Modified starch based adhesion agent for lumber and preparation method

An adhesive, starch-based technology, used in the fields of fine chemicals and polymer materials, can solve the problems of increased viscosity, poor chemical stability, and less addition of adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

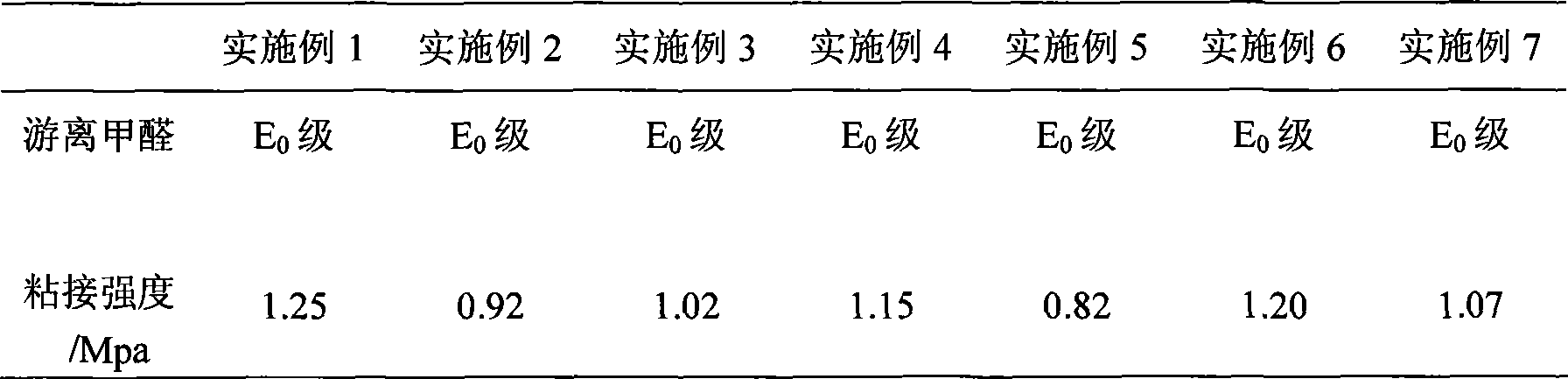

Embodiment 1

[0027] (1) Gelatinization and oxidation of starch:

[0028] Add 8.0g of starch and 100ml of distilled water to a three-port reactor equipped with a stirring device and a constant temperature water bath to form a starch emulsion, raise the temperature to 45°C, stir for 20min, raise the temperature to 85°C, and adjust the pH value with 10% NaOH solution To 9-10, react for another 20 minutes, add 1.2 g of hydrogen peroxide with a mass fraction of 20% and continue to react for 30 minutes to complete the starch gelatinization and oxidation treatment;

[0029] (2) Grafting of starch and PVA:

[0030] Next, add 12.0g of PVA to the three-port reactor equipped with gelatinized and oxidized starch, heat to 95°C and stir, adjust the pH value to 2-3 with HCl solution with a mass fraction of 10%, and add 2.5g of PVA in turn. Potassium persulfate solution with a concentration of 1% by mass fraction and 1.0 g of emulsifier OP-10 were reacted for 30 minutes to obtain the main adhesive agent;...

Embodiment 2

[0034] In step (1), glutinous rice flour consumption is 10.0g, and oxidant is the hydrogen peroxide of massfraction 20%, and consumption is 0.5g; In step (2), PVA consumption is 20.0g, and initiator is massfraction 1% ammonium persulfate, consumption 2.0g. G; Modifier is urea modified melamine-formaldehyde resin in step (3), and consumption is 15.0g; Other raw materials and reaction conditions are with embodiment 1.

Embodiment 3

[0036]In the step (1), the starch is cornstarch, the gelatinization and oxidation temperature of the starch are 80° C., the oxidizing agent is a 10% sodium hypochlorite solution in an amount of 4.0 g; the modifying agent in the step (3) is an aqueous SBS emulsion, and the amount is 15.0 g , filler is silica powder, consumption is 50g; Other raw materials and reaction conditions are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com