Polyamide composition, and preparation method and application thereof

A polyamide composition and a polyamide technology, applied in the field of polyamide compositions, can solve the problems of application limitation, low GWIT, etc., and achieve the effects of good flame retardant performance, improved light-off temperature, good tensile performance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

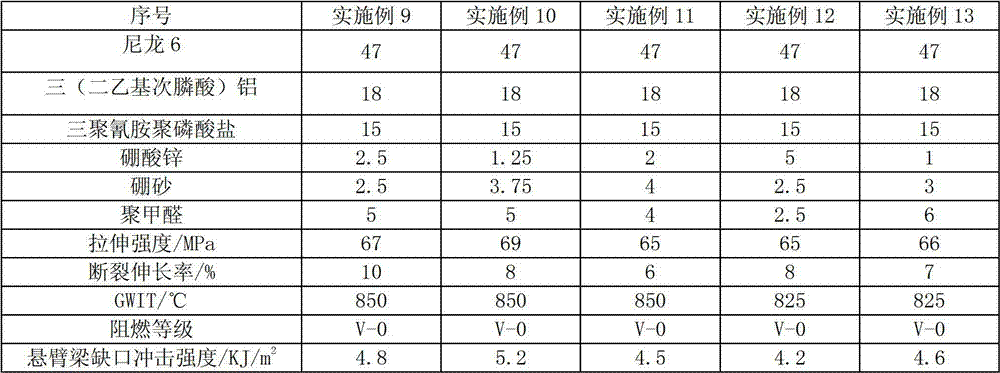

Examples

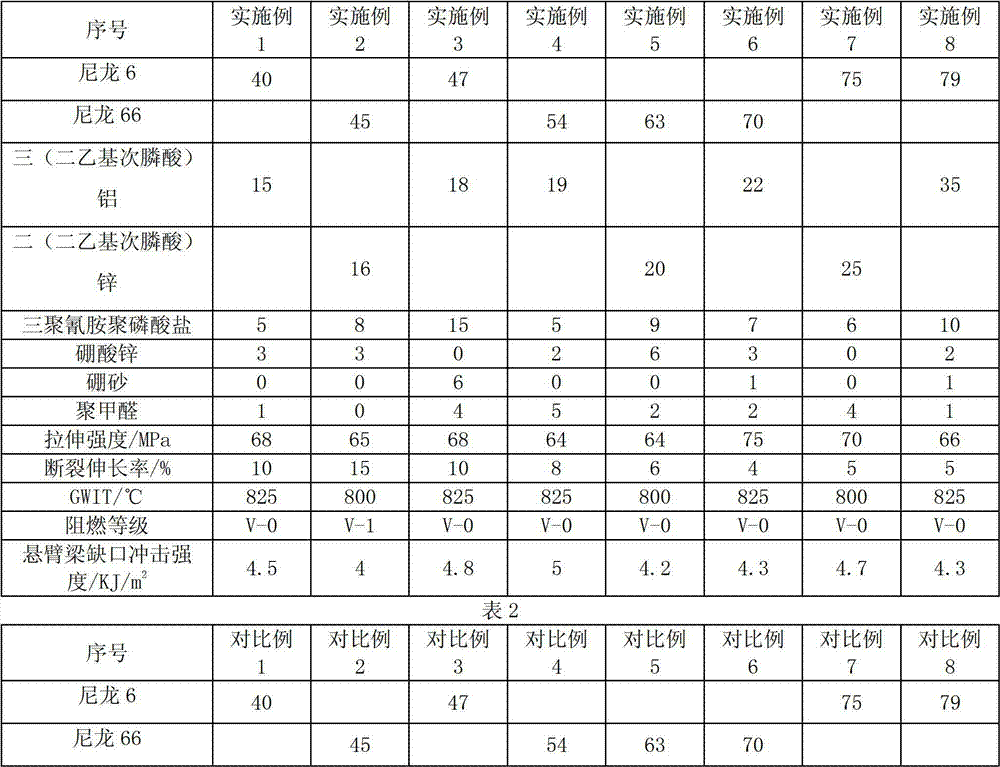

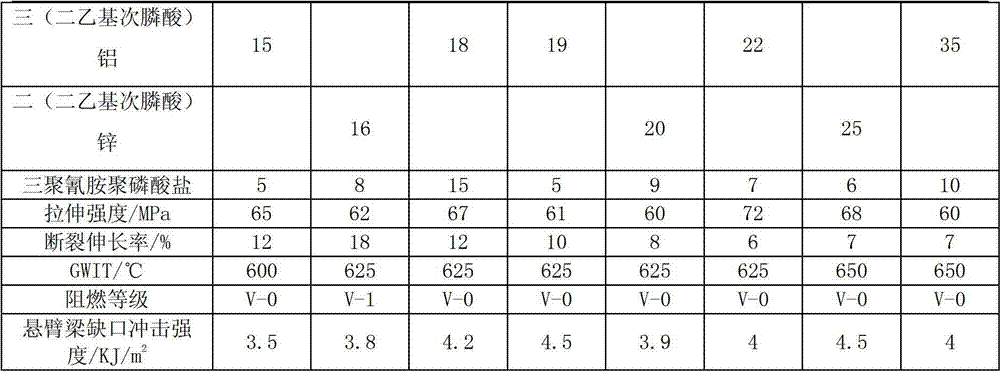

Embodiment 1

[0058] Add nylon 6, tris(diethylphosphinate) aluminum, melamine polyphosphate, zinc borate and polyoxymethylene into the twin-screw extruder through the main feed port of the twin-screw extruder according to the weight parts in Table 1 The polyamide composition is obtained after extrusion granulation, cooling, and drying; wherein, the process conditions of the extruder are: the temperature of the first and second stages of the twin-screw extruder is 230~250°C, and the temperature of the third and fourth stages is 250~270°C, the temperature of the fifth and sixth stages is 260~280°C, the temperature of the seventh and eighth stages is 240~270°C, the temperature of the head is 230~270°C, and the screw speed is 150~350 rpm.

Embodiment 2

[0060] Nylon 66, bis(diethylphosphinate) zinc, melamine polyphosphate and zinc borate are added into the twin-screw extruder through the main feed port of the twin-screw extruder according to the weight parts in Table 1 and extruded to produce After pelleting, cooling, and drying, the polyamide composition is obtained; wherein, the process conditions of the extruder are: the temperature of the first and second stages of the twin-screw extruder is 230~250°C, and the temperature of the third and fourth stages is 250~270°C °C, the temperature of the fifth and sixth stages is 260~280°C, the temperature of the seventh and eighth stages is 240~270°C, the temperature of the head is 230~270°C, and the screw speed is 150~350 rpm.

Embodiment 3

[0062] Nylon 6, tris(diethylphosphinate)aluminum, melamine polyphosphate, borax and polyoxymethylene were added into the twin-screw extruder through the main feed port of the twin-screw extruder according to the weight parts in Table 1 and extruded After granulation, cooling, and drying, the polyamide composition is obtained; wherein, the process conditions of the extruder are: the temperature of the first and second stages of the twin-screw extruder is 230~250°C, and the temperature of the third and fourth stages is 250°C. ~270°C, the temperature of the fifth and sixth stages is 260~280°C, the temperature of the seventh and eighth stages is 240~270°C, the temperature of the head is 230~270°C, and the screw speed is 150~350 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com