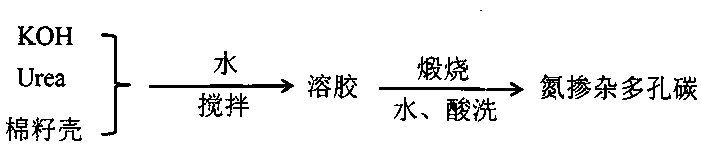

Method for preparing nitrogen-doped porous carbon by taking cottonseed hull as raw material and application

A nitrogen-doped porous carbon and cottonseed hull technology, applied in the field of nanomaterials, can solve the problems of low specific surface area of porous carbon materials, unsuitable chemical composition, great differences in physical and chemical properties, etc., and achieves large pore volume and resource source range. Wide, energy-saving and consumption-reducing significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] a. Pretreatment of cottonseed hulls: crush cottonseed hulls, put 4g of sodium hydroxide into the container as an evaporating dish, add 15mL of water and stir to dissolve, then add 4g of urea, stir to dissolve, at a temperature of 15°C Add 4g of pulverized cottonseed hulls and stir vigorously for 30 minutes to obtain a uniform sol, which is placed in a magnetic boat;

[0063] b. Preparation of nitrogen-doped porous carbon material: put the sol obtained in step a in a type furnace, first evacuate the tube type furnace, and then inject nitrogen gas for 5 minutes, raise the temperature to 800 °C at a rate of 5 °C / min, and keep it warm Carry out carbonization activation for 2 hours to obtain a black solid, which is then washed with water in sequence, washed with 10wt% hydrochloric acid until neutral, and dried at 120°C for 4 hours to obtain a specific surface area of 1010cm 3 / g, the pore volume is 0.6-0.9cm 3 / g, elemental analysis element content is: C: 66.3%, N: 2.07%,...

Embodiment 2

[0065] a. Pretreatment of cottonseed hulls: crush cottonseed hulls, put 8g of sodium hydroxide into a beaker, add 15mL of water and stir to dissolve, then add 12g of urea, stir to dissolve, at a temperature of 15°C Add 4g of pulverized cottonseed hulls and stir vigorously for 35 minutes to obtain a uniform sol, which is placed in a magnetic boat;

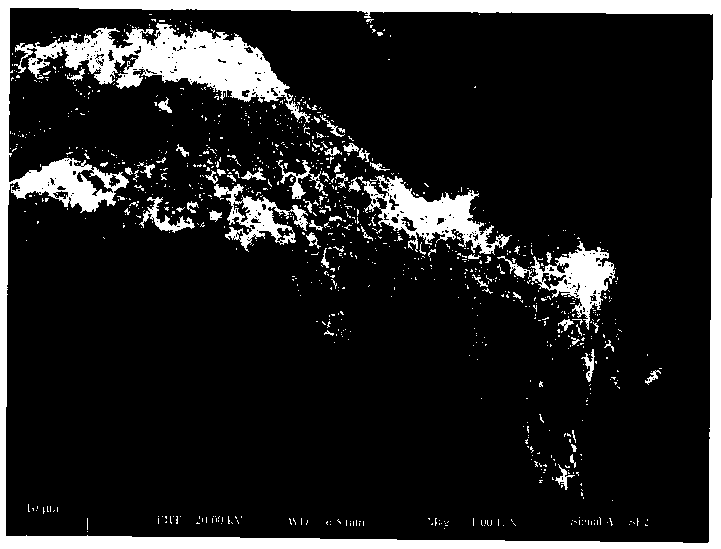

[0066] b. Preparation of nitrogen-doped porous carbon material: put the sol obtained in step a in a type furnace, first evacuate the tube type furnace, and then inject nitrogen gas for 5 minutes, and raise the temperature to 800 °C at a rate of 5 °C / min, and keep it warm Carry out carbonization activation for 2 hours to obtain a black solid, which is then washed with water in turn, washed with 10wt% hydrochloric acid until neutral, and dried at 120°C for 4 hours to obtain a specific surface area of 1650cm 3 / g, the pore volume is 0.9-1.12cm 3 / g, elemental analysis element content is: C: 65.8%, N: 5.2%, H: 1.59%; XPS surface anal...

Embodiment 3

[0068] a. Pretreatment of cottonseed hulls: crush the cottonseed hulls, put 8g of sodium hydroxide into a cylindrical container, add 15mL of water and stir to dissolve, then add 8g of urea, stir to dissolve, at a temperature of 25°C Add 6g of pulverized cottonseed hulls at the same time, and mechanically stir vigorously for 40min to obtain a uniform sol, which is placed in a magnetic boat;

[0069]b. Preparation of nitrogen-doped porous carbon material: put the sol obtained in step a in a type furnace, first evacuate the tube type furnace, and under the protection of nitrogen, raise the temperature to 800 °C at a rate of 5 °C / min, and keep it for 2 hours Carry out carbonization and activation to obtain a black solid, which is then washed with water in sequence, washed with 10wt% hydrochloric acid until neutral, and dried at 60°C for 8 hours to obtain a solid with a specific surface area of 2150 cm 3 / g, the pore volume is 1.23-1.36cm 3 / g, elemental analysis element content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com