Whole-process intelligent operation regulation and control system of wet desulphurization device

A wet desulfurization and control system technology, applied in the field of air pollutant control, can solve the problems of high energy consumption and material consumption in the operation of desulfurization devices, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

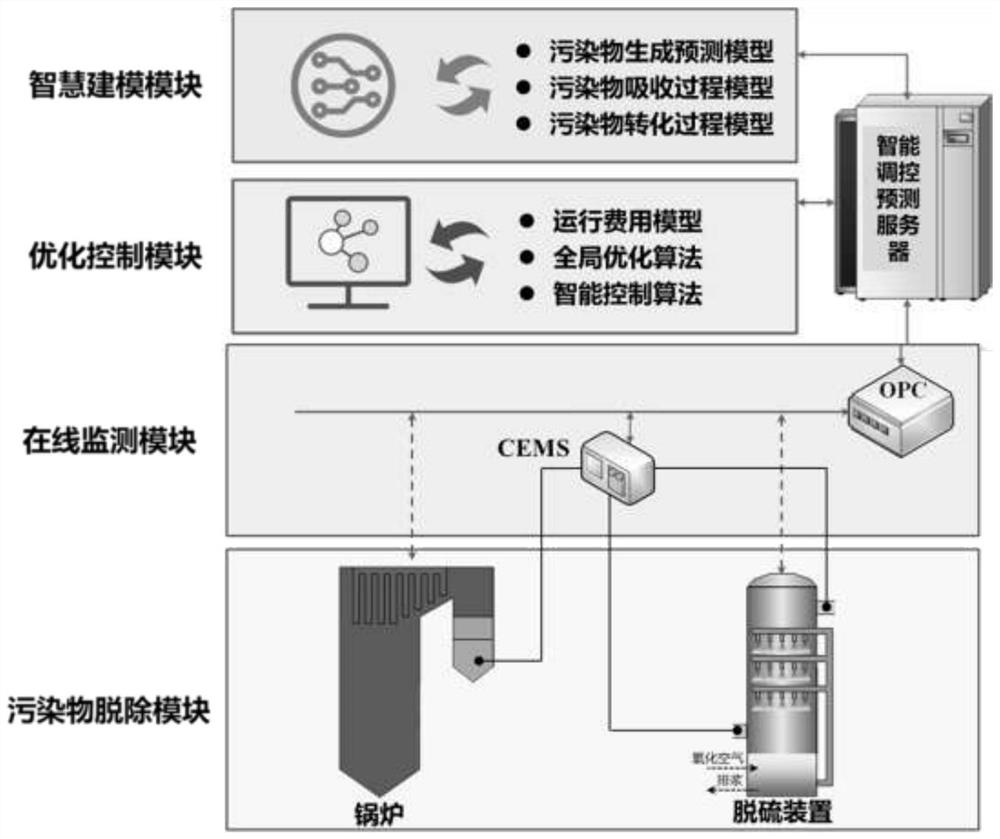

[0070] refer to figure 1 A whole-process intelligent operation control system of a wet desulfurization device, the system includes a pollutant removal module, an online monitoring module, an optimization control module and an intelligent modeling module. The pollutant removal module includes a desulfurization device for pollutant removal; the desulfurization device is the main pollutant removal device. The online monitoring module is used to monitor and collect historical operation data and real-time operation data of the desulfurization device and transmit them to the intelligent modeling module and optimization control module. It has a series of important functions such as information collection, preprocessing, integration, storage, and transmission. According to the real-time operating conditions, the optimization control module evaluates the operating cost of the pollutant absorption and removal system under different operating conditions in real time through a multi-objec...

Embodiment 2

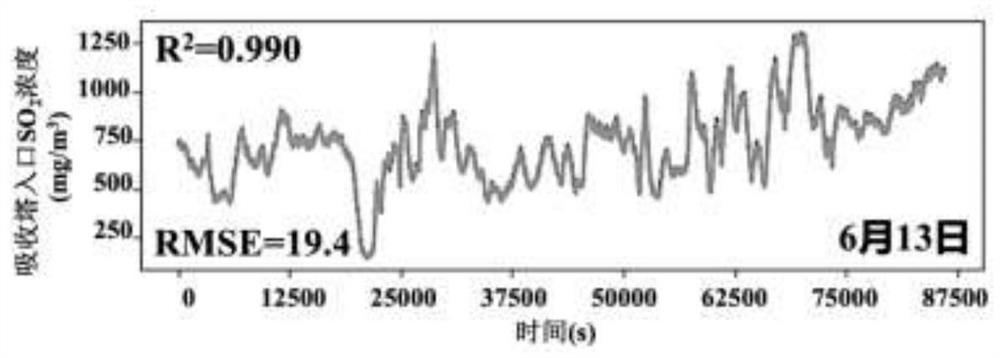

[0115] A combined heat and power unit uses coal-blended sludge as fuel, with a rated evaporation capacity of 220t / h, and is equipped with a 50MW backpressure turbine generator. The whole-process intelligent operation control system of the wet desulfurization device is used for engineering verification. The whole-process intelligent operation and control system of the desulfurization device includes a pollutant removal module, an online monitoring module, an optimization control module and an intelligent modeling module. The main body of the desulfurization device is an absorption tower, with a total of four spray layers, and each spray layer is equipped with an independently operating circulation pump. The online monitoring module (online monitoring device) equipped with the desulfurization device is connected with the optimization control module through the distributed control system (DCS), and the real-time monitoring, query and export of historical data and partial control f...

Embodiment 3

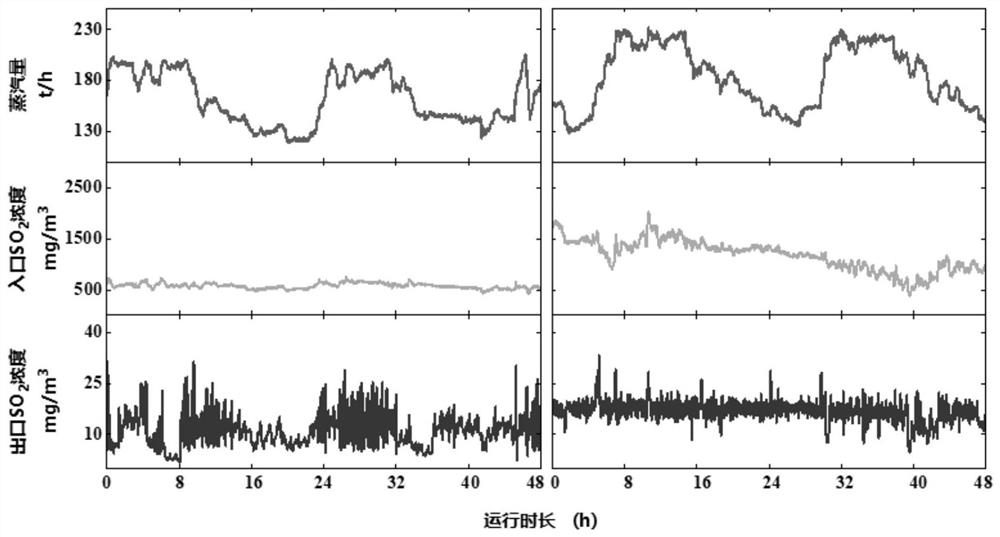

[0121] A combined heat and power unit uses coal blended combustion sludge as fuel, with a rated evaporation capacity of 130t / h, and is equipped with a 25MW backpressure turbine generator. The whole process intelligent operation control system and method of the wet desulfurization device are used for engineering verification . In a 130t / h coal-fired thermal power unit, steam volume, inlet SO 2 Concentration and outlet SO 2 The change trend of the concentration is as Figure 5 shown. It can be seen from Figure 5 that the entrance loads of the two are basically the same, and the intelligently regulated entrance SO 2 The concentration fluctuated greatly, but the outlet SO under the control of the original DCS 2 The concentration fluctuates greatly and exceeds the sulfur dioxide emission standard many times, while the outlet concentration control under intelligent regulation is stable, which proves that intelligent regulation can effectively improve the shortcomings of the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com