Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

403results about How to "Remarkable effect of energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

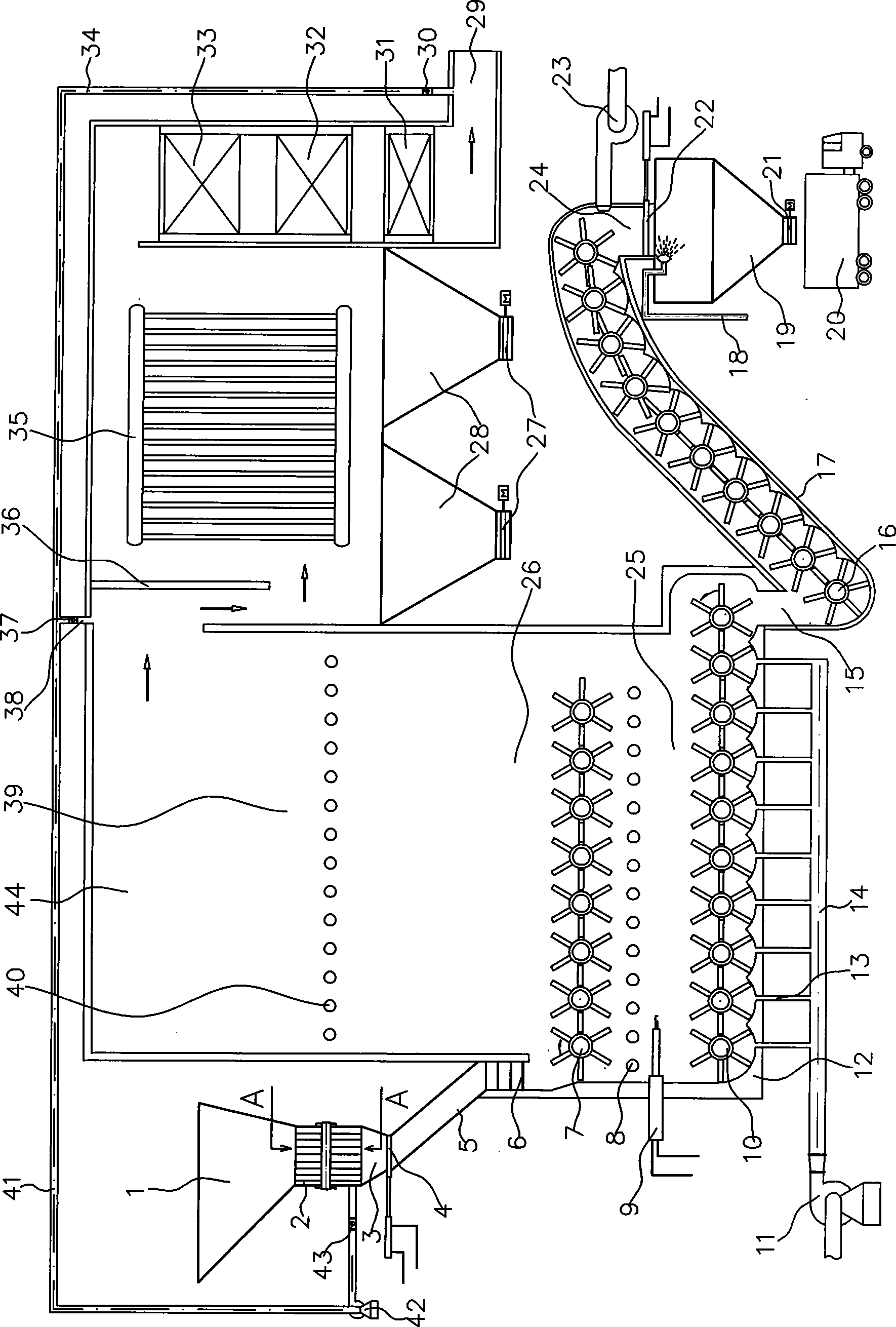

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Preparation method of cubic ultra-fine calcium carbonate particles

ActiveCN103663527AParticle size controllableNarrow rangeCalcium/strontium/barium carbonatesNanotechnologySodium bicarbonateSucrose

The invention provides a preparation method of cubic ultra-fine calcium carbonate particles. The method comprises the following steps: (1) adding a nucleation promoter to calcium hydroxide suspension liquid, wherein the nucleation promoter is selected from more than one of glucose, sucrose or sodium citrate; (2) carbonizing by introducing carbon dioxide until the pH value is 8-12, adding a crystal modifier and ageing for 0.5-10 hours, wherein the crystal modifier is selected from one of sodium chloride, sodium carbonate, sodium bicarbonate or sodium hydroxide; (3) further introducing carbon dioxide and carbonizing until the pH value is 6.5-7.0; (4) coating by adding a coating agent, filtering and drying to obtain a product, wherein the coating agent is selected from a resin acid, a resin acid alkali metal salt, a fatty acid or a fatty acid alkali metal salt. According to the calcium carbonate particles, the particle sizes are 90-180nm, the calcium carbonate particles are in a cubic shape, and the specific surface area is 10-18m<2> / g. Thus, the cubic ultra-fine calcium carbonate particles can be used as functional fillers in coating, rubber, plastic and sealant industries.

Owner:建德华明科技有限公司

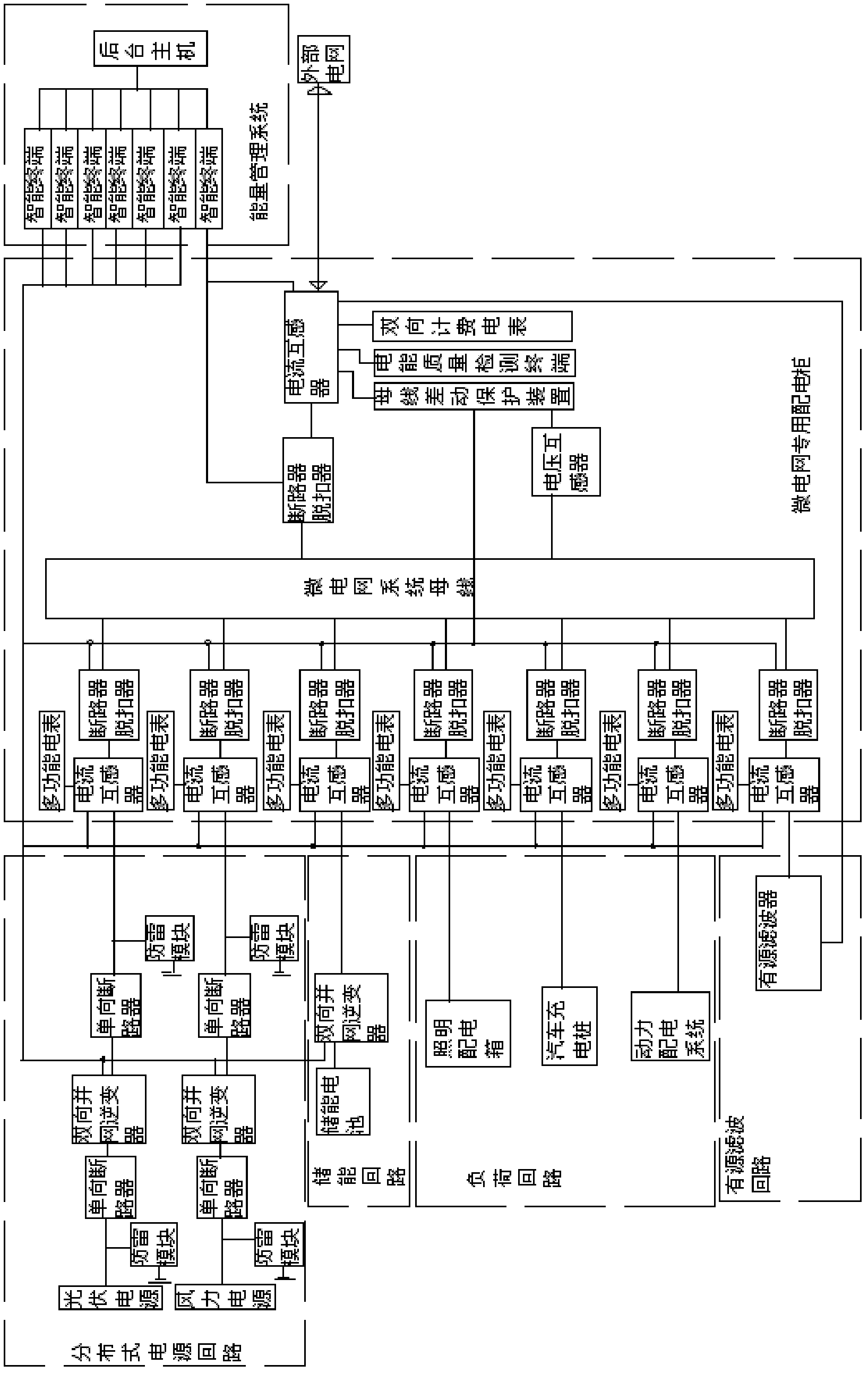

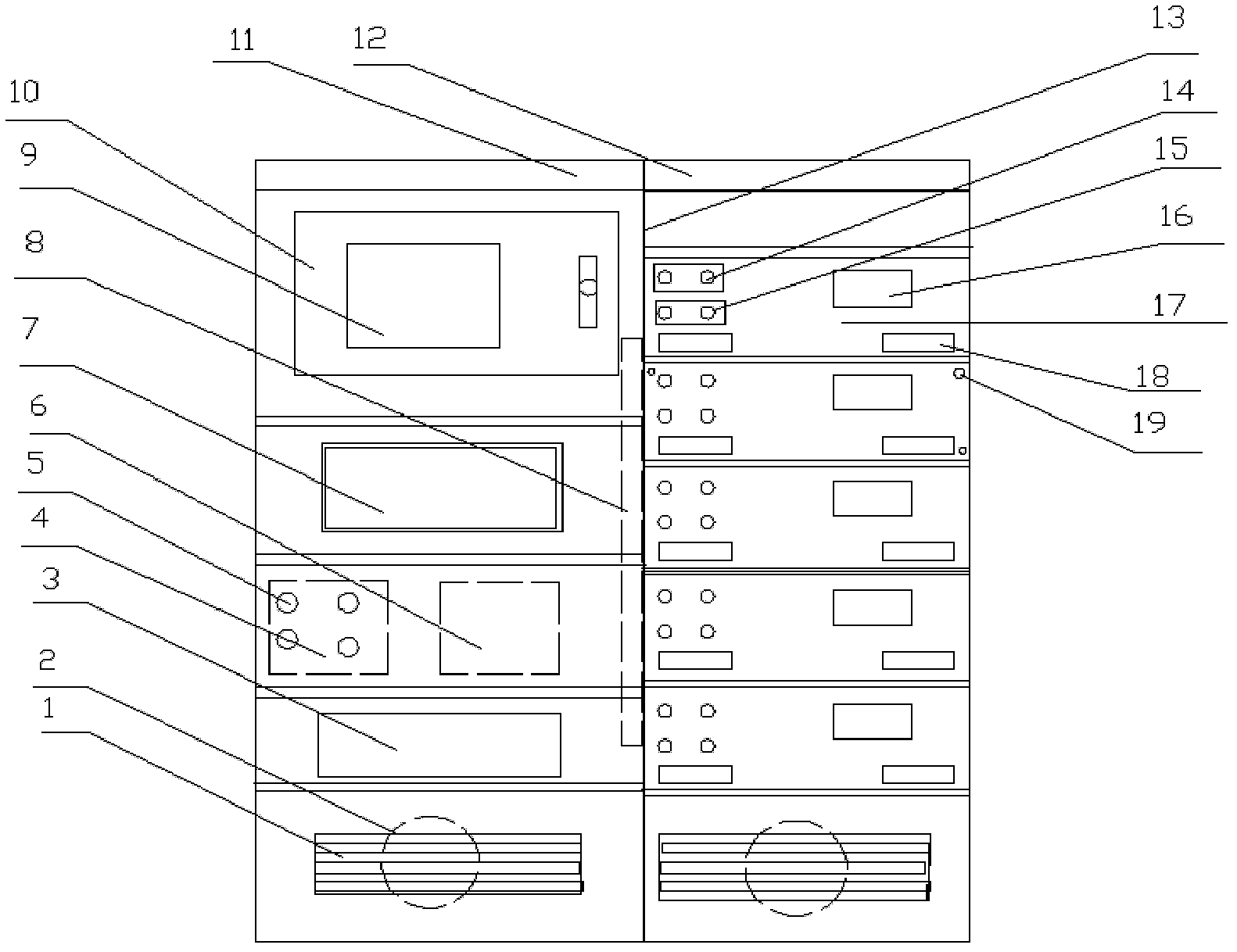

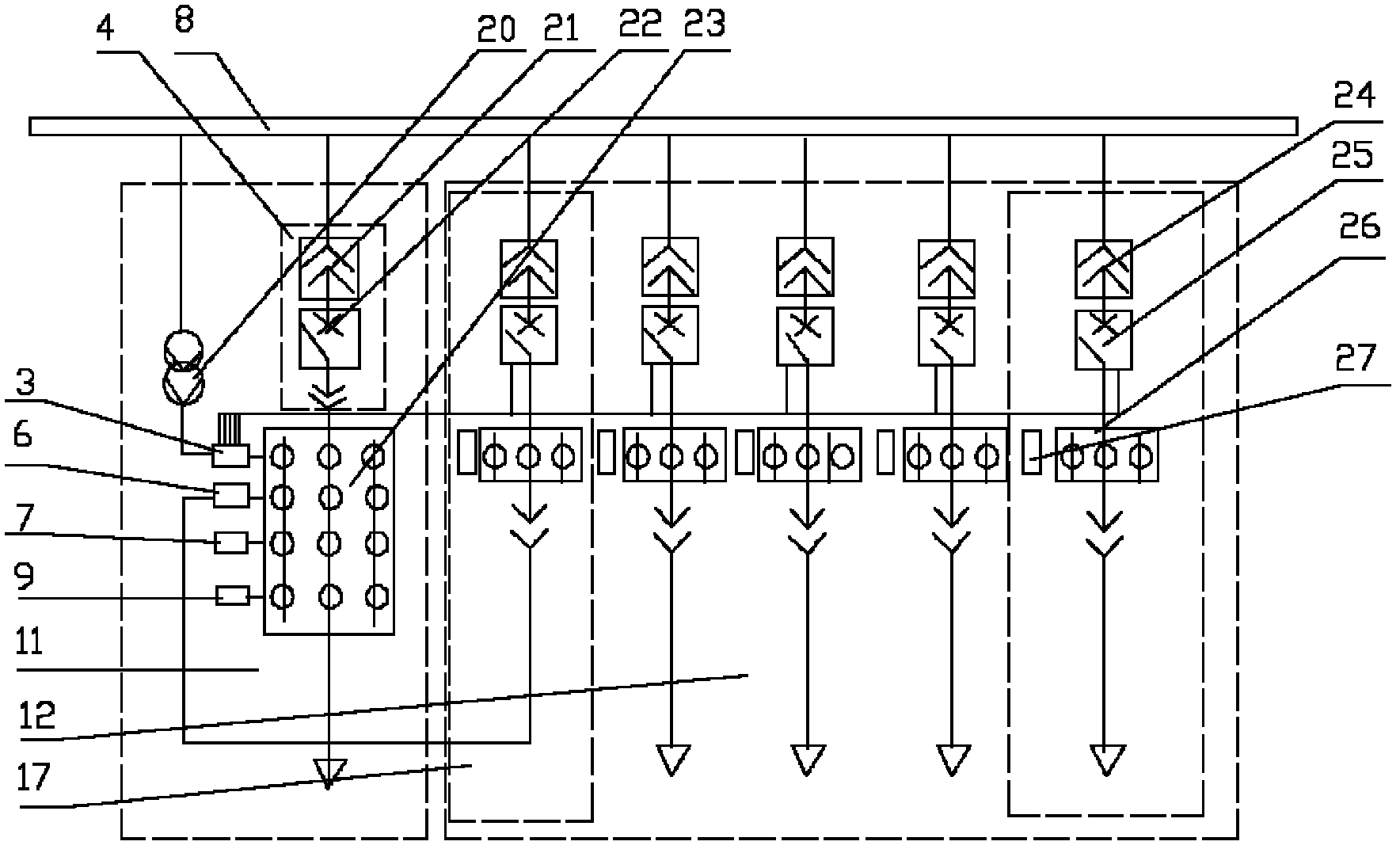

Intelligent microgrid power-supply system

ActiveCN102570455AImprove reliabilityImprove securityBoards/switchyards circuit arrangementsEmergency protective circuit arrangementsSmart microgridElectricity price

The invention relates to an intelligent microgrid power-supply system which is formed by a power distribution cabinet special for a microgrid, an energy management system, a distributed power source loop, a load loop, an energy storage loop and an active filtering loop. The intelligent microgrid power-supply system achieves diversified application of a novel power source and a novel load in an intelligent building power-supply system, the problem of negative influence of complexity of the building power-supply system on a power distribution system is solved, and novel intelligent building power supply can be accepted by a large power distribution system. By control of the energy management system, multifunctional innovation of the power distribution cabinet special for the microgrid, reasonable coordinating operation of the distributed power source loop and the energy storage loop and peak valley electrovalence adjustment, the intelligent microgrid power-supply system achieves the aims of the demand side response load adjustment and peak clipping and valley filling of a distributed power source, and the running of the microgrid is safe and reliable through conversion of grid connection and an islanding mode.

Owner:STATE GRID TIANJIN ELECTRIC POWER +2

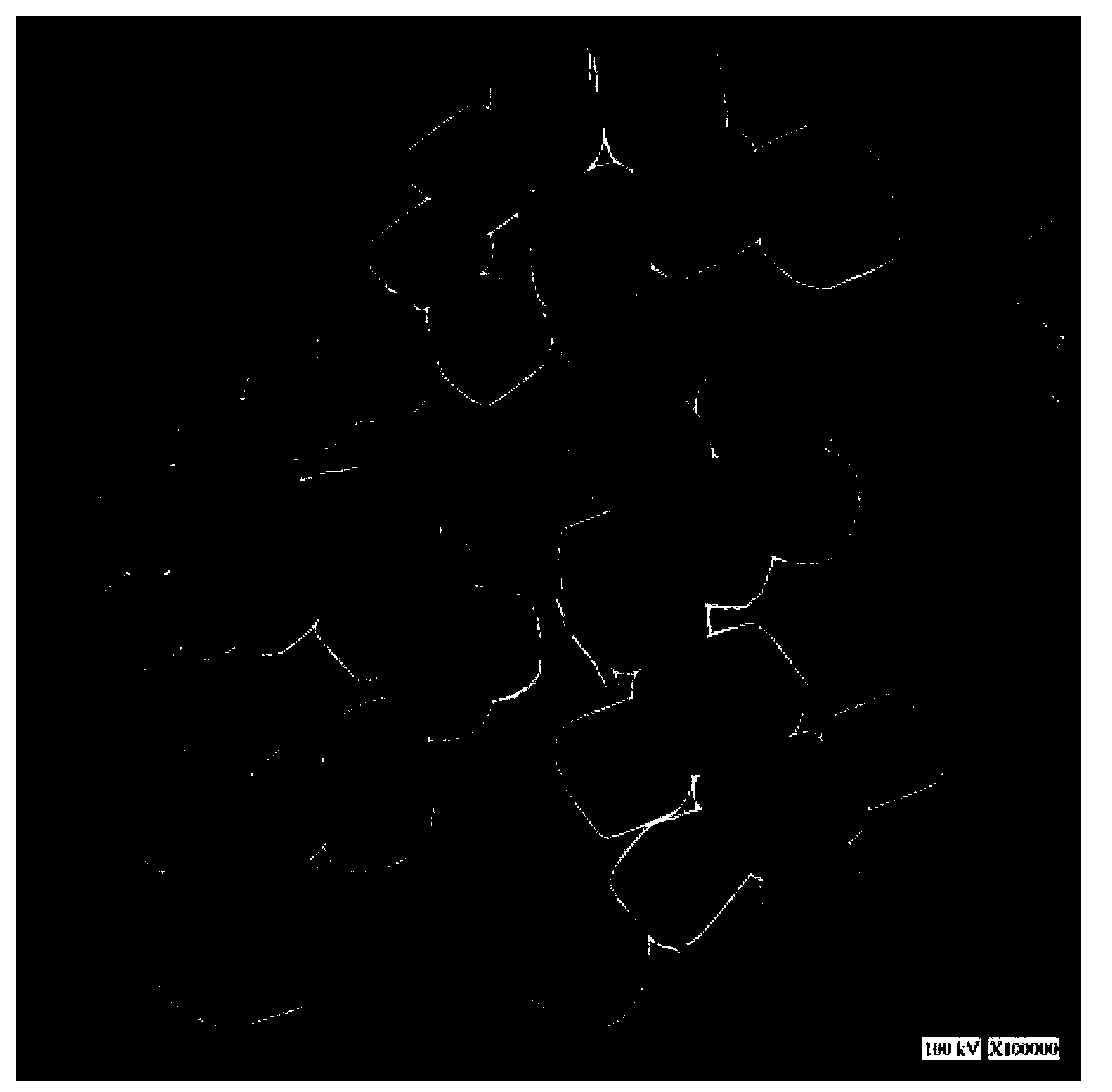

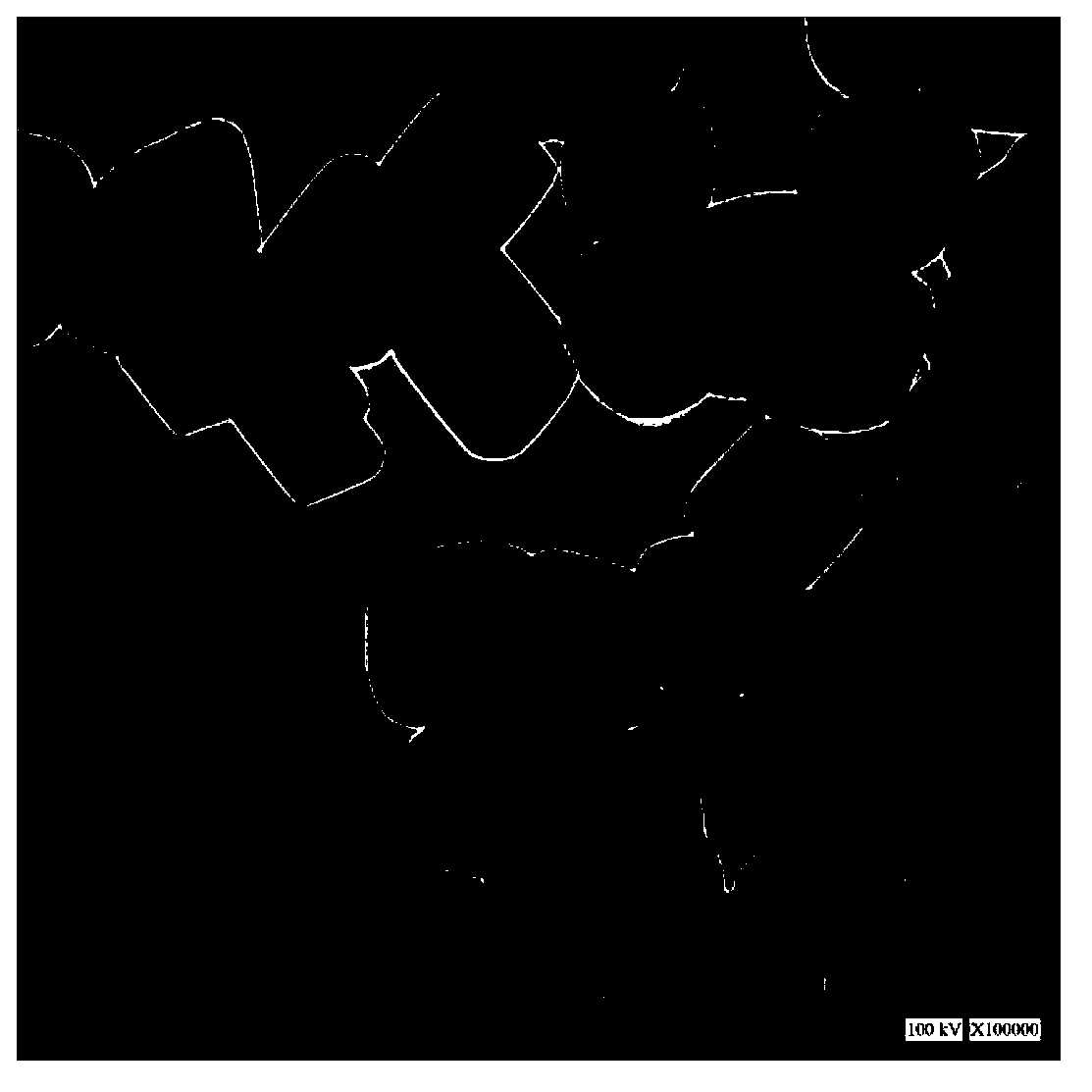

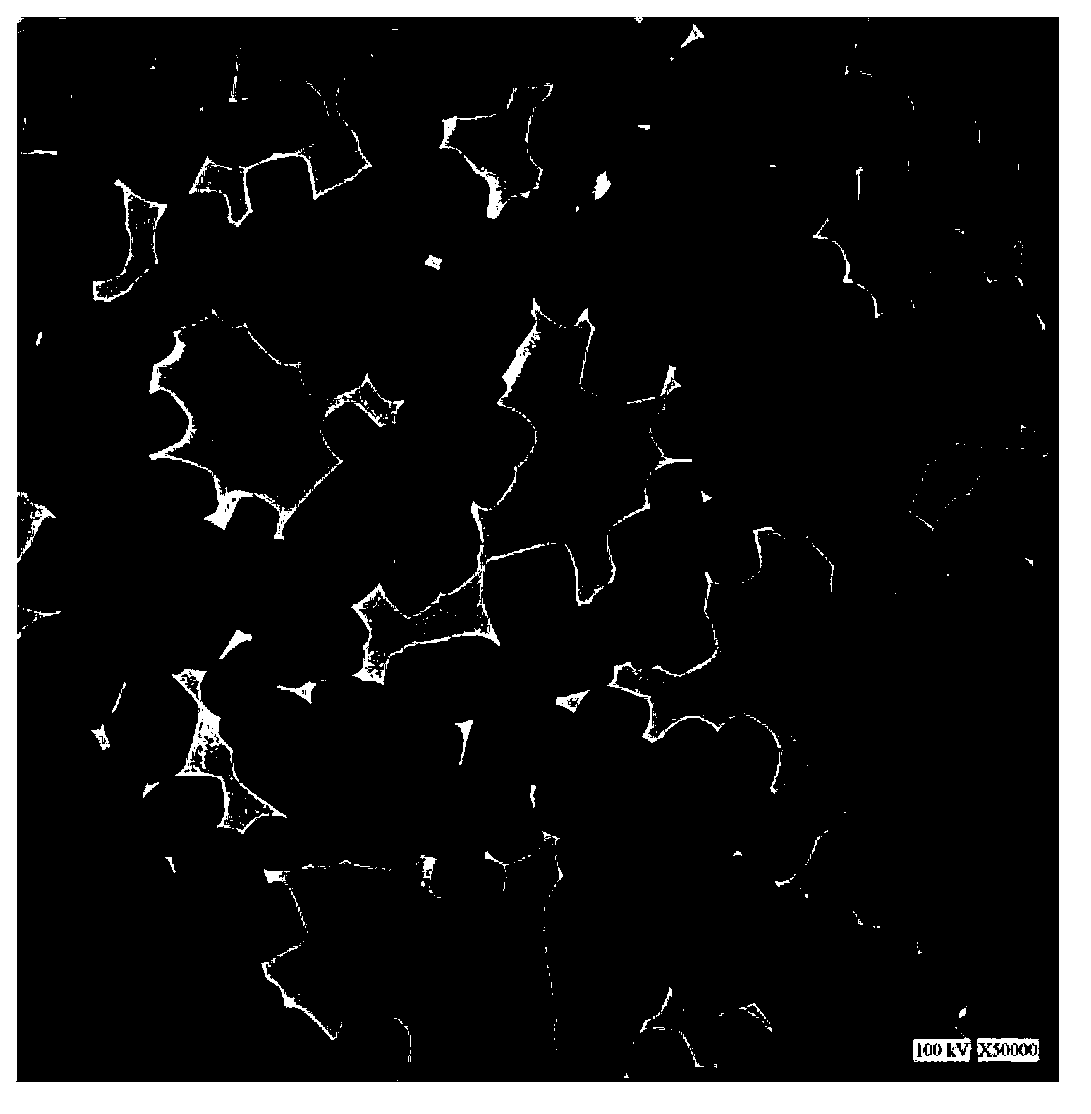

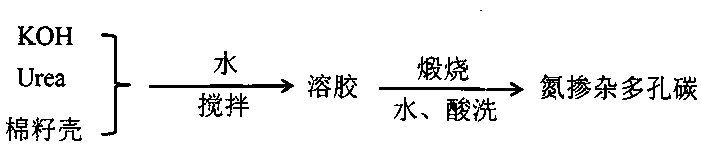

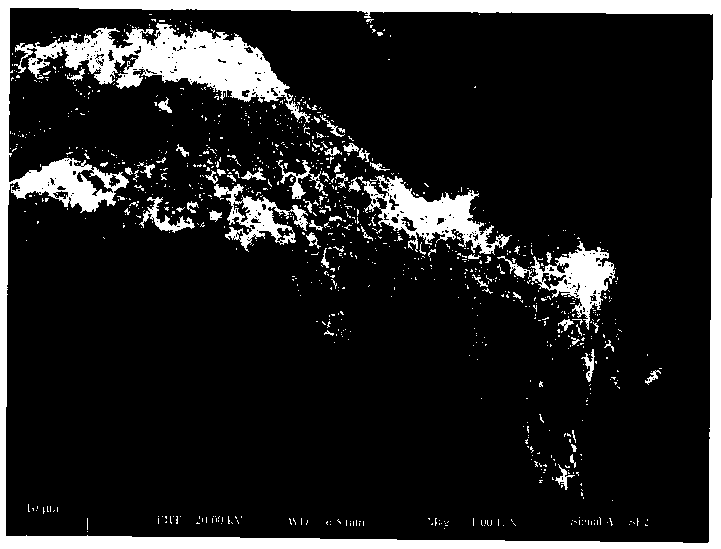

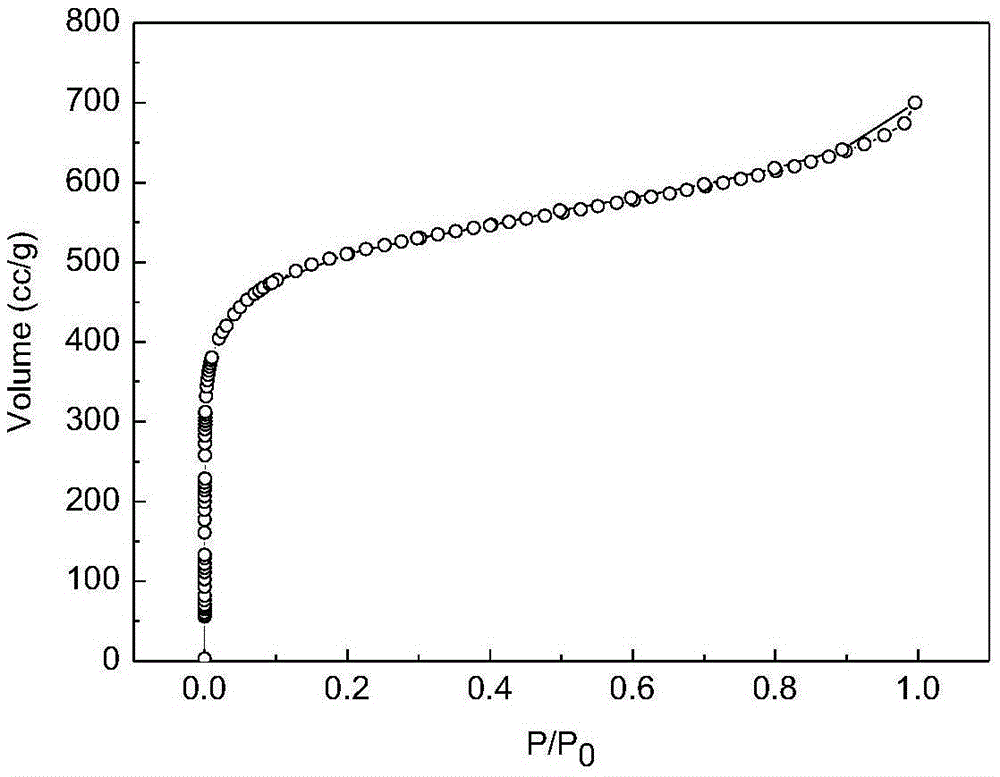

Method for preparing nitrogen-doped porous carbon by taking cottonseed hull as raw material and application

InactiveCN108455597AWide range of resource sourcesLow costCarbon preparation/purificationCapacitancePorous carbon

The invention discloses a method for preparing nitrogen-doped porous carbon by taking cottonseed hull as a raw material and application. The method is characterized in that the nitrogen-doped porous carbon material is prepared by taking the cottonseed hull as a raw material and urea as a nitrogen source, stirring and uniformly mixing the substances with a sodium hydroxide solution, and then carrying out high-temperature carbonization and activation. An electron microscope photo shows that the prepared nitrogen-doped porous carbon material is of a three-dimensional inner cross-linking network structure. XPS and elemental analysis show that the nitrogen element is successively and uniformly doped in a carbon matrix; the XPS analysis shows that the nitrogen content is 1.84 to 7.35%; the elemental analysis shows that the nitrogen content is 2.07 to 6.52 % and the specific surface area is 1010 to 2500m<2> / g. The super-capacitor experiment shows that the prepared nitrogen-doped porous carbonmaterial has good electrochemical properties and the specific capacitance can reach 320 to 340F / g (current density is 0.5A / g). The method has the advantages of simplicity in preparation, wide range of renewable resources as raw materials, low price, low cost, easiness in large-scale industrialization application and capability of being applied to the field of energy storage.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

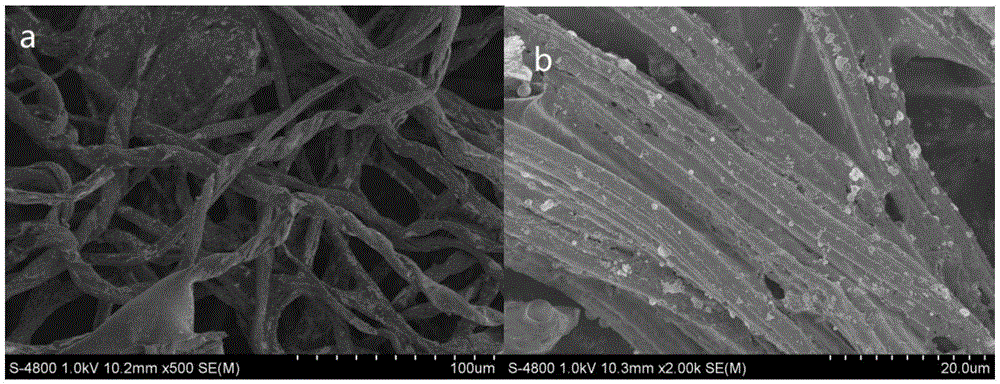

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

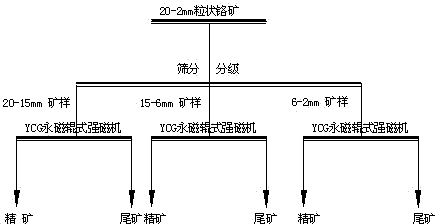

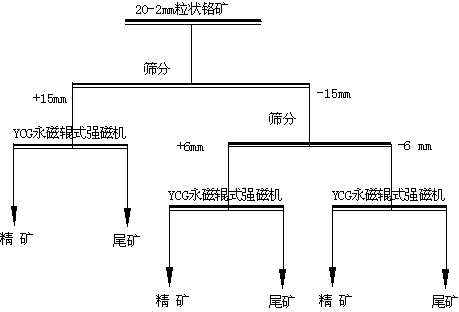

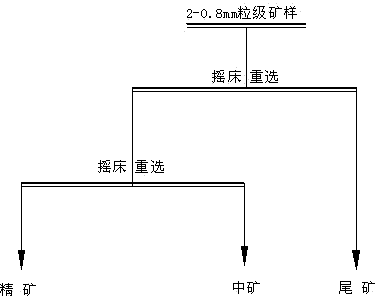

Novel beneficiation technology of high-grade ferrochrome ore

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

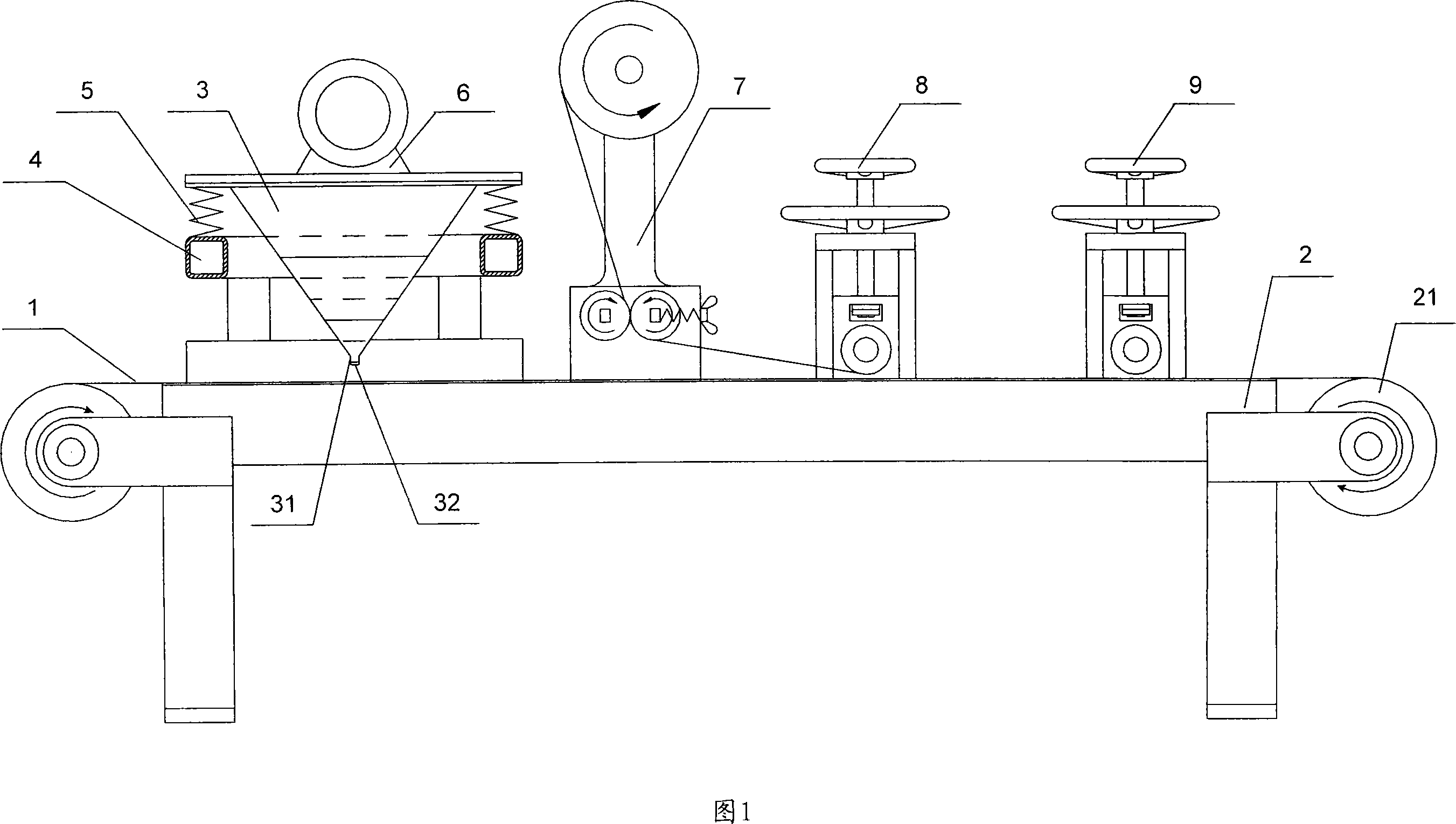

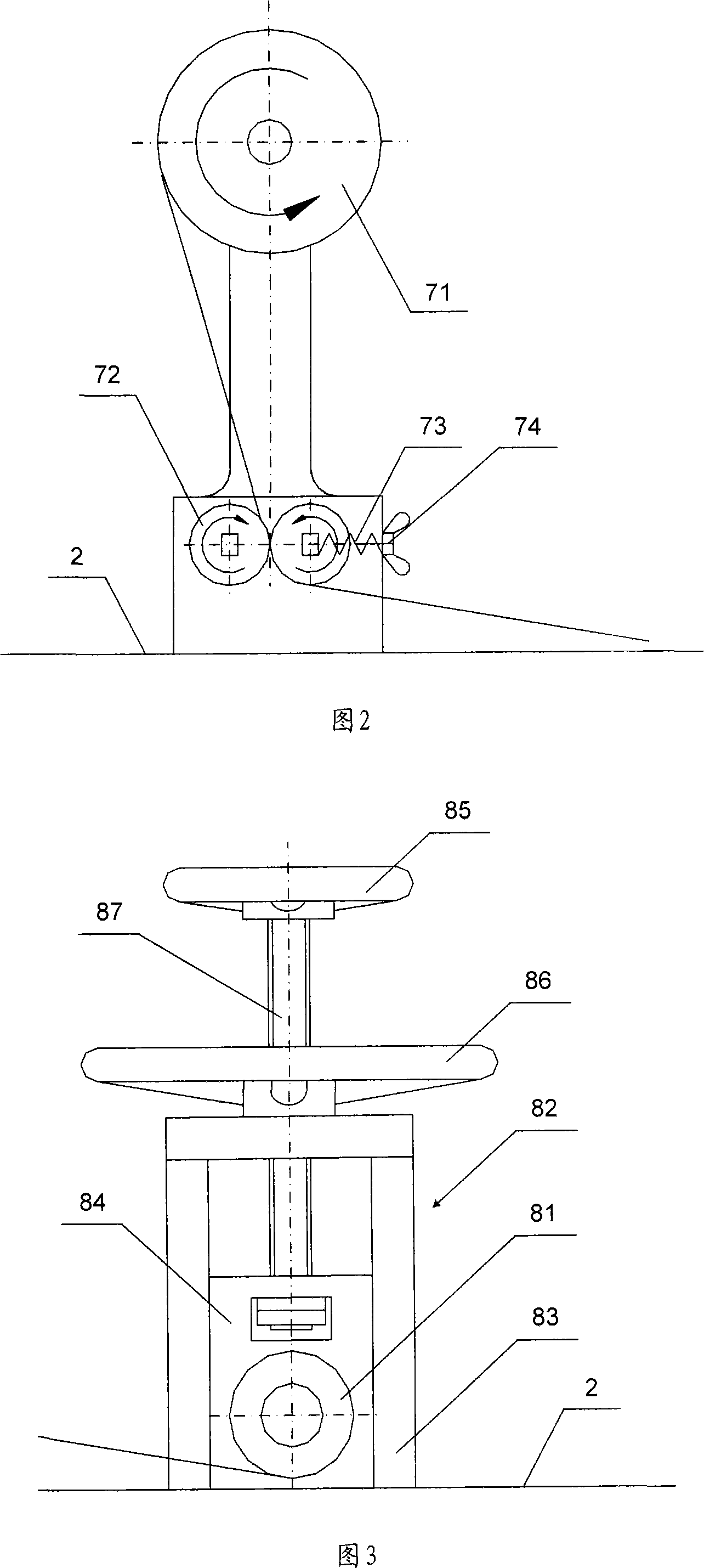

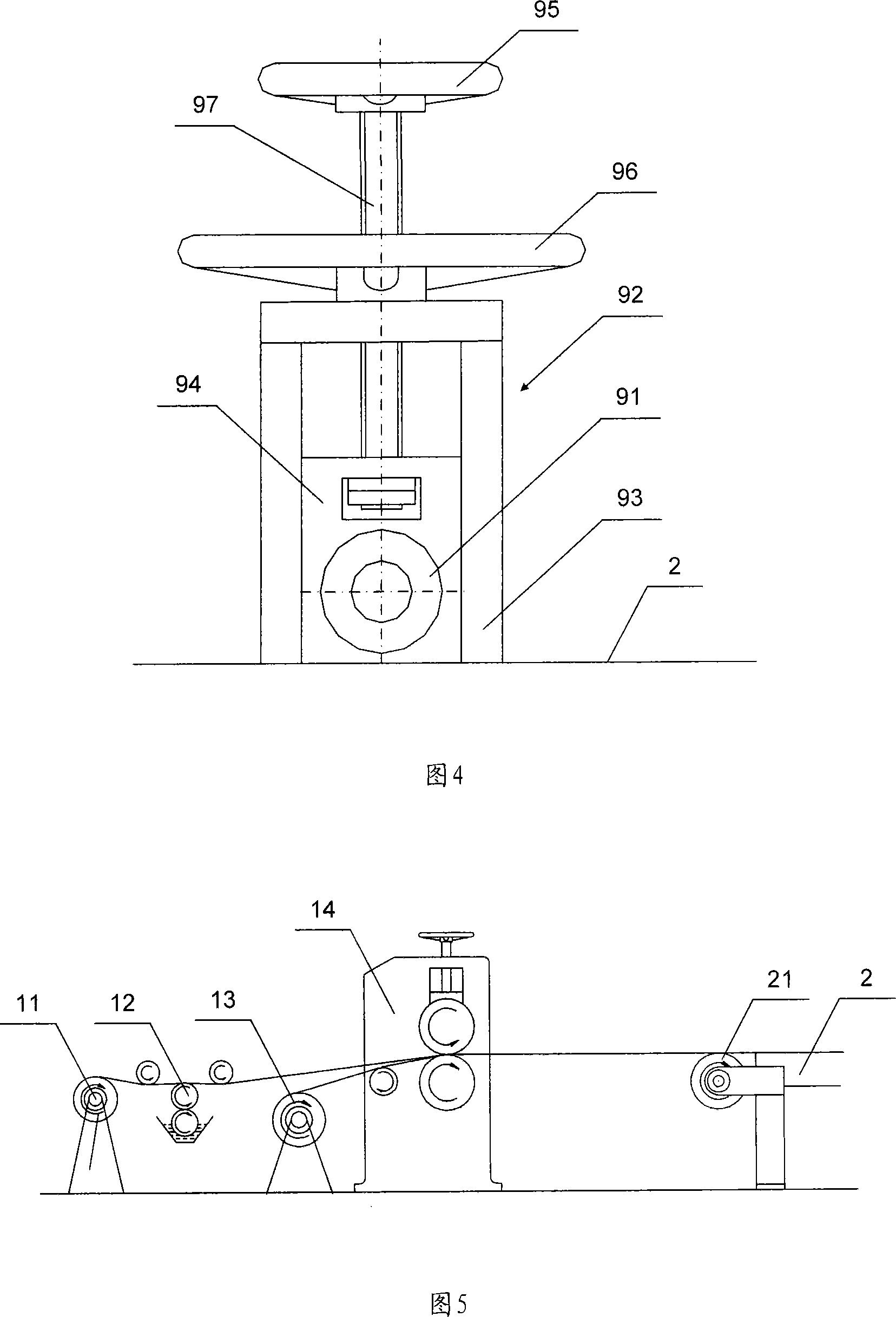

Nano-plate plane glue distributing device and method

InactiveCN101085563AConsistent thicknessImprove efficiencyLamination plant layoutLamination ancillary operationsFiberglass meshGlass fiber

The invention relates to the nanometer plate surface glue equipment and the cloth glue that comprises the working platform, cloth hopper distributing nanometer fluid on the compound extractor, vibrating device connected with the cloth hopper, cloth applying device setting the glass fiber net on the nanometer glue band, and the scraping device and compression device. The compound extraction band moving horizontally on the working platform and forming nanometer band, setting glass fiber net cloth with tension on the nanometer band, compressing the glass fiber net cloth and the nanometer band into nanometer compound band, compressing the compound band tightly. It is heat and sound insulation, radiation resistant, and improved in product feature and reduced in production cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

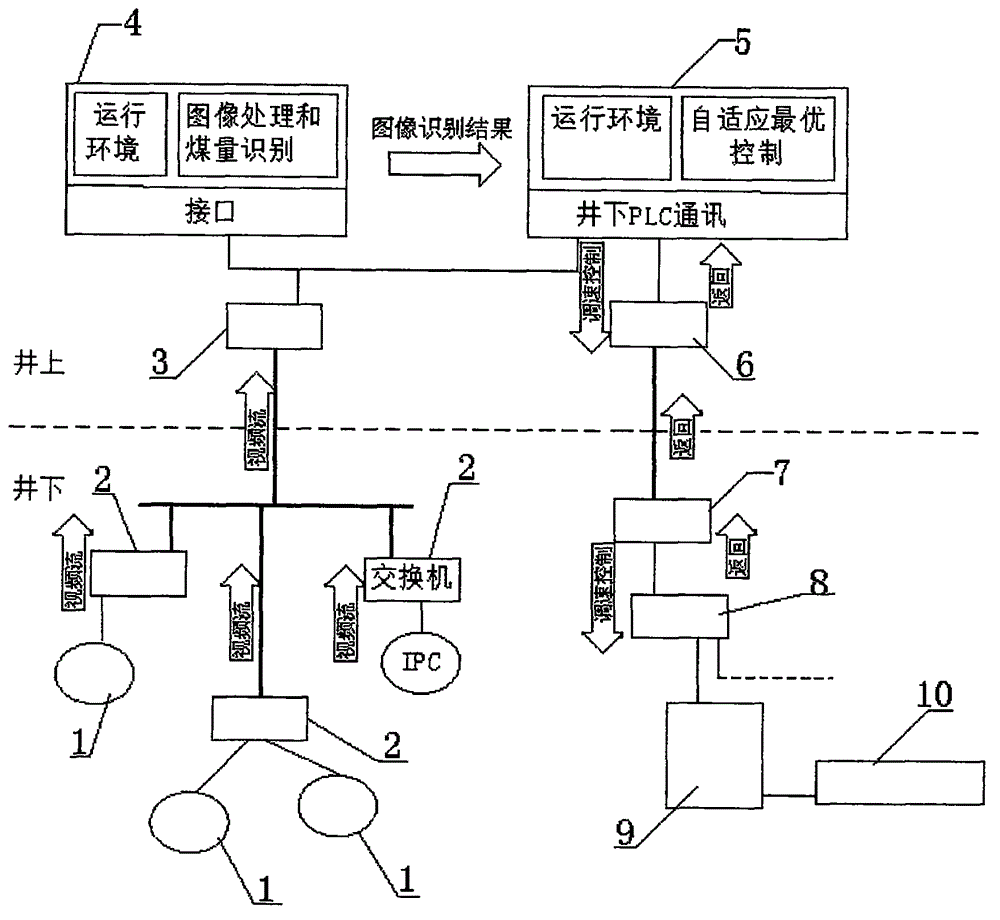

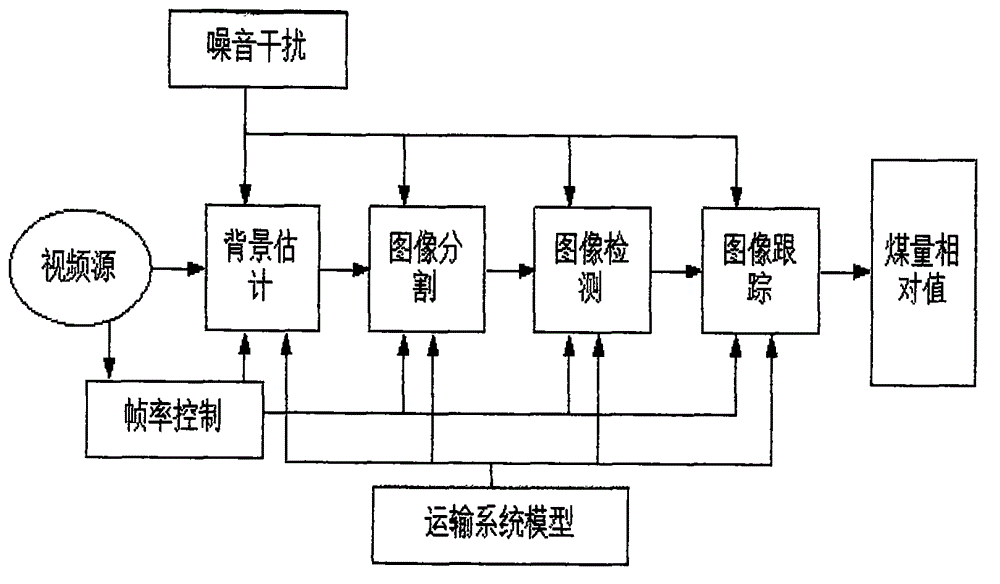

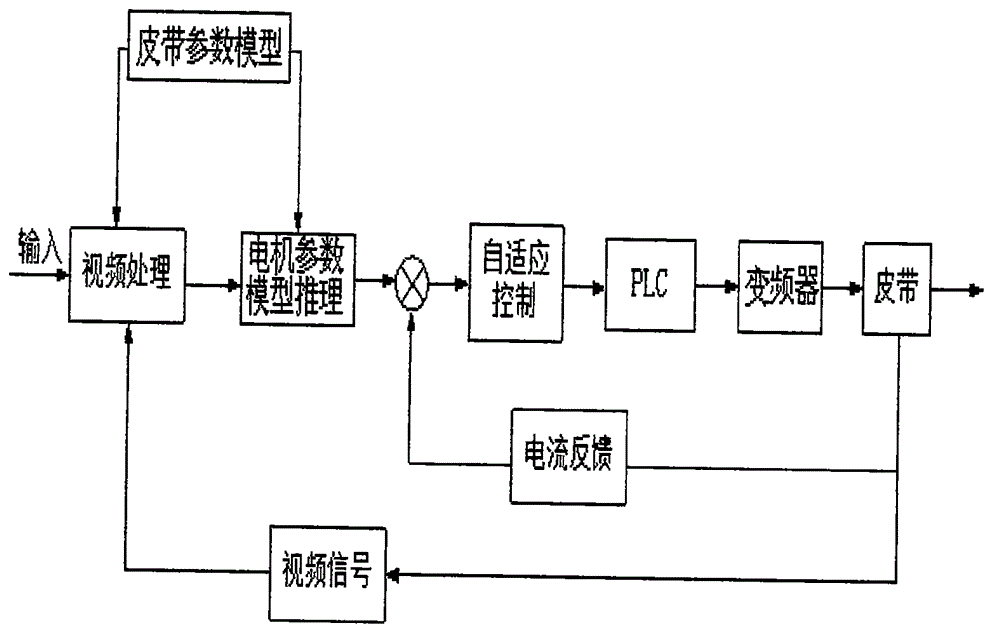

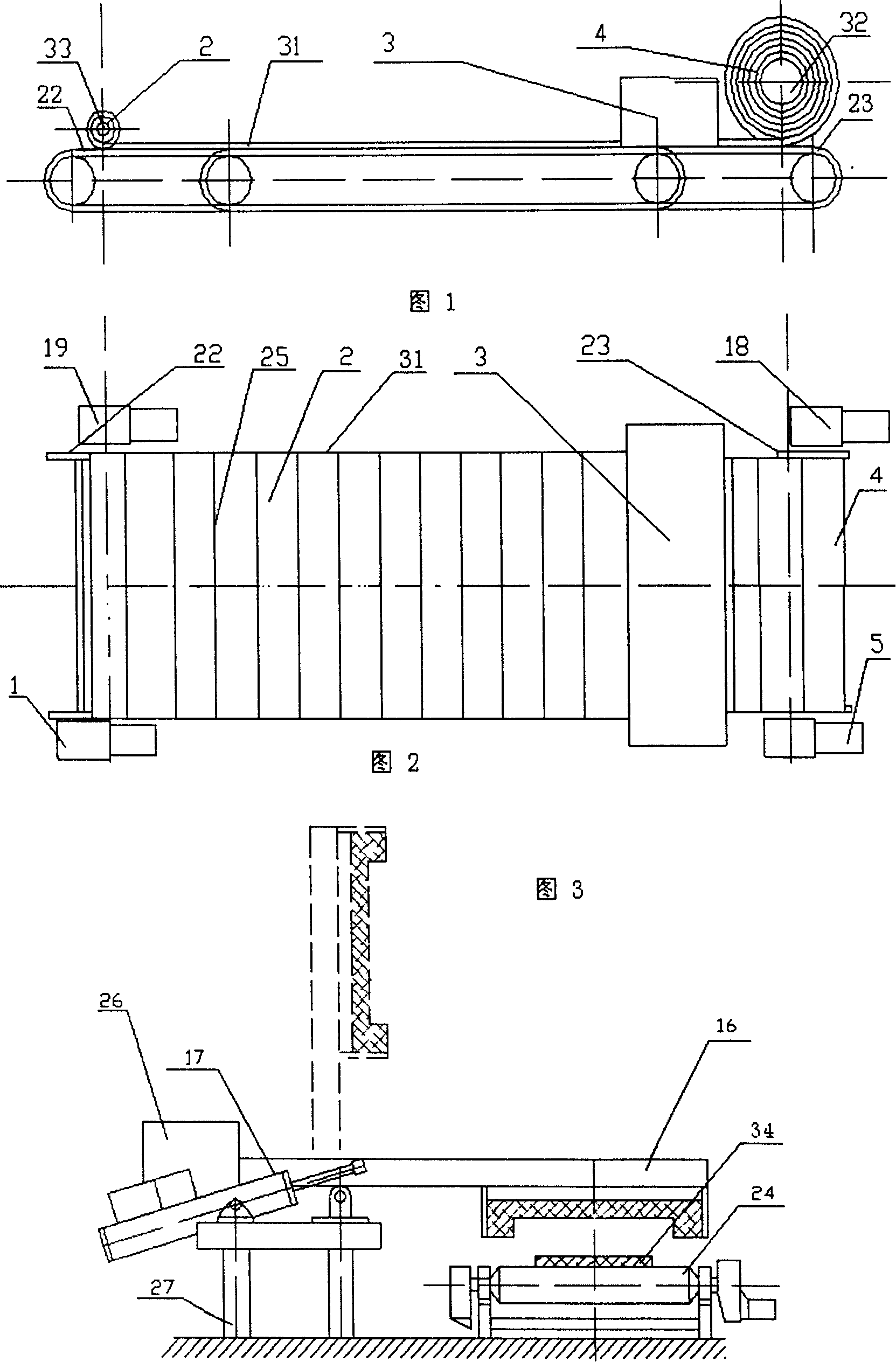

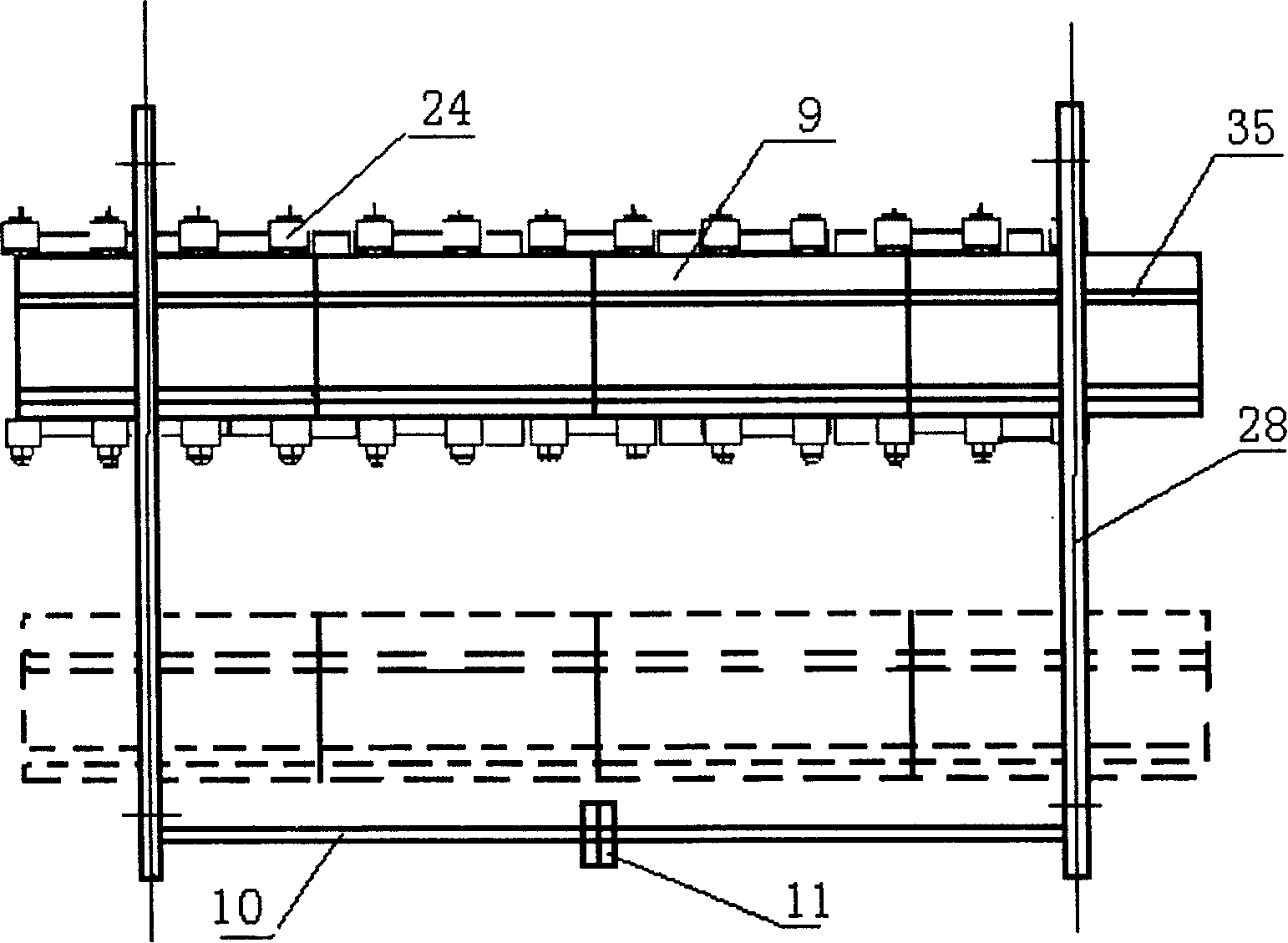

Self-adaptive control method based on video recognition for belt conveying system

ActiveCN105217271AImprove performanceImprove electricity efficiencyControl devices for conveyorsEngineeringFeedback control

The invention discloses a self-adaptive control method based on video recognition for a belt conveying system. The self-adaptive control method comprises the following steps that (1) the instant total coal quantity and the instant coal quantity distribution on a belt conveyer are obtained dynamically; (2) the total coal quantity and the coal quantity distribution information which are obtained in the step (1) are sent to a self-adaptive optimum control server, and a frequency converter outputs a current frequency to adjust the operating speed of the belt conveyer; and (3) the operating state of a belt is monitored through a programmable logic controller (PLC), and feedback control is conducted by combining the motor current and the coal quantity distribution information so that the speed of the belt conveyer can meet a predetermined requirement. The self-adaptive control method based on video recognition for the belt conveying system has the advantages that configuration is flexible, the performance is excellent, and cost is low.

Owner:XIAN HUA GUANG INFO

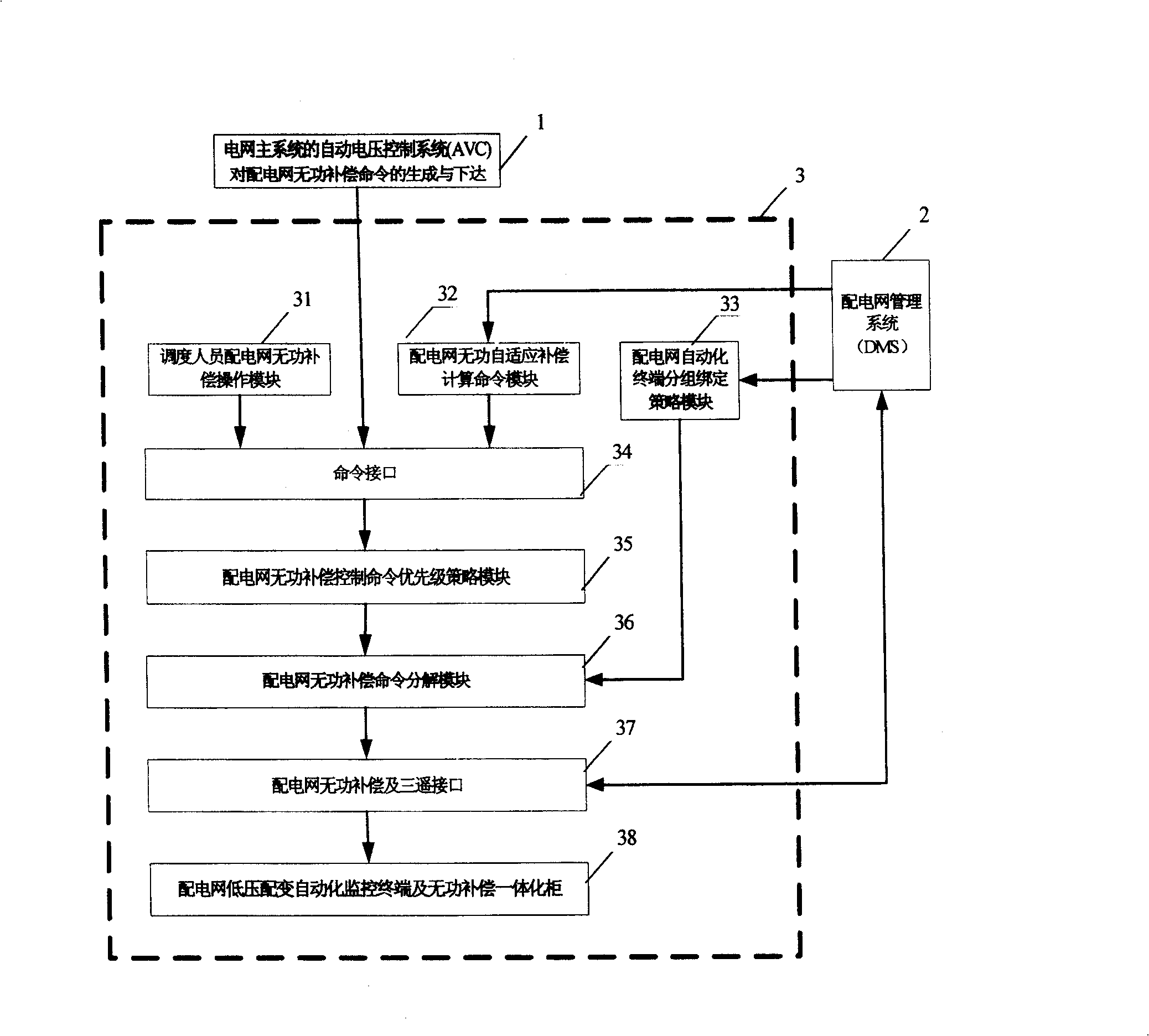

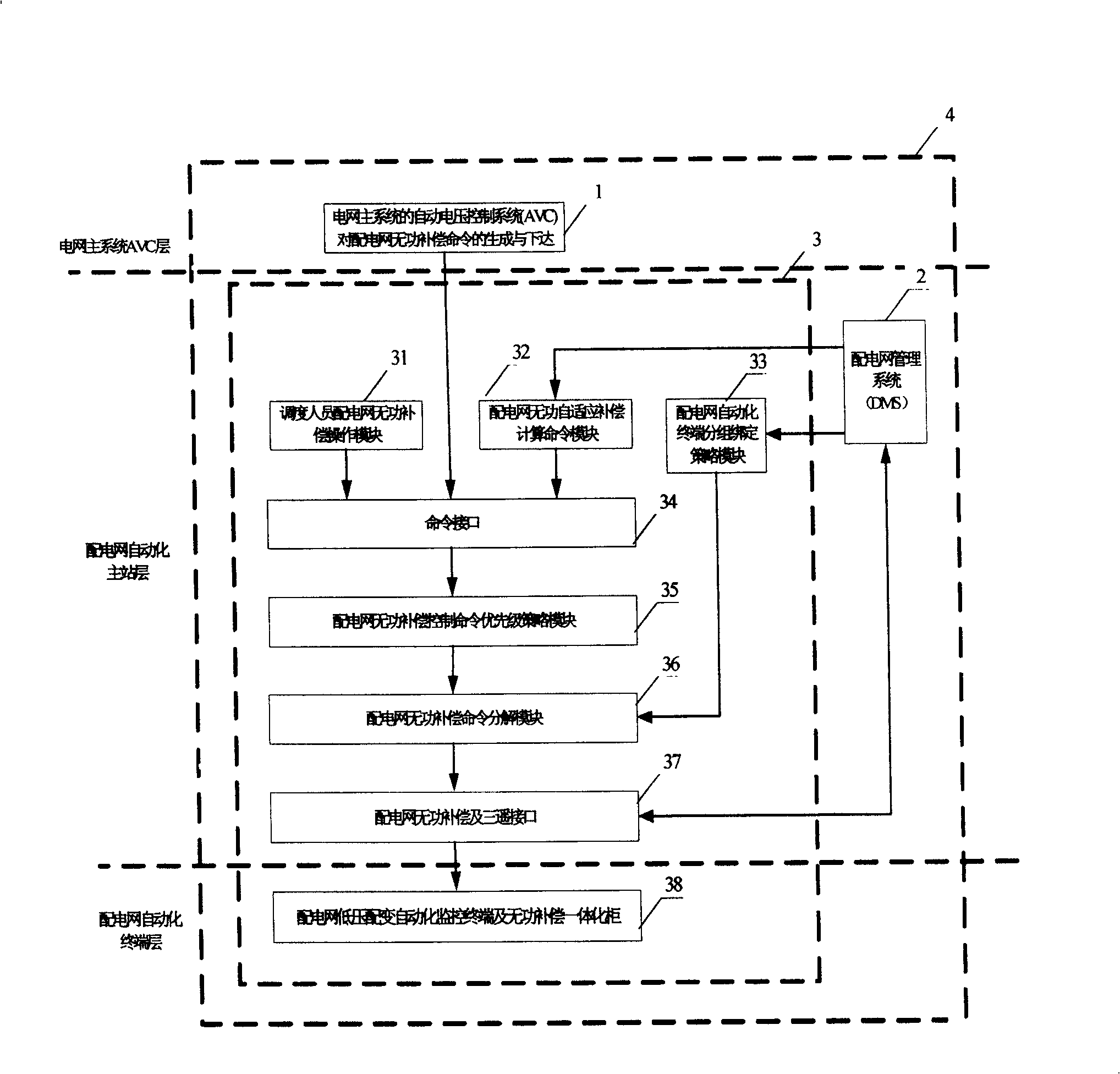

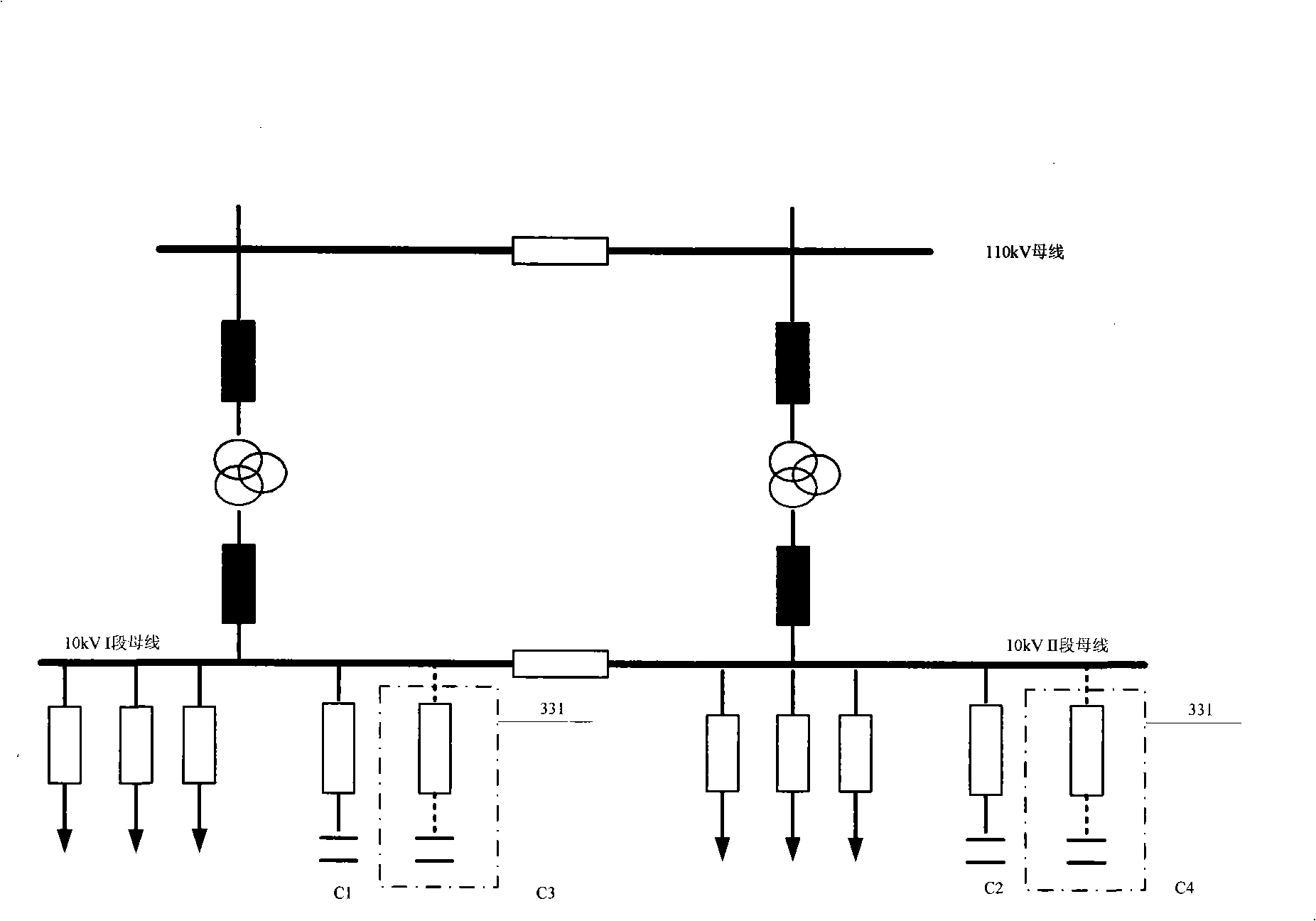

Reactive layered self-adapting control method for power distribution network

ActiveCN101340095AGood control effectRealize integrated deploymentReactive power adjustment/elimination/compensationAc network voltage adjustmentAutomatic controlLow voltage

The invention relates to a reactive power hierarchical and adaptive control method which is used for a distribution network. By creating a reactive power hierarchical and adaptive subsystem for the distribution network, the method connects the subsystem, a management system of the distribution network and an automatic voltage control system of a main power grid to control an automatic monitoring terminal for low-voltage distribution transformation of the distribution network and a reactive power compensation integrated cabinet, thus forming an automatic management system for the distribution network which has reactive power hierarchical and adaptive function of the distribution network. The system has certain adaptability, can recognize change of environment and automatically correct control actions, achieves optimal or near optical control effect, realizes reactive power integrated allocation of the whole power network and has obvious energy-saving and consumption reducing effect.

Owner:安徽中鑫继远信息技术股份有限公司

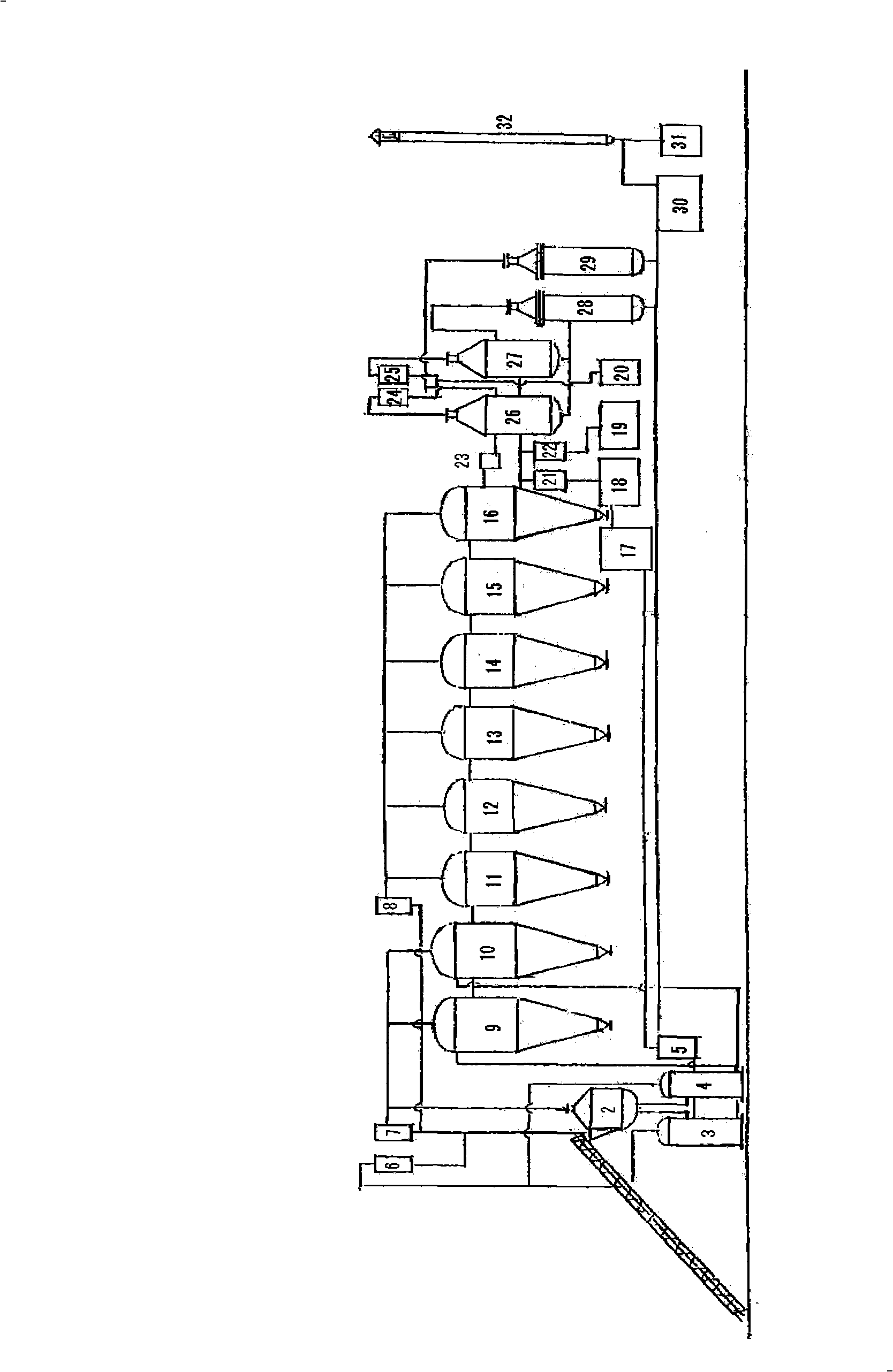

Pine gum processing method and equipment

InactiveCN101343509AIncrease productionRosin quality improvementNatural resin purificationTurpentineRosin

The invention discloses a processing technology of turpentine by a steaming process and the device. The invention adopts the technology that the turpentine is previously preheated and then dissolved, the dissolved turpentine enters into the clearing procedure after adopting the transitional clearing step, the turpentine liquid is preheated after being filtered, then oil gas and colophony are distilled out, turpentine oil is obtained through the condensation of the oil gas, and the distilled high-temperature tail gas and oil gas are recovered to preheat the turpentine and the turpentine liquid; the device adopts that a turpentine preheating pot is arranged in front of a liquating pot; a transitional clarifying kettle is arranged before a clarifying kettle; a distilling and preheating pot is arranged between a turpentine liquid filter and a distillatory kettle. Compared with the prior discontinuous process technology, the processing technology can greatly increase the production, the quality of the colophony is greatly improved, more than 98 percent of the colophony can reach the special grade and the first-grade, the distilling degree of the top grade turpentine reaches 97 percent, half of the standard coal consumed by one ton of colophony is approximately saved, half of the steam and the cooling water are also reduced, and the energy saving and consumption reducing effects are remarkable.

Owner:李国鸿

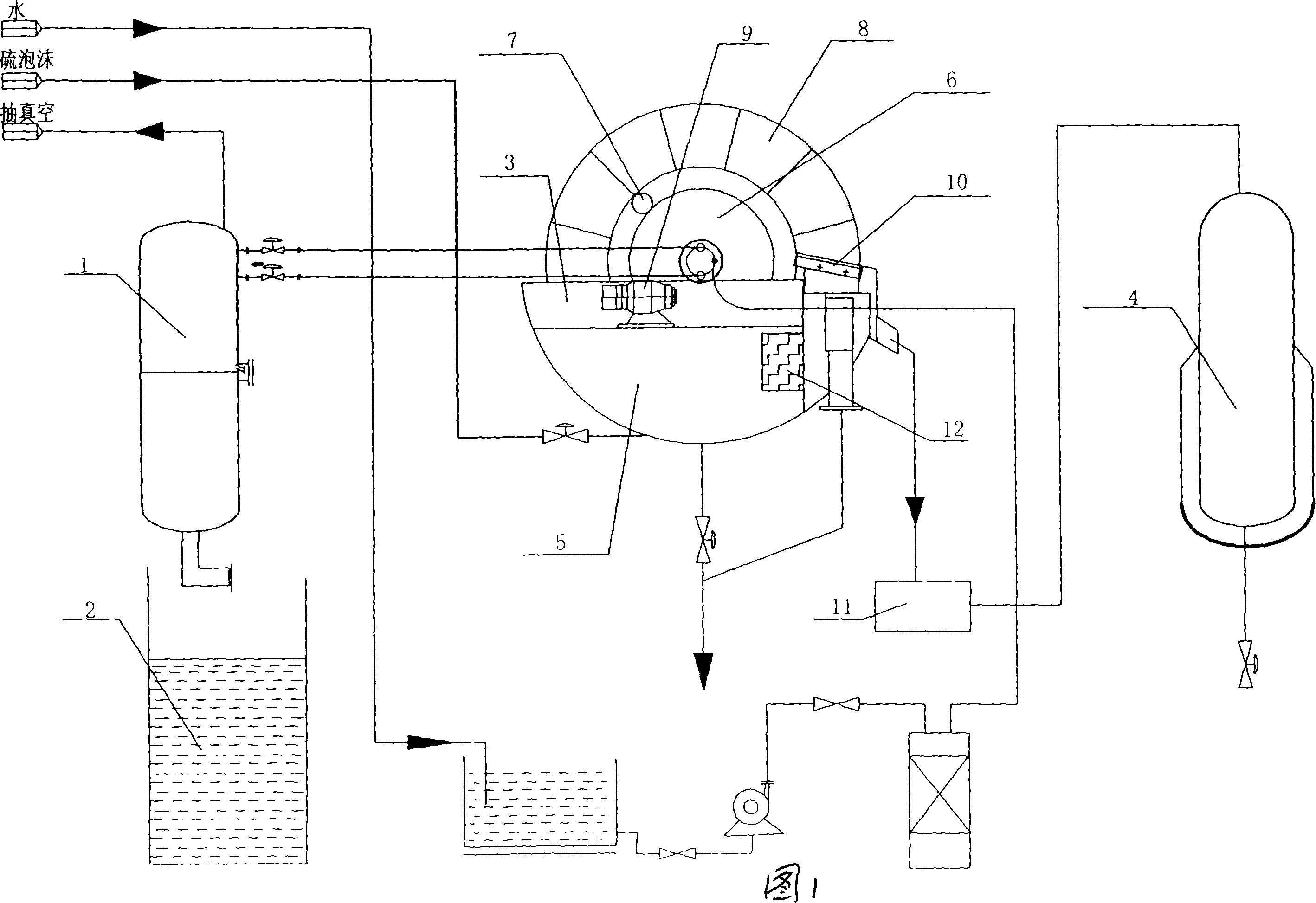

Technique for sulfur recovery in process of wet desulphurization

ActiveCN101130429AReduce consumptionReduce pollutionSulfur preparation/purificationStationary filtering element filtersSulfurCapillary action

The invention discloses a recycling technique of sulphur in the wet process desulfurizing course, which comprises the following steps: transmitting sulfur foam into the hopper of filter; filtering and separating liquid from sulphur in the sulphur foam; sucking the filtrate into drainage tank on the ceramic filter board under negative pressure and capillary action; sucking the filtrate into the drainage tank to return to desulfuring system to recycle; adsorbing a layer of sulfur filter pie on the surface of ceramic filter board; transmitting the stripped sulphur pie on the surface into sulphur fusing autoclave through scraper at filter drainage position; doing backwash the ceramic filter board in connection with backwash groove; finishing one circulation. The invention uses advanced inorganic ceramic filter to filter the sulphur foam to reduce energy consumption in the sulphur fusing course obviously, which eliminates large amount of residual liquid and side salt in the sulphur fusing course and cooling course respectively to reduce the pollution in the reacting course.

Owner:CHANGCHUN DONGSHI TECH & TRADING INDAL

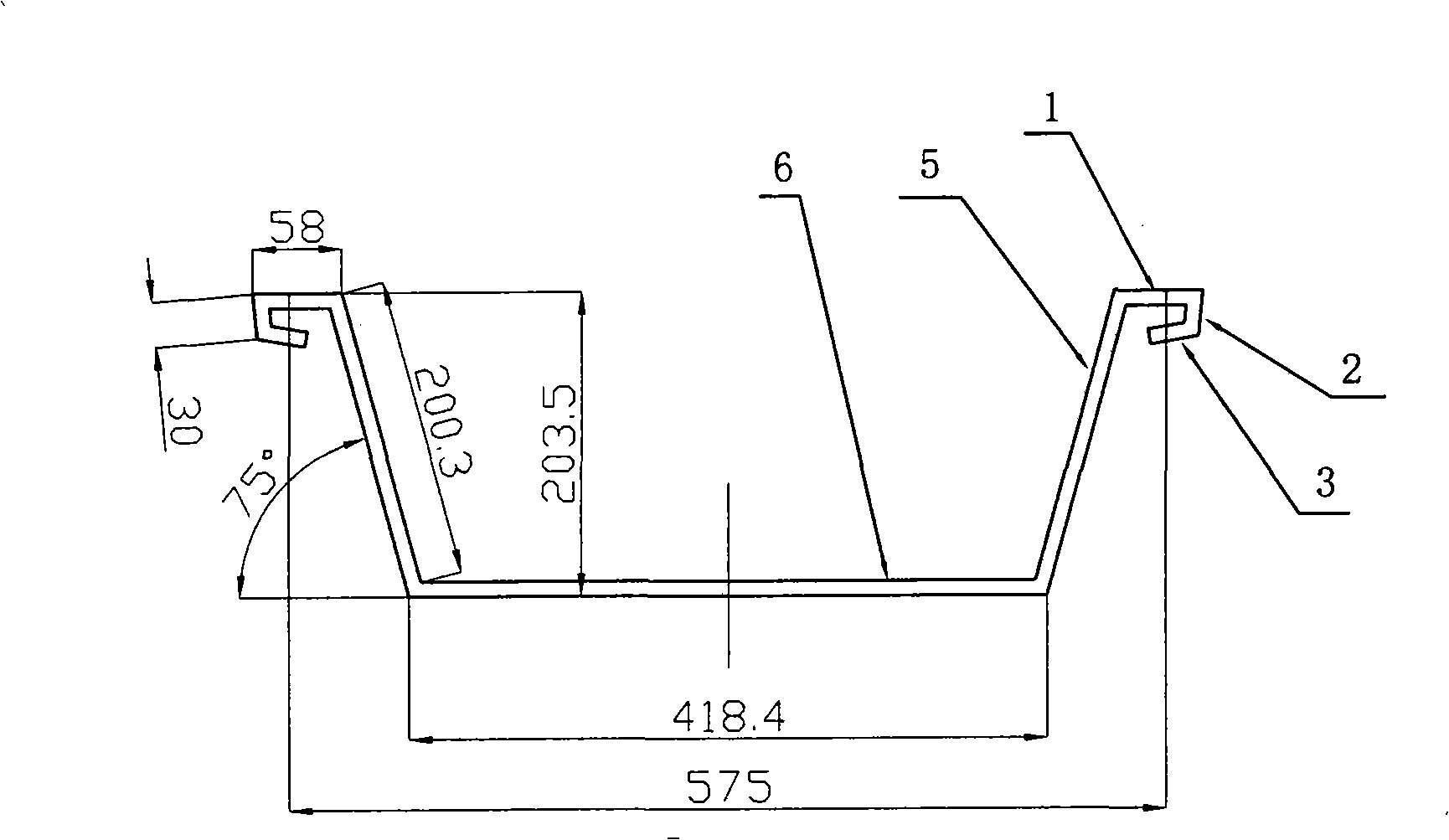

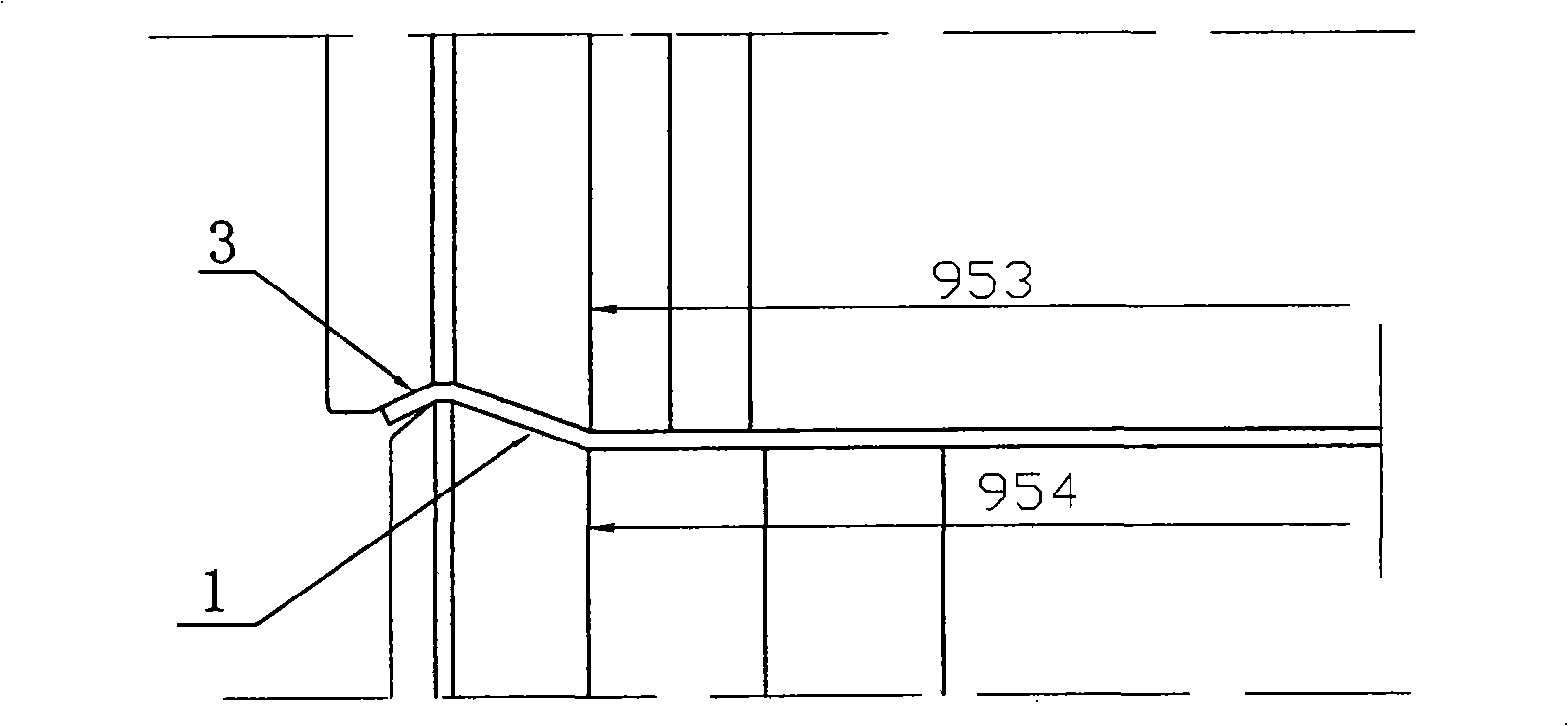

Continuous roller type cold bending shaping method for metal sheet pile

The invention relates to a continuous roll type cold-bending forming method for a steel sheet pile, including scrolling, continuous cold-bending forming and cutting; the method is characterized in that the continuous cold-bending forming refers to that the scrolled steel band is fed into a production line of a multi-pass continuous roll type cold-bending forming machine set for multi-pass continuous roll type cold-bending forming, a frame at each pass is provided with an upper rotation axis and a lower rotation axis which are equipped with inosculated dies, the upper rotation axis and the lower rotation axis rotate oppositely, one rotates along the clockwise direction, while the other rotates along anticlockwise direction; in this way, a scrolled steel plate moves forwards depending on friction force in the roll gap of rotation dies inosculated up and down after being well adjusted and enters the next pass for continue forming, when entering each pass for forming, the steel plate is forced to deform under the action of the inosculated dies, each pass completes setting forming amount, and the forming of the steel sheet pile is finally completed through a plurality of passes, thus rolling the products of the steel sheet pile in line with requirements. The method has the advantages of energy saving, environmental protection, high production efficiency and complete specification, length and size of products.

Owner:江苏顺力冷弯型钢实业有限公司

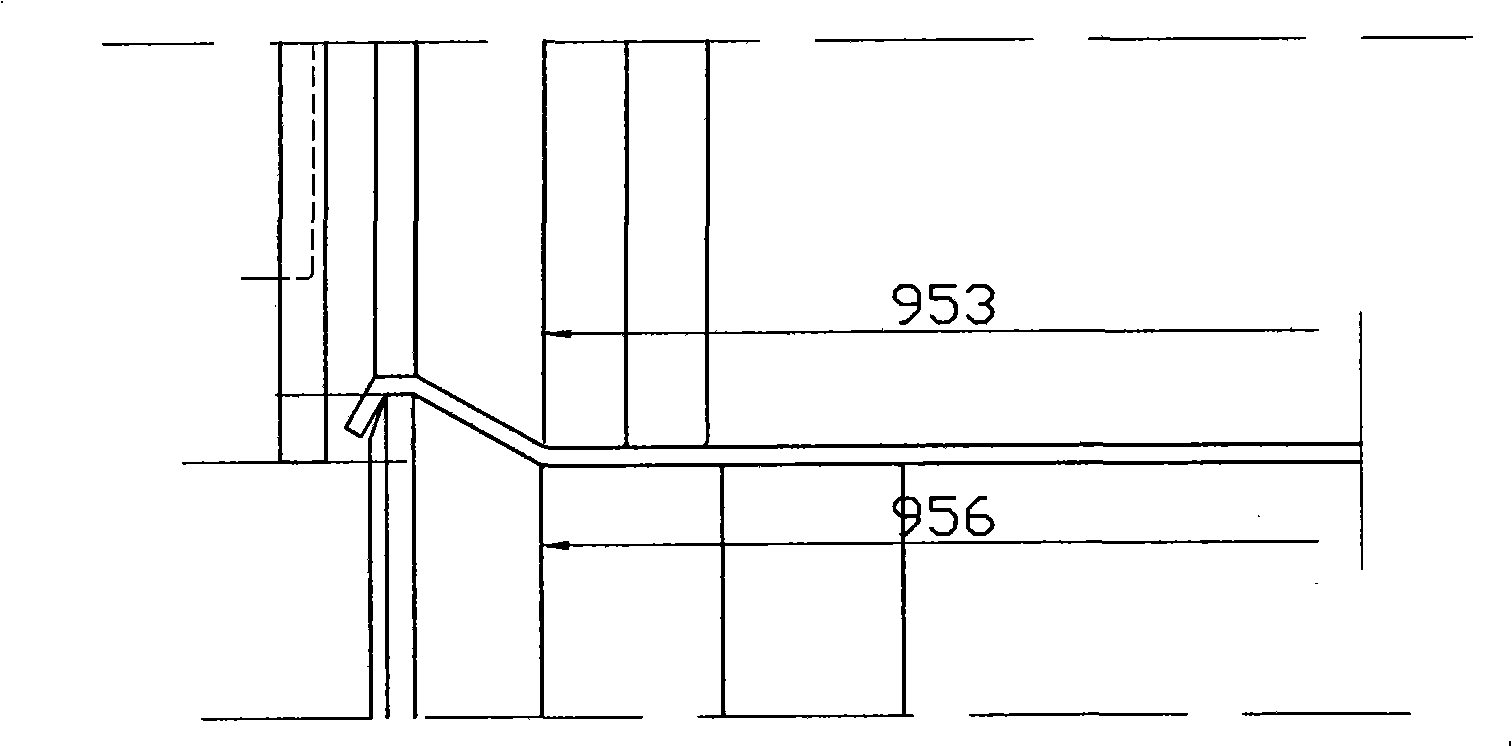

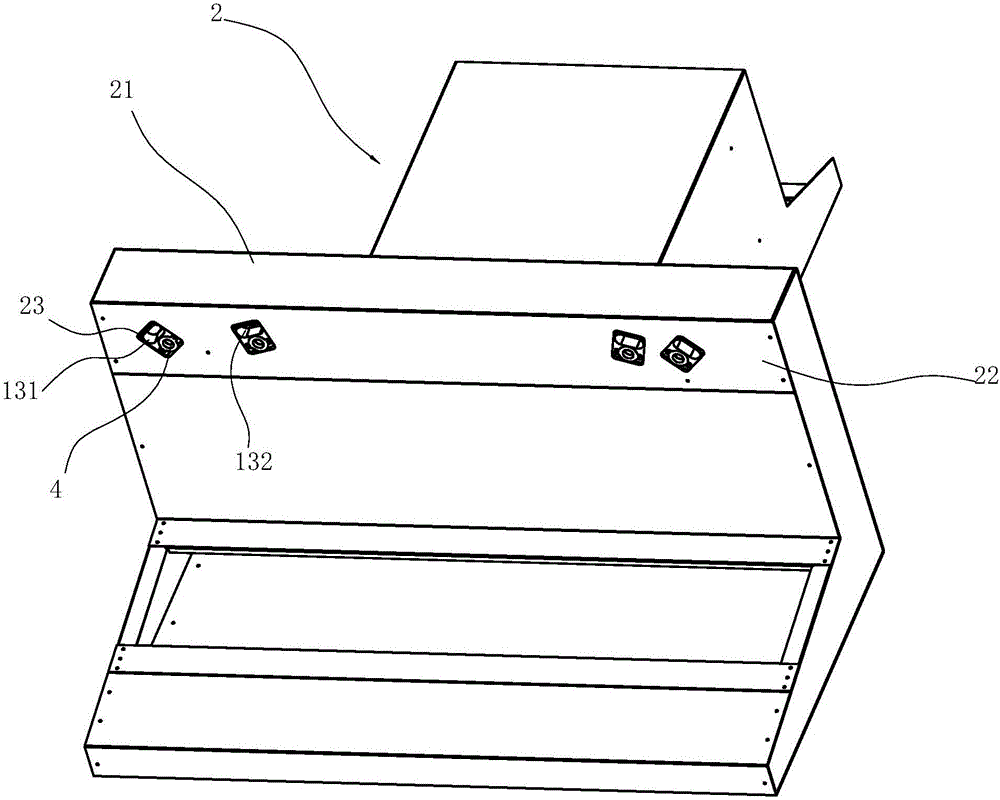

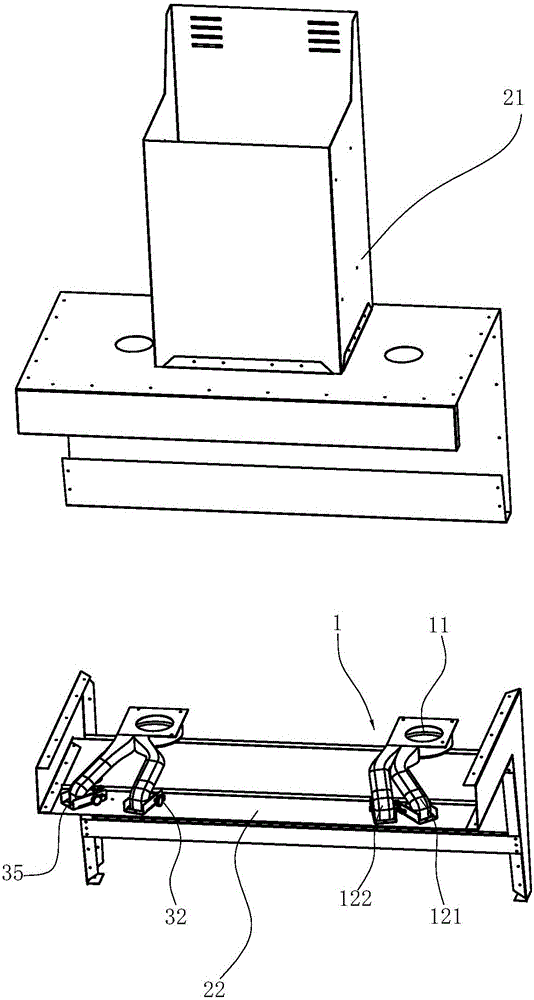

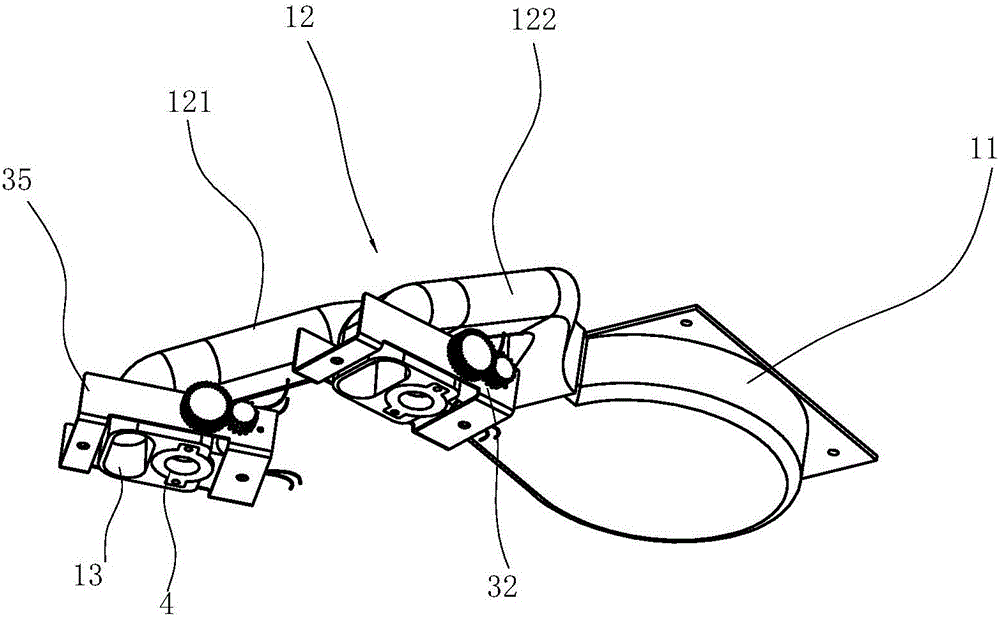

Extractor hood with absorption assisting device and method for pumping and absorbing oil fume

ActiveCN105783064ALow powerWill not be stainedDomestic stoves or rangesLighting and heating apparatusCentrifugal fanWaste management

The invention relates to an extractor hood with an absorption assisting device and a method for pumping and absorbing oil fume. The extractor hood comprises an extractor hood main body and air supply devices arranged on the extractor hood main body, and is characterized by further comprising driving devices, detectors used for detecting the position of cookware, and a control device; each air supply device comprises a centrifugal fan, the exhaust port of the centrifugal fan is connected with an air duct, the air duct is provided with at least one air outlet, and the air outlet is downward or obliquely downward; the driving devices are connected with the air supply devices in a driving way and used for changing the direction of airflow output by the air supply devices; and the driving devices and the detectors are both connected with the control device. The air supply airflow of the extractor hood with an absorption assisting device directly blows into the cookware, and can propel the oil fume to gather to the exhaust opening of the extractor hood at the beginning of generation of the oil fume, thus thoroughly avoiding overflow of the oil fume in rising.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

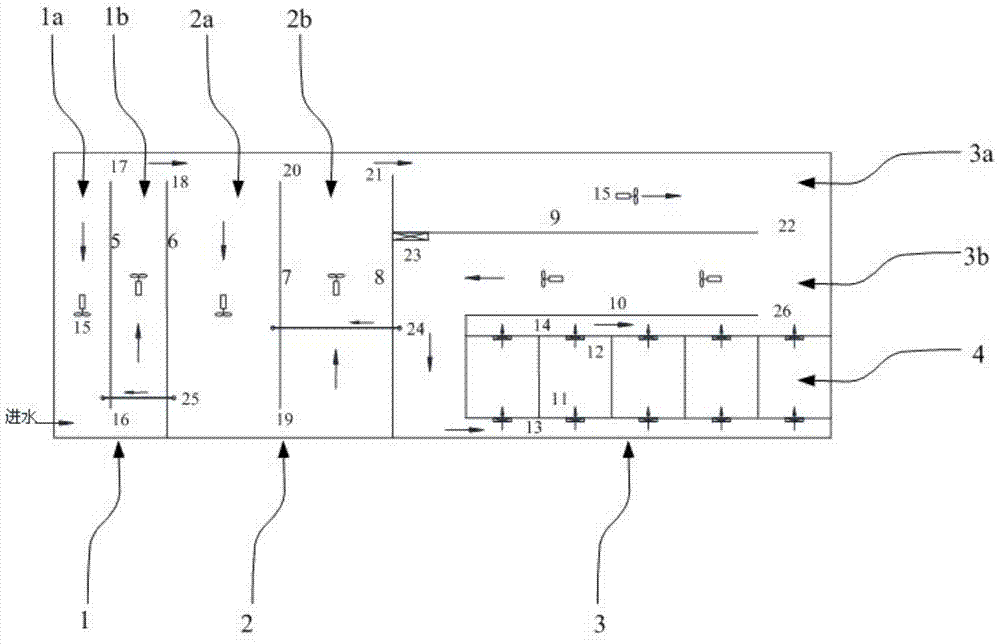

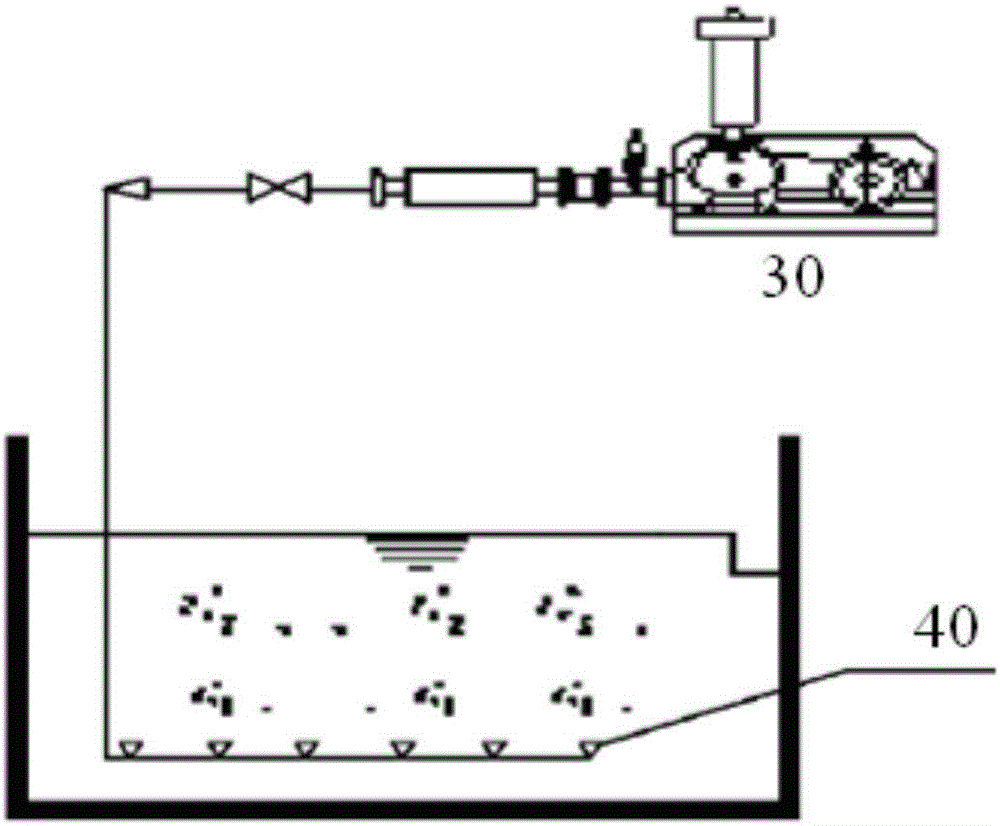

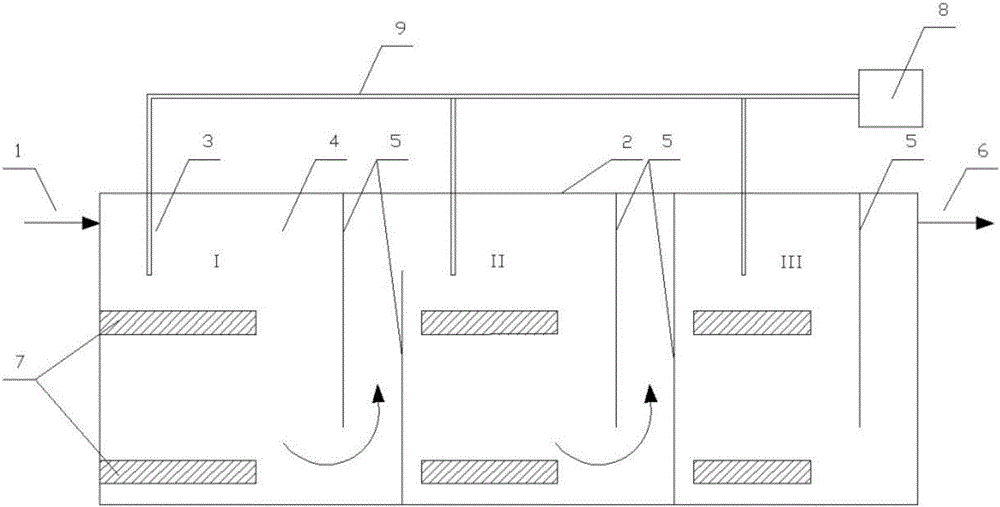

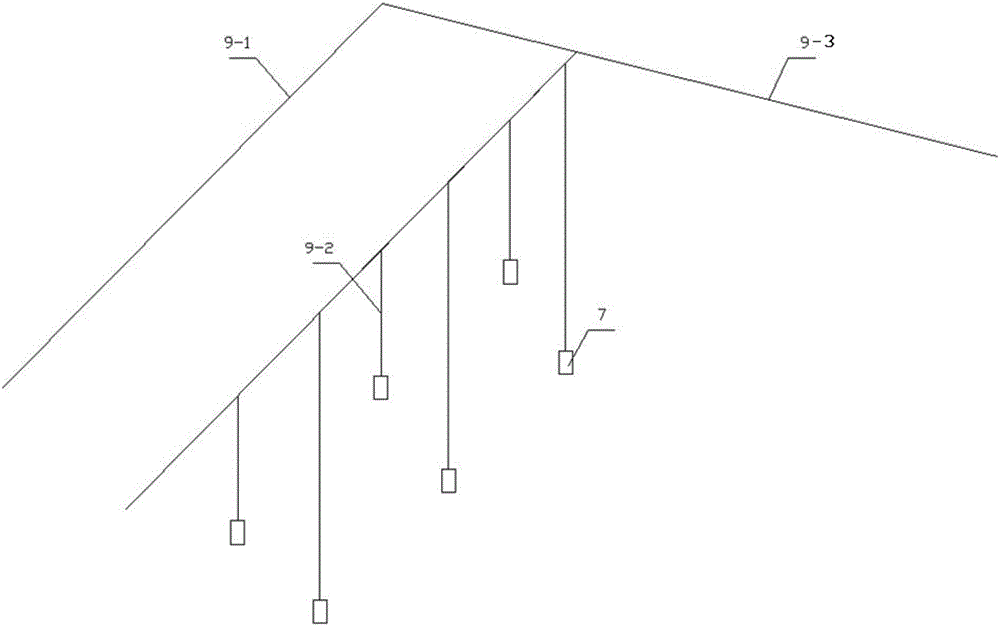

Process for treating sewage by using annular circulating flow membrane bioreactor

ActiveCN103570129AEasy to operate and manageOptimal Reaction TechnologyTreatment with aerobic and anaerobic processesSewageMembrane bioreactor

The invention relates to a process for treating sewage by using an annular circulating flow membrane bioreactor. The sewage is treated by using the annular circulating flow membrane bioreactor; the annular circulating flow membrane bioreactor comprises an anaerobic zone, an anoxic zone, an aerobic zone and a membrane bioreaction zone which are sequentially arranged, wherein the membrane bioreaction zone is arranged in the aerobic zone; the sewage is sequentially treated through the anaerobic zone, the anoxic zone, the aerobic zone and the membrane bioreaction zone and reflows from the membrane bioreaction zone to the aerobic zone, from the aerobic zone to the anoxic zone and from the anoxic zone to the anaerobic zone, so that the higher sludge concentration is kept in the whole reactor. Through the optimized combination of the reactor, the process for treating sewage by using the annular circulating flow membrane bioreactor has the advantages of greatly improving the flexibility of a system, remarkably reducing the engineering investment and reducing the energy consumption.

Owner:四川蓉信开工程设计有限公司

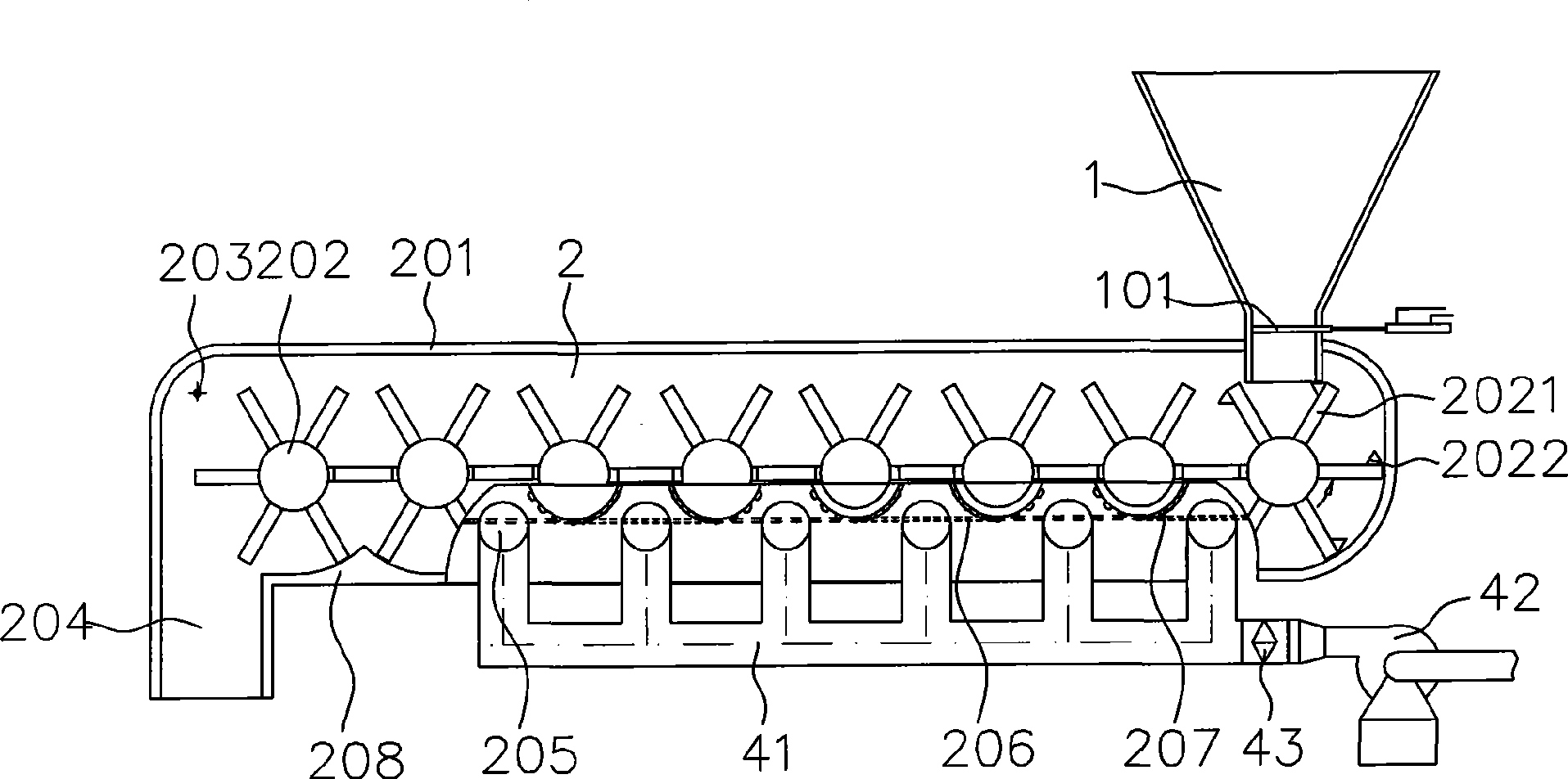

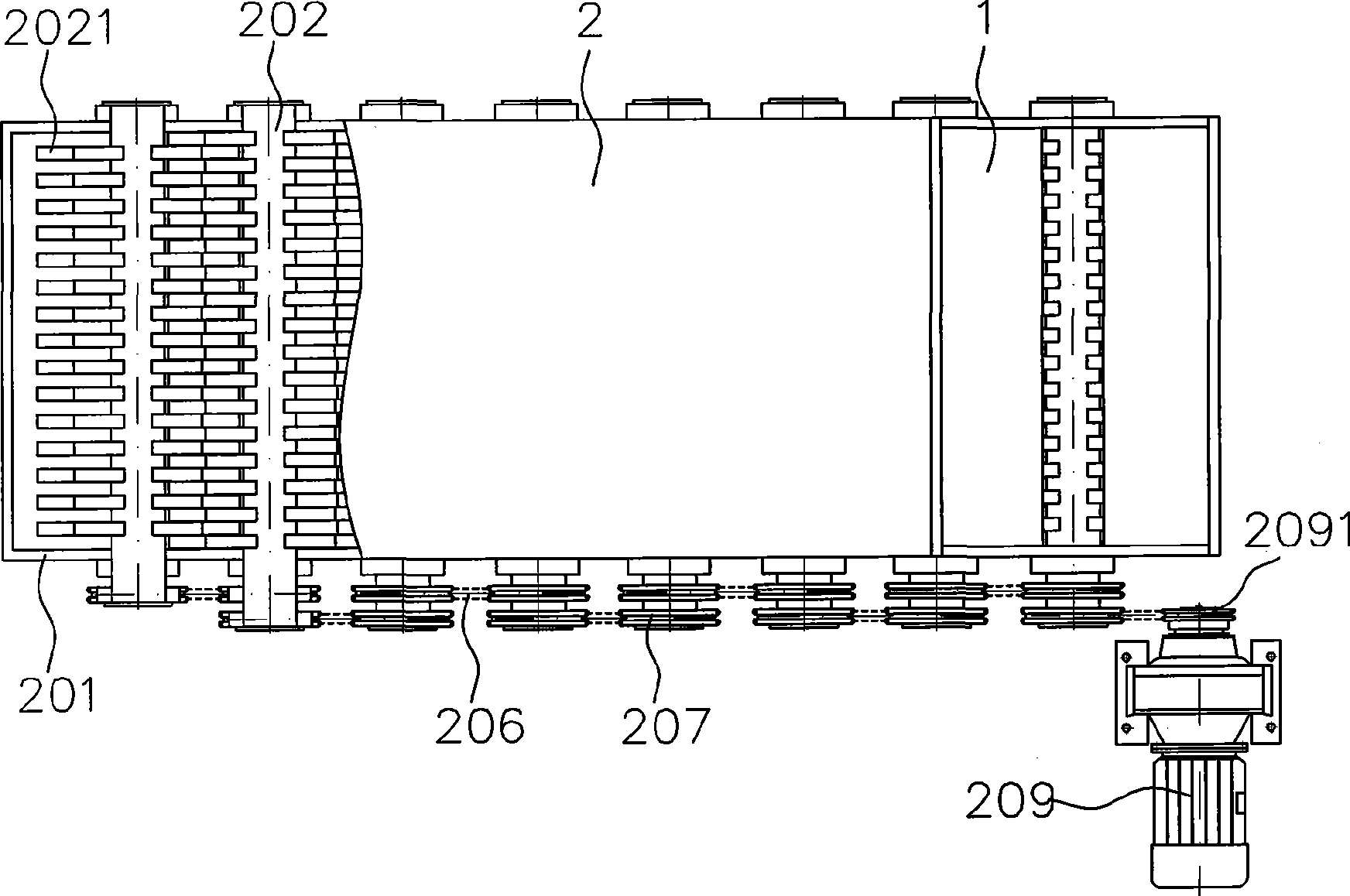

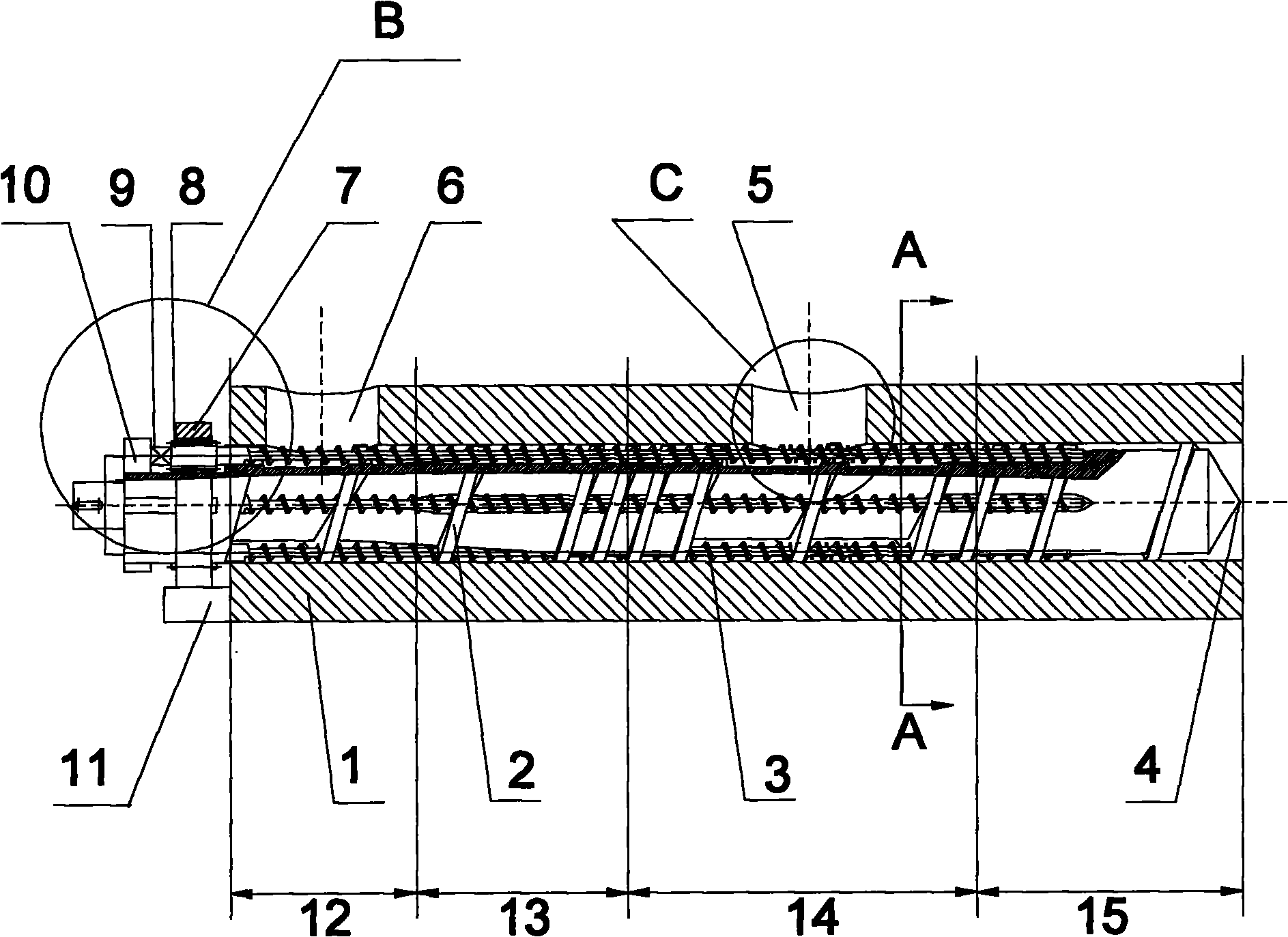

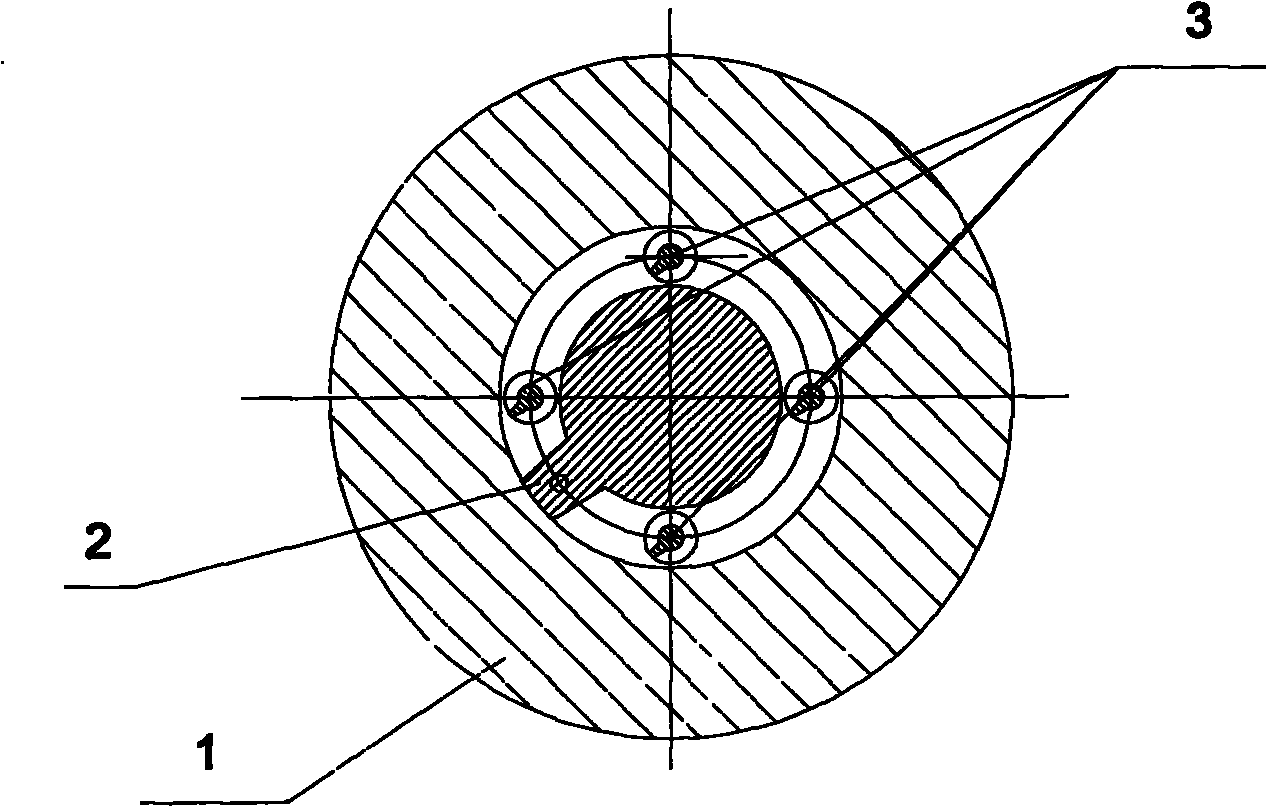

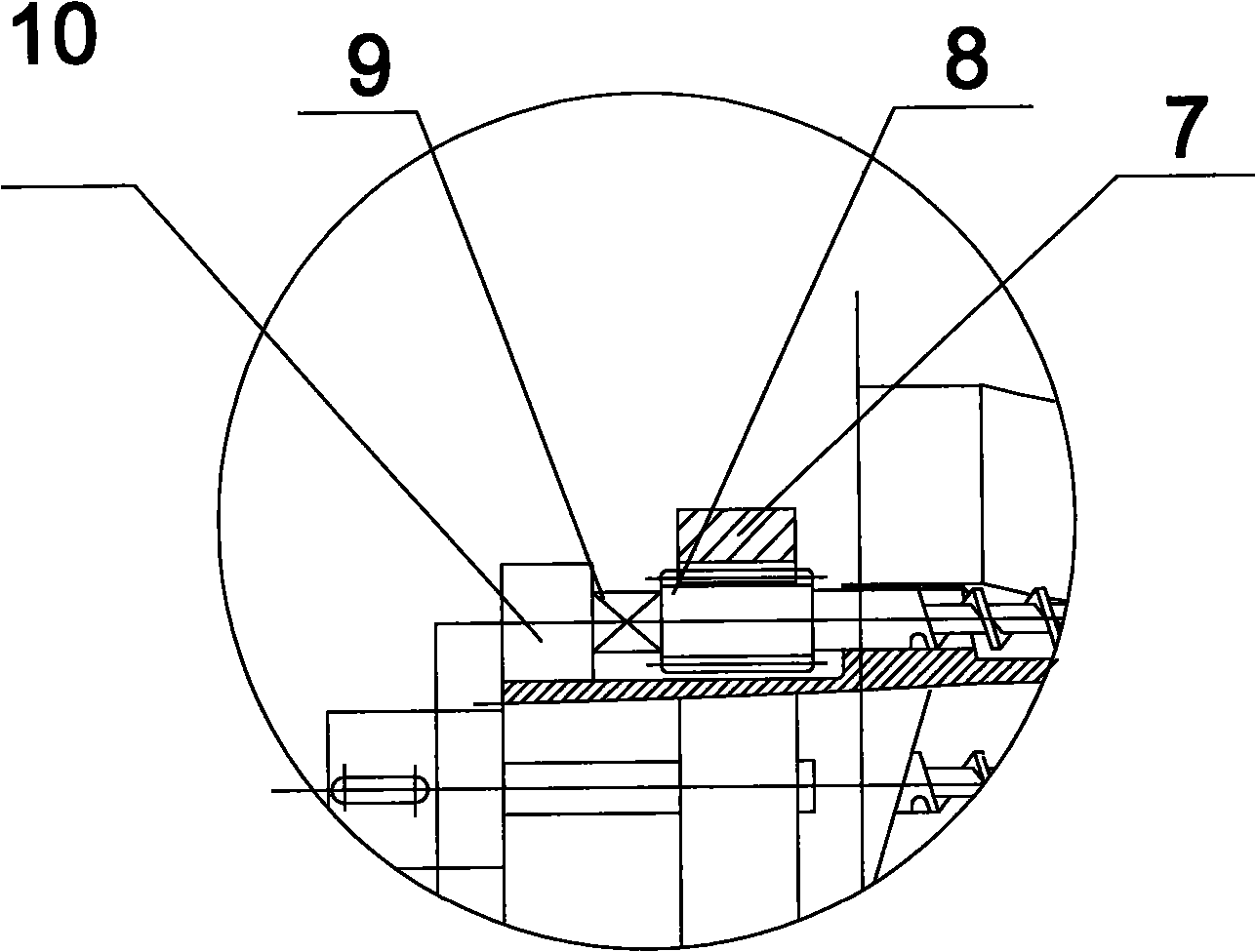

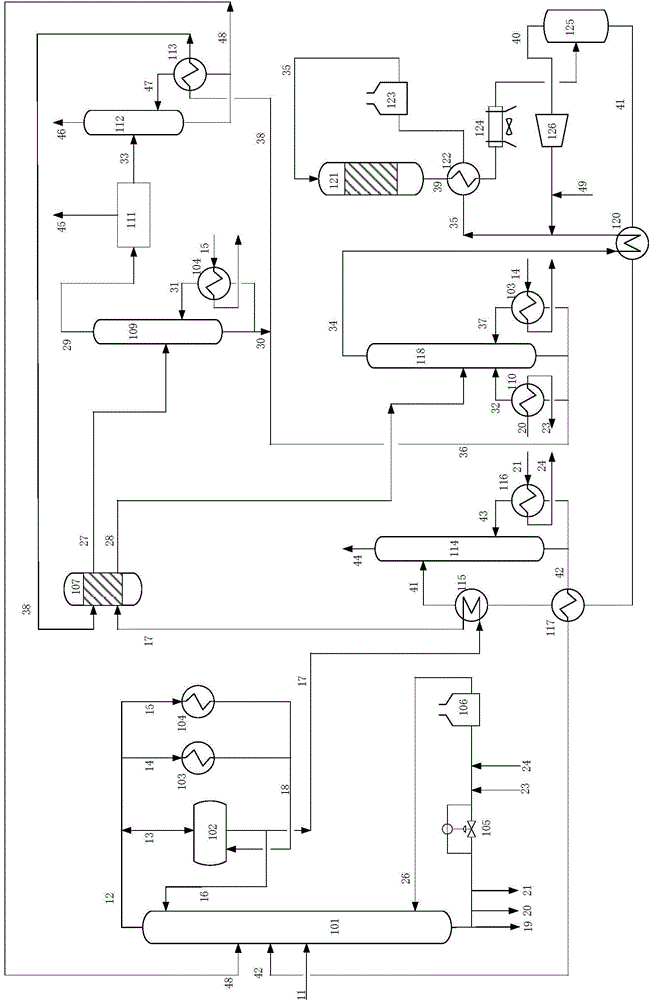

Embedded planetary-screw pulsation plasticizing exhaust extruder and method

The invention provides an embedded planetary-screw pulsation plasticizing exhaust extruder, which comprises a screw mechanism, a cylinder, a feed inlet, an air outlet, a discharge outlet and an actuating unit, wherein the screw mechanism comprises a main screw and a plurality of planetary screws, and the axis of the main screw is coincident with the axis of the cylinder; the screw arris of the main screw is provided with a plurality of holes which are matched with the planetary screws; the planetary screws are respectively inserted in the holes of the screw arris of the main screw, embedded into a screw slot and distributed around the main screw; the axes of the planetary screws are parallel to the axis of the main screw; the actuating unit comprises pulsation gears, planetary gears and a pulsation-gear transmission mechanism; the planetary gears are fixed at the ends of the planetary screws and are engaged with the pulsation gears; and the pulsation gears are connected with the pulsation-gear transmission mechanism. The invention also provides an embedded planetary-screw pulsation plasticizing exhaust method implemented by the device. The embedded planetary screw pulsation plasticizing exhaust extruder and the embedded planetary-screw pulsation plasticizing exhaust method have the advantages of adjustable retention time, low energy consumption, thorough exhaust, good uniformity of phase structure control, and the like.

Owner:GUANGDONG IND TECHN COLLEGE

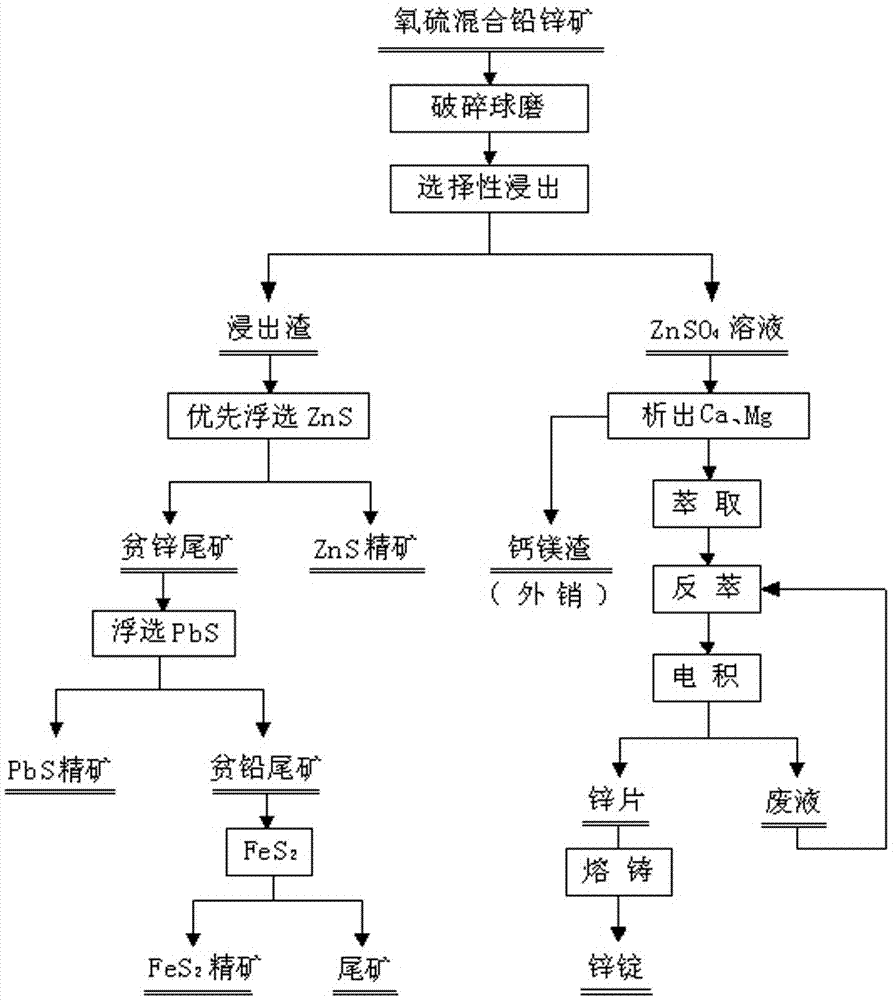

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

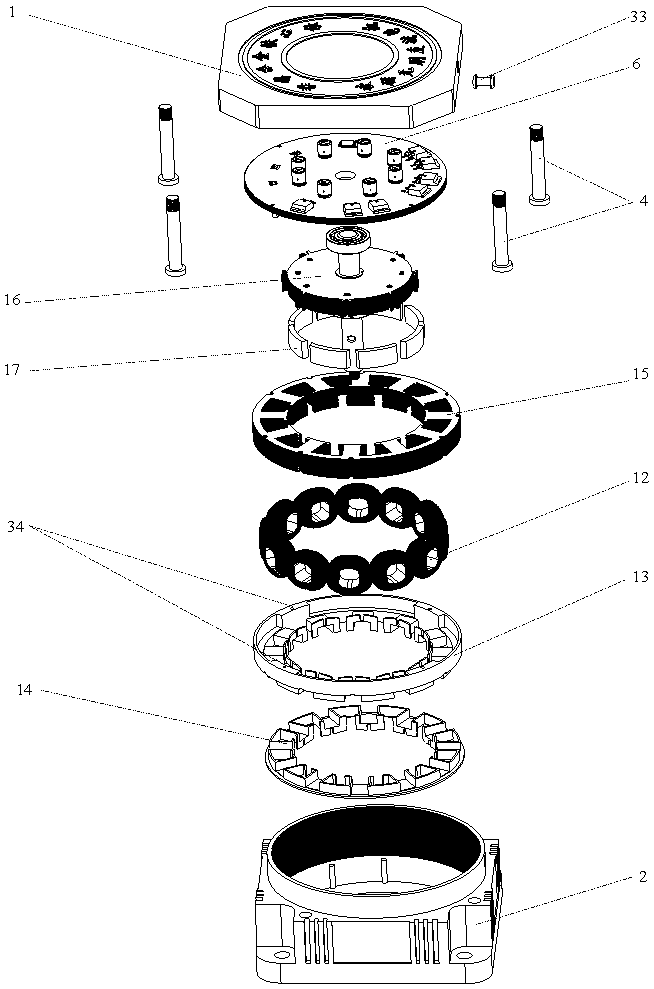

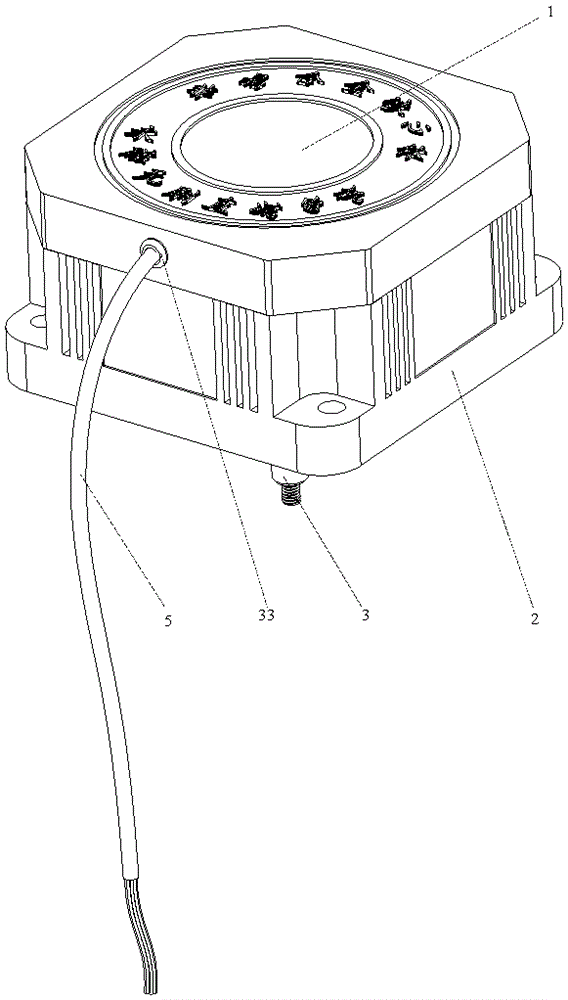

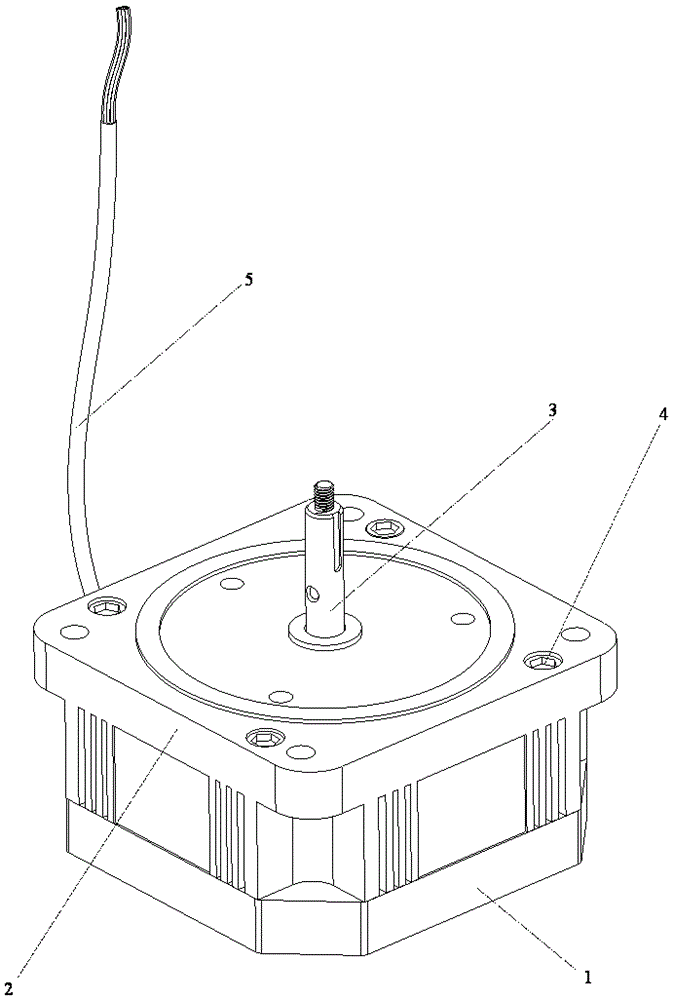

Amorphous alloy iron core permanent magnet brushless direct-current motor

ActiveCN106208545AImprove reliabilityImprove efficiencyAssociation with control/drive circuitsSupports/enclosures/casingsHall elementStator coil

An amorphous alloy iron core permanent magnet brushless direct-current motor consists of the two portions including a motor body and a controller, wherein the motor body portion comprises a motor upper end cap, a motor lower end cap, a motor output shaft, a shaft sleeve, an upper framework, a lower framework, a stator coil, a stator iron core body, a rotor iron core body and neodymium iron boron permanent magnet block, and the controller portion comprises an aluminum metal based printing circuit board, a control cable, a double-core single chip microcomputer, a power VMOS tube and a Hall element. The amorphous alloy iron core permanent magnet brushless direct-current motor is characterized in that both the stator iron core body and the rotor iron core body are formed by superposing iron based amorphous alloy sheets, the stator iron core body is fixed through joint supporting of the upper framework and the lower framework, the stator coil is made by winding an anaerobic copper line, all of controller elements and circuits are integrated on the aluminum metal based printing circuit board, an outer thread is carved on the supporting aluminum metal cylinder of the aluminum metal based printing circuit board, the cylinder is screwed into the inner wall thread of the motor lower end cap during installation to form a motor body and controller mechanical-electrical integrated structure.

Owner:彭希南

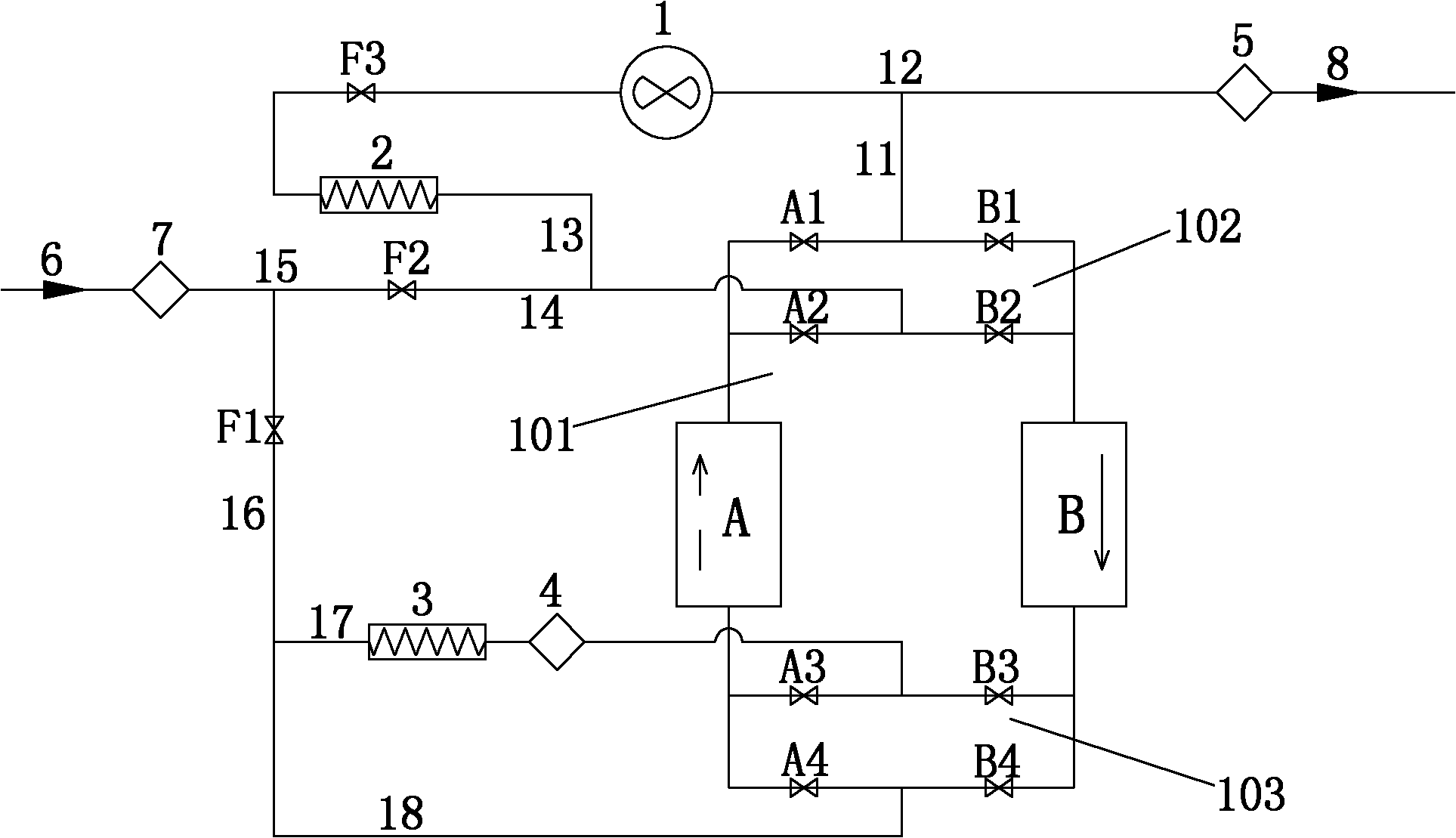

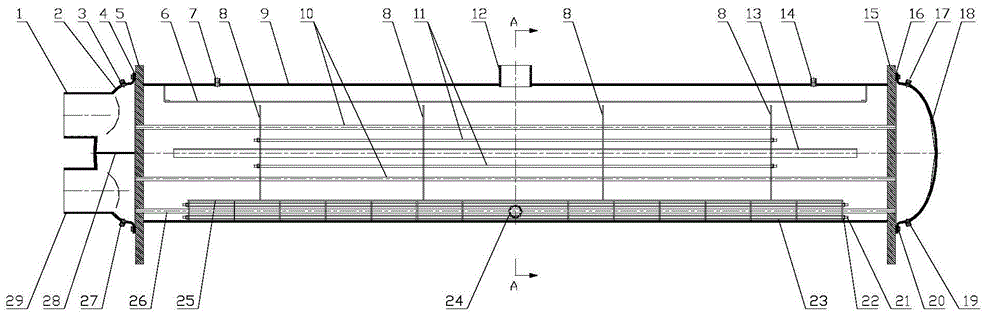

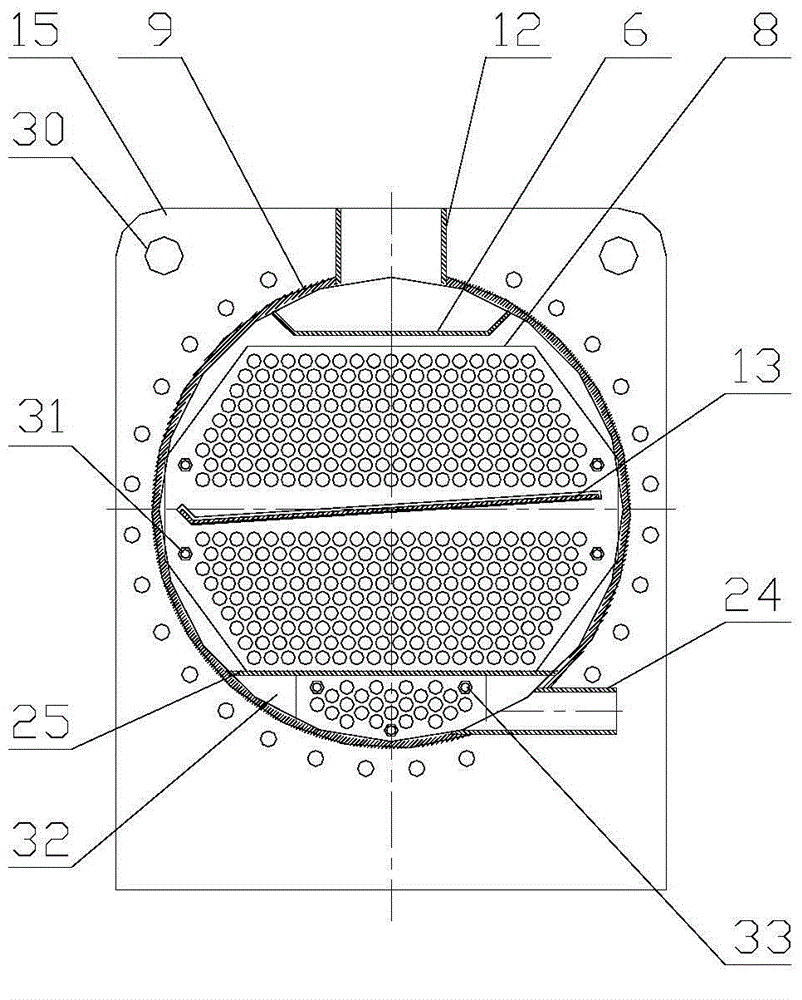

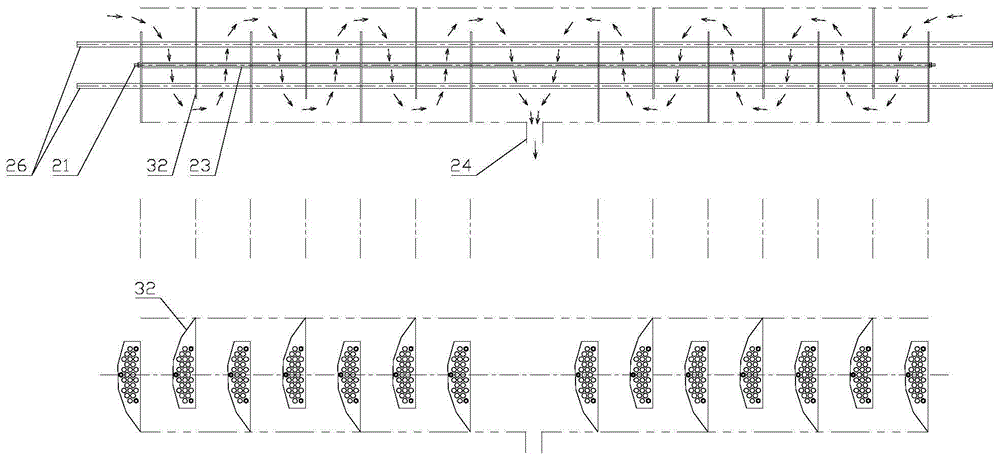

Process and device for drying adsorption type compressed gas regenerated by using compression heat

ActiveCN102101003ARemarkable effect of energy saving and consumption reductionAchieve regenerationGas treatmentDispersed particle separationEngineeringProcess engineering

Aiming at overcoming the defects of the traditional absorption drying method and a large adsorption type compressed air dryer, the invention provides a process and device being used for drying an adsorption type compressed gas regenerated by using compression heat, being capable of obtaining a drying gas with lower dew point and recycling a blast-cold gas. According to the invention, an exhaust and pressure-reduction process does not exist, the regenerated and heated blast-cold gas is recycled, the compressed air and the energy are saved, and the energy consumption is lowered.

Owner:XIAN UNIONFILTER PURIFICATION EQUIP

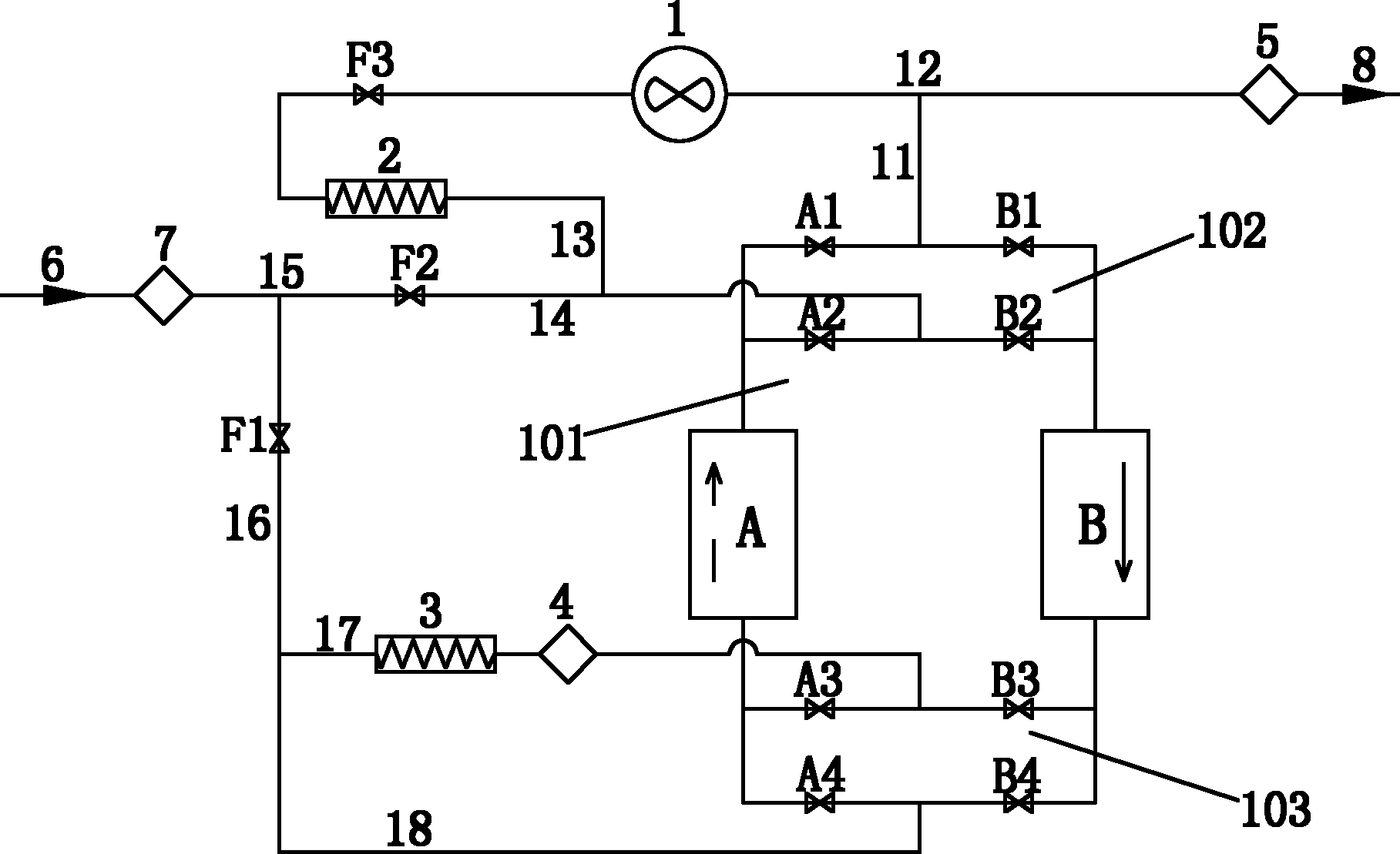

Manufacturing method of puffed corn dregs

InactiveCN102726814AEnsure continuous operation of productionReduce production accident rateFeeding-stuffAnimal feeding stuffEconomic benefitsProcess engineering

The invention belongs to the field of processing of feed, in particular to a manufacturing method for puffing cone and a puffing auxiliary playing a lubrication role in an annular gap discharging manner after matching and mixing. The manufacturing method comprises the following steps of: adopting cone as the main material, adding the puffing auxiliary playing a lubrication role according to a proportion, and obtaining puffed corn dregs by adopting a 3600C annular gap discharging and puffing process. The manufacture method disclosed by the invention has the characteristics of being simple in production process, obvious in energy saving and consumption reduction effect, high in production efficiency, high in aging degree, high in animal digestion utilization ratio and low in production cost. By means of the manufacturing method, the economic benefit is increased; quality and sanitary safety of products are ensured; development of breeding industries is indirectly pushed forward; the utilization rate of grains in the cultivation process is increased; and the waste of grain resources is reduced.

Owner:石晓岭

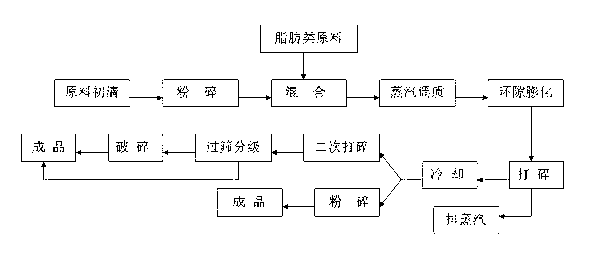

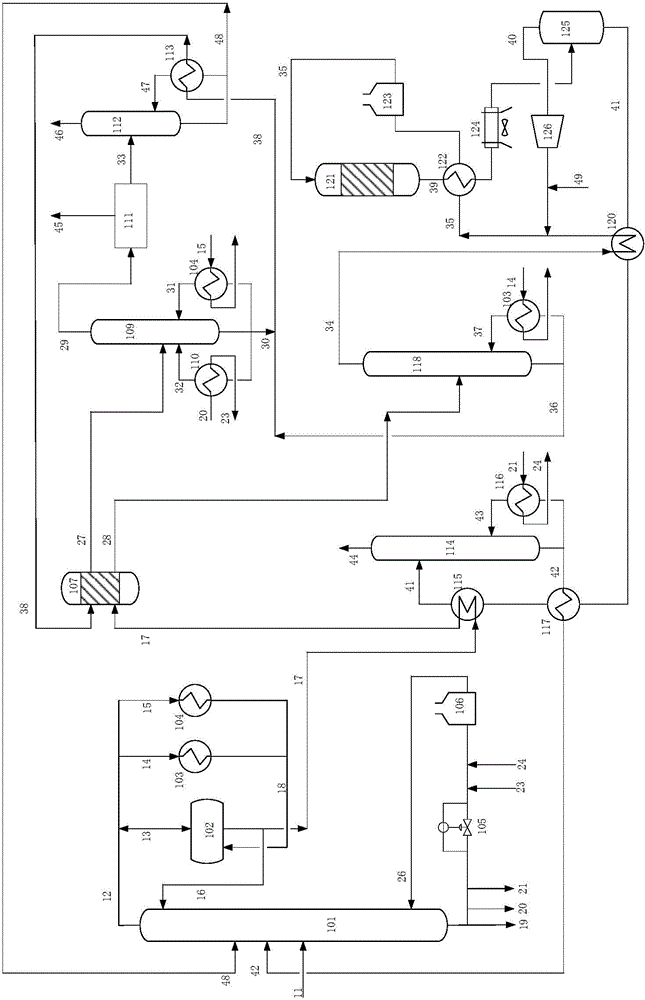

Method of producing p-xylene and heat exchanger network therein

ActiveCN105837389ARemarkable effect of energy saving and consumption reductionReduce consumptionSolidificationLiquefactionChemistryDistillation

A method of producing p-xylene and a heat exchanger network therein. The method includes the steps of: a) feeding a raw material comprising C8 aromatic hydrocarbon in a xylene rectification column to remove the hydrocarbons having more than nine carbon atoms to obtain an adsorption separation material; b) feeding the adsorption separation material into an adsorption separation chamber to perform adsorption separation to obtain an extract liquid and a raffinate liquid; c) feeding the extract liquid into an extract liquid column for distillation separation to obtain a material being rich in p-xylene on the top of the column, and performing crystallizing separation to obtain high-purity p-xylene product, wherein a desorption agent is obtained at the bottom; d) feeding the raffinate liquid into a raffinate liquid column for distillation separation, wherein a material from the top is fed into an isomerization reactor and the desorption agent is obtained at the bottom and is fed back to the adsorption separation material for being recycled; e) feeding an isomerization product to a heptane removal column for separation to obtain hydrocarbons having more than eight carbon atoms, which is then fed into the xylene rectification column. With the xylene rectification column as a core for heat integration to supply heat for the rectification columns, such as the extract liquid column, the raffinate liquid column and the heptane removal column, the method and the heat exchanger network fully utilizes the heat resource in the apparatus, reduces consumption of fuel, electricity and steam and has significant energy-saving and consumption-reducing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermo-mechanical treatment process of great-length Cu-Cr-Zr-Si alloy contact line

InactiveCN104928603ACauses a dynamic recrystallization effectRefining as-cast grainContact lineHeavy duty

The invention discloses a thermo-mechanical treatment process of a great-length Cu-Cr-Zr-Si alloy contact line. The process includes: smelting Cu-Cr-Zr-Si alloy, with Cu accounting for 0.30% to 0.50%, Cr accounting for 0.10% to 0.15% and Zr accounting for 0.01% to 0.02% in content, with a combined protective layer composed of mixed inert gas and a covering dried charcoal protective layer, in an induction furnace; and performing drag casting with a horizontal continuous casting system with electromagnetic stirring and a local heater to obtain rods 16 to 120mm in length. By high-frequency inductive thermal rolling, step heating and water-cooling solidification, cold rolling, split ageing and finish drawing or cold rolling, the alloy contact line having symmetrical grooves in two sides, 110 mm<2> to 150 mm<2> in sectional area and 1800 to 2000 m in singular length. The process has the advantages that metallurgical quality of products is high, and the performances meet the needs of various overhead line systems for modern high-speed railways and low-speed heavy duties.

Owner:YANTAI JINHUI COPPER +2

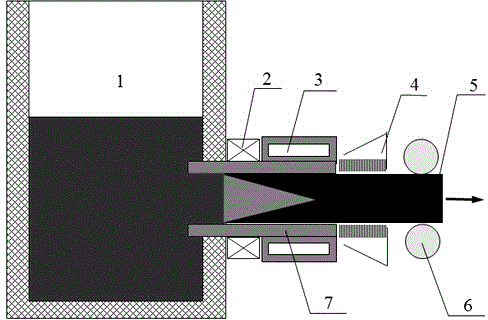

Efficient oxygenation system for confined space

ActiveCN106145315AIncrease hydraulic retention timeIncrease transfer rateTreatment using aerobic processesSpecific water treatment objectivesSludgeConfined space

The invention discloses an efficient oxygenation system for a confined space. The system comprises an aeration tank, a plurality of flow guiding plates are arranged in the aeration tank in the water flow direction and divide the aeration tank into a plurality of areas, different quantities of aerators are arranged in the areas in a concentrated mode according to the oxygen dissolving requirements of the areas, the aerators are rotary-cutting and mixed-flowing aeration devices, a flow guiding cutter is arranged over a water outlet of each rotary-cutting and mixed-flowing aeration device and arranged outside a corresponding central air inlet pipe, and a buffer distance is formed between each flow guiding cutter and the corresponding water outlet; each flow guiding cutter is an inverted cone with the conicity of 60 degrees to 65 degrees. According to the efficient oxygenation system for the confined space, the problems that in actual engineering, aeration in an aerobic tank is not uniform, the total oxygen dissolving efficiency is low, sludge in the tank is deposited, the aerators are prone to fall off and be blocked and aged, the oxygen utilization efficiency is rapidly lowered, management and maintenance are inconvenient, and the cost is high are solved.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

Complete stroke thermal insulating cover for continuous casting conveying roller way

The present invention provides an omnirange heat-insulating cover for continuous casting roll gang. It is formed from several heat-insulating cover bodies. In the whole roll gang, including casting billet cutting zone roll gang, dummy bar roll gang and dressing machine roll gang, over every roll gang a heat-insulating cover body which can be opened is set respectively. The heat-insulating cover body positioned over the casting billet cutting zone roll gang is made into drawing-pulling type structure, the heat-insulating cover body positioned over the dummy bar roll gang is a tilting structure, formed from several heat-insulating cover bodies, at one side of every heat-insulating cover body its respective tilting mechanism is mounted; and the heat-insulating cover body positioned over the dressing machine is a translational structure, the transverse beam in the top portion of heat-insulating cover body can make the several cover bodies be connected into one body, and two ends of said transverse beam are respectively slide-connected with two transversely-moved guideways by means of pulleys.

Owner:ANGANG STEEL CO LTD

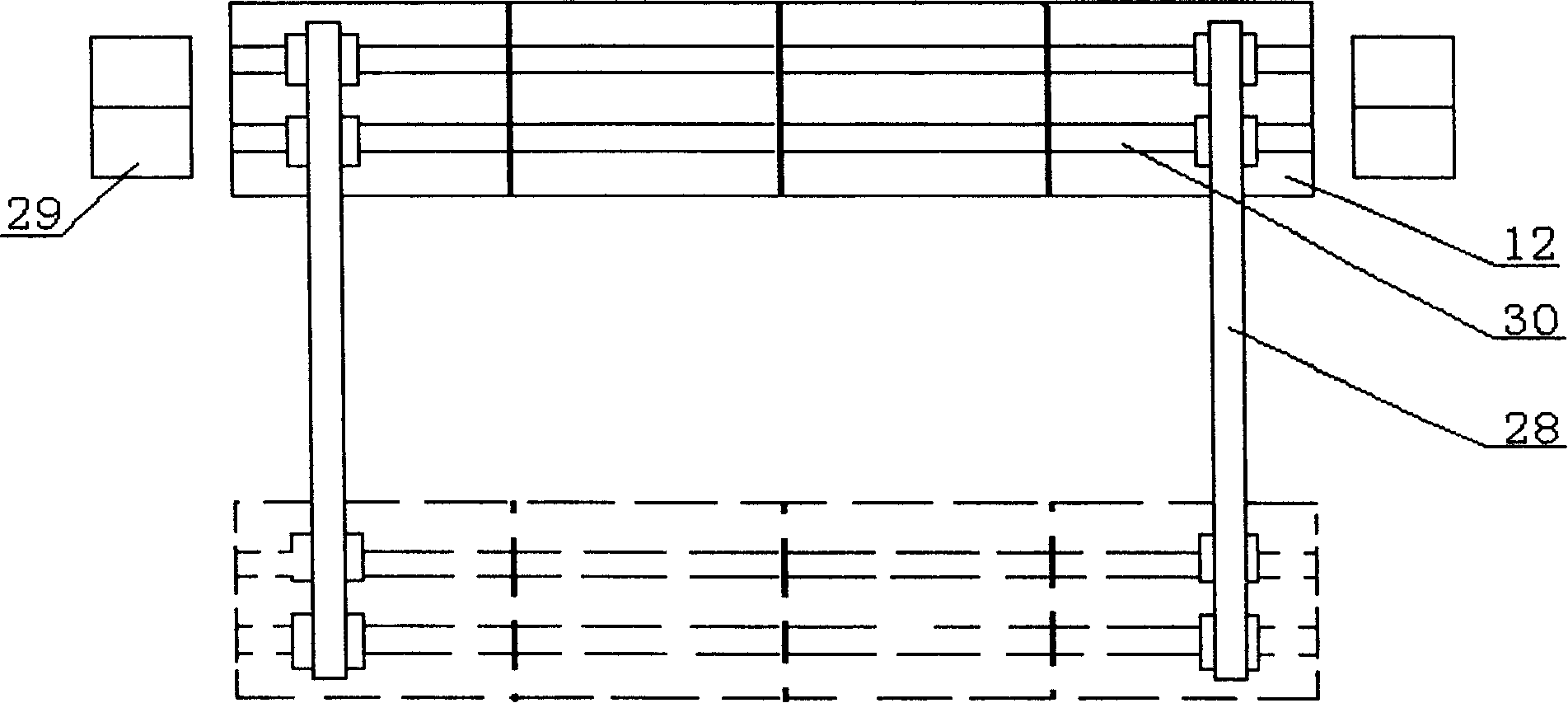

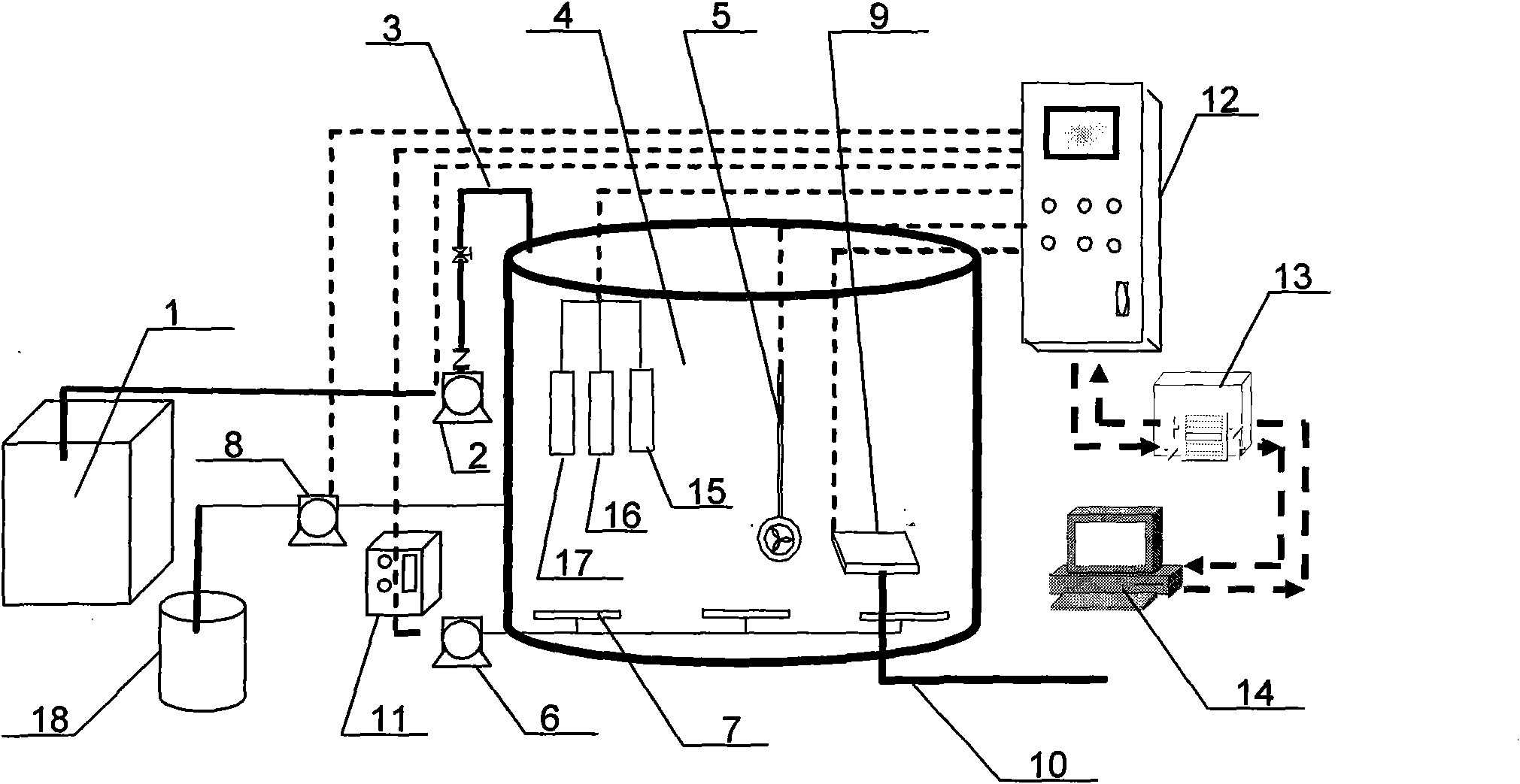

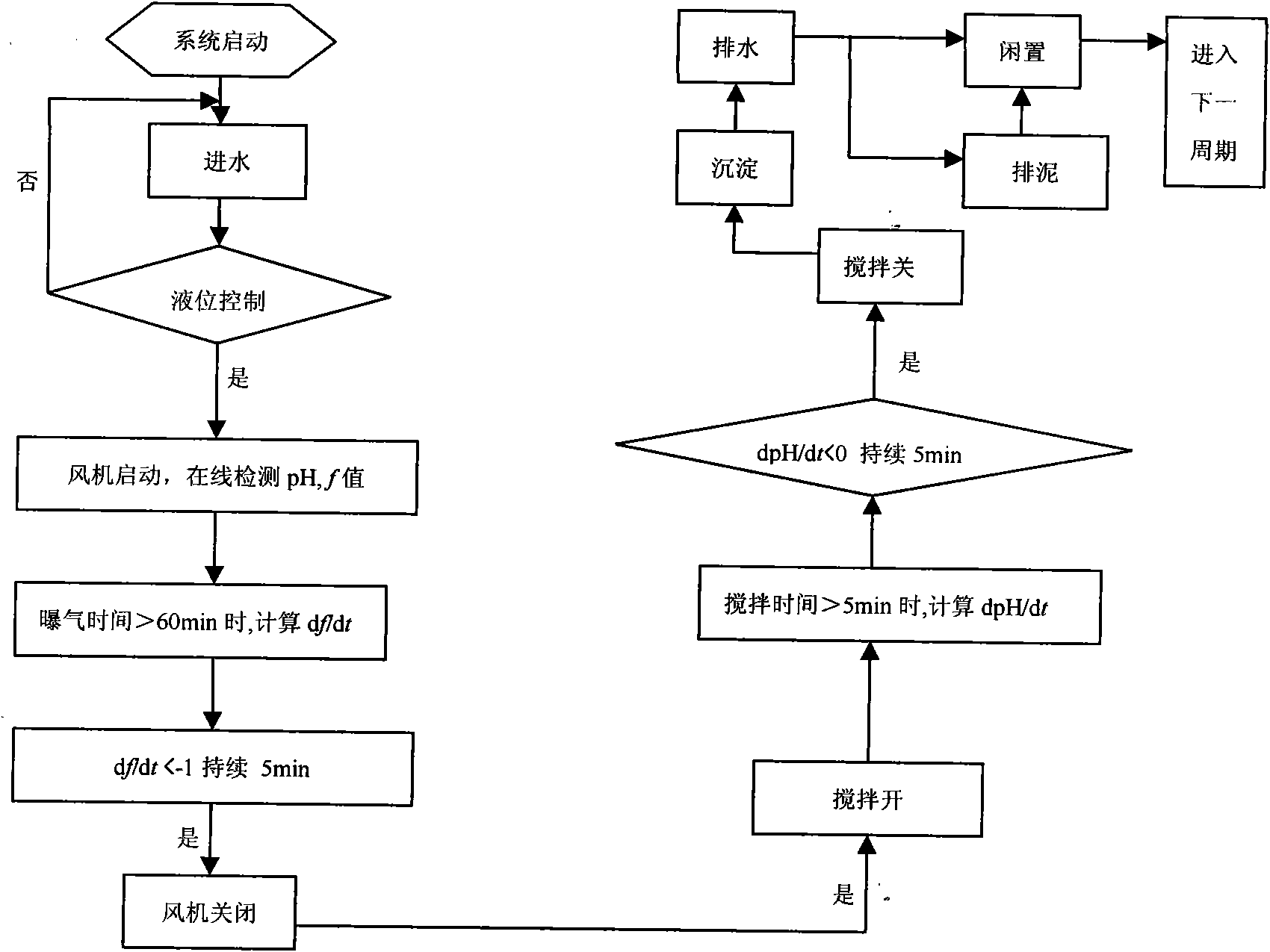

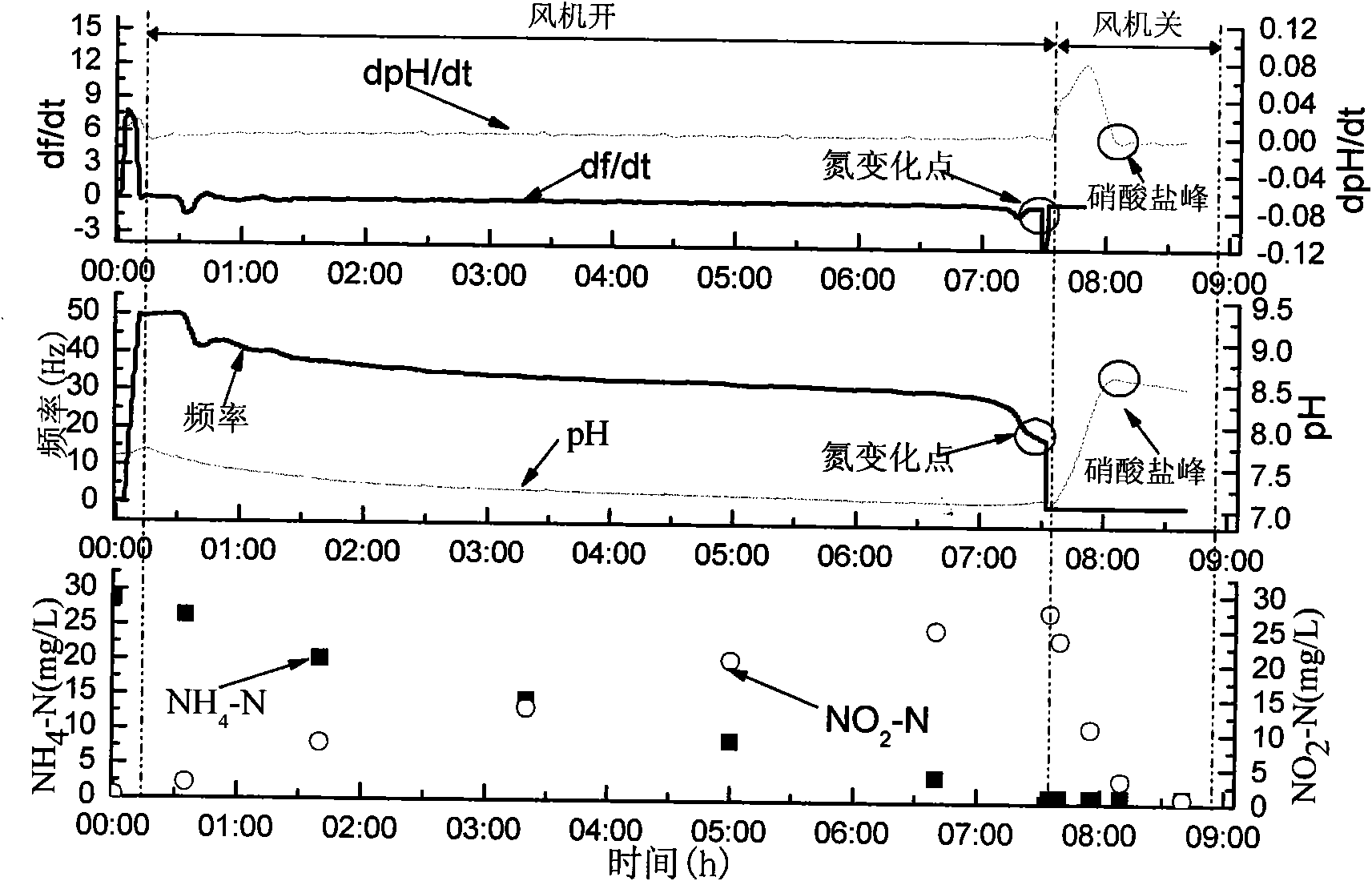

Quick start method for short-range deep denitrification by SBR (Sequencing Batch Reactor) process at low temperature

ActiveCN102079609ARemarkable effect of energy saving and consumption reductionLow running costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSequencing batch reactorRetention time

The invention relates to a quick start method for a nitrogenous wastewater biological treatment technique, in particular to a quick start method for a short-range deep denitrification technique by an SBR (Sequencing Batch Reactor) process at low temperature. The existing short-range deep denitrification technique can not be easily started at low temperature. The time for the short-range deep denitrification in the starting stage in the invention is short. The method provided by the invention comprises the steps of water injecting, aerating, denitrifying, precipitating, water discharging, sludge discharging, and standing. In the invention, frequency is used as the process control parameter in the aerating stage, and the retention time of the sludge is kept within 30-40 days, thereby realizing the quick start of short-range deep denitrification by the SBR process at low temperature (11-17 DEG C). The invention has the advantages of high denitrification efficiency and operating cost saving, can easily realize automation, can realize quick start at low temperature, and can also stably operate at normal temperature.

Owner:北控水务(中国)投资有限公司

Efficient condenser

ActiveCN104990315AImprove heat transfer efficiencyReduce thicknessEvaporators/condensersHeat transfer modificationEngineeringRefrigeration

The invention discloses an efficient condenser which comprises a shell. A condensation heat exchange area and a supercooling area are formed in the shell from top to bottom through a plurality of heat exchange pipes and a supercooling pipe. The condensation heat exchange area is divided into an upper layer and a lower layer. The heat exchange pipes on the upper layer and the lower layer are separated by a fluid baffle penetrating through supporting plates. The whole fluid baffle tilts by 10-15 degrees towards one side in the width direction. The condensation heat exchange area and the supercooling area are separated by a supercooling area upper sealing plate covering the supercooling area. According to the efficient condenser, due to the fact that the fluid baffle is arranged between the upper layer and the lower layer of the condensation heat exchange area and the supercooling area upper sealing plate is arranged between the condensation heat exchange area and the supercooling area, the thickness of fluid films outside the heat exchange pipes below the fluid baffle is effectively reduced, the heat exchange performance of the supercooling area is enhanced, and the energy efficiency of a refrigeration system is obviously improved.

Owner:南京冷德节能科技有限公司 +1

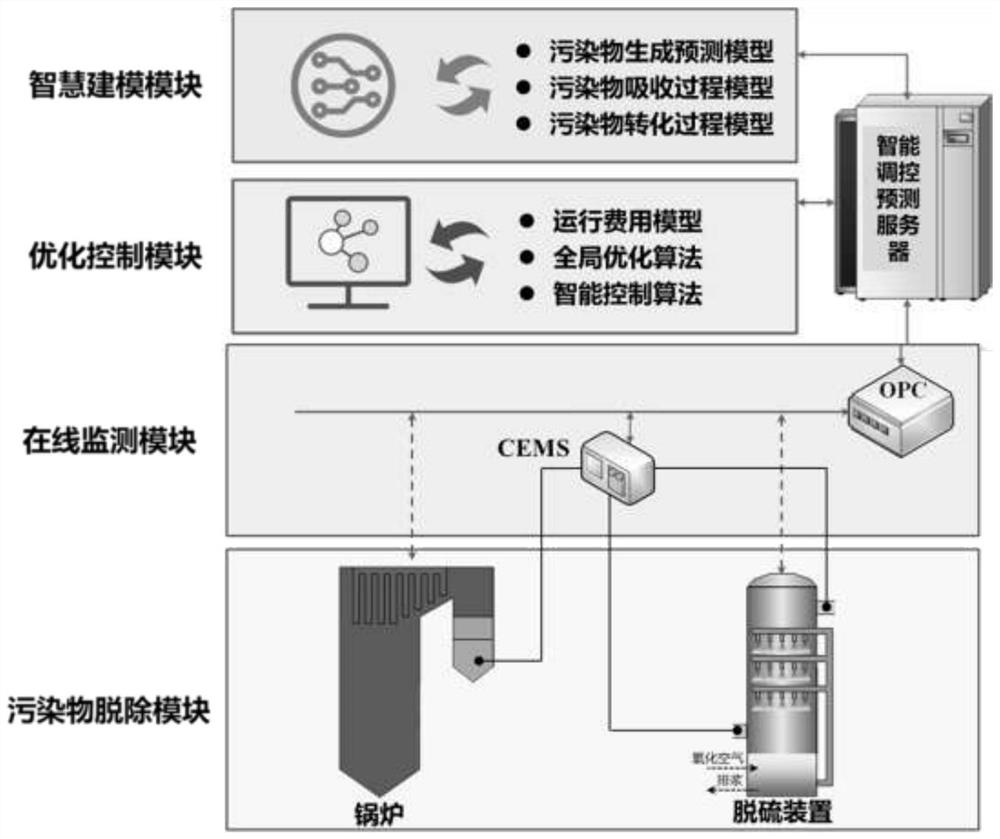

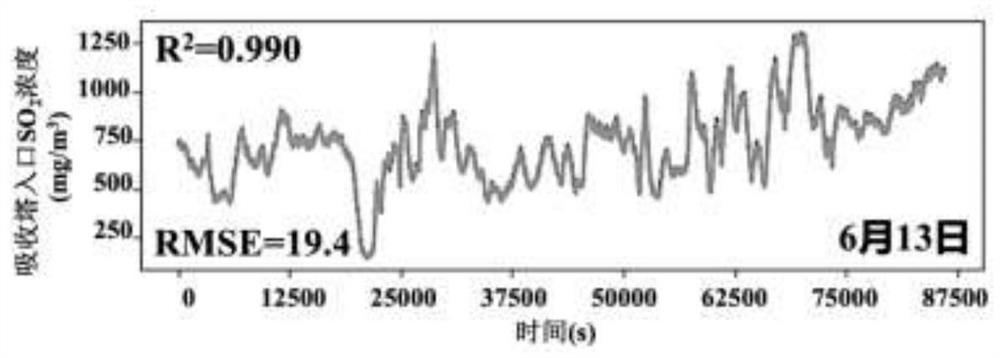

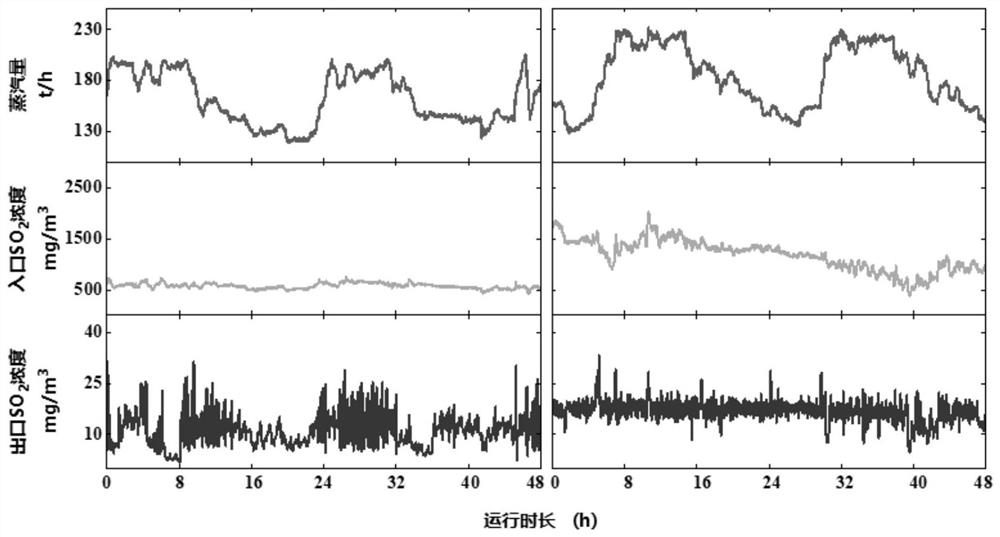

Whole-process intelligent operation regulation and control system of wet desulphurization device

ActiveCN113082954AImprove reliabilityConcentrated concentration distributionGas treatmentDispersed particle separationCirculator pumpIntelligent modeling

The invention relates to a whole-process intelligent operation regulation and control system of a wet desulphurization device. The whole-process intelligent operation regulation and control system comprises a pollutant removal module, an online monitoring module, an optimization control module and an intelligent modeling module. The system can accurately predict the influence of each control variable on the desulfurization efficiency, the operation cost and the product quality of the wet desulfurization system, accurately regulate and control the operation parameters such as the pH value, the frequency and the liquid level, and ensure that the outlet concentration stably reaches the standard under the working conditions of variable load and variable coal quality; energy consumption and material consumption distribution among devices such as a circulating pump, an oxidation fan and a gypsum dehydrator is coordinated, so that the cost of the wet desulphurization system is optimal; by-product components are controlled to ensure that the purity of the target substance reaches the standard; and safe, stable, economical and efficient operation of the wet desulphurization device is realized.

Owner:ZHEJIANG UNIV

Ceramic welding materials for high temperature kiln and a method

ActiveCN102086128ARemarkable effect of energy saving and consumption reductionExtended service lifeMicroparticleOxygen delivery

The invention discloses a method and corresponding ceramic welding materials for restoring damaged high temperature industrial kiln by ceramic welding technology, and the method comprises the following steps of: selecting materials the same as or similar torefractory materials at the kiln damaged position as base materials; selectively adding metal inflammable microparticles accounting for 10% to18% by weight of the base materials, such as aluminium, magnesium, silicon, zirconium and the like, and selecting chloride accounting for no more than 2% by weight of the base materials as additive; after mixing well under conveying of oxygen jetting the prepared welding material to a position of the kiln to be repaired; reacting the inflammable microparticles with the oxygen to produce a high temperature to allow the refractory materials rapid softening and fusion; combining together very tightly the refractory materials at the position to be prepared and the welding material; fully filling holes, junctions and slits with fused substance; and continuously filling on the heat repairing surface to achieve the purpose of kiln restoration.

Owner:山西高科耐火材料股份有限公司

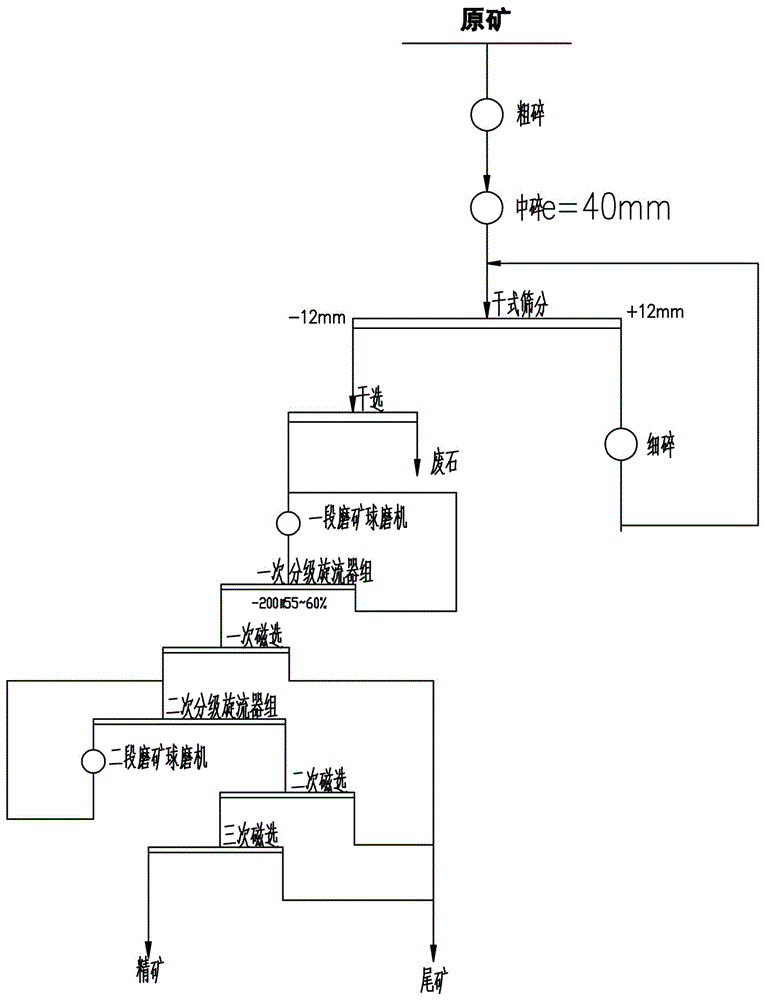

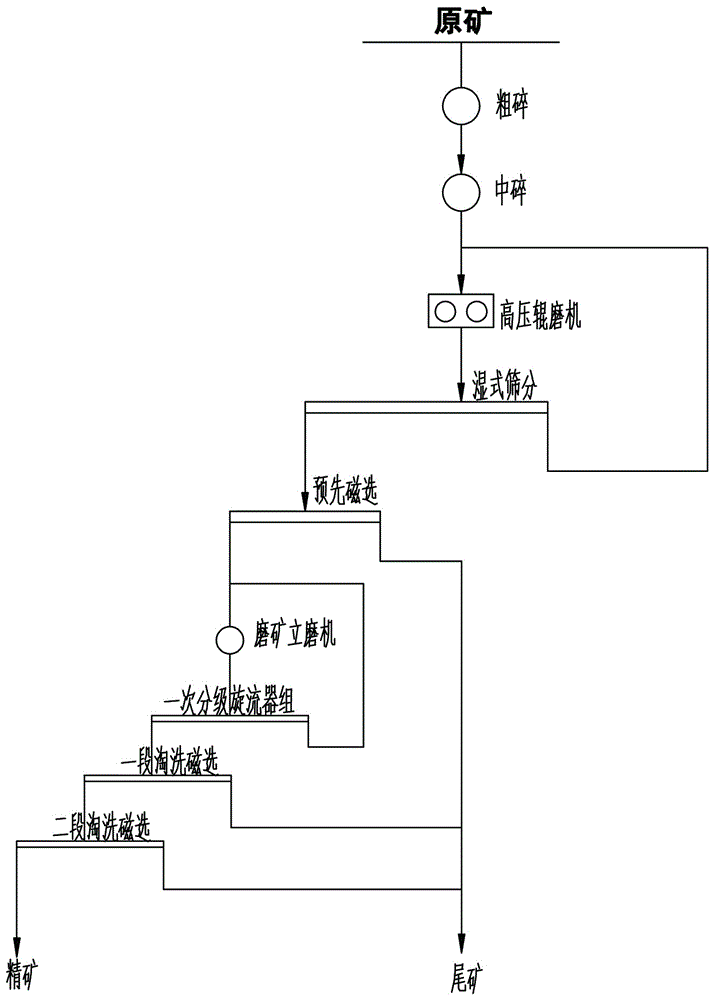

Crushing-ore milling-magnetic separation technique for magnetic iron ore

InactiveCN106824508AReduce the number of auxiliary equipmentSignificant energy savingWet separationMagnetiteClosed loop

The invention relates to a crushing-ore milling-magnetic separation technique for magnetic iron ore. The technique comprises the step that raw ore is crushed into 0 mm-50mm through coarse crushing and middle crushing, and the technique is characterized by further comprising the following steps that middle crushed products are directly fed into a closed loop system formed by a high-pressure roller mill and a constant thickness screen; high-pressure roller mill products are fed into a pre-selection wet-type magnetic separator to be subjected to pre-selection wet-type magnetic separation, and concentrate and tailings are selected correspondingly; the pre-selection wet-type magnetic separation concentrate is fed into a vertical mill machine for milling, vertical mill machine products are fed into a primary classification whirlcone for classification, primary classification is conducted, the products with the diameters being below 0.074 mm are fed into a two-stage washing magnetic separator for separating operation, and the products with the diameters being above 0.074 mm are returned to the vertical mill machine; and concentrate of two-stage washing magnetic separator separating operation is final concentrate with the grade being 67.00%, and the pre-selection wet-type magnetic separation tailings and two-stage washing magnetic separator tailings are combined into final tailings. The crushing-ore milling-magnetic separation technique for the magnetic iron ore has the advantages that the technological process is shortened, energy consumption is reduced, and cost is reduced.

Owner:中冶北方(大连)工程技术有限公司

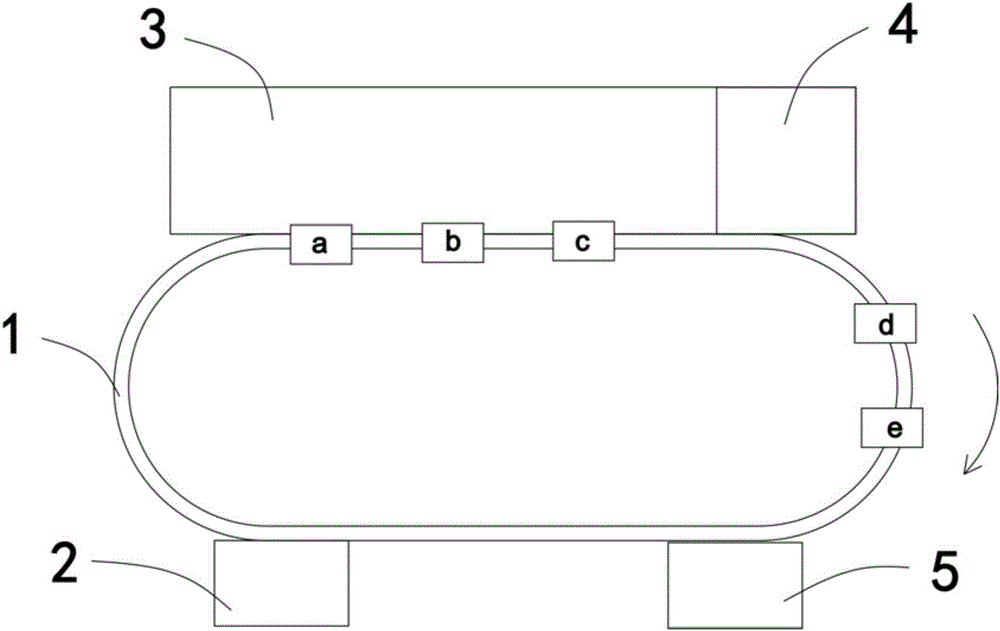

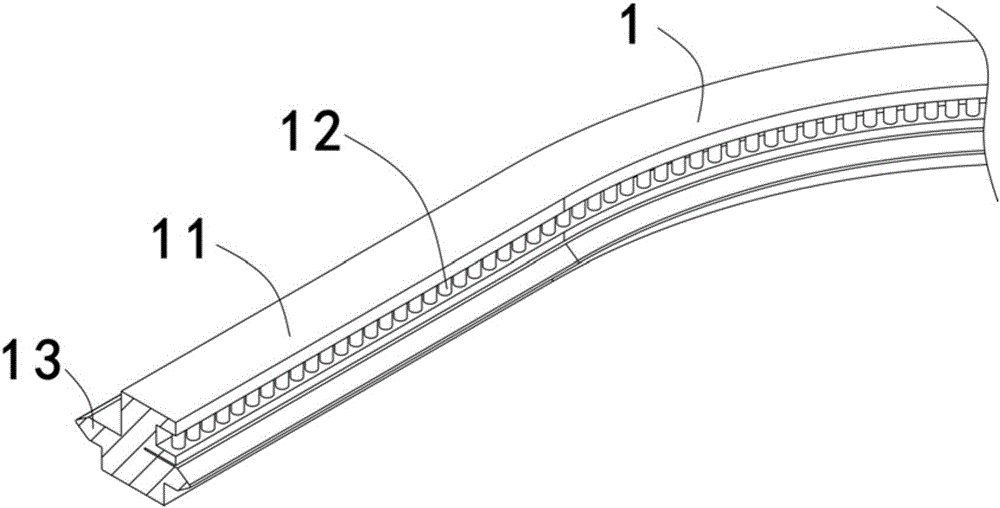

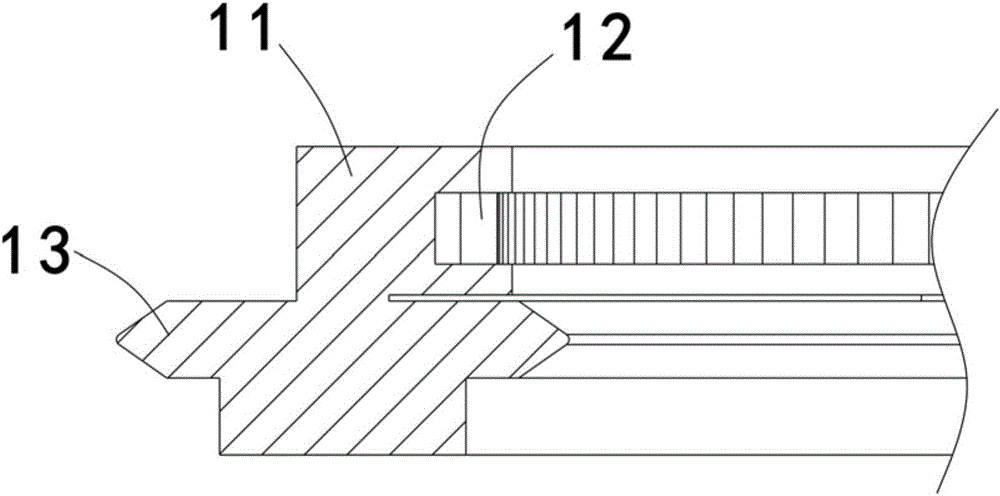

Centrifugal-type small part hot galvanizing system with parts

ActiveCN106222597ASimple structureGood galvanizing effectHot-dipping/immersion processesZincEngineering

The invention discloses a centrifugal-type small part hot galvanizing system with parts. The hot galvanizing system comprises a track mechanism, a feeding area, a galvanizing area and a discharging area, wherein the feeding area, the galvanizing area and the discharging area are arranged along the track mechanism. The track mechanism is movably provided with at least two feeding mechanisms. A centrifugal area is arranged at the terminal of the galvanizing area. The centrifugal area comprises centrifugal equipment and a grabbing mechanism. The grabbing mechanism can transfer charging baskets containing the parts to be machined to the grabbing mechanism from the feeding mechanisms for centrifugal galvanizing. According to the hot galvanizing system, the galvanizing area and the centrifugal area are adjacently arranged, the structure is simplified, and the galvanized machined parts can enter the centrifugal area at once for centrifugal galvanizing. The galvanizing effect is good, the process of repeatedly heating molten zinc to a designated temperature is omitted, and the energy-saving and cost-reducing effects are obvious. Moreover, the phenomenon that the galvanizing effect is influenced due to the fact that the machined parts are polluted when being transferred to the centrifugal area from the galvanizing area is avoided, so that production efficiency is improved, the coating quality is good and safety performance is high.

Owner:嘉兴宝利机械股份有限公司

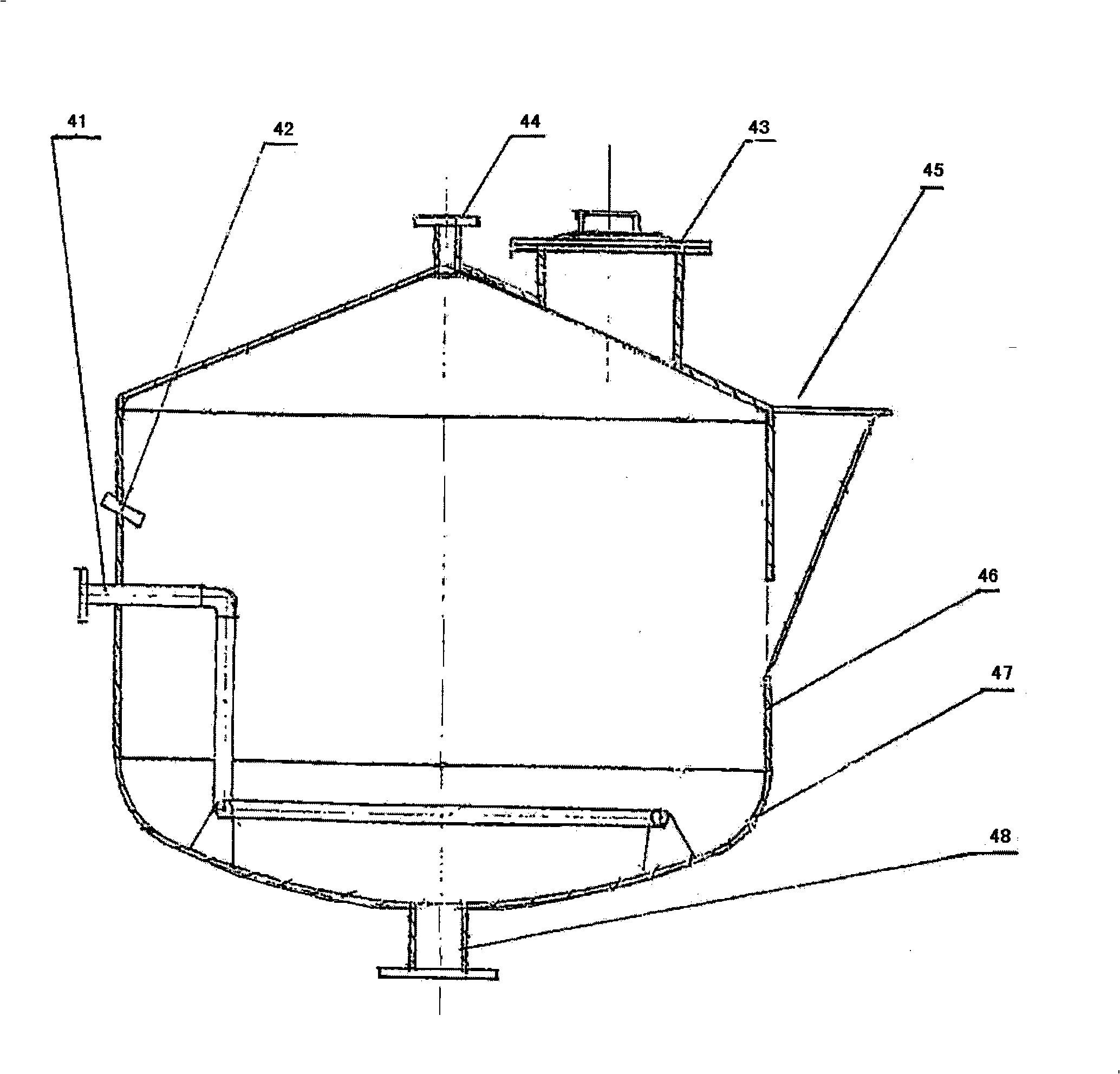

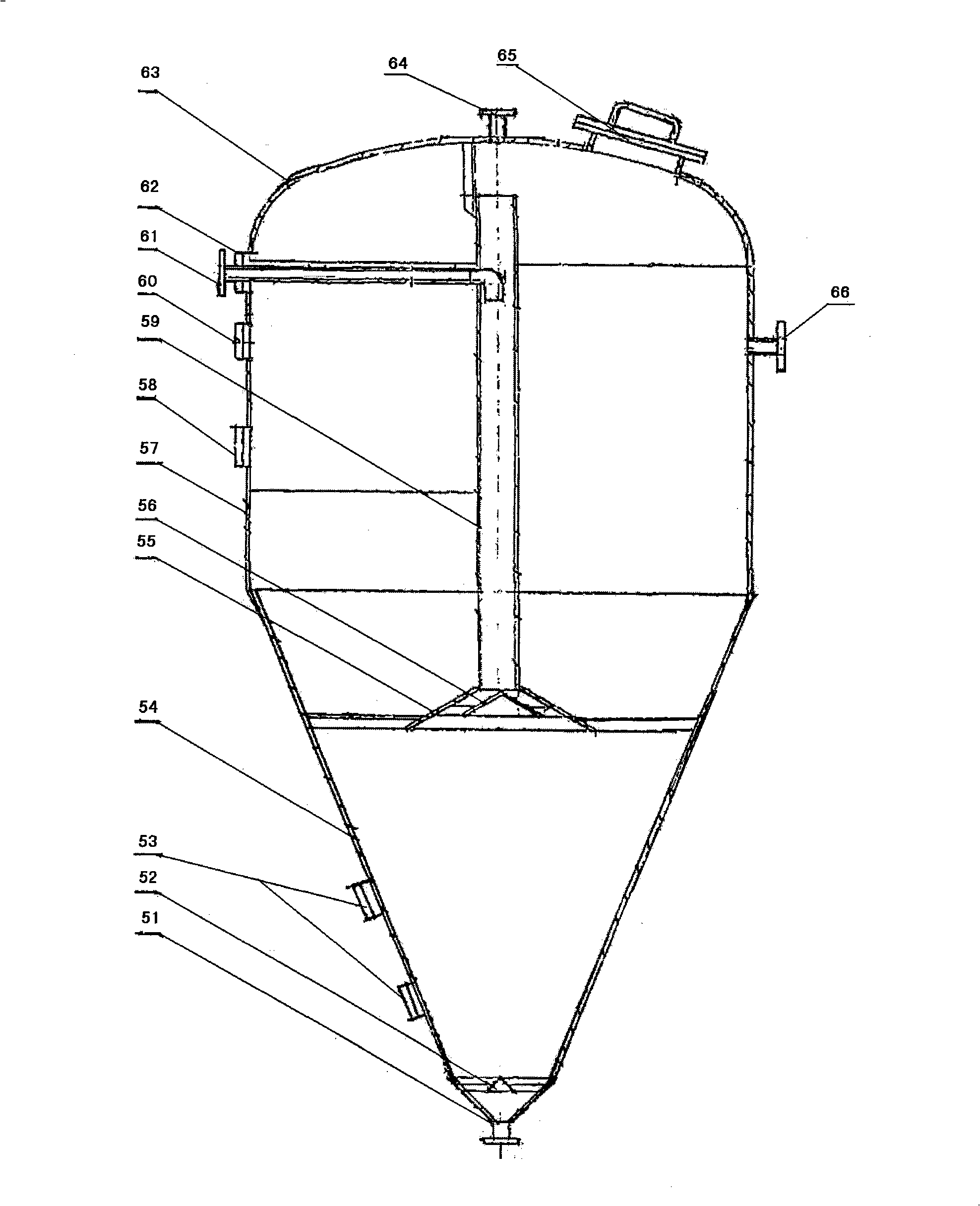

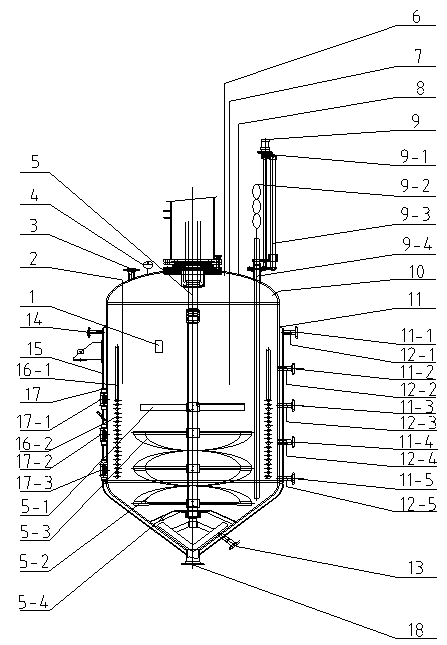

Extraction kettle apparatus for separating coal tar through mild extraction method

InactiveCN103275743AHigh recovery rateEmission reductionTar working-up by solvent extractionInsulation layerAgitator

The invention relates to an extraction kettle apparatus for separating coal tar, and concretely relates to an extraction kettle apparatus for separating coal tar through a mild extraction method. A strong magnetic stirrer is arranged in the center of a top cover, and a temperature measuring port, a pressure measuring port, a material inlet, an extractant inlet, a nitrogen inlet, a nitrogen outlet, a diffusing port, and valves connected with relevant tube ports are uniformly arranged in the circumference of the top cover respectively; an electric lift type lift tube lightweight component discharging system is arranged at the upper right side of the top cover; two hot steam heating coilers and corresponding hot steam inlets are arranged at the center outside a kettle; the material outlets of downward spreading valves are arranged at the outside surface portion of the kettle, and the downward spreading valves are respectively connected with a glass sight cup; three groups of sight glasses are arranged at the center outside the kettle; an interlayer heat insulation layer is arranged at the center outside the kettle; and a steam outlet, a material outlet and a valve are arranged at the bottom of the kettle. The apparatus has the advantages of simple operation, obvious energy saving and consumption reduction, high solvent recovery rate, easy automatic operation, low-carbon clean production, low investment cost, and less discharge of waste residues, the exhaust gas and wastewater.

Owner:ZAOZHUANG MINING GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com