Process for treating sewage by using annular circulating flow membrane bioreactor

A membrane bioreactor, membrane biological reaction technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. problems, to achieve the effect of flexible operation mode, expansion of optional space, and uniform space distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

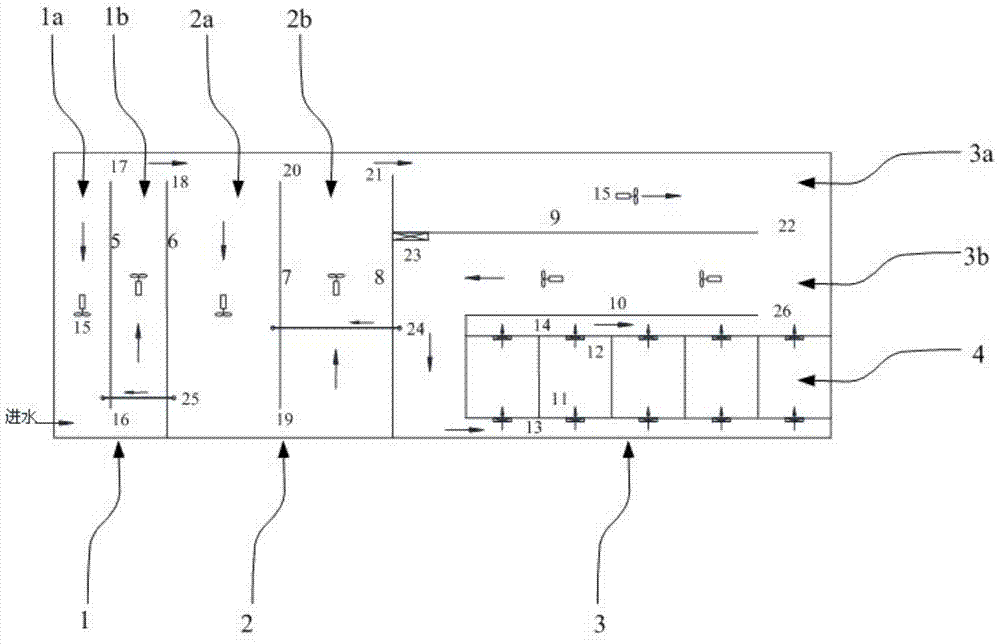

[0071] use as figure 1 A circulating flow loop membrane bioreactor (CCFP-MBR) and sewage treatment process shown in the figure treat 10,000m 3 / d domestic sewage.

[0072] Design water quality:

[0073] COD cr 400mg / L; NH 3 -N40mg / L; TP3mg / L; SS180mg / L

[0074] Outlet water quality requirements: meet the first-class A standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0075] The relevant design parameters are as follows: average inflow flow rate 416.67m 3 / h; maximum flow 658.33m 3 / h; the design anaerobic zone 1 mixed liquid suspended solids concentration MLSS is 2600mg / L (actual operation can be 2000~3000mg / L), anoxic zone 2 mixed liquid suspended solids concentration MLSS is 5650mg / L (actual operation can be 4800 mg / L) ~6000mg / L), the MLSS of mixed liquid suspension in aerobic zone 3 is 7000mg / L (actual operation can be 7000~9000mg / L); the maximum sludge load in aerobic zone 3 is 0.13kgBOD 5 / kgMLSS·d; the hydraulic r...

Embodiment 2

[0080] use as figure 1 A circulating flow loop membrane bioreactor (CCFP-MBR) and sewage treatment process shown in the figure treat 5000m 3 / d domestic sewage.

[0081] Design water quality:

[0082] COD cr 350mg / L; NH 3 -N35mg / L; TP4mg / L; SS200mg / L

[0083] Outlet water quality requirements: meet the first-class A standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0084] The relevant design parameters are as follows: the average flow rate of influent water is 208.33m 3 / h; maximum flow 362.50m 3 / h; design anaerobic zone 1 mixed liquid suspended solids concentration MLSS is 3000mg / L (actual operation can be 2000~3000mg / L), design anoxic zone 2 mixed liquid suspended solids concentration MLSS is 6000mg / L (actual operation can be according to 4500~6000mg / L), the design aerobic zone 3 mixed liquid suspension concentration MLSS is 8000mg / L (actual operation can be 7500~9000mg / L); the maximum sludge load of aerobic zone 3 is...

Embodiment 3

[0089] use as figure 1 A circulating flow loop membrane bioreactor (CCFP-MBR) and sewage treatment process shown in the figure treat 30,000m 3 / d domestic sewage.

[0090] Design water quality:

[0091] COD cr 450mg / L; NH 3 -N40mg / L; TP4mg / L; SS200mg / L

[0092] Outlet water quality requirements: meet the first-class A standard in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0093] The relevant design parameters are as follows: the average flow rate of influent water is 1250m 3 / h; maximum flow 1812.50m 3 / h; design anaerobic zone 1 mixed liquid suspended solids concentration MLSS is 2000mg / L (actual operation can be 1800~3000mg / L), design anoxic zone 2 mixed liquid suspended solids concentration MLSS is 6000mg / L (actual operation can be according to 4800~6000mg / L), the design aerobic zone 3 mixed liquid suspension concentration MLSS is 8000mg / L (actual operation can be 7500~9000mg / L); the maximum sludge load of aerobic zone 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com