Glistening glaze for glass mosaic, and glass mosaic preparation process

A technology of glass mosaic and preparation process, which is applied in the direction of coating, etc., can solve the problem of single surface effect, and achieve the effect of good applicability and good dirt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

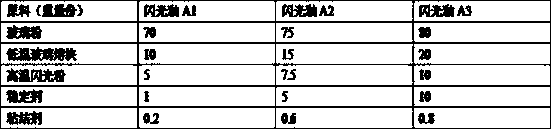

[0021] A flash glaze for glass mosaics, the flash glaze includes the following raw materials in parts by mass: 70-80 parts of glass powder, 10-20 parts of low-temperature glass frit, 5-10 parts of high-temperature flash powder, and 0 parts of stabilizer -10 parts, 0.2-0.8 parts of binder and water; and the fineness of the flash glaze is 200-250 mesh.

[0022] Although the mosaic pattern of the glass mosaic in the prior art is very rich, the surface effect of a single glass mosaic product is very single, which is not enough to meet the needs of users. The present invention proposes a flash glaze for the surface of glass mosaic. The flash glaze includes the following raw materials in parts by mass: 70-80 parts of glass powder, 10-20 parts of low-temperature glass frit, 5-10 parts of high-temperature flash powder, stable 0-10 parts of agent, 0.2-0.8 parts of binder and water; since the flash glaze is used on the surface of glass mosaic, its raw material formula uses the same glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com