Heat exchange system and process of atmospheric and vacuum distillation unit

A technology of atmospheric and decompression devices and heat exchange systems, applied in the direction of indirect heat exchangers, heat exchanger types, petroleum industry, etc., can solve problems such as inability to recover heat to the maximum extent, heat loss, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

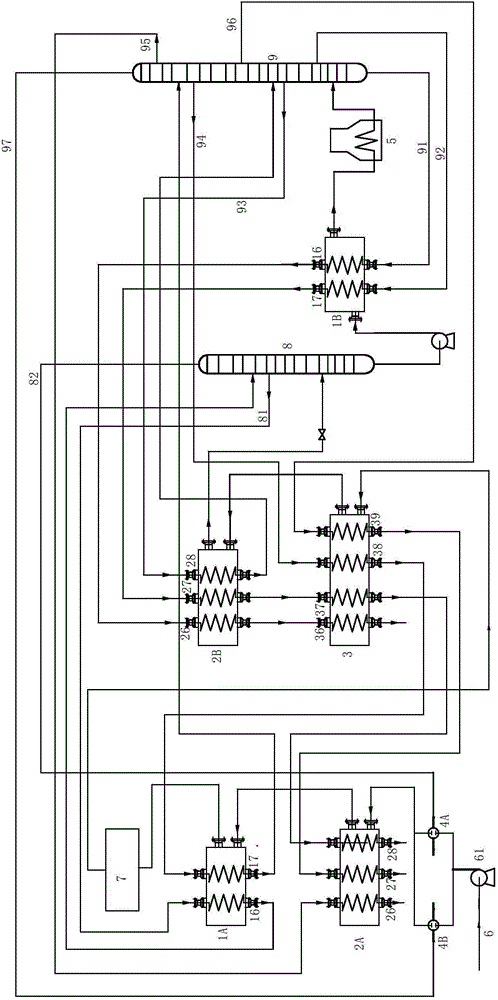

Image

Examples

Embodiment 2

[0086] Such as figure 2 As shown, this embodiment uses a third dual-stream heat exchanger 1C to replace the two single-stream heat exchangers 4A, 4B. The structure of the third dual-stream heat exchanger 1C is the same as that of the first and second dual-stream heat exchangers.

[0087] Crude oil from outside the boundary with a temperature of 25~50℃ enters the shell side of the third dual-stream heat exchanger 1C through the first pump, and the overhead oil from the atmospheric column with a temperature of 115~135℃ and from the primary The top oil of the distillation column with a temperature of 120-150°C exchanges heat sequentially to 85-105°C; wherein, the mass flow ratio of crude oil to atmospheric column top oil and primary distillation top oil is 100:8:24.

[0088] Then enter the shell side of the first three-stream heat exchanger 2A.

[0089] The rest of the content is the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com