Epoxy resin adhesive with high comparative tracking index and preparation method thereof

A tracking index, epoxy resin technology, applied in epoxy resin glue, polymer adhesive additives, non-polymer adhesive additives and other directions, can solve problems such as difficulty in meeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

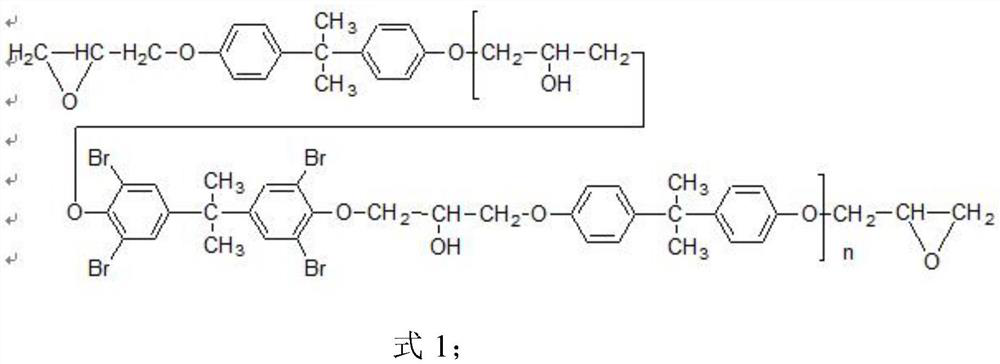

Method used

Image

Examples

Embodiment 1

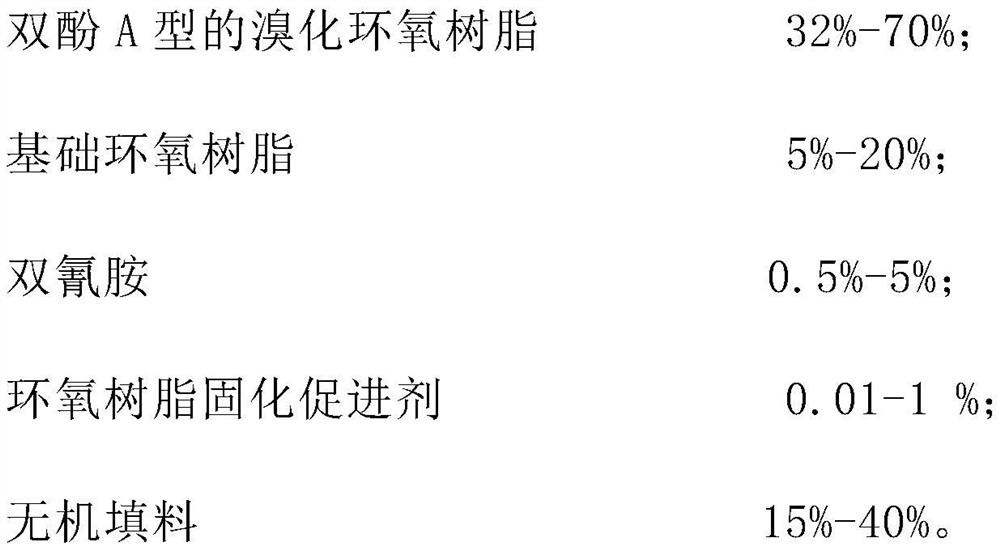

[0042] 1. the mass percent composition of the solids in the resin composition is 69%, and all the other are organic solvents (such as dimethylformamide), wherein, the formula of the solids is shown in the following table 1 (by weight);

[0043] Table 1

[0044]

[0045] 2. Glue baking:

[0046] The prepreg gluing speed is 12m / min.

[0047] 3. Prepreg control parameters:

[0048] The gel time is 90 seconds; the resin content is 48.1%;

[0049] Resin fluidity is 19%; volatile matter is 0.18%;

[0050] 4. Platen parameters:

[0051] The vacuum degree is -0.088MPa; the pressure is 120-500psi;

[0052] The hot plate temperature is 100-220°C; the curing time is >170°C for 30 minutes.

[0053] 5. The performance parameters of the substrate are shown in Table 2:

[0054] Table 2

[0055] project Test Results Glass transition temperature (DSC), °C 141 Copper Foil Peel Strength(1oz),lb / in 9.3 T260(TMA),min 20 Flame retardant (UL-94, rating) ...

Embodiment 2

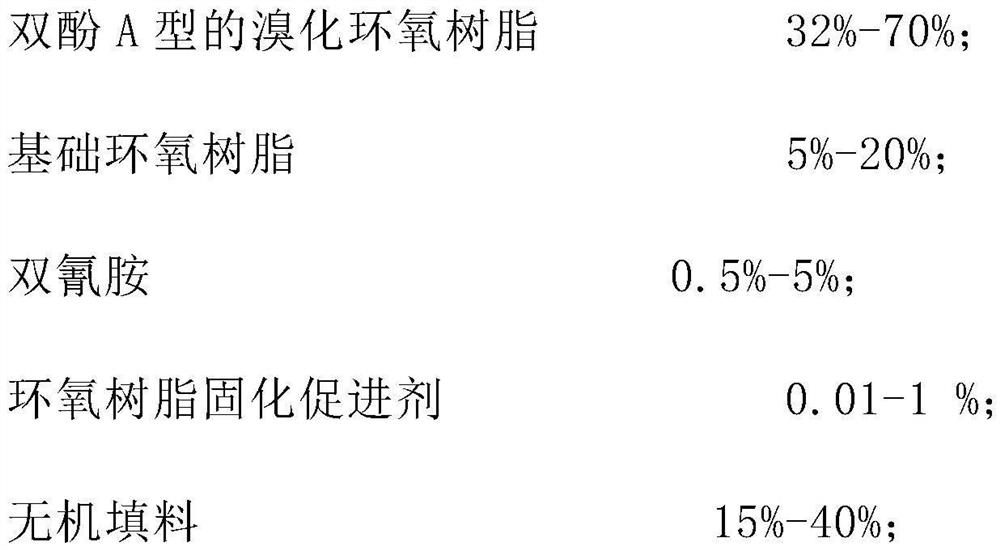

[0057] 1. the mass percent composition of the solids in the resin composition is 65%, and all the other are organic solvents (such as dimethylformamide), wherein, the formula of the solids is shown in the following table 3 (by weight);

[0058] table 3

[0059]

[0060] 2. Glue baking:

[0061] The prepreg gluing speed is 14m / min.

[0062] 3. Prepreg control parameters:

[0063] The gel time is 93 seconds; the resin content is 49%;

[0064] Resin fluidity is 18%; volatile matter is 0.15%;

[0065] 4. Platen parameters:

[0066] The vacuum is -0.090MPa; the pressure is 120-500psi;

[0067] The hot plate temperature is 100-220°C; the curing time is >170°C for 30 minutes.

[0068] 5. The performance parameters of the substrate are shown in Table 4:

[0069] Table 4

[0070] project Test Results Glass transition temperature (DSC), °C 143 Copper Foil Peel Strength(1oz),lb / in 9.1 T260(TMA),min 22 Flame retardant (UL-94, rating) V-0 CT...

Embodiment 3

[0072] 1. the mass percent composition of the solids in the resin composition is 63%, and all the other are organic solvents (such as dimethylformamide), wherein, the formula of the solids is shown in the following table 5 (by weight):

[0073] table 5

[0074]

[0075] 2. Glue baking:

[0076] The prepreg gluing speed is 15m / min.

[0077] 3. Prepreg control parameters:

[0078] The gel time is 96 seconds; the resin content is 49.5%;

[0079] Resin fluidity is 17%; volatile matter is 0.16%;

[0080] 4. Platen parameters:

[0081] The vacuum is -0.085MPa; the pressure is 120-500psi;

[0082] The hot plate temperature is 100-220°C; the curing time is >170°C for 30 minutes.

[0083] 5. The performance parameters of the substrate are shown in Table 6:

[0084] project Test Results Glass transition temperature (DSC), °C 139 Copper Foil Peel Strength(1oz),lb / in 9.8 T260(TMA),min 18 Flame retardant (UL-94, rating) V-0 CTI(V) >600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel time | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Copper foil peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com