Curing agent and copper-clad plate

A technology of curing agent and copper clad laminate, which is applied in the direction of printed circuit components, etc., can solve the problems of poor heat resistance, high price, poor interlayer bonding force, etc., and achieve the effect of low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Preparation of hydroxylphenol

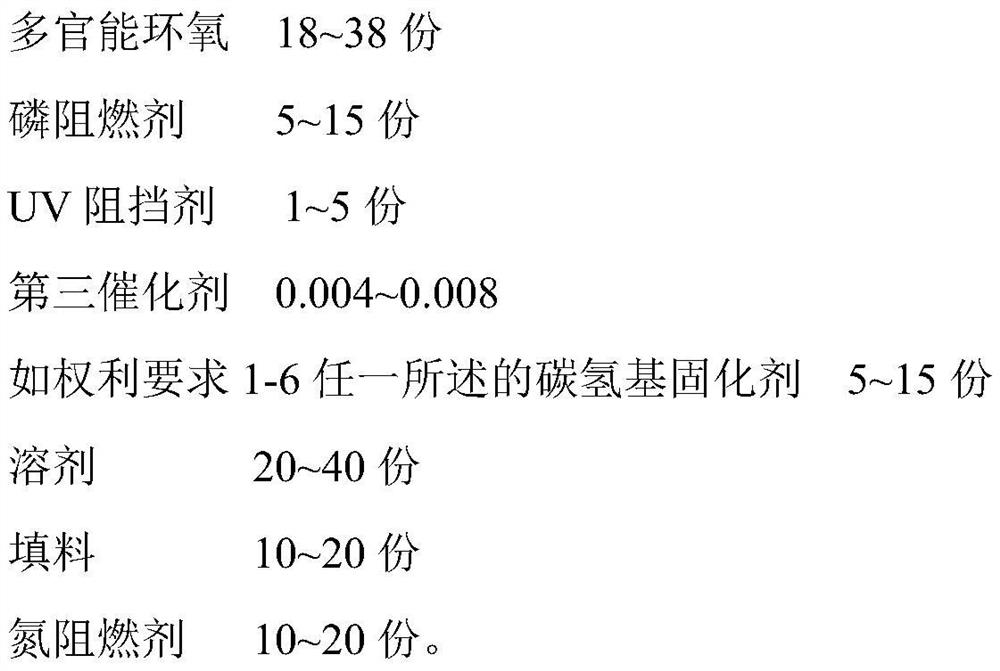

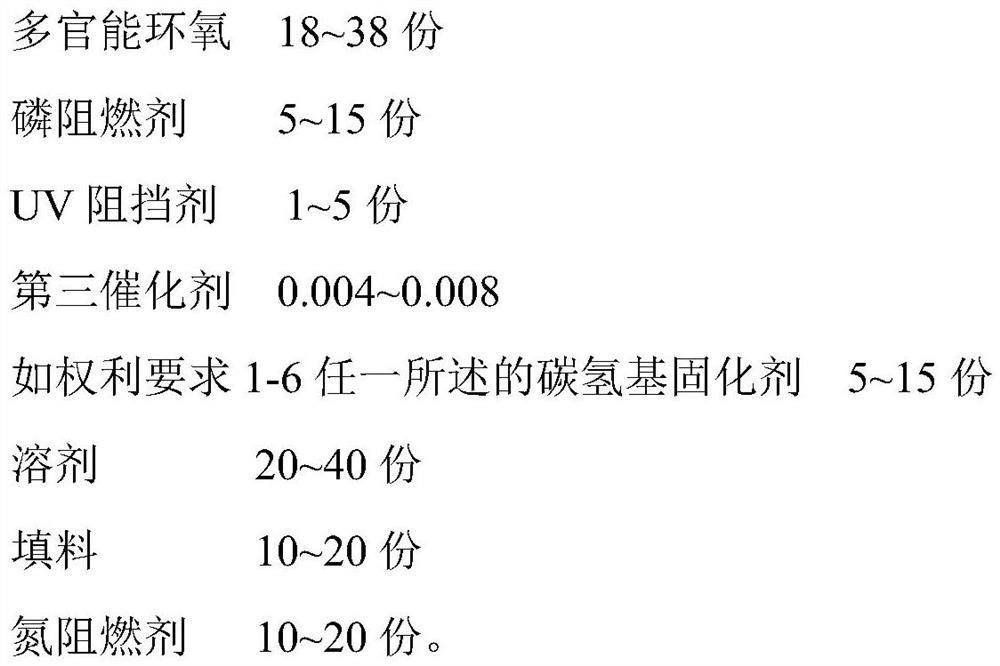

[0023] Raw material ratio:

[0024] Phenol: a double-toroidal olefin = 1.3: 1 (Mol ratio); olefin is propylene.

[0025] The addition of phenol is selected from the four-mouth flask equipped with a stirrer, a thermometer, a constant voltage drip funnel, and a condenser, and a dioble olefin uses a dropwise method, and the drip speed is 50 g / min.

[0026] Catalyst: Cation exchange resin, catalytic reaction temperature 95 ° C and 100 ° C, reaction time, and purified to obtain a hydrohydrohydrothyol intermediate.

[0027] Step 2: Preparation of long chain carbon-based curing agent:

[0028] The resulting hydroxophenol intermediate 0.25 mol is melted in four flasks equipped with a stirrer, a thermometer, a constant pressure drip funnel and a condenser, and 0.005 mol catalyst acetate, and zinc. The reaction was reacted in 4 to 6 hours under 90 to 100 ° C, toluene, fractionated dehydration layer, dense benzene in 240 to 260 ° C, and the re...

Embodiment 2

[0042] Generally with Example 1, different places in, in step 1, phenol: a di-bond olefin = 1.1: 1 (Mol ratio); olefin is diusobutylene.

[0043] In step 2, the molar ratio of the hydroxophenol intermediate, formaldehyde, and the first catalyst is 0.25: 0.2: 0.006.

Embodiment 3

[0045] In general, in the first embodiment, in terms of, in step 1, phenol: a di-bond olefin = 1.4: 1 (mol ratio); olefin is cyclopentene.

[0046] In step 2, the molar ratio of the hydrocarbylpol intermediate, formaldehyde, and the first catalyst is 0.25: 0.4: 0.004.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com