High-GWIT flame-retardant PBT/PET alloy material as well as preparation method and application thereof

An alloy material and PBT resin technology, which is applied in the field of engineering plastics, can solve the problems that the GWIT value of flame-retardant PBT/PET alloy materials cannot reach 850 °C and cannot meet the GWIT requirements, and achieve the effect of excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

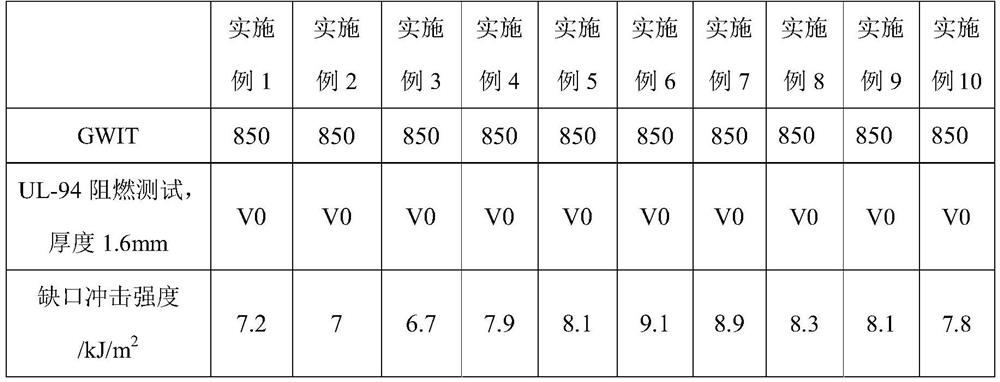

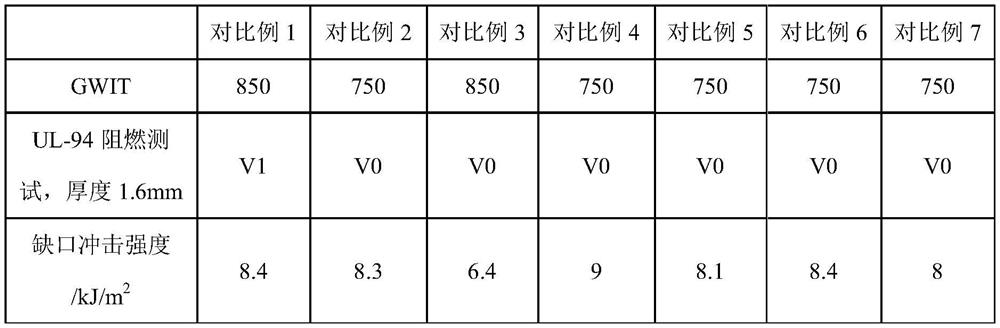

Examples

Embodiment 1~7

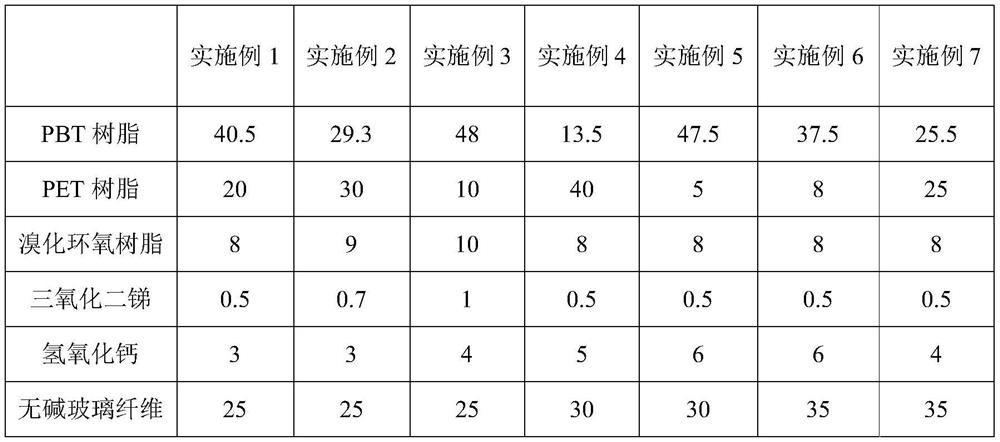

[0037] A flame-retardant PBT / PET alloy material with high GWIT, including the components shown in Table 1 by weight percentage.

[0038] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C. Manufacturer: Taiwan Changchun Chemical Industry, Brand: PBT 1200-211M

[0039] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270°C. Manufacturer: Sinopec Yizheng Chemical Fiber, Brand: PET FG600

[0040] The particle size of calcium hydroxide is 5 μm. commercially available.

[0041] Brominated flame retardants are brominated epoxy resins. Manufacturer: Israel Chemical Group, Brand: Powder-F-2100.

[0042] The preparation method of the flame-retardant PBT / PET alloy material with high GWIT is as follows:

[0043] 1) Dry PBT at 135°C for 4 hours and set aside;

[0044]2) Mix PBT resin, PET resin, brominated flame retardant, antimony trioxide, and calcium hydroxide evenly, and add them to the twin-screw extruder. The alkali-fre...

Embodiment 8

[0048] A flame-retardant PBT / PET alloy material with high GWIT, by weight percentage, comprises the following components:

[0049] 25.5 parts of PBT resin

[0050] 25 parts PET resin

[0051] 8 parts brominated flame retardant

[0052] 0.5 parts of antimony trioxide

[0053] 4 parts calcium hydroxide

[0054] 35 parts of E-glass fiber.

[0055] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C.

[0056] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270°C.

[0057] Brominated flame retardants are brominated epoxy resins.

[0058] Calcium hydroxide is calcium hydroxide having a particle diameter of 8 μm.

[0059] The preparation method of the flame-retardant PBT / PET alloy material with high GWIT is the same as that in Example 1.

Embodiment 9

[0061] A flame-retardant PBT / PET alloy material with high GWIT, by weight percentage, comprises the following components:

[0062] 25.5 parts of PBT resin

[0063] 25 parts PET resin

[0064] 8 parts brominated flame retardant

[0065] 0.5 parts of antimony trioxide

[0066] 4 parts calcium hydroxide

[0067] 35 parts of E-glass fiber.

[0068] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230°C.

[0069] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270°C.

[0070] Brominated flame retardants are brominated epoxy resins.

[0071] Calcium hydroxide is calcium hydroxide having a particle diameter of 10 μm.

[0072] The preparation method of the flame-retardant PBT / PET alloy material with high GWIT is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com