Composite material compounded with atomic mixed grade alloy for catalyzing nitrobenzene hydrogenation as well as preparation method and application of composite material

A composite material and atomic-level technology, which is applied in the preparation of amino compounds, organic compounds, catalyst activation/preparation, etc., can solve problems such as uneven mixing and affecting the activity of nano-alloys, so as to improve catalytic performance, enhance synergy, The effect of simple and easy carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The invention provides a method for preparing a composite material compounded with an atomically mixed grade alloy, comprising the following steps:

[0065] A) After mixing cerium oxide with oxygen vacancies, a dispersant, two or more monoatomic metal source aqueous solutions and water, a composite material compounded with two or more monoatomic metals is obtained;

[0066] B) Under the condition of hydrogen or hydrogen gas mixture, the composite material composited with two or more single-atom metals obtained in the above steps is subjected to heat treatment and reduced to obtain a composite material composited with an atomic-mixed alloy.

[0067] In the present invention, the composition, structure and requirements of the composite material compounded with atomically mixed grade alloys in the above preparation method, as well as the corresponding optimization principles, and the composition, structure and requirements corresponding to the aforementioned composite mater...

Embodiment 1

[0108] Pt 1 PD 1 Synthesis and catalytic characterization of NAs

[0109] 200mg CeO 2 Dissolve in 40mL of water, stir for half an hour, then add NH 4 HCO 3 Adjust the pH value, then add 20mL platinum palladium aqueous solution, wherein HPtCl 4 ·6H 2 O and PdCl 2 The content of each is 2 mg, and then the obtained solution is centrifuged and directly dried in the air at 70°C, washed with water and centrifuged several times after drying, and then dried in an oven at 70°C for 12 hours to obtain Pt 1 / Pd 1 SAs, followed by a mixture of hydrogen and argon (H 2 10%, Ar 90%) at 800°C for 2 hours to obtain Pt 1 PD 1 NAs. At this time, the loadings of Pt and Pd obtained are close to 0.2%, and the mass ratio is 1:1.

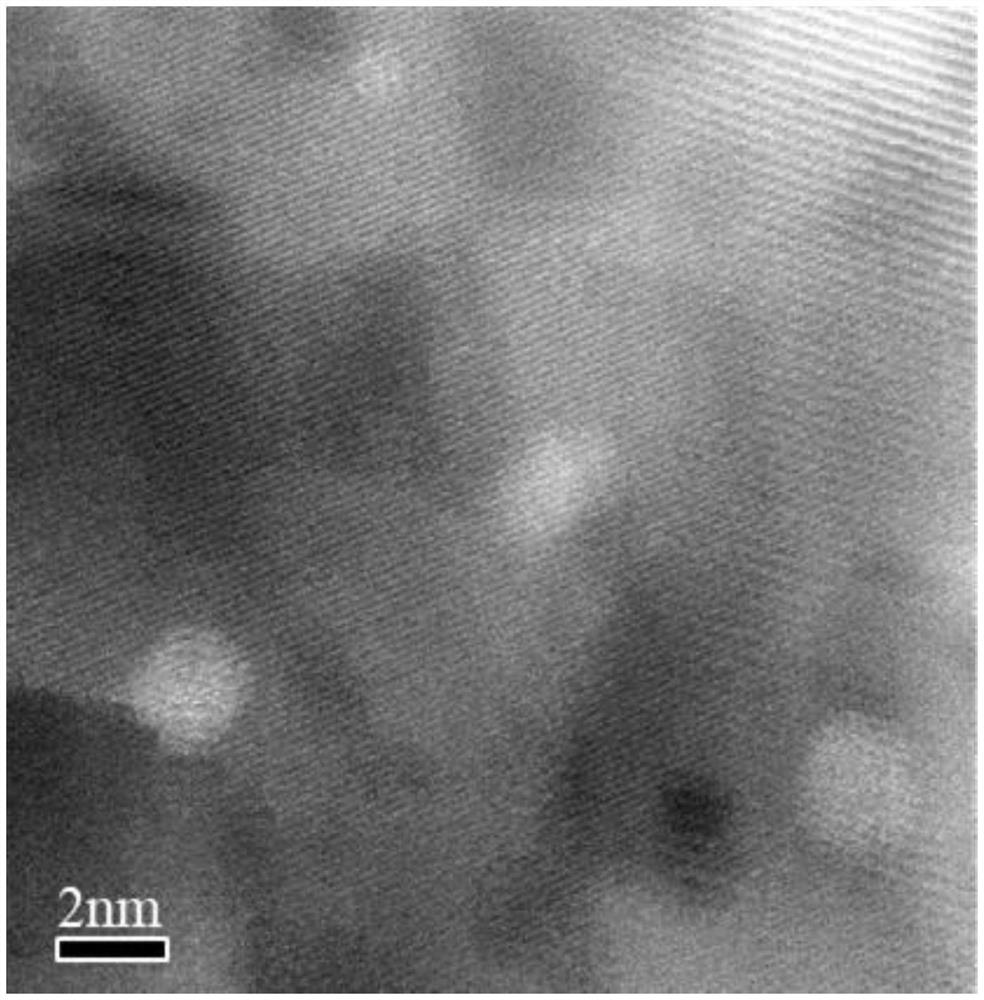

[0110] The composite material compounded with platinum-palladium nano-alloy of atomic mixing level prepared in Example 1 of the present invention was characterized.

[0111] see figure 1 , figure 1 Spherical aberration transmission electron micrograph of ...

Embodiment 2

[0122] Pt 1 PD 1.5 Synthesis and catalytic characterization of NAs

[0123] 200mg CeO 2 Dissolve in 40mL of water, stir for half an hour, then add NH 4 HCO 3 Adjust the pH value, then add 20mL platinum palladium aqueous solution, wherein HPtCl 4 ·6H 2 O and PdCl 2 The contents are 2mg and 4mg, respectively, and then the obtained solution is centrifuged and dried directly in the air at 70°C. After drying, it is washed and centrifuged several times, and then dried in an oven at 70°C for 12 hours to obtain Pt / Pd SAs, followed by a mixture of hydrogen and argon (H 2 10%, Ar 90%) were calcined at 800℃ for 2h to obtain PtPd NAs. At this time, the loading of Pt is close to 0.2%, and the loading of Pd is close to 0.3%, and the mass ratio is 1:1.5.

[0124] Performance testing was performed on the composite material compounded with the platinum-palladium alloy of atomic mixing grade prepared in Example 2 of the present invention.

[0125] The catalyst obtained in Example 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com