Latex-type waterborne pigment oil ink for inkjet printing of non-absorbed substrate as well as preparation method and applications thereof

A technology of non-absorbent substrates and water-based pigments, applied in inks, applications, printing devices, etc., can solve problems such as difficulties, poor scratch resistance, and poor light fastness, and achieve high precision and good printing fluency , Excellent anti-smudge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of emulsion-type water-based pigment red ink

[0038] The formula of table 1 emulsion type water-based pigment red ink

[0039]

[0040] Note: Cab-O-Jet pigment is a kind of self-dispersing pigment, purchased from American Cabot Company.

[0041] According to the formula of the red ink in Table 1, surfactant, water-soluble co-solvent and deionized water are mixed at normal temperature, stir 50min under 800rad / min rotating speed with agitator, obtain mixed solution; Continue to stir and add to mixed solution Slowly add the polymer emulsion AC-570JW, and stir for 30 minutes; finally, slowly add the pigment dispersion while stirring, and continue stirring for 60 minutes. After the various components are fully mixed to form a uniform dispersion system, filter with a 0.2-2 μm microporous membrane to obtain the emulsion-type water-based pigment red ink for inkjet printing.

[0042] The physical properties of this ink at 20°C are as follows: surface tension 28...

Embodiment 2

[0044] Preparation of emulsion-type water-based pigment yellow ink

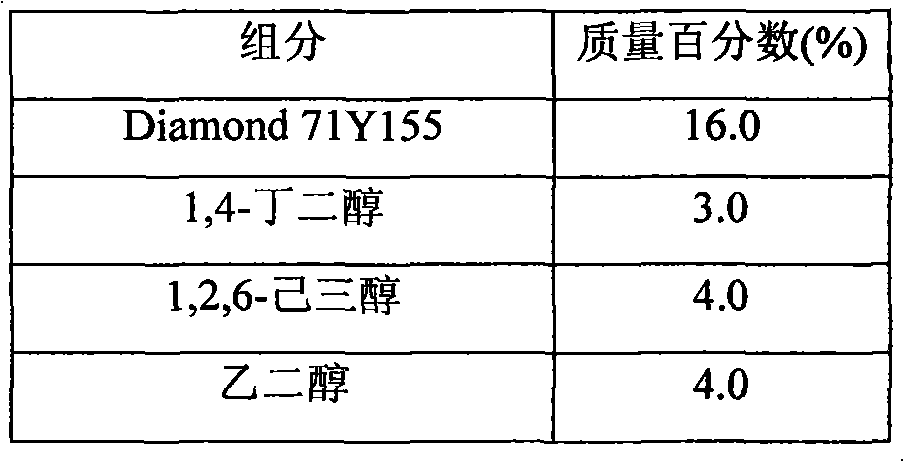

[0045] The formula of table 2 emulsion type water-based pigment yellow ink

[0046]

[0047]

[0048] Note: Diamond pigment is a self-dispersing pigment purchased from Diamond Dispersions.

[0049] According to the formula of yellow ink in Table 2, surfactant, water-soluble co-solvent and deionized water are mixed at normal temperature, stir 60min under 800rad / min rotating speed with agitator, obtain mixed solution; Continue to stir and add to mixed solution Slowly add the polymer emulsion AS-26080VP, and stir for 20 minutes; finally, slowly add the pigment dispersion while stirring, and continue stirring for 70 minutes, after the various components are fully mixed to form a uniform dispersion system; filter with a 0.2-2 μm microporous membrane , to obtain the emulsion type water-based pigment yellow ink for inkjet printing.

[0050] The physical properties of this ink at 20°C are as follows: surface ...

Embodiment 3

[0052] Preparation of emulsion-type water-based pigment blue ink

[0053] Formulation of table 3 emulsion type water-based pigment blue ink

[0054]

[0055] Note: Diamond pigment is a self-dispersing pigment purchased from Diamond Dispersions.

[0056] According to the formula of blue ink in table 3, surfactant, water-soluble co-solvent and deionized water are mixed at normal temperature, stir 55min under 700rad / min rotating speed with agitator, obtain mixed solution; Continue to stir and add to mixed solution Slowly add polymer emulsion WA-2016 into the medium, stir for 50 minutes, and finally add the pigment dispersion slowly while stirring; continue stirring for 90 minutes, after the various components are fully mixed to form a uniform dispersion system; After filtration, the emulsion-type water-based pigment blue ink for inkjet printing is obtained.

[0057] The physical properties of this ink at 20°C are as follows: surface tension 27.9mN / m (measured by BZY-2 automa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com