Ignition system for micron metal powder and liquid water mixture

An ignition system and metal powder technology, applied in the field of ignition systems, can solve problems such as complex systems, seldom used, and high cost, and achieve the effects of simple operation, easy implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

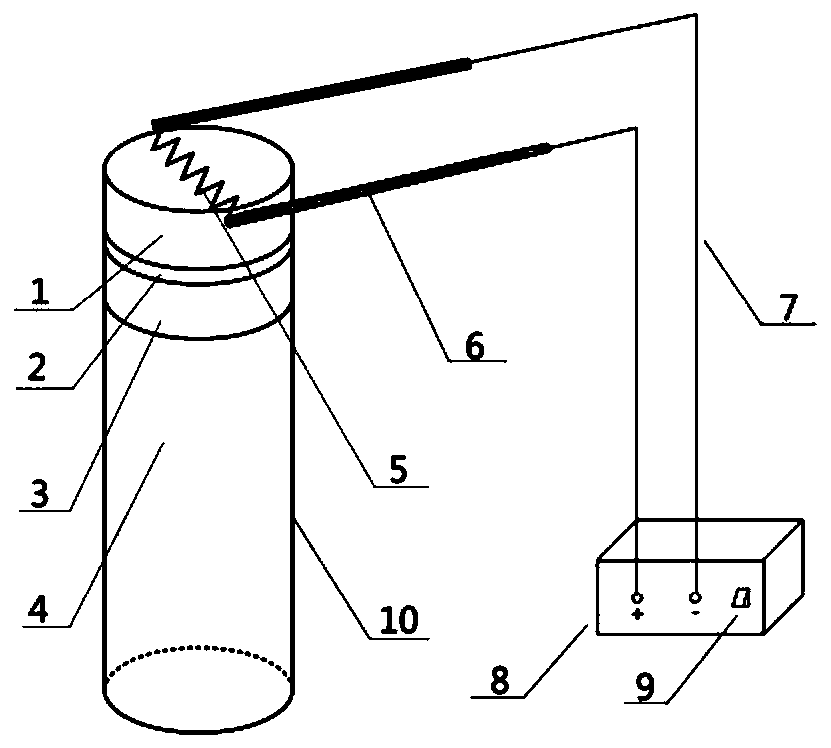

[0029] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0030] In the first embodiment of the present invention, an ignition system for a mixture of micron metal powder and liquid water is provided, comprising an ignition unit that provides heat from a redox reaction, an ignition unit for triggering combustion of the ignition unit, and a combustion unit ignited by an ignition unit;

[0031] The ignition unit is a control circuit containing a heating wire;

[0032] The combustion unit is a gel system formed by dispersing micron metal powder that is difficult to ignite and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com