Method for synthesizing methylated melamine formaldehyde resin cross-linking agent with low free formaldehyde content

A technology of methyl etherifying melamine and formaldehyde resin with formaldehyde, which is applied in the fields of dyeing, textiles and papermaking, and can solve the problems of short shelf life and achieve the effects of stable performance, less pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

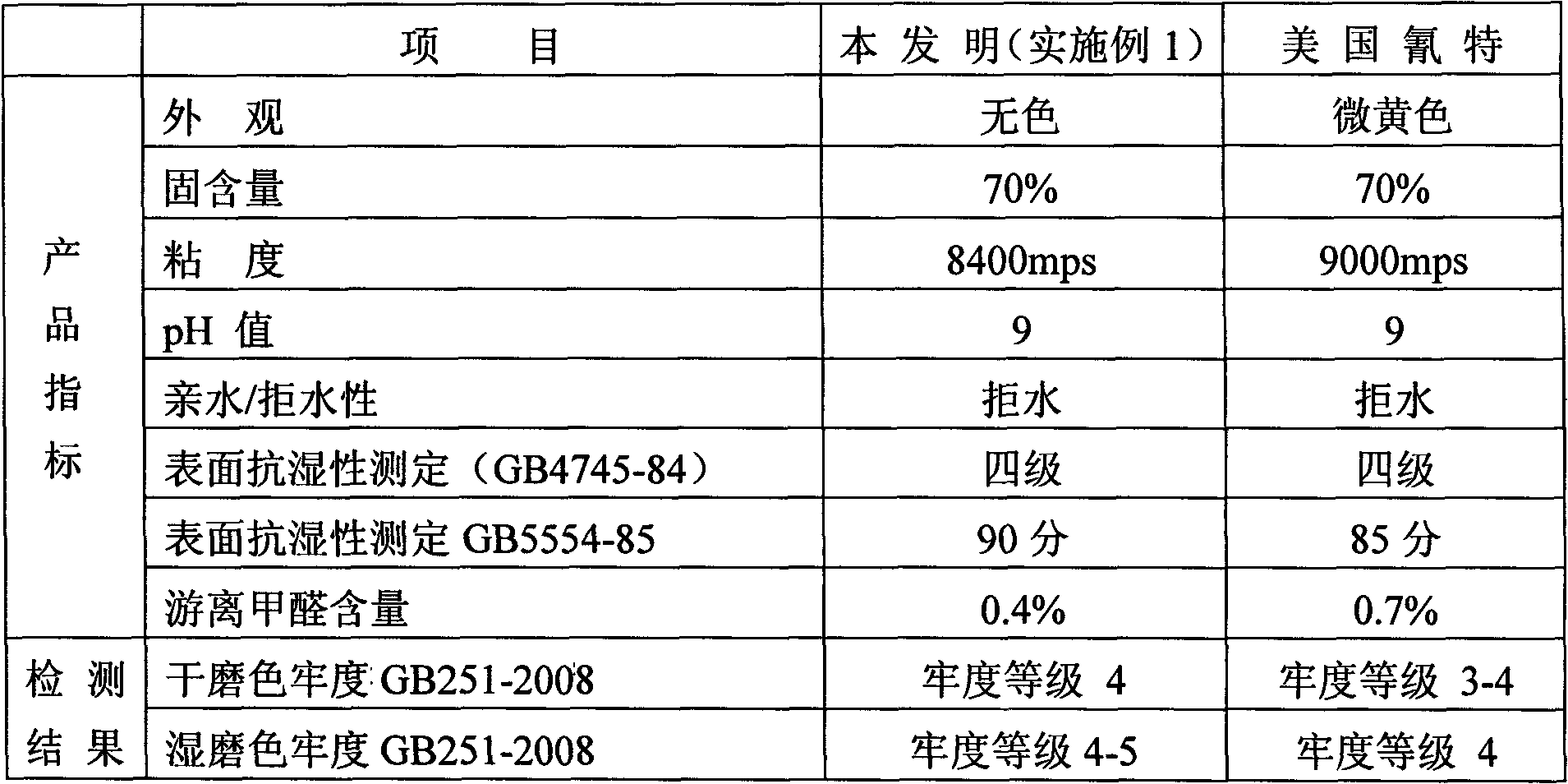

Examples

Embodiment 1

[0025] The synthetic method of embodiment 1 low free formaldehyde etherification melamine formaldehyde resin cross-linking agent

[0026] (1) Put melamine 1200g (9.5mol), 37% (m / m) formaldehyde 3090g (38mol) and methanol 3030g (95mol) into the reactor, adjust with triethylamine (triethanolamine or diethanolamine can also be used) The pH value is 8, the temperature is raised slowly, the reaction temperature is controlled at 70°C to 80°C, and the solution is kept warm for 1.5 hours after the solution is clarified.

[0027] (2) Cool the reaction liquid to 60°C, add phthalic anhydride to adjust the pH value to 5, control the reaction temperature at 50°C-60°C, react for about 1 hour, and determine the end of the reaction by water tolerance.

[0028] (3) Cool down to 30°C, add triethylamine to adjust pH to 9, and obtain mixed solution A.

[0029] (4) Add formaldehyde scavenger (formaldehyde scavenger is the mixture of urea and borax, its proportioning is by mass and number ratio, m...

Embodiment 2

[0033] The synthetic method of embodiment 2 low free formaldehyde etherification melamine formaldehyde resin cross-linking agent

[0034] (1) Put melamine 1200g (9.5mol), 37% (m / m) formaldehyde 4626g (57mol) and methanol 2432g (76mol) into the reaction kettle, adjust the pH value with sodium hydroxide (potassium hydroxide can also be used) 10. Raise the temperature slowly, control the reaction temperature at 80°C to 90°C, and keep the temperature for 1.5 hours after the solution is clarified.

[0035] (2) Cool the reaction solution to 60°C, add hydrochloric acid (nitric acid or sulfuric acid can also be used) to adjust the pH value to 6, control the reaction temperature at 50°C to 60°C, react for 1 hour, and determine the end of the reaction by water tolerance.

[0036] (3) Cool down to 30° C., add triethanolamine (diethanolamine can also be used) to adjust the pH value to 10, and obtain a mixed solution A.

[0037] (4) Add formaldehyde scavenger (according to the ratio of pa...

Embodiment 3

[0041] The synthetic method of embodiment 3 low free formaldehyde etherification melamine formaldehyde resin cross-linking agent

[0042] (1) Formaldehyde 2313g (28.5mol) and methyl alcohol 2727g (85.5mol) of melamine 1200g (9.5mol), 37% (m / m) are dropped in the reactor, adjust the pH value 7 with basic magnesium carbonate, slowly heat up, Control the reaction temperature at 70°C to 80°C, and keep it warm for 1.5 hours after the solution is clarified;

[0043] (2) Cool the reaction solution to 60°C, add formic acid (or acetic acid) to adjust the pH value to 5, control the reaction temperature at 50°C to 60°C, react for 1 hour, and determine the end of the reaction by water tolerance;

[0044] (3) Lower the temperature to 30°C, adjust the pH to 8 with sodium hydroxide (or potassium hydroxide), and obtain a mixed solution A.

[0045] (4) Add formaldehyde scavenger to mixed solution A (according to the ratio of mass and number, mixed solution A: urea: borax = 1000: 45: 10), stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com