Oxygen-enriched combustion process for improving cement kiln clinker calcining temperature and apparatus thereof

A technology of oxygen-enriched combustion and clinker calcination, which is applied in the field of oxygen-enriched combustion technology and its device to increase the calcination temperature of cement kiln clinker, which can solve the problems of affecting the quality of cement clinker and unstable temperature, so as to save coal consumption and reduce Labor cost, to ensure the effect of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

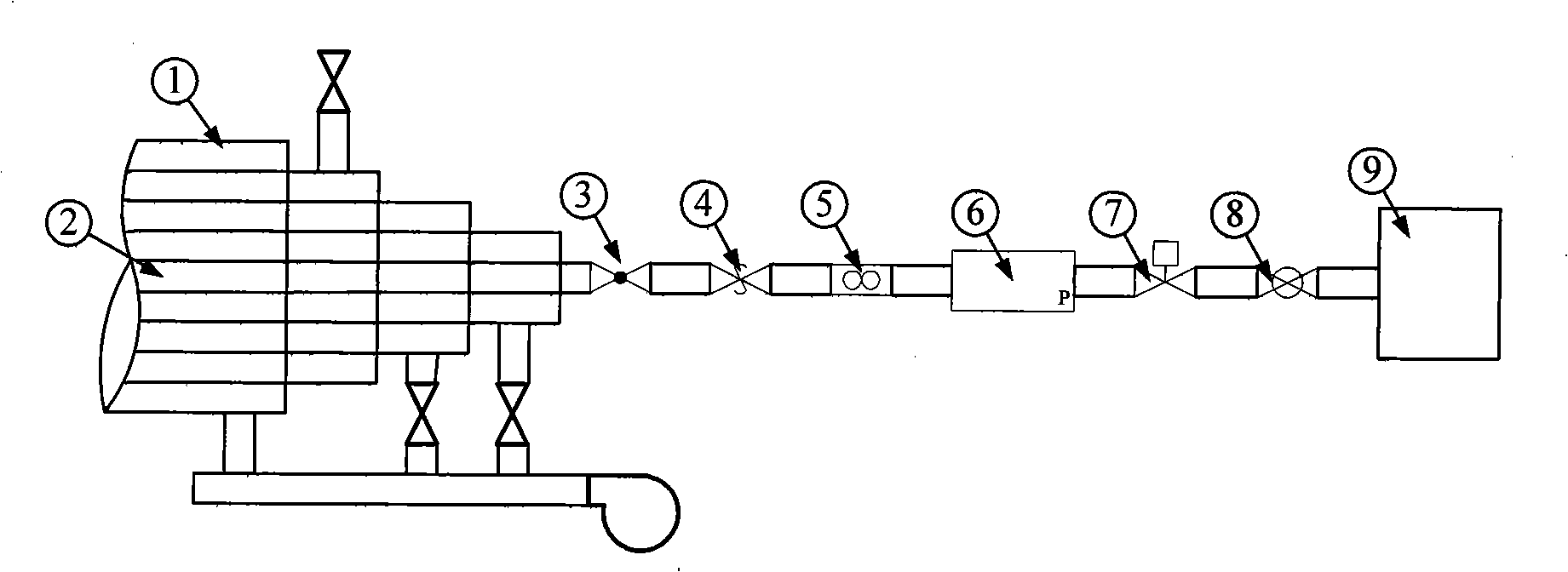

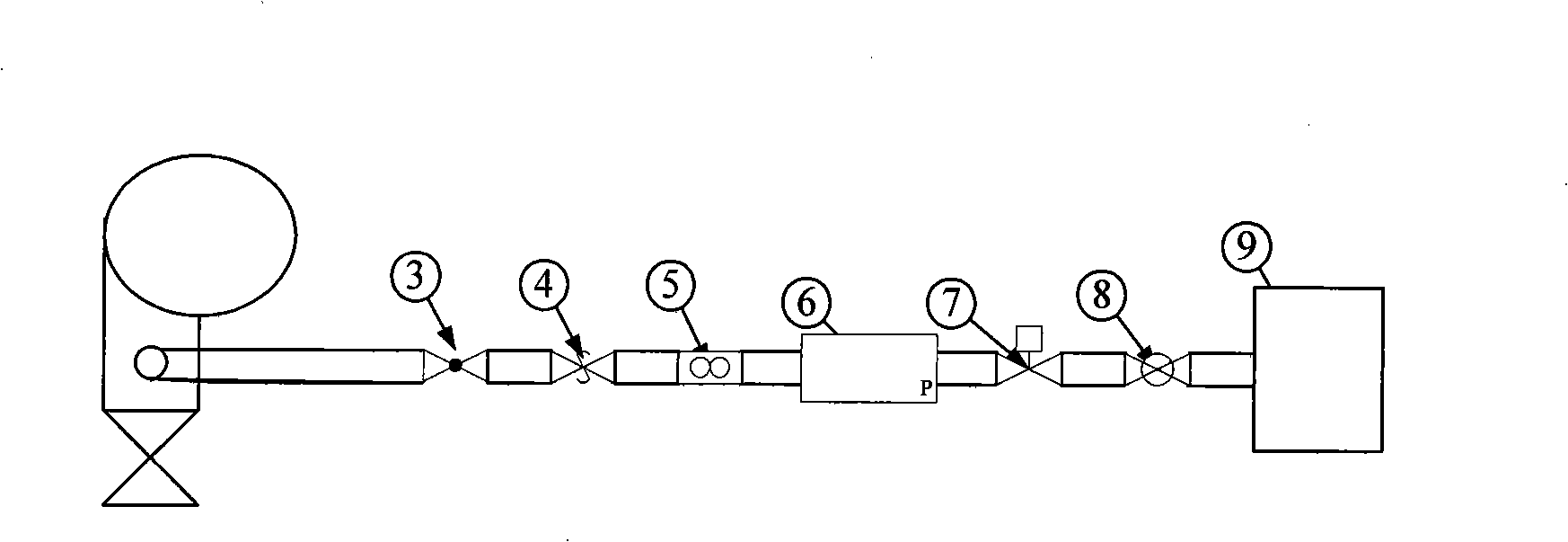

[0036] Application of 2000t / d new dry process kiln combustion system:

[0037] Project introduction: This project was put into production test in 2005. By the end of 2006, the calorific value of the coal used was basically guaranteed to be above 20090KJ / KG, and the feed rate is generally above 175t / h, and the production is relatively normal. In 2007, due to the increase in the supply gap of high-quality coal, the calorific value of the coal used was basically around 17,200KJ / KG, resulting in the average temperature of the kiln head cover around 1000℃ (design value 1350℃) and the average secondary air temperature around 850℃ (design value) Above 950℃), the average temperature of the three winds is about 650℃ (design value is greater than 800℃), and the average feed rate is about 140t / h (design value 175t / h). The actual output is seriously insufficient, and the life of each equipment cannot meet the design requirements. The cost has increased significantly. The adjustment of the ope...

Embodiment 2

[0047] The nozzle installation method is as follows:

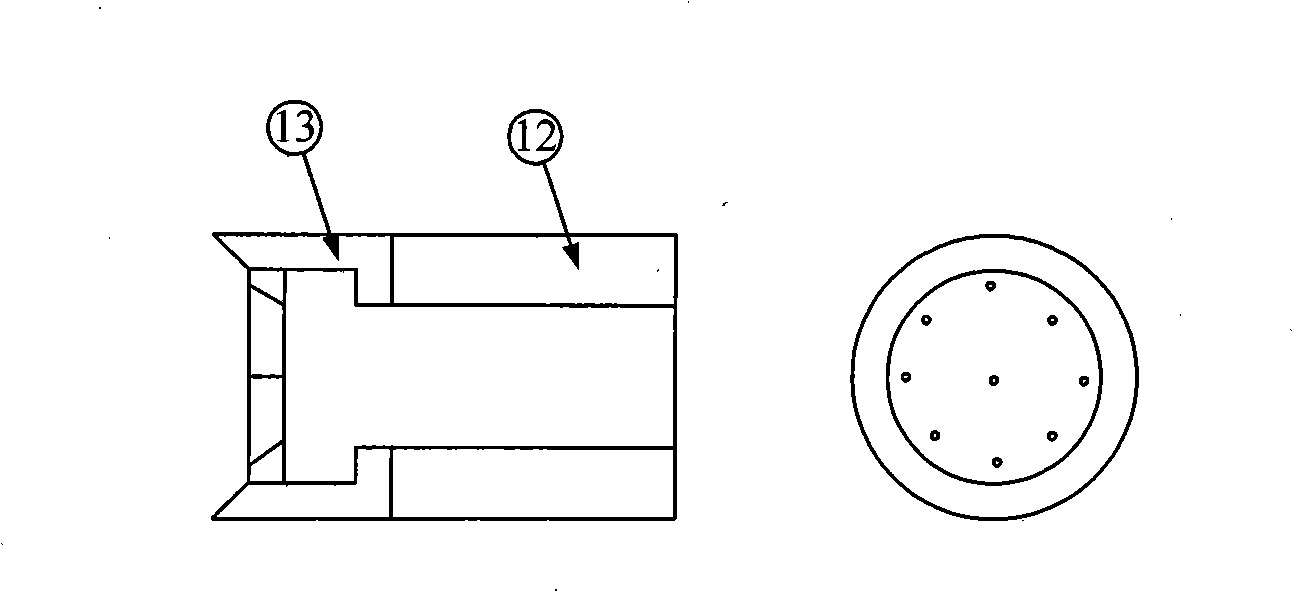

[0048] 1. Kiln head: remove the fuel injection nozzle of the original coal injection nozzle system of the kiln head, and install a special oxygen delivery high temperature nozzle for the rotating flow channel, such as Figure 4 .

[0049] 2. Kiln tail: transform the original two-channel coal injection nozzle into a three-channel coal injection nozzle, and the middle channel conveys oxygen-enriched combustion air, such as Figure 7 .

[0050] The rest is the same as in Example 1.

Embodiment 3

[0052] The nozzle installation method is as follows:

[0053] 1. Kiln head: transform the original five-channel coal injection nozzle into a six-channel coal injection nozzle, and the middle channel transports industrial oxygen, such as Figure 5 .

[0054] 2. Kiln tail: install a high temperature nozzle with rotating flow channel at the place where the tertiary air pipe is connected to the shell of the calciner Figure 8 .

[0055] The rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com