Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

187results about How to "Improve dirt resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorochemical free aqueous coating compositions and methods of use thereof

InactiveUS20050215678A1Avoid healthGood wettingAqueous dispersionsPhosphorus organic compoundsOrganic phosphatesFluoride

Fluorochemical free aqueous coating compositions are disclosed. The compositions comprise a film-forming polymer and an organophosphate surfactant. The compositions exhibit superior wetting and leveling properties compared to fluoroaining sulfur based surfactants. Inventive compositions are particularly suitable for use as floor finishes. Methods of makinge aqueous coating compositions are also described.

Owner:JOHNSONDIVERSEY INC

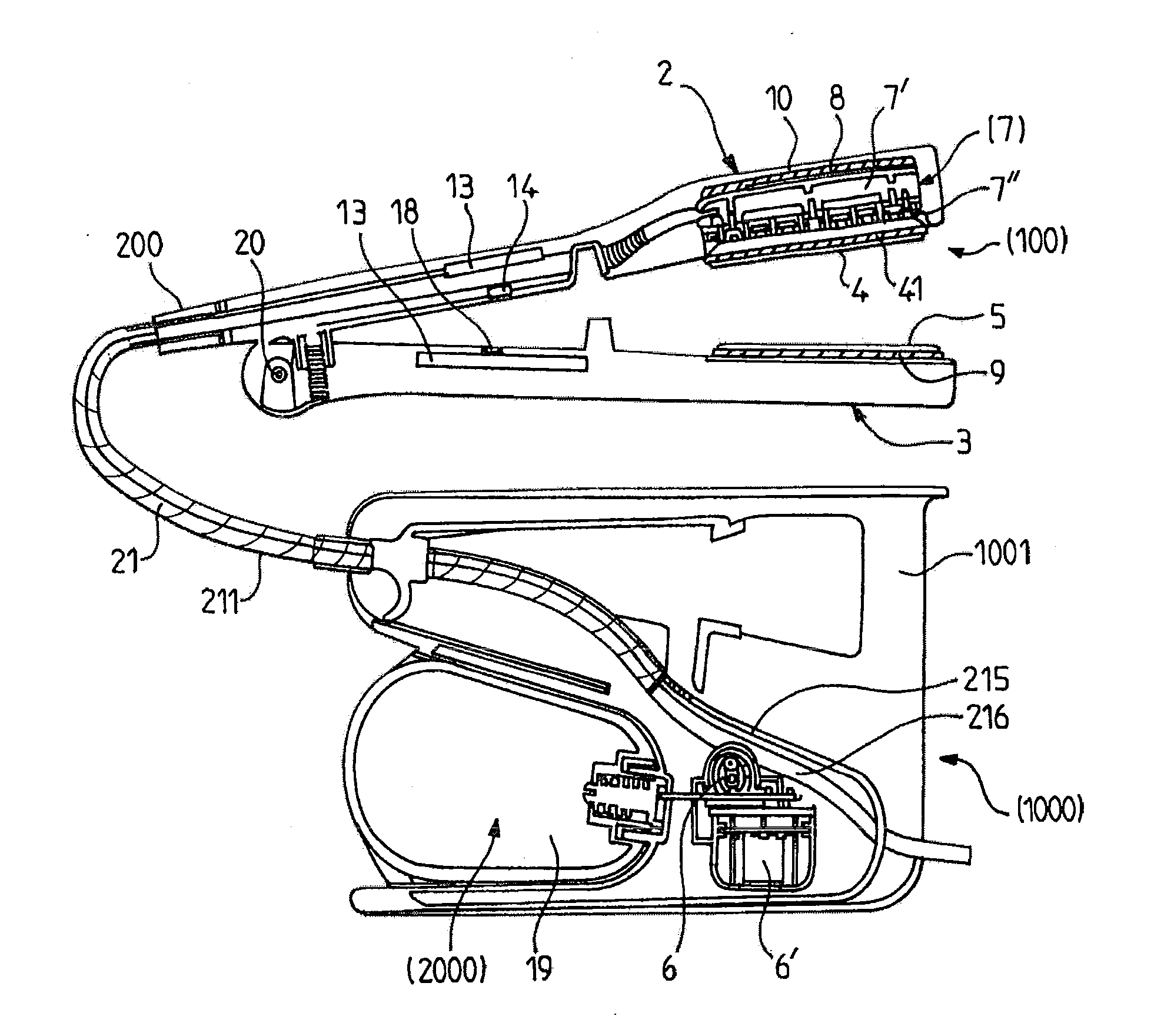

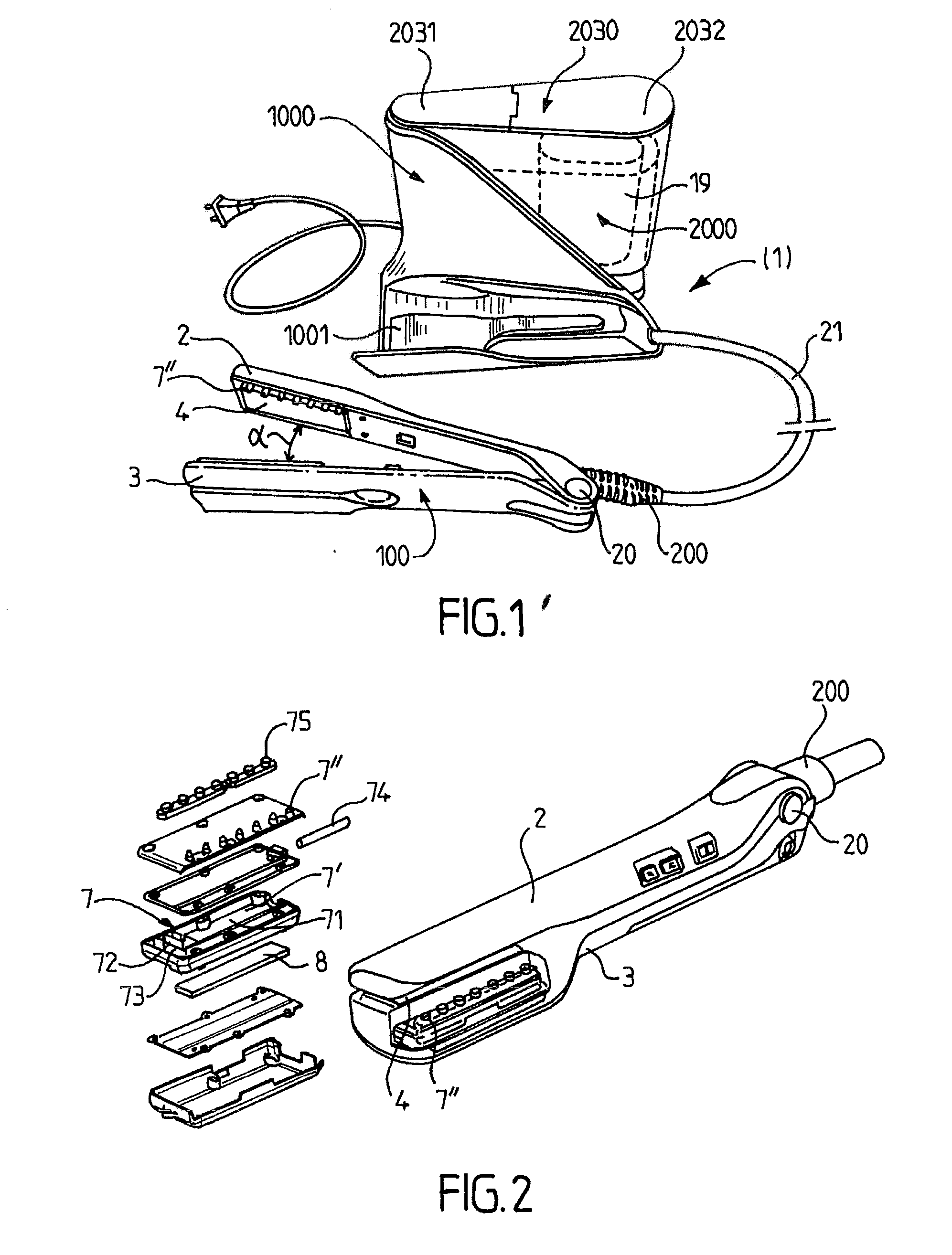

Steam Hairdressing Apparatus

InactiveUS20120111356A1Improve dirt resistanceEasy to useCurling-ironsCurling-tongsThermodynamicsEngineering

A steam hairdressing apparatus to style the hair, including: a first and a second jaw arranged facing one another, a first treatment surface borne by the first jaw and a second treatment surface borne by the second jaw, the surfaces intended to grasp a lock of hair, a reservoir of liquid, a means of vaporization of the liquid in fluid communication with the reservoir, a steam distribution means in communication with the means of vaporization, comprising one or more steam distribution orifices in the direction of a lock of hair, the means of vaporization comprising a first vaporization chamber forming a unique volume, a second vaporization chamber equipped with a plurality of baffles, said chambers in fluid communication, the internal volume (V1) of the first chamber being greater than the internal volume (V2) of the second chamber.

Owner:SEB SA

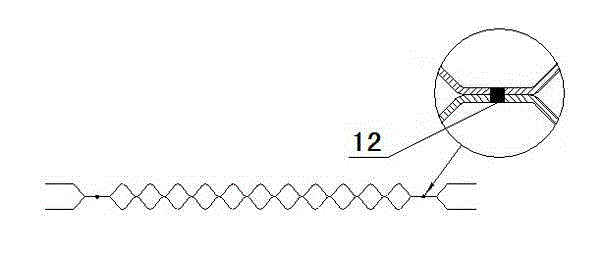

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

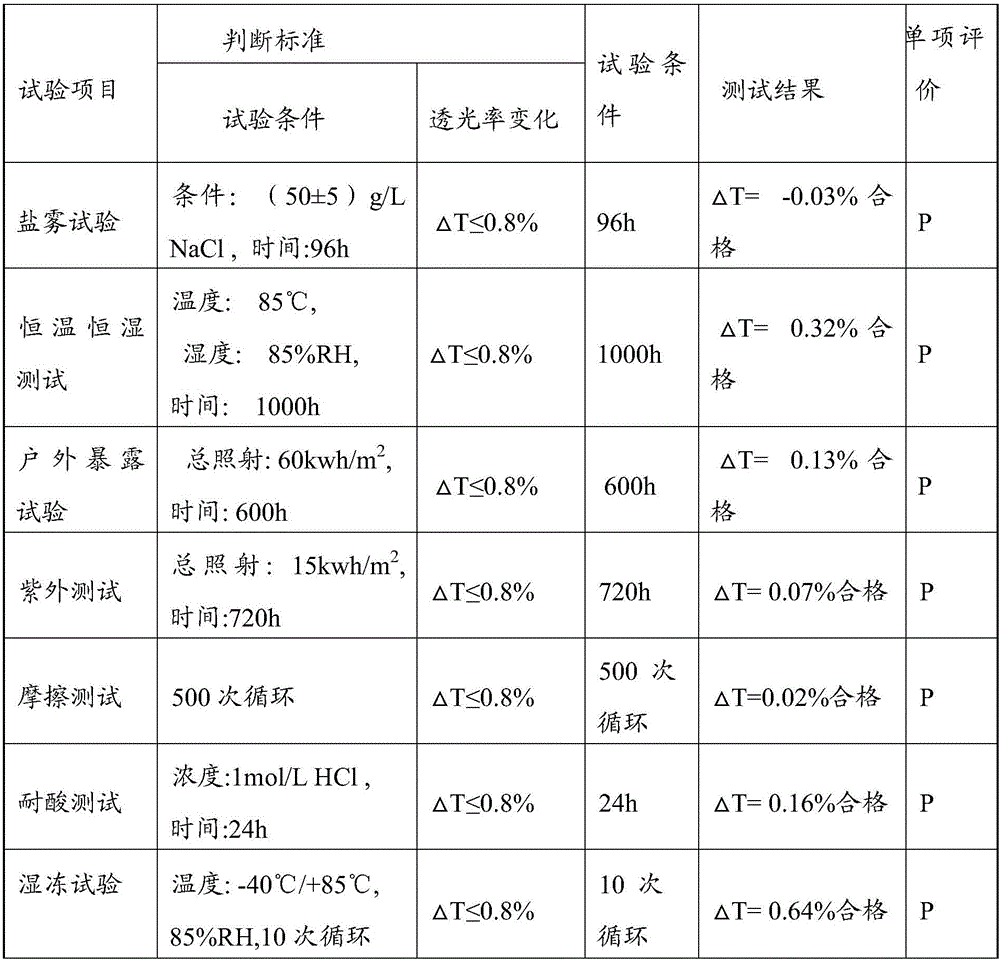

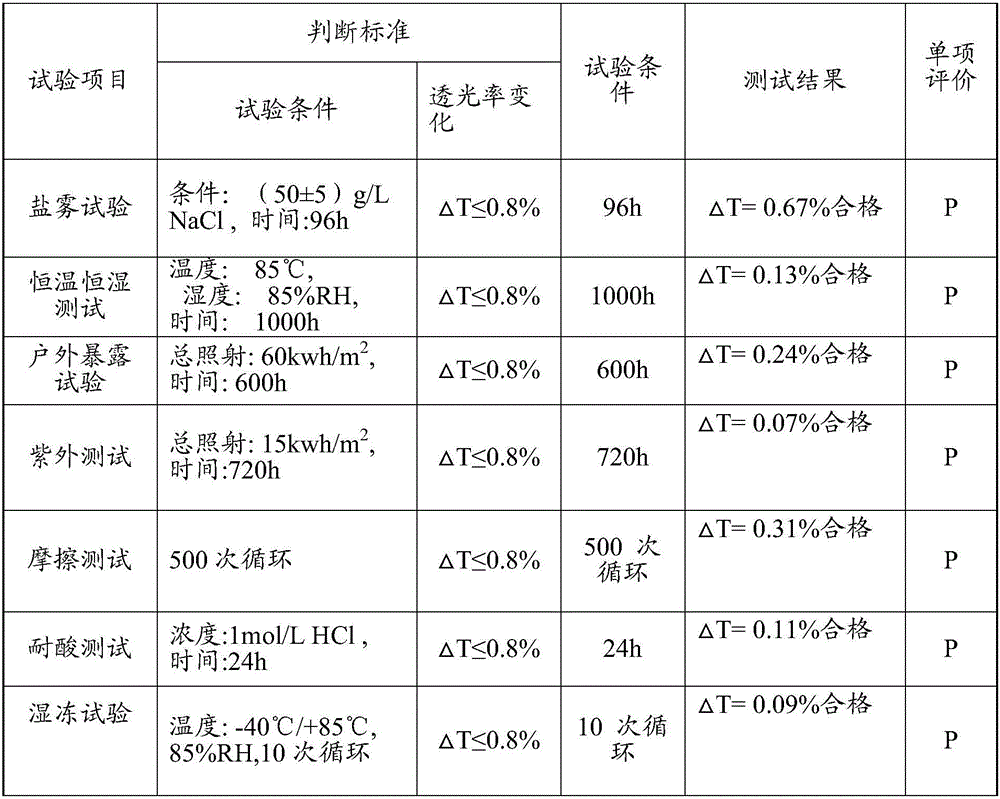

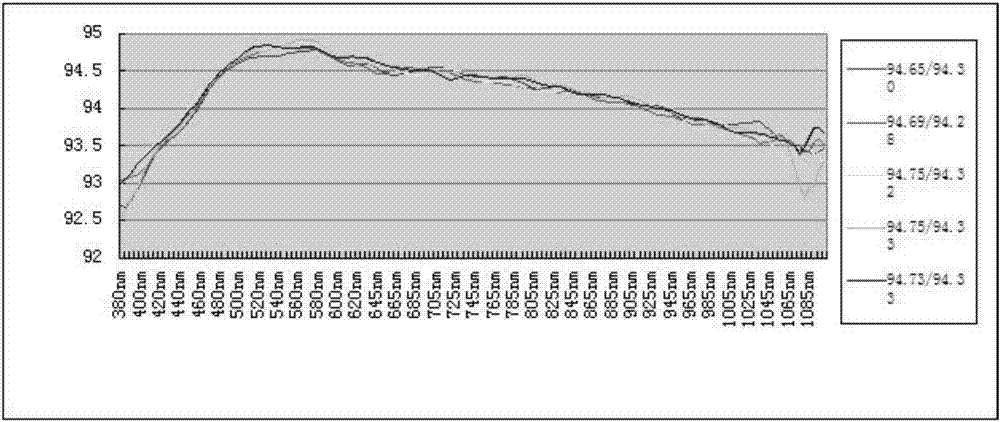

Nanometer core-shell silicon dioxide microsphere as well as preparation and application of antireflection composite coating solution

ActiveCN105964195AHigh light transmittanceHigh mechanical strengthCoatingsMicroballoon preparationPorosityMicrosphere

The invention relates to the field of anti-reflection technology for the surface of glass, and concretely relates to a nanometer core-shell silicon dioxide microsphere and a composite coating solution which is compounded by the nanometer core-shell silicon dioxide microspheres and aluminum silicon sol as well as preparation methods thereof. A cation type polystyrene emulsion is used as a hard template in order to prepare silicon dioxide dispersion liquid with a nanometer core-shell structure, the dispersion liquid and the aluminum silicon sol are compounded in order to prepare the coating solution for an antireflection film, toughening treatment is carried out for the coating solution in order to obtain the antireflection film. The raw materials are easy to obtain, and the antireflection film with a hollow structure is prepared by a simple process; pore spaces are arranged in particles and are not arranged in a silicon dioxide network, so that high light transmittance of the film is guaranteed, the light transmittance reaches 94.5% or above, and the porosity is high; the film has excellent smudginess resisting performance, the antireflection film and a glass substrate can be firmly combined, and the hardness of the film is high; because the surface of the film is compact, the film has good blocking effects for steam erosion, good weatherability, and industrialized application values.

Owner:DONGGUAN CSG SOLAR GLASS +1

Differential arc oxidation electrolytic solution and differential arc oxidation method

ActiveCN101476143AImprove corrosion resistanceImprove dirt resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a micro-arc oxidation electrolyte which is a water solution comprises phosphate and silicate, and has 6-12 PH value. The electrolyte has characteristics that the electrolyte also comprises colorant, the colorant comprises A and B components, wherein, A comprises one or some of potassium fluoride, sodium fluoride, sodium sulfate and borax, B comprises cupric pyrophosphate and / or bluestone. The micro-arc oxidation electrolyte and the method for micro-art oxidating provided by the invention can make micro-arc oxidation film of light metal material obtaining uniform color for having beautiful decorating effect. At the same time, the obtained micro-arc oxidation film of light metal material surface has better stain resistance and compactness that increases additive value and practical using value of magnesium alloy greatly.

Owner:BYD CO LTD

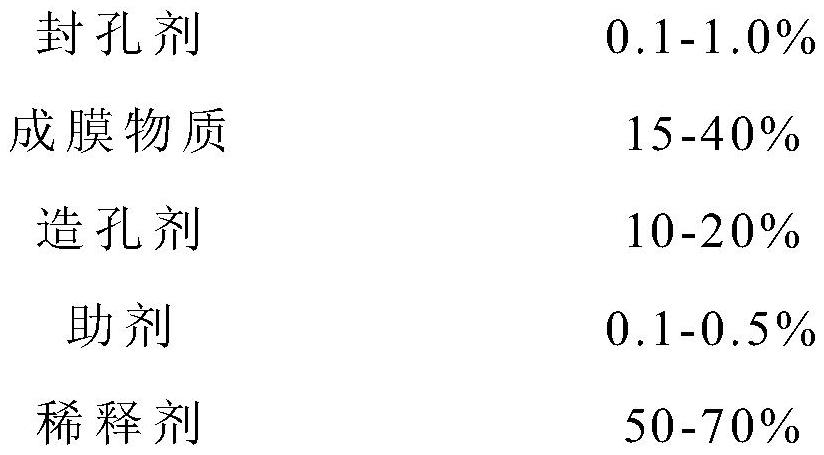

Template agent for antireflection film coating liquid as well as preparation method and application of template agent

The invention relates to the field of antireflection film coating liquid and particularly relates to a template agent for the antireflection film coating liquid as well as a preparation method and application of the template agent. The preparation method comprises the following steps: firstly preparing the template agent: reacting by virtue of at least three monomers, a solvent, an initiator and an aid; preparing silica sol: putting alkoxy silane and a solvent into a reaction container, adding a catalyst at a temperature of the room temperature to 90 DEG C, so as to react; and finally preparing the antireflection film coating liquid: mixing the synthesized template agent and the synthesized silica sol, adding a silane coupling agent to react, and adding a diluent for dilution. By carrying out molecular designing according to the property of the silica sol, the template agent with good consistency with the silica sol is synthesized, so that the development efficiency is improved; and by adding the silane coupling agent, the stability of the antireflection film coating liquid is enhanced, the film forming property of the film coating liquid is improved, and the antireflection rate and dirt resistance of an antireflection film are increased.

Owner:DONGGUAN CSG SOLAR GLASS +1

Terminated unsaturated polyester resin and preparation method thereof

The invention relates to a terminated unsaturated polyester resin which is a polycondensate of dihydric alcohol and a dibasic acid or estolide. The dibasic acid or estolide comprises a saturated dibasic acid or estolide and an unsaturated dibasic acid or estolide; a reaction system of the dihydric alcohol and the dibasic acid or the estolide is terminated by monohydric alcohol; the terminated unsaturated polyester resin has molecular weight of 800-1500 and comprises the following components by mass percent; 22-30 percent of dihydric alcohol, 24-30 percent of saturated dibasic acid, 15-19 percent of unsaturated dibasic acid, 3-6 percent of monohydric alcohol and 22-29 percent of cross linker, wherein the monohydric alcohol is one of isooctanol, cyclohexanol and phenylcarbinol. The invention has the advantages as follows: a termination method is used for preparing the unsaturated polyester resin, thus being capable of improving the hydrolysis resisting stability and the scale-resisting performance and reducing the volatilization and shrinkage of resin; and when the resin prepared by the method is taken as matrix resin to produce boards such as rostone, deck plate, quartz and the like, the yield of products can be improved, the cracking phenomenon can be reduced, and the products can be used in occasions with higher water-proof requirement.

Owner:上海新天和树脂有限公司 +1

Ultraviolet curing matte coating gloss oil with high pollution resistance

ActiveCN107011768AImprove dirt resistanceIncreased durabilityAntifouling/underwater paintsPaints with biocidesIonPhotoinitiator

The invention discloses ultraviolet curing matte coating gloss oil with high pollution resistance. The ultraviolet curing matte coating gloss oil is prepared from, by weight percent, 55-85% of positive ion curable compound, 3-15% of free radical curable compound, 6-18% of extinction powder, 0.1-6% of curable surface assistant, 3-12% of photoinitiator, and 0.5-5% of assistant. The ultraviolet curing matte coating gloss oil with high pollution resistance can be constantly cured under the conditions of ordinary ultraviolet light and H-UV and LED-US narrow wave section ultraviolet light; the gloss oil adopts a flexible printing or glue printing coating method; the post-printing coating is carried out on a plastic substrate and a paper printing product, and the gloss oil is featured by matte and high transparency; the printing product surface is protected on the basis of not influencing the appearance of the printing product basically; the pollution resistance of the printing product is obviously improved, and the durability of the printing product is improved.

Owner:CHINA BANKNOTE INK +1

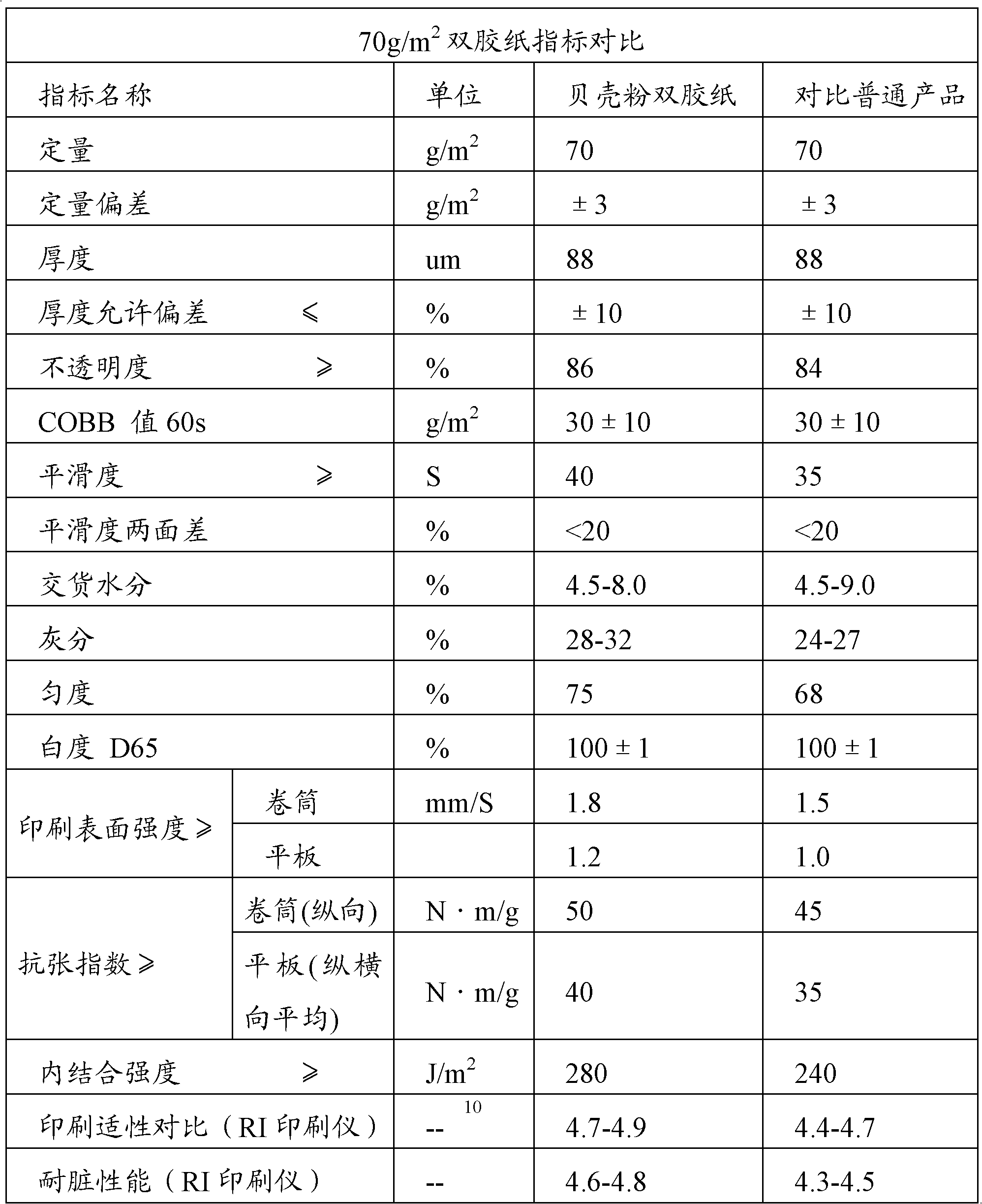

Side offset paper and preparation method thereof

ActiveCN102154927AReduce dosageHigh bonding strengthWater-repelling agents additionPaper coatingPapermakingUltimate tensile strength

The invention relates to the technical field of papermaking, in particular to a side offset paper produced by shell powder and a preparation method thereof. In the side offset paper, high-whiteness hard wood pulp and high-whiteness chemical-mechanical pulp serve as the main material, and meanwhile, shell powder is auxiliary filler for producing the side offset paper; oxidized Cual is added into surface amylopectin to improve the printing surface strength of the side offset paper and avoid the defects of printing hair slip and duslting because of high paper forming ash content; meanwhile, the paper forming printing adaptability and dirty resistance can be obviously improved; and the colorful printing quality of the product is substantially improved.

Owner:ASIA SYMBOL GUANGDONG PAPER

Self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating

InactiveCN106590385AGood gloss and color retentionThe advantage is: polyurethane resin has good heat resistanceAntifouling/underwater paintsPaints with biocidesDibenzoyl PeroxideOrganic inorganic

The invention discloses a self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating which is prepared from the following raw materials: perfluoroalkyl ethanol, methyl isobutyl ketone, HDI trimer, methyl methacrylate, styrene, hydroxyethyl methacrylate, perfluorooctyl methacrylate, benzoyl peroxide, 25-28 parts of methanol silica sol, propylene glycol methyl ether acetate, titanium dioxide, sodium hexametaphosphate, ethyl orthosilicate, vinyl triethoxysilane, an appropriate amount of ammonia water, an appropriate amount of silane coupling agent KH570, an appropriate amount of methyl hydroxyl silicone oil, an appropriate amount of 10% dibutyltin dilaurate, a dispersant, a leveling agent, a defoamer, an appropriate amount of butyl acetate, an appropriate amount of anhydrous ethanol, and an appropriate amount of deionized water. The super-amphiphobic polymer coating provided by the invention is simple and feasible in preparation method, can be firmly combined with a variety of substrates, and has universality, good self-cleaning performance, dirt resistance, scrub resistance, corrosion resistance and other performance, and good application prospects.

Owner:TIANCHANG YINHU PAINT

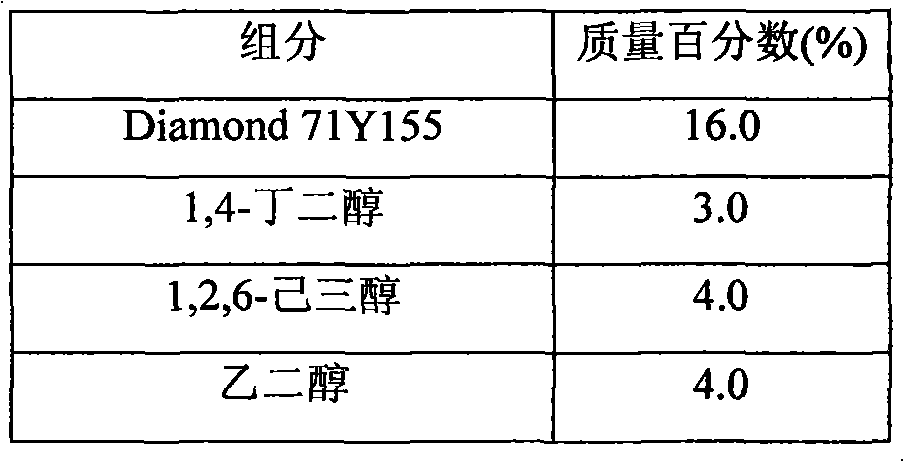

Latex-type waterborne pigment oil ink for inkjet printing of non-absorbed substrate as well as preparation method and applications thereof

ActiveCN101899237AGood printing fluencyHigh precisionInksOther printing apparatusWater basedWater soluble

The invention relates to latex-type waterborne pigment oil ink for the inkjet printing of a non-absorbed substrate, which is prepared from the following components in percentage by weight: 1-15 percent of pigment dispersant, 0.01-2.0 percent of surface active agent, 10-40 percent of water-soluble co-solvent, 0.1-30 percent of water-based polymer emulsion and the balance of deionized water. The preparation method comprises the following steps of: stirring and mixing the surface active agent, the water-soluble co-solvent and the deionized water under a normal temperature; then, slowly adding the waterborne polymer emulsion, continuously stirring; and finally, adding the pigment dispersant, fully mixing the contents to form an even dispersing system and filtering the even dispersing system to obtain latex-type waterborne pigment oil ink. The latex-type waterborne pigment oil ink for the inkjet printing has wide range of suitable substrates, is environment-friendly in the oil ink preparation process and the printing process and has good printing smoothness and high accuracy; and printed images on the non-absorbed substrate have excellent resistance to rubbing, scraping, sunshine and water and are suitable for outdoor use.

Owner:上海英威喷墨科技有限公司 +1

Paraffin putty paste and its prepn process

The paraffin putty paste is prepared with paraffin, polyacrylamide, zinc sulfate, heavy calcium carbonate, talcum powder, cement modifier, calcium hydroxide and water, and the cement modified is one or several of APR-968LO, AC-200P and ARS200AP. The preparation process of paraffin putty paste is also disclosed. The paraffin purity paste has fine and smooth hand feeling, no crack produced, no toxic matter, can be water washed and has no need of covered with other paint and thus results in low construction cost.

Owner:王天龙

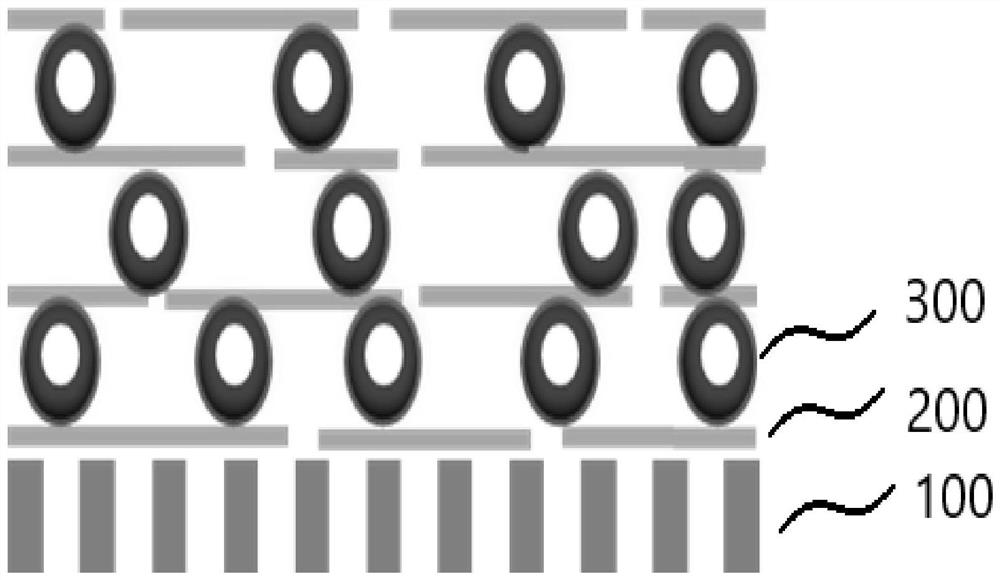

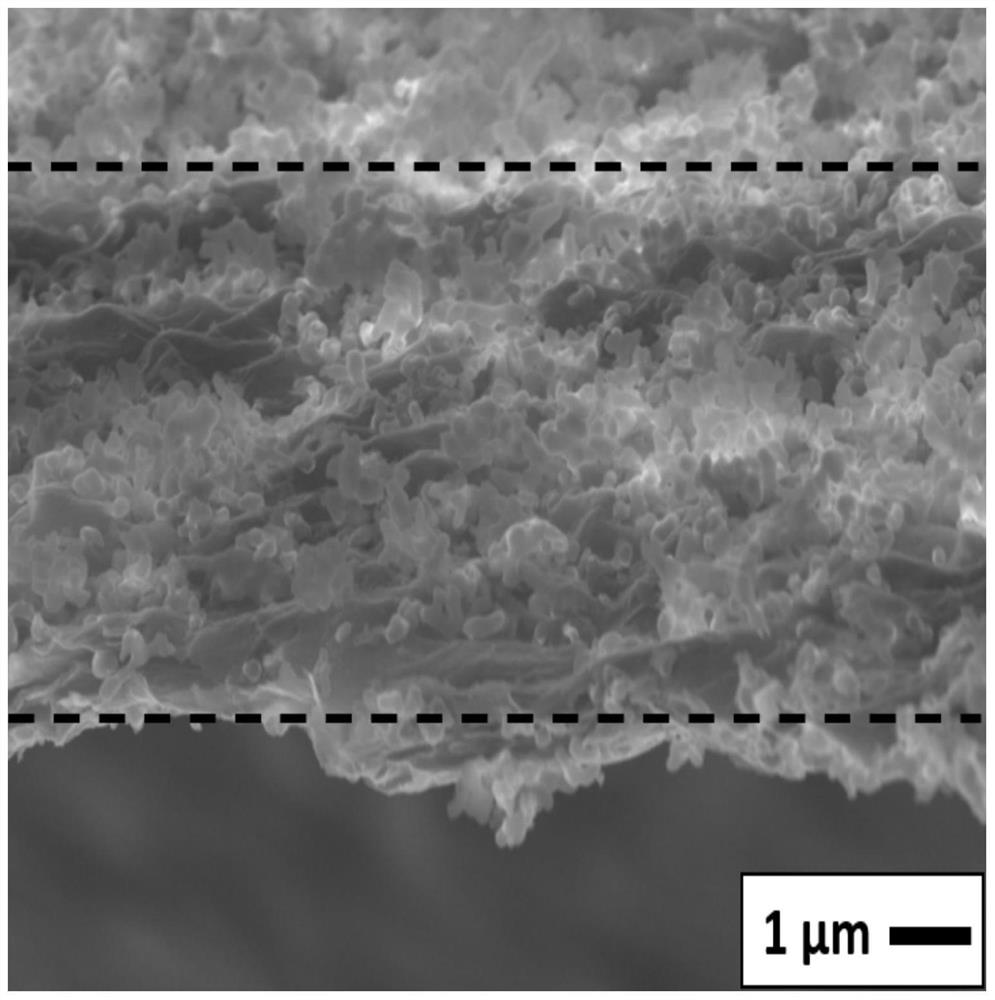

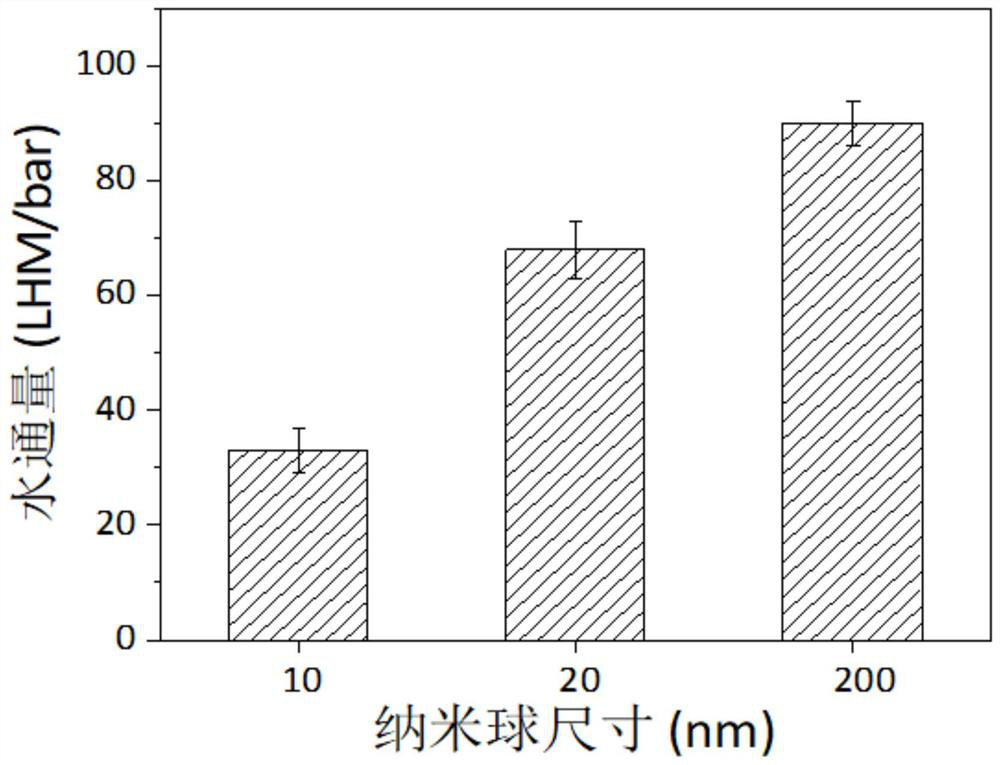

Two-dimensional layered composite film and preparation method and application thereof

PendingCN113083036AImprove stabilityEasy to separateMembranesSemi-permeable membranesComposite filmMembrane surface

The invention discloses a two-dimensional layered composite film and a preparation method and application thereof. The two-dimensional layered composite film comprises a base film; two-dimensional nanosheets which are vertically arranged on the surface of the base film to form a nanosheet layer; and nanospheres which are dispersed among the nanosheet layers. According to the prepared two-dimensional layered composite film, the stability of the layered channel of the film is improved through positive and negative electrostatic assembly, and then the stable nanofiltration separation performance is guaranteed; the size of the layered channel can be effectively regulated and controlled by utilizing the nanospheres with different sizes, so that the film pores can just intercept ions and molecules, the problem of poor molecular ion interception effect when the water flux is large is effectively solved, and the energy consumption in the separation process can be reduced; meanwhile, the hydrophilic nanospheres are introduced to enhance the anti-dirt and antibacterial capabilities, so that the film pollution and film degradation are effectively reduced.

Owner:GUANGZHOU UNIVERSITY

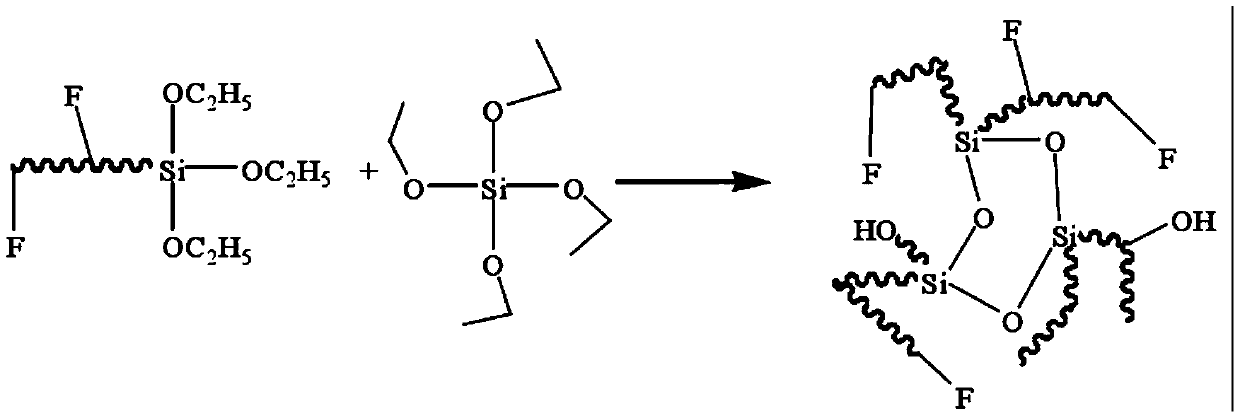

Organic silicon fluoro water proofing agent and its preparation method

ActiveCN1718665AGood solvent resistanceImprove acid resistanceOther chemical processesHigh resistanceSolvent

An organic Si-F water-proofing agent is composed of solvent and the organic Si-F resin prepolymer which is prepared from one or more alkyl siloxane coupling agents and hydroxy F-Si oil through catalytic hydrolysis reaction. Its preparing process is also disclosed. Its advantages are high water-proofing effect and high resistance to solvent, acid, alkali and ageing.

Owner:GUANGZHOU BAIYUN CHEM IND +1

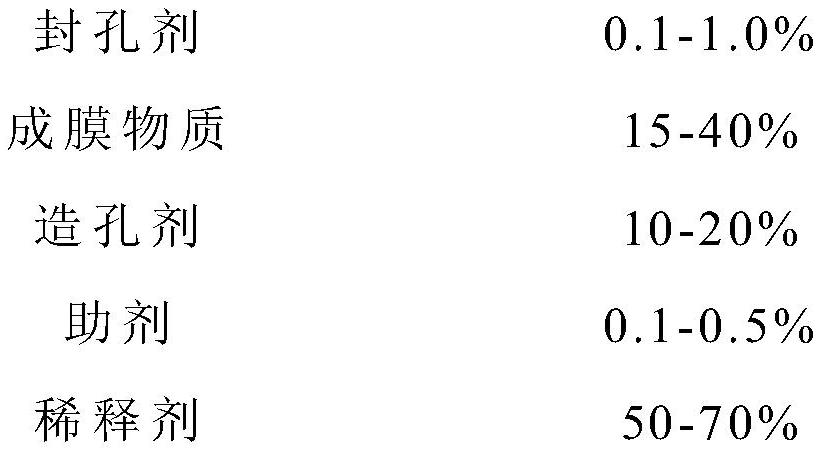

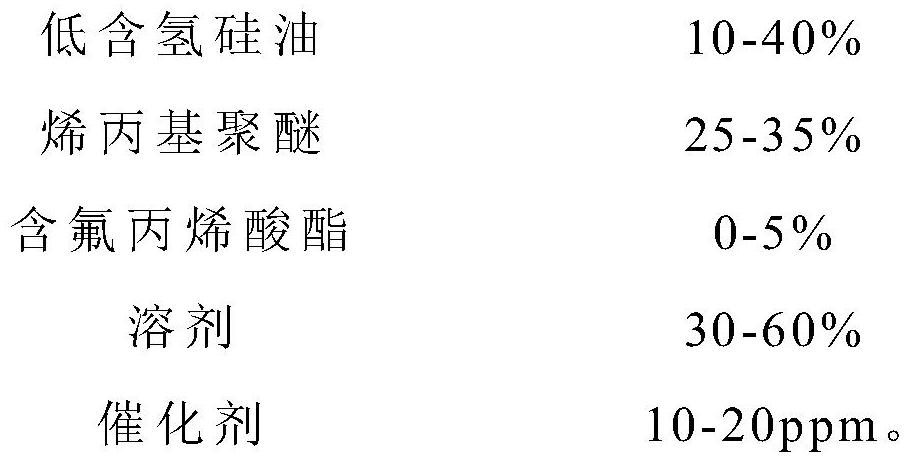

Antireflection coating liquid, preparation method thereof, antireflection coated glass and photovoltaic module

InactiveCN111849349ALower surface energyDense film structureAntifouling/underwater paintsPaints with biocidesSilicone resinOrganosilicon

The invention discloses a hole sealing agent for improving the anti-fouling performance of an antireflection coating, a preparation method of the hole sealing agent and an antireflection coating solution, and the hole sealing agent comprises the following components in percentage by mass: 10-40% of low-hydrogen silicone oil, 25-35% of allyl polyether, 30-60% of a solvent and 10-20 ppm of a catalyst. According to the antireflection coating solution, the hole sealing agent for improving the anti-fouling performance of the anti-reflection coated glass is added, the surface energy of the hole sealing agent is low, by adding into an antireflection coating solution, migration to the surface of the film layer is easy, in a high-temperature curing process, the anti-fouling agent can be crosslinkedwith the organic silicon resin in the coating solution to form the compact structure so as to provide the hole sealing effect on the surface of the film layer, such that the binding force between theEVA adhesive film, the sealing silica gel and other media and the film layer surface group is reduced, and the excellent anti-fouling performance is provided on the basis of the high transmittance ofthe film layer when the anti-fouling agent is used in the antireflection coating.

Owner:WUJIANG CSG GLASS CO LTD

3D effect surface treatment process

ActiveCN105543933ARich structureStrong metal feelingSurface reaction electrolytic coatingAnodic oxidationSurface finishing

The invention relates to the technical field of electronic equipment, in particular to a 3D effect surface treatment process. According to the 3D effect surface treatment process, anodic oxidation is carried out after the surface of an aluminum alloy is subjected to shielding sand blasting for two times at least by a shielding jig on the basis of conventional sand blasting. Through at least two times of sand blasting by the shielding jig, sand thicknesses and pressures of adjacent patterns are different, structure layers of surfaces of products are enriched, and through anodic oxidation, the 3D effect is achieved. Products manufactured by the process have excellent metallic appearance, are good in smudginess resistance, and are quite suitable to be used as appearance products of electronic and communication equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

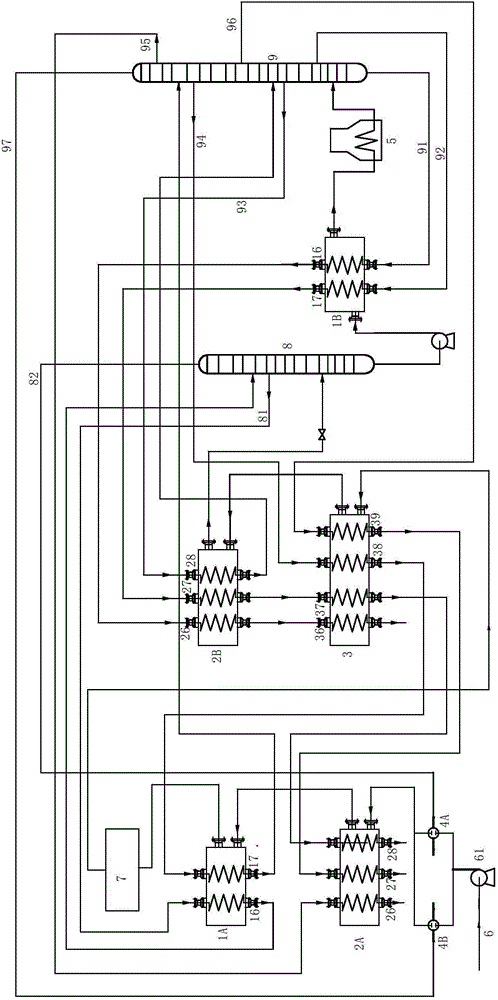

Heat exchange system and process of atmospheric and vacuum distillation unit

ActiveCN104479735AIncrease temperatureLess drag dropStationary tubular conduit assembliesHydrocarbon oils treatmentExchange networkEngineering

The invention relates to a heat exchange system and process of an atmospheric and vacuum distillation unit. Heat exchangers having special structures are adopted, multiple streams of material flow are simultaneously or sequentially subjected to heat exchange with material flow in shell pass, the resistance is reduced, the heat exchange efficiency is high, the temperature difference at a hot end is small, the operation is stable, the fouling resistance is good, the occupation area and investment of equipment are reduced, a heat exchange network is optimized, the temperature of a crude oil heat exchange terminal is increased, the crude oil heat exchange temperature can be increased by 4-5 DEG C under the condition that a heat exchange source is unchanged, and the energy saving and consumption reducing effects are very remarkable.

Owner:ZHENHAI PETROCHEM JIANAN ENG

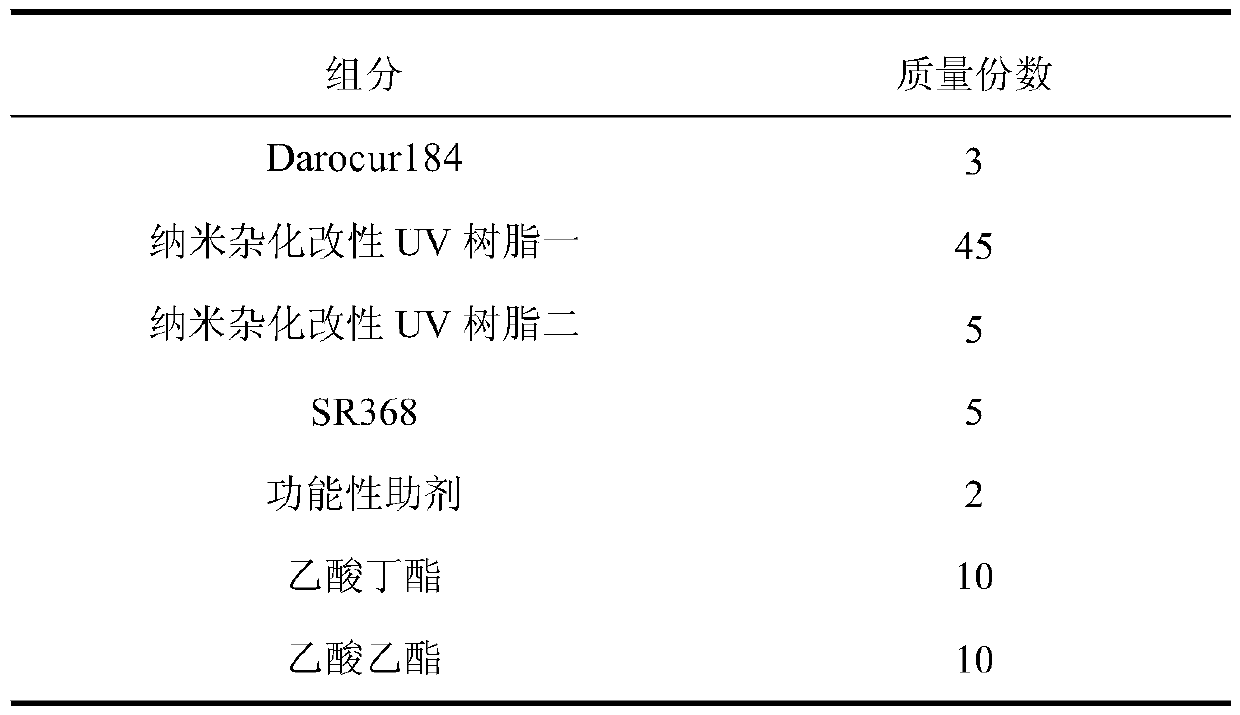

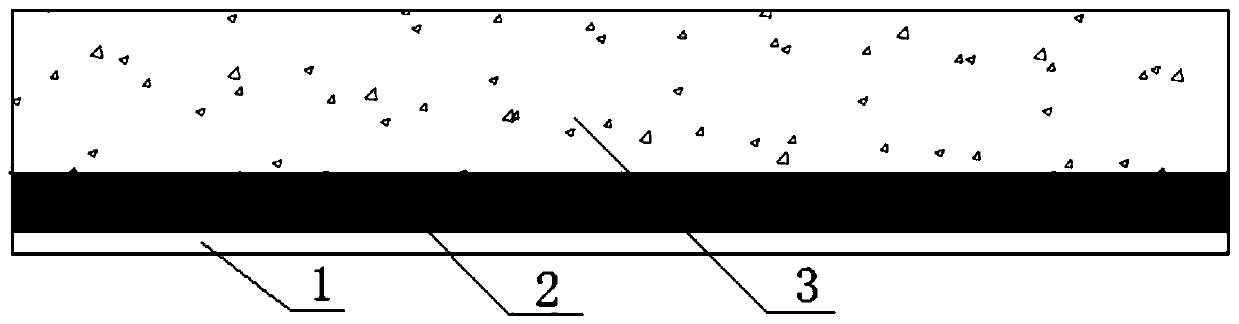

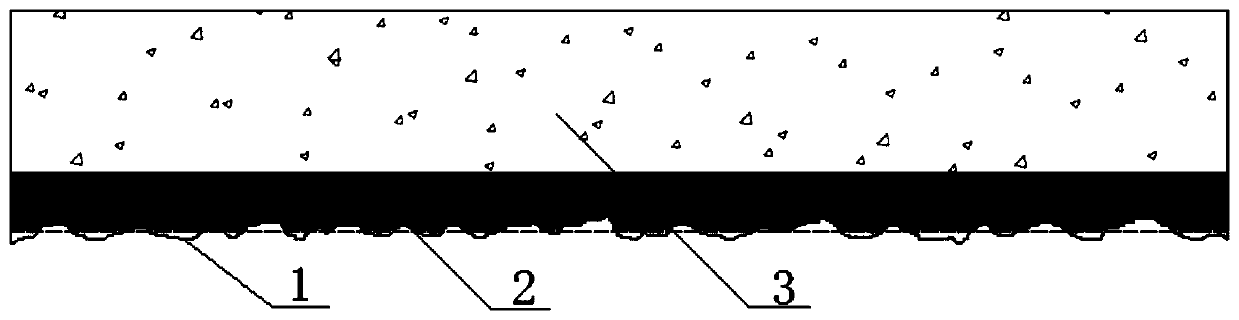

Ultra-wear-resistant flow coating UV coating material, preparation method and applications thereof

ActiveCN110358340AExcellent hydrophobicityDirt-resistant and smoothAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention discloses an ultra-wear-resistant flow coating UV coating material, a preparation method and applications thereof, wherein the ultra-wear-resistant flow coating UV coating material comprises, by weight, 40-60 parts of a nanometer hybrid modified UV resin A, 2-20 parts of a nanometer hybrid modified UV resin B, 3-5 parts of a photoinitiator, 1-5 parts of an active monomer, 0.5-5 partsof a functional auxiliary agent, and 30-40 parts of a solvent, wherein the nanometer hybrid modified UV resin A uses a nanometer hybrid fluorine-silicon modified acrylic resin with super wear resistance, and the nanometer hybrid modified UV resin B uses a nanometer hybrid fluorine-silicon modified acrylic resin with flexibility. According to the present invention, by using the nanometer hybrid modified UV resin A and the nanometer hybrid modified UV resin B as the main film forming substances, the obtained ultra-wear-resistant flow coating UV coating material has advantages of excellent hydrophobicity, excellent oleophobicity, stain resistance and smooth surface feeling property, and integrates good flexibility, superior abrasion resistance and superior scratch resistance.

Owner:HUNAN SOKAN NEW MATERIAL

Method for preparing silicon dioxide/titanium dioxide composite film containing branch porous structure on substrate

ActiveCN110272211ASuper hydrophilic performance and good durabilityImprove performanceCoatingsComposite filmSilicon dioxide

The invention relates to a porous structure control method for preparing a functional oxide SiO2 / TiO2 composite film on a substrate through a low-temperature sol-gel method, and belongs to the field of nanometer function material preparation. Ethyl orhosilicate is adopted as a raw material for preparing SiO2 sol, butyl titanate is adopted as a raw material for preparing TiO2 sol, the two kinds of sol are mixed according to a certain ratio, and the prepared SiO2 / TiO2 composite film has abundant regular branch-shaped structures, and by controlling the cross linking reaction among a high-molecular polymer, the SiO2 sol and the TiO2 sol, the porous structure is effectively controlled. The coating is unique in structural design, and the porous structure distributed regularly in a branch shape is shown; the porous structure facilitates water conveying and storage water characteristics, the super-hydrophilic effect and the durability are good, and the self-cleaning function film material is excellent in performance.

Owner:FUJIAN UNIV OF TECH

Polished metal brick and production process thereof

The invention discloses polished metal bricks and a production process thereof. The polished metal bricks are made from a green brick material and a glaze slip in a weight ratio of 60-80: 1. The green brick material comprises the following components in percentage by weight: 8 to 15 percent of plaster, 5 to 10 percent of white mud, 1 to 3 percent of talcum, 10 to 20 percent of feldspars, 10 to 15 percent of pottery stone, 30 to 50 percent of ceramic sands and 15 to 20 percent of high-temperature sands; and the glaze slip comprises the following components in percentage by weight: 3 to 10 percent of kaoline, 10 to 20 percent of calcspar, 5 to 15 percent of calcined talcum, 30 to 50 percent of feldspars, 2 to 5 percent of calcined zinc oxide, 0 to 10 percent of barium carbonate, 5 to 15 percent of calcined aluminum and 12 to 42 percent of inert metal powder. The production process comprises the following steps of: subjecting the green brick material to wet-method ball milling, screening, stirring and spray drying sequentially, the press molding the green brick material and drying the molded green brick material to obtain green bricks; subjecting a glaze to wet-method ball milling and screening to obtain the glaze slip; applying the glaze slip on the green bricks; and sequentially sintering, polishing and grinding the green bricks applied with the glaze slip to obtain the product. The polished metal bricks are wearable, shinning and dirt durable and have the effect of metal luster.

Owner:台山市海棠陶瓷有限公司

UHPC stone-like outer wall hanging plate and manufacturing process thereof

InactiveCN109989548AReduce energy consumptionReduce usageCovering/liningsCeramic shaping apparatusSlurryEngineering

The invention provides a UHPC stone-like outer wall hanging plate. The UHPC stone-like outer wall hanging plate comprises a first decorating layer, a second decorating layer and a structural layer which are sequentially arranged in a laminated mode, and are all made of UHPC mortar; the first decorating layer and the second decorating layer are different in color RGB value; and the surface of the second decorating layer is partially exposed out of the surface of the first decorating layer. The invention further provides a manufacturing process of the UHPC stone-like outer wall hanging plate. The manufacturing process comprises the following steps: S1, material blending is conducted; S2, first decorative layer slurry is poured; S3, second decorative layer slurry is poured; S4, structural layer slurry is poured and vibrated; S5, curing and forming is carried out; and S6, demolding is carried out, and treatment of one or a combination of two or more of shot blasting, chiseling, hammering,mincing and burning stripping is carried out. According to the technical scheme, the UHPA outer wall hanging plate adopts a double-decorative-layer structure form, inorganic pigments with different colors or different proportions are added, so that the tones of the two decorative layers are inconsistent, and various decorative effects can be provided for buildings.

Owner:筑友智造新材有限公司

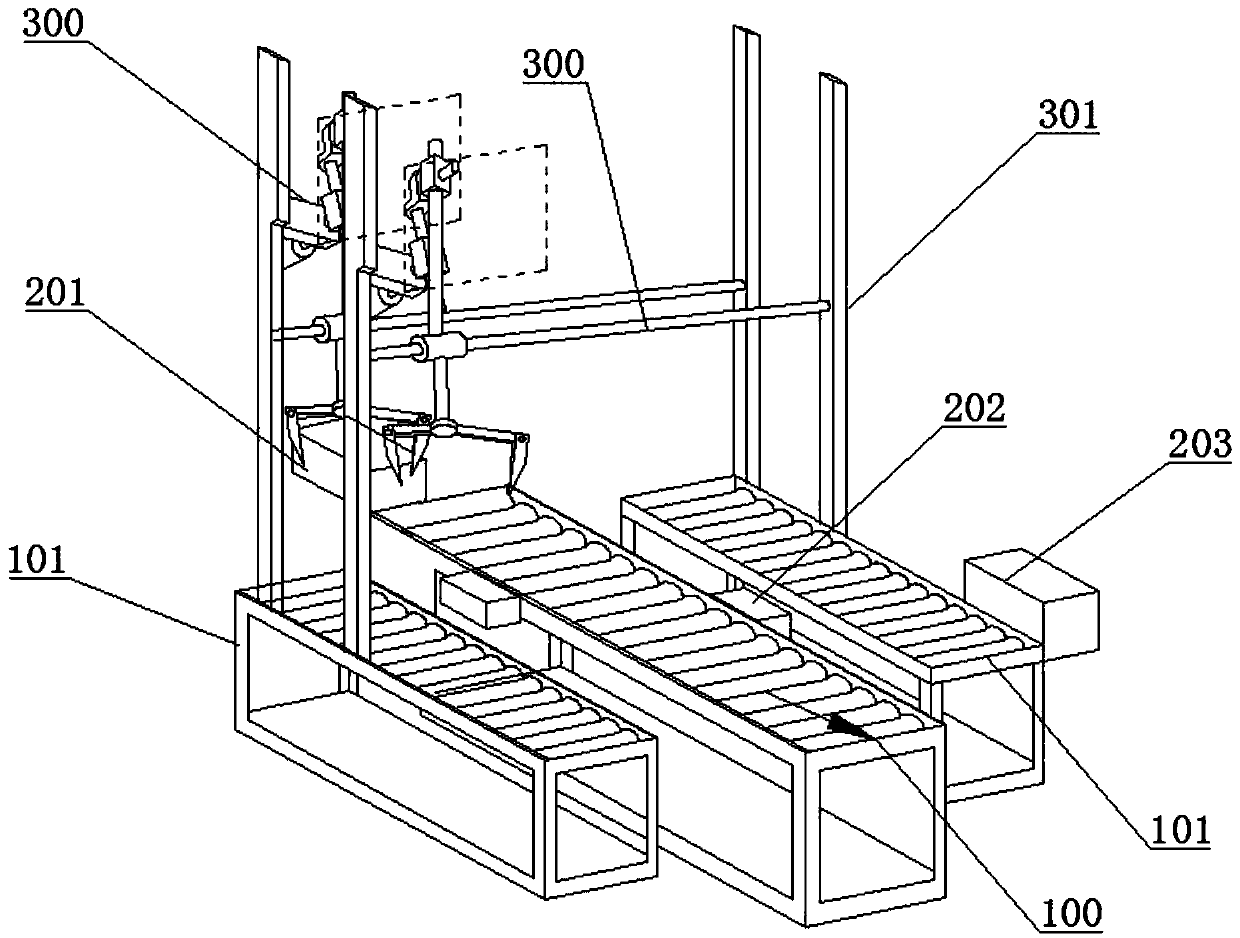

Sorting machine system with automatic identifying function and large sorting scope

The invention discloses a sorting machine system with automatic identification and a large sorting range, which belongs to the technical field of sorting and solves the problems of high robot cost and limited sorting range in the existing sorting system. It includes a transmission channel. The transmission channel is equipped with an identification mechanism, a handling mechanism, and a control system. The transmission channel, the identification mechanism, and the handling mechanism are all electrically connected to the control system. The transmission channel is also connected to a sorting channel. The frame on the transmission channel is provided with a handling component. The handling component includes a track axis set on the frame. A sliding base is set on the track axis. A mechanical claw component is connected to the sliding base. Rod, the middle slider is set on the connecting rod, the middle slider is hinged with a joint, the joint is fixedly connected to the rotation rod, the rotation slider is set on the rotation rod, the servo motor is set on the frame, and the output shaft of the servo motor is fixed to the rotation slider. connect. The invention is used for product sorting.

Owner:CHENGDU KECHUANGGU TECH CO LTD

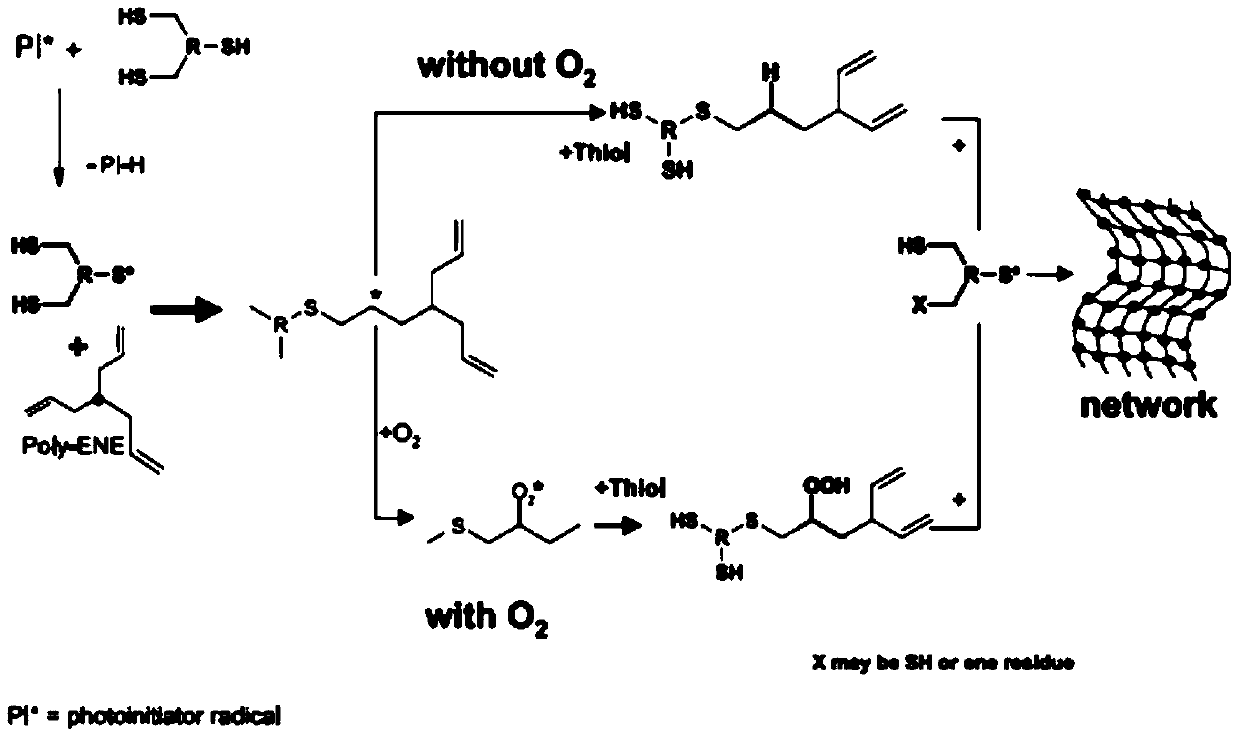

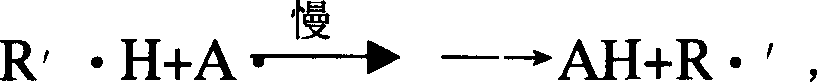

Ultraviolet curing super-hydrophobic material used for 3D printing, composition and preparation method thereof

InactiveCN107722188AImprove dirt resistanceReduce hardnessAdditive manufacturing apparatusOligomerUltraviolet

The invention provides an ultraviolet curing super-hydrophobic material composition used for 3D printing and a preparation method thereof. The composition comprises 30-60 parts of an oligomer component, 10-30 parts of a reactive diluent and 1-5 parts of a photoinitiator. The invention also provides a preparation method of an ultraviolet curing super-hydrophobic material used for 3D printing. The method at least comprises the following steps: mixing and stirring 30-60 parts by weight of an oligomer and 10-30 parts by weight of a diluent, so that a first mixed liquor is obtained; and adding 1-5parts by part of the photoinitiator into the first mixed liquor, stirring until the photoinitiator is dissolved, and keeping in a dark place, so that a second mixed liquor is obtained. The prepared ultraviolet curing super-hydrophobic material used for 3D printing has stronger hydrophobicity, foul resistance of the material is improved, and hardness, tensile strength, viscosity, volume shrinkage and other properties of the material are not reduced. Besides, the ultraviolet curing super-hydrophobic material composition used for 3D printing is simple in preparation technology, and industrialization can be easily realized.

Owner:上海多睿电子科技有限公司

Method of forming double-color double-texture PVD film layer on metal substrate and metal substrate obtained thereby

ActiveCN108239745AStrong adhesionImprove adhesionVacuum evaporation coatingSputtering coatingSand blastingPrinting ink

The invention relates to the technical field of pattern processing and discloses a method of forming a double-color double-texture PVD film layer on a metal substrate and the metal substrate obtainedthereby. The method comprises the following steps: (1) carrying out primary PVD coating treatment on the metal substrate to form a bottom film layer and a top film layer different in color on the metal substrate; (2) designing a needed pattern on the top film layer, and coating shielding printing ink to the pattern region to be cured; (3) carrying out sand blasting treatment on the substrate obtained in the step (2); (4) removing the top film layer exposed in a non-pattern region; and (5) removing the shielding printing ink cured in the pattern region. The method can plate the double-color double-texture PVD film layer on the metal substrate at one time within a same furnace body without a film exploding phenomena, so that the PVD coating step is reduced, the time is shortened greatly, thecost is lowered, and the product yield is increased obviously.

Owner:BYD CO LTD

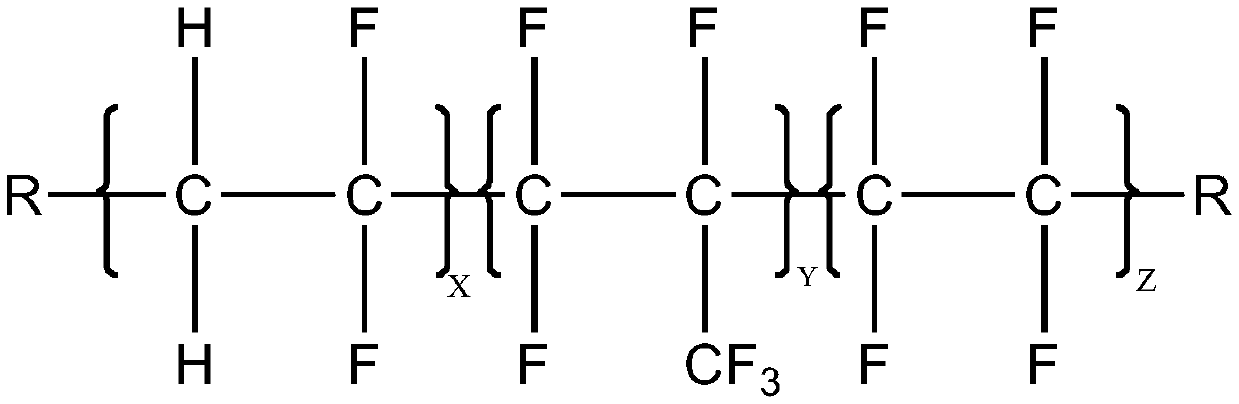

Ternary peroxide fluororubber and preparation method thereof, and intelligent wearable material and preparation method thereof

InactiveCN111363076AGood colorExcellent resistance to oleic acidBraceletsWrist-watch strapsSide chainViton

The invention provides ternary peroxide fluororubber and a preparation method thereof, and an intelligent wearable material and a preparation method thereof. The invention aims to solve the technicalproblem that wrist strap and watchband materials in the prior art cannot well meet requirements for swimming pool water resistance, sweat resistance, artificial sebum resistance, oleic acid resistanceand dirt resistance required by intelligent wearable wrist straps and watchbands at the same time. According to the preparation of fluororubber in the invention, iodine is used as a crosslinking active point, iodine used as the crosslinking active point is bonded to the tail end of a fluororubber polymer molecular chain or the tail end of a side chain of a vulcanization point monomer, and vulcanization crosslinking can be easily carried out with peroxide. A polymer prepared in the invention is used for preparing the intelligent wearable material. The prepared intelligent wearable wrist strapmaterial or watchband material can meet the requirements for swimming pool water resistance, sweat resistance, artificial sebum resistance, oleic acid resistance and dirt resistance, and a intelligentwearable wrist strap or watchband prepared from the material is safe, environmentally-friendly and durable to use, soft in hand feeling, good in texture and comfortable in somatosensory feeling and can better meet the high technical requirement for continuous changing of the material for the intelligent wearable wrist strap or watchband.

Owner:四川道弘科技有限公司

Semi-welded plate heat exchanger

InactiveCN102798305AIncrease gasket compression ratioIncrease contact areaLaser beam welding apparatusLaminated elementsPhysicsLaser soldering

The invention relates to a semi-welded plate heat exchanger which comprises a fixed clamping plate, a movable pressing plate, an upper guide rod, a lower guide rod, a supporting column, semi-welded plate pairs, sealing gaskets and a clamping bolt pair. The fixed clamping plate, the movable pressing plate, the upper guide rod, the lower guide rod and the supporting column form the frame of the heat exchanger. A plurality of semi-welded plate pairs are assembled by the sealing gaskets to form a plate which is arranged between the fixed clamping plate and the movable pressing plate and fixed by the clamping bolt pair. A plurality of semi-welded plate pairs at the plate are sealed by the sealing gaskets. Meanwhile, the sealing position of a plate A and a plate B of the semi-welded plate pairs adopts the structure of two-sided laser welding, so as to effectively overcome the deformation of the plate pairs during welding and eliminate the deformation stress during welding. The heat exchanger has the advantages of simple and reasonable structure, convenience in use and good heat exchanging effect.

Owner:四平市巨元瀚洋板式换热器有限公司

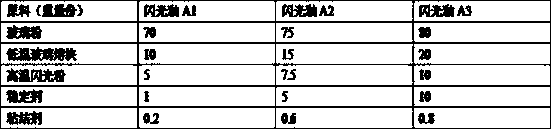

Glistening glaze for glass mosaic, and glass mosaic preparation process

A glistening glaze for glass mosaic is disclosed, and includes following raw materials by mass: 70-80 parts of glass powder, 10-20 parts of low-temperature glass frit, 5-10 parts of high-temperature glistening powder, 0-10 parts of a stabilizer, 0.2-0.8 part of a binder and water. The fineness of the glistening glaze is 200-250 meshes. According to a technical scheme, the low-temperature glass frit and the high-temperature glistening powder are blended according to a certain ratio, a melting temperature difference between the low-temperature glass frit having a low softening temperature and the high-temperature glistening powder having a high melting temperature is utilized, the fineness of powder materials is controlled to be 200-250 meshes, finally a certain amount of the stabilizer, thebinder and the water are added, and the mixture is ground to obtain the low-temperature glaze that can be applied onto a glass mosaic surface. After the glaze is applied onto the glass mosaic surfaceto form a glaze layer and low-temperature firing is performed, the glaze layer on the glass mosaic surface has fine, smooth and glistening decorative effects, and has good stain resistance and betterapplicability.

Owner:佛山市唯格建材有限公司

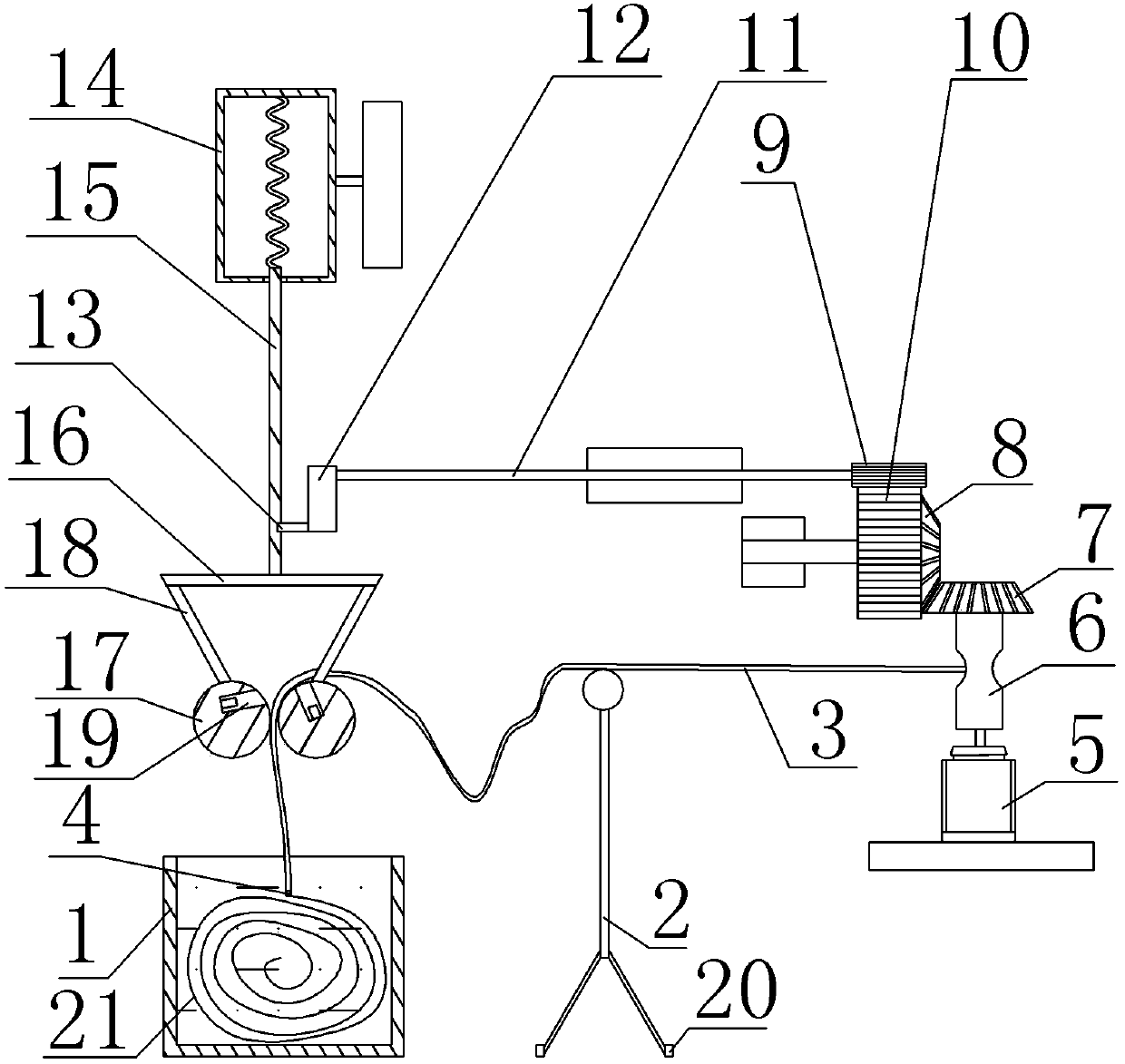

Cloth dyeing technology

InactiveCN107904821ARealize automatic hangingDyeing speed is fastDyeing processTextile treatment carriersEngineeringDyeing

The invention relates to the field of cloth dyeing and printing, in particular to a cloth dyeing technology. The cloth dyeing technology comprises the following steps that 1, a dye is prepared for use; 2, a dye vat used for containing the dye, a soaking mechanism used for soaking cloth, a drawing mechanism used for drawing the cloth to move and a drying rack used for drying the cloth are prepared,wherein the soaking mechanism comprises a rotating unit, a swinging unit and a support clamping unit; 3, after the cloth is connected with the drawing mechanism, the cloth is thrown into the dye vatto be soaked for a period of time, and the cloth is soaked under cooperation of the rotating unit, the swinging unit and the support clamping unit; 4, the drawing mechanism draws the cloth to move, and the cloth is wrung and rolled out under cooperation of the rotating unit, the swinging unit and the support clamping unit; 5, the drawing mechanism draws the cloth to continue moving, and the clothis hung on the drying rack for drying. By means of the technical scheme, the cloth can be prevented from wrinkling in the dyeing and squeezing process, and meanwhile the cloth can be rolled out.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Ethene compressor cleaning media

An ethylene compressor anti-scale agent consists of phenols antioxidant 2í½15wt%, organo phosphorous compound 10í½40wt%, amine inhibitor 6í½30wt% and solvent residue. It has good anti-scale effect.

Owner:浙江杭化科技股份有限公司

Composite for manufacturing trash can and preparation method of composite

The invention relates to a composite for manufacturing a trash can and a preparation method of the composite. The composite is prepared from, by mass, 35-55 parts of PVC resin, 10-25 parts of glass fibers, 10-25 parts of acrylonitrile-butadiene-styrene copolymer, 5-18 parts of ceramic fibers, 0.5-1.5 parts of tetraethoxysilane, 0.2-0.8 part of di-n-octyl ortho-phthalate, 0.1-0.6 part of phenyl salicylate, 0.1-0.5 part of diphenylamine, 2-8 parts of asbestos powder, 1-7 parts of phosphite ester, 0.3-0.8 part of alkyl sodium sulfonate and 0.2-0.6 part of simethicone. The trash can made of the composite is excellent in oil contamination resistance and dirt resistance, meanwhile, the trash can has antistatic, flame retardant, impact-resistant and aging-resistant performance, and the composite is a good material for manufacturing the trash for outdoor use.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com