Continuous roller type cold bending shaping method for metal sheet pile

A cold-formed, steel sheet pile technology, applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of large investment, high energy consumption, limited length, etc., to achieve low energy consumption, low energy consumption, saving effect of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

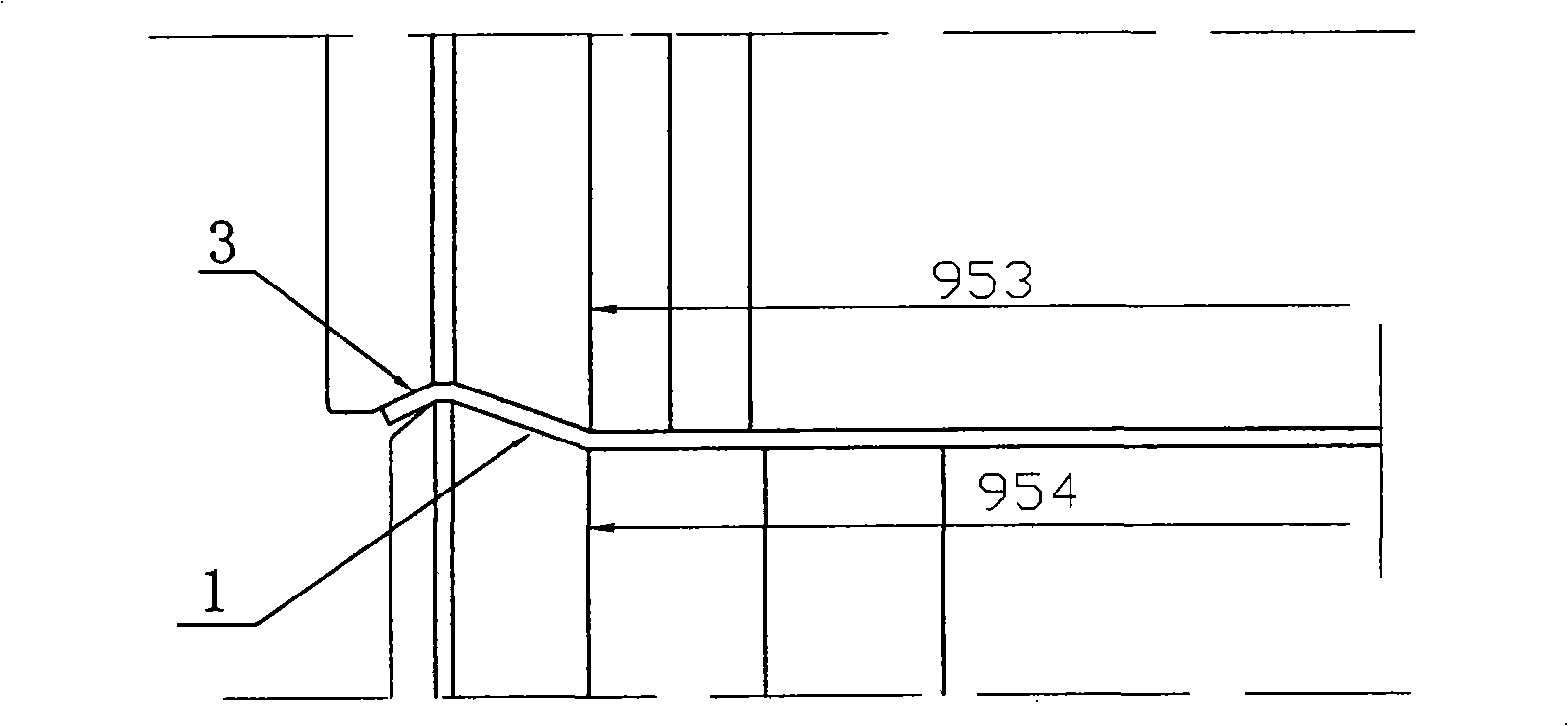

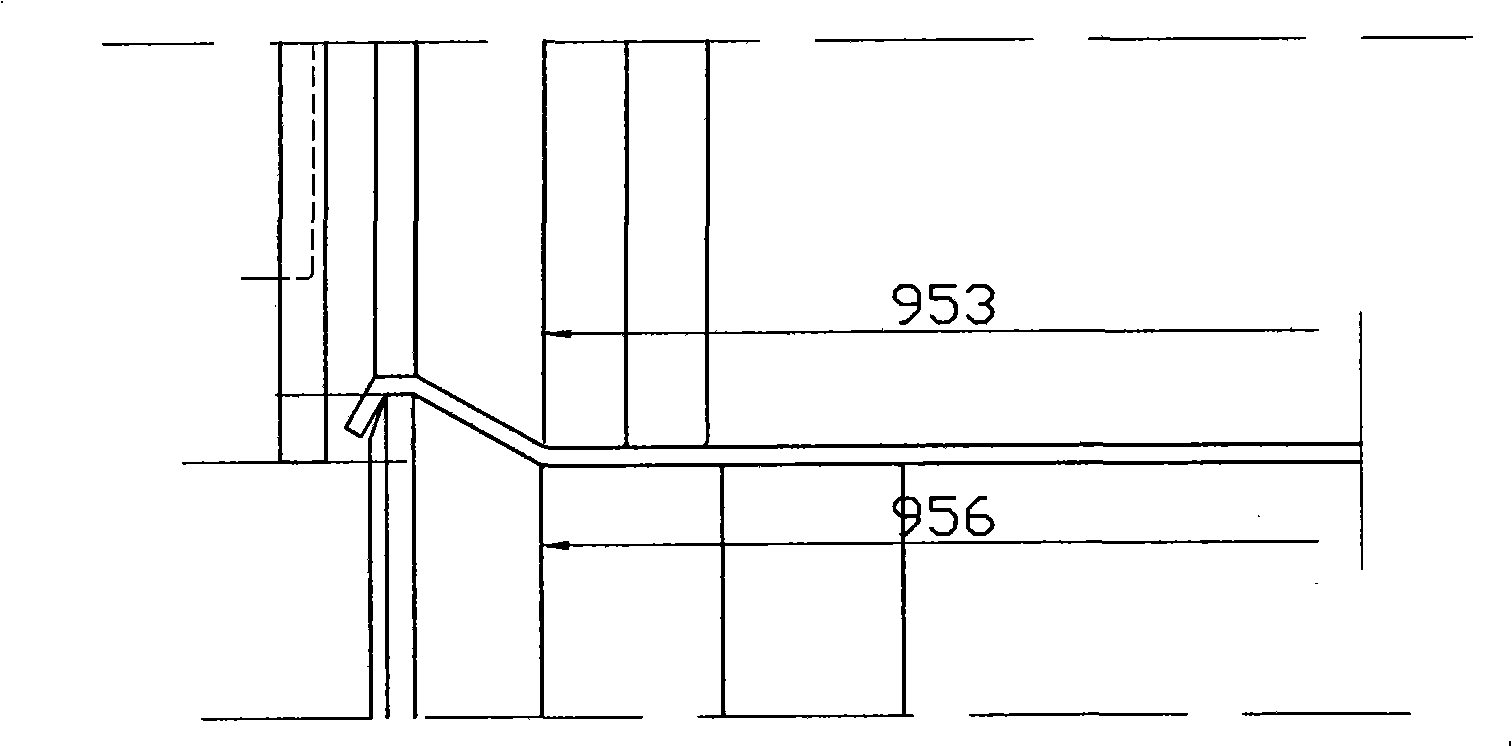

[0065] Such as Figure 1-15 shown.

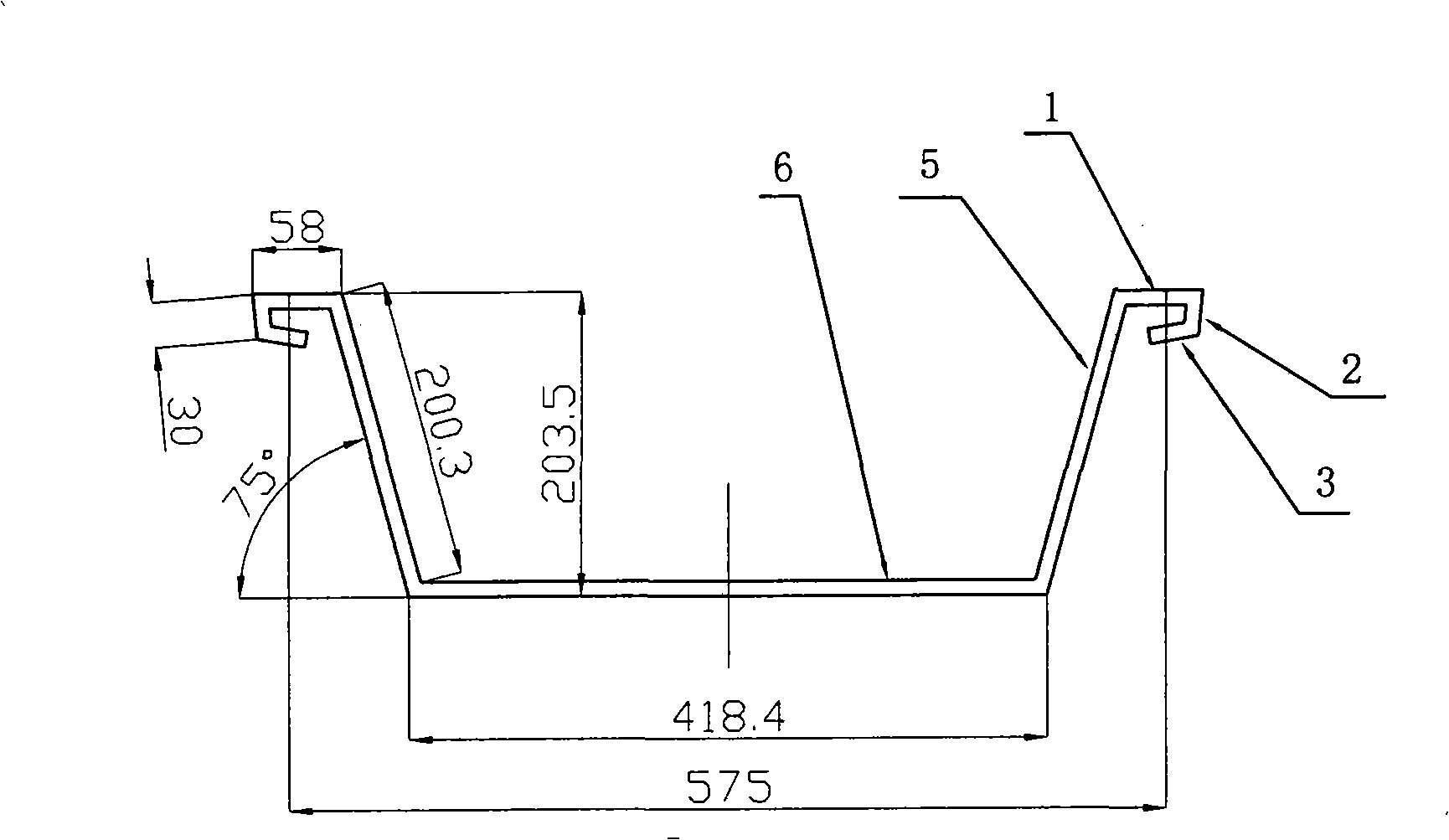

[0066] Such as figure 1 As shown, a steel sheet pile is mainly composed of a horizontal connection flange 1, a corner edge 2, a tail bend 3, a hypotenuse 5, and a groove bottom edge 6, wherein the horizontal connection flange 1, the corner edge 2, and the tail bend 3 are related to The hypotenuses 5 are connected and symmetrically located on both sides of the bottom edge 6 of the groove. The following is an example of one-side roll-joint cold-bending forming.

[0067] A continuous roll cold bending forming method for steel sheet piles, which includes the following steps:

[0068] 1. Roll-up: refers to cutting the coiled steel plate to the required width according to the unfolded size of the steel sheet pile and placing it at the feeding end of the production line;

[0069] 2. Roller continuous cold bending defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com