percentage by weight: 23-41% of PP, 22-41% of PA11, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT and high CTI, is environment-friendly, has balanced overall performances and can be widely applied to low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com