High-CTI (Creepage Tracking Index) high-GWIT (Glow-Wire Ignition Temperature) environmental-friendly flame-retardant glass fiber reinforced PP/PPO (Polypropylene/Polyphenylene Oxide) alloy material and preparation method thereof

An alloy material and an environmentally friendly technology, which is applied in the field of environmentally friendly flame-retardant glass fiber reinforced PP/PPO alloy materials and their preparation, to achieve the effects of improving impact performance, high CTI value, and improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Preparation of PP / PPO alloy material of the present invention (1)

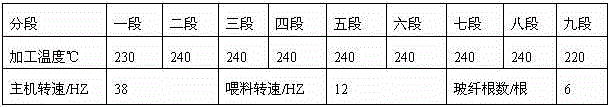

[0061] Weigh raw materials by weight percentage: PP 25%, PPO (intrinsic viscosity: 1.0dl / g) 25.1%, compound flame retardant 12%, antimony trioxide 4%, alkali-free glass treated with silane coupling agent Fiber 30%, maleic anhydride grafted SEBS 3%, antioxidant 1330 0.4%, iron oxide 0.5%; put the weighed raw materials into a high mixer and mix for 5 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 35HZ, and the specific processing conditions are shown in the table below.

[0062]

Embodiment 2

[0063] Example 2 Preparation of PP / PPO alloy material of the present invention (2)

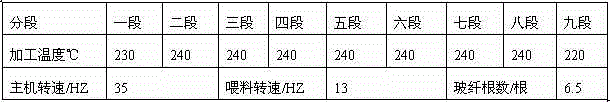

[0064] Weigh raw materials by weight percentage: PP 25%, PPO (intrinsic viscosity: 1.0dl / g) 23%, compound flame retardant 12%, antimony trioxide 4%, alkali-free glass treated with silane coupling agent Fiber 30%, maleic anhydride grafted SEBS 5%, antioxidant 1330 0.4%, iron oxide 0.6%; put the weighed raw materials into a high mixer and mix for 2 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 35HZ, and the specific processing conditions are shown in the table below.

[0065]

Embodiment 3

[0066] Example 3 Preparation of PP / PPO alloy material of the present invention (3)

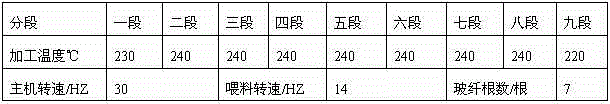

[0067] Weigh raw materials by weight percentage: PP 23%, PPO (intrinsic viscosity: 1.0dl / g) 22%, compound flame retardant 20%, antimony trioxide 4.3%, alkali-free glass treated with silane coupling agent Fiber 20%, maleic anhydride grafted SEBS 10%, antioxidant 1330 0.1%, iron oxide 0.6%; put the weighed raw materials into a high mixer and mix for 2 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 30HZ, and the specific processing conditions are shown in the table below.

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com