Composite moderate temperature type red disperse dyes

A technology of disperse red and dye, applied in the field of dye compositions, can solve the problems of reproducibility, poor coloring rate, large three-waste pollution, poor sublimation fastness, etc., and achieves good color fastness, excellent lifting force, synergy Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

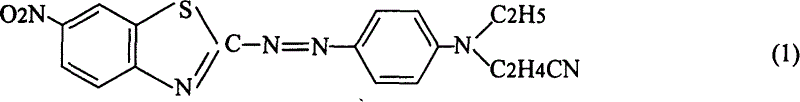

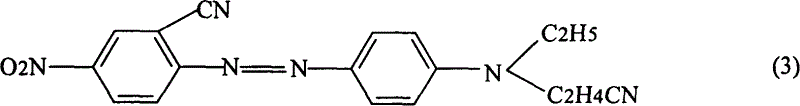

[0020] Mix dye monomer A, dye monomer B, dye monomer C, and auxiliary agents with water, grind and disperse with a sand mill, and then spray dry to obtain a composite medium-temperature disperse red dye. C.I.DISP.RED 145# dye (the main components are dye monomer A and auxiliary agent) produced by Zhejiang Runtu Co., Ltd., Tianjin Dyestuff Factory, Shandong Qingdao Dyestuff Factory and other manufacturers, Zhejiang Runtu Co., Ltd., Jiangsu Wujiang C.I.DISP.RDE 153# dye (or CAS: 78564-87-1) produced by Dongfeng Chemical Factory, Jiangsu Suzhou Dye Factory and other manufacturers (mainly composed of dye monomer B and auxiliaries) and Zhejiang Runtu Co., Ltd., C.I.DISP.RED 73# dye produced by Tianjin No. 5 Dyestuff Factory and Shanghai No. 5 Dye and Chemical Factory. The auxiliary agent is methylnaphthalenesulfonic acid formaldehyde condensate (MF), diffusing agent benzylnaphthalenesulfonic acid formaldehyde condensate (CNF ), diffusing agent naphthalene sulfonate formaldehyde con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com