Flame-retardant reinforced high temperature nylon composite material and its preparation method

A nylon composite material and composite material technology are applied in the field of flame retardant reinforced high temperature nylon composite material and its preparation to achieve the effects of improving strength, improving processing performance and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A flame-retardant reinforced high-temperature nylon composite material is made by blending materials including the following raw materials in parts by weight:

[0046] 5 parts of high temperature nylon PPA, 3 parts of medium viscosity nylon PA66, 15 parts of glass fiber, 15 parts of brominated flame retardant, 4 parts of metal oxide flame retardant, 0.4 part of antioxidant, 0.1 part of lubricant and 0.1 part of coupling agent.

[0047] The high-temperature nylon PPA is preferably polyphthalamide, such as polyphthalamide produced by DuPont.

[0048] The intrinsic viscosity of medium viscosity nylon PA66 can be 2.4-3.0, preferably 2.6-2.7, such as PA66 produced by Shenma Group with the model number EPR27.

[0049] The glass fiber is any one or both of long glass fiber and short glass fiber with a diameter of 13-14 μm, preferably with a diameter of 14 μm, such as long fiber 910A produced by Jushi Group.

[0050] Preferably the glass fibers are hydrolysis resistant glass fi...

Embodiment 2

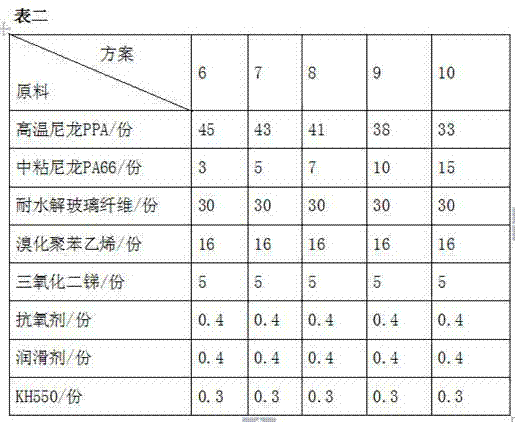

[0057] The difference between the present embodiment and embodiment 1 is that the parts by weight of raw materials are different, specifically as follows:

[0058] 65 parts of high temperature nylon PPA, 15 parts of medium viscosity nylon PA66, 50 parts of glass fiber, 22 parts of brominated flame retardant, 10 parts of metal oxide flame retardant, 1 part of antioxidant, 1 part of lubricant and 1 part of coupling agent.

Embodiment 3

[0060] The difference between the present embodiment and embodiment 1 is that the parts by weight of raw materials are different, specifically as follows:

[0061] 45 parts of high temperature nylon PPA, 8 parts of medium viscosity nylon PA66, 35 parts of glass fiber, 17 parts of brominated flame retardant, 6 parts of metal oxide flame retardant, 0.7 part of antioxidant, 0.6 part of lubricant and 0.6 part of coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com