Preparation and Application of Flame Retardant Recyclable Insulation Modified Materials, Insulation Parts

A modified material and insulating varnish technology, which is applied to organic insulators, plastic/resin/wax insulators, polyester coatings, etc., can solve the problems of unrecyclable production efficiency, non-flammability of insulating parts, heavy weight, etc., and improve leakage current Tracking index, reduced water absorption, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] According to the formula of insulating modified materials: Weigh 20.0kg of PA6 resin, 3.3kg of microencapsulated red phosphorus, and 0.1kg of additives, pre-mix for about 10 minutes, add to the feeding port of the twin-screw extruder, and initially melt at 250°C; add glass 10.0kg of fibers were melt-extruded, cooled, dried and pelletized to make granular modified materials. The modified material is pre-dried before use, and the treatment conditions are: 110°C, 6-8h. The modified material is injected into related products in the mold of the injection molding machine. The injection molding conditions are: zone 1, 250±10°C; zone 2, 245±10°C; zone 3, 245±10°C; nozzle, 255±10°C, Mold temperature, 70~80℃; back pressure 15~20MPa.

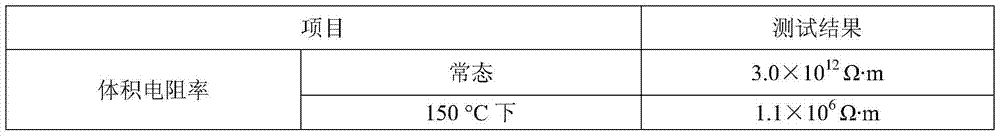

[0025] The relevant electrical performance tests were carried out on the insulating parts of PA6 modified materials, and the results are as follows:

[0026]

[0027]

[0028] Note: This test is tested by Guilin Electric Science Research Ins...

Embodiment 2

[0030] According to the formula of insulating modified materials: Weigh 20.0kg of PA66 resin, 3.3kg of microencapsulated red phosphorus, and 0.1kg of additives, pre-mix for about 10 minutes, add to the feeding port of the twin-screw extruder, and initially melt at 275°C; add glass 10.0kg of fibers were melt-extruded, cooled, dried and pelletized to make granular modified materials. The modified material is pre-dried before use, and the treatment conditions are: 110°C, 6-8h. The modified material is injected into related products in the mold of the injection molding machine. The injection molding conditions are: zone 1, 270±10°C; zone 2, 285±10°C; zone 3, 285±10°C; nozzle, 285±10°C, Mold temperature, 70~80℃; back pressure 15~20MPa.

Embodiment 3

[0032] Spray the mixed liquid containing A resin, B resin and xylene on the surface of the injection molded part in Example 1, and pre-cure at 50°C for 60 minutes, and then perform secondary curing at 160°C for 5 hours to form an insulating varnish coating with a thickness of 50 ~150μm, to obtain insulating parts with better electrical properties.

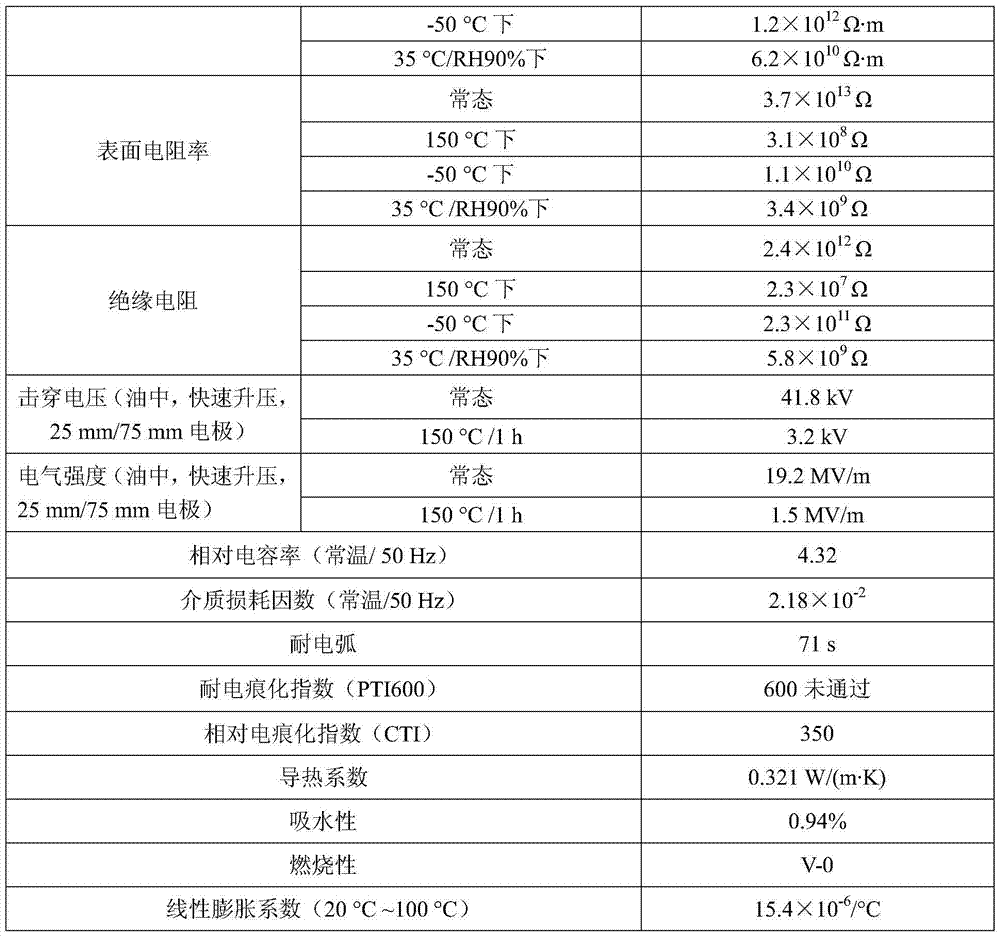

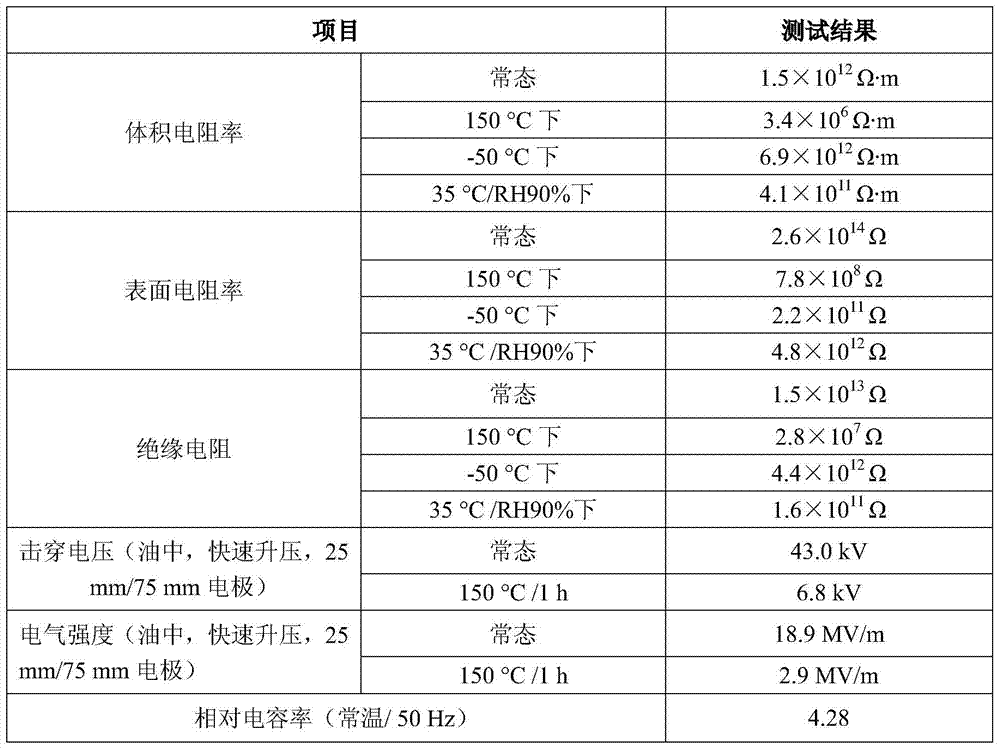

[0033] After the surface of the insulating part of the PA6 modified material is sprayed, the relevant electrical performance test is carried out, and the test results in the first and third examples are compared: the invented flame-retardant recyclable insulating material and the preparation process of the insulating part can be applied to medium-voltage equipment. In the manufacture of insulating devices, the treatment of insulating varnish on the surface of insulating parts can improve the insulating performance to a certain extent.

[0034]

[0035]

[0036] Note: This test is tested by Guilin Electric Science Research Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com