Red phosphorus flame retardant enhanced PA66 and POK alloy material and preparation method thereof

An alloy material, PA66 technology, applied in the field of red phosphorus flame-retardant reinforced PA66 and POK alloy materials and their preparation, can solve the problems affecting the electrical properties of materials, materials containing halogen, dimensional deviation, etc., to achieve excellent mechanical properties, stable processing, The effect of excellent combustion resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

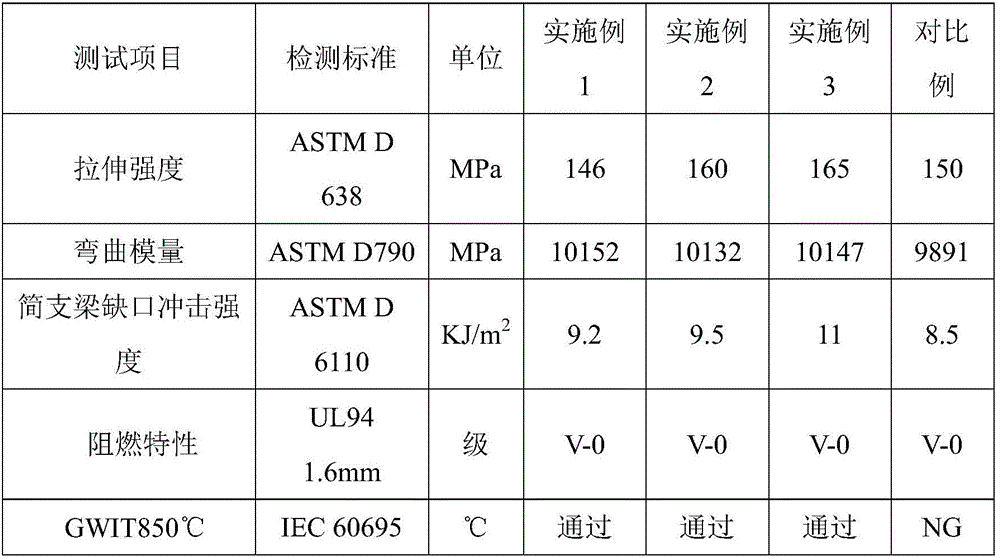

[0027] In order to better understand the present invention, the present invention will be further described below in conjunction with examples and comparative examples.

[0028] Prepare embodiment 1-3 and comparative example according to following preparation method, the proportioning of its each component is as shown in Table 1:

[0029] (1) Dry PA66 at 100-110°C for 3-4 hours, take 5-50 parts of PA66, 15-25 parts of POK, 10-25 parts of red phosphorus masterbatch, 5-10 parts of synergistic flame retardant, Add 0.2-0.5 parts of antioxidant and 0.1-0.5 parts of lubricant into the high mixer and mix for 2-5 minutes; among them, the relative viscosity of PA66 is 2.4-2.8Pa·S; the red phosphorus masterbatch is made of polyamide resin As a carrier, two or three layers of red phosphorus masterbatch with a red phosphorus content of 25% to 60%; the synergist is one or more of zinc borate, zinc oxide, magnesium hydroxide or aluminum hydroxide The mixture of antioxidants; the main antio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com