Novel beneficiation technology of high-grade ferrochrome ore

An iron ore, high-grade technology, applied in the direction of magnetic separation, solid separation, filtration, etc., can solve the problems that cannot be realized on a large scale and high energy consumption, achieve the effect of energy saving and consumption reduction, reduce the number of equipment, and reduce the amount of ore Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

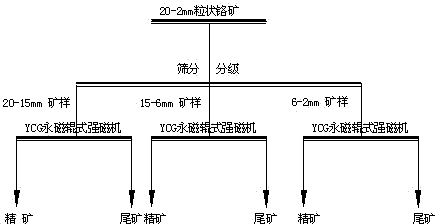

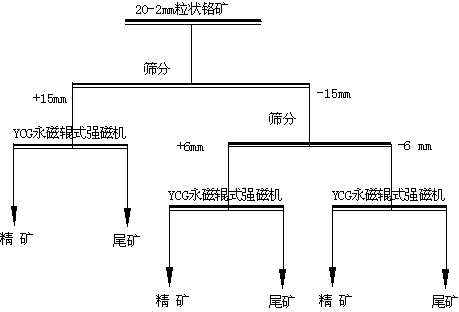

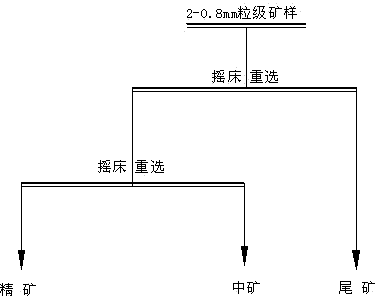

[0030] In order to describe the present invention, a new beneficiation process of high-grade chromite ore of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0031] The ore sample is DCM chrome ore of Sinosteel South Africa Chrome Industry Co., Ltd. The main valuable elements of the ore are chromium, Cr 2 o 3 The content is 34.49%; the main impurity components are SiO 2 , MgO and Al 2 o 3 , the contents of the three are 14.66%, 13.90% and 11.15% respectively. The results of chemical multi-element analysis of raw ore are shown in Table 1, and the analysis of other properties of raw ore are shown in Table 2, Table 3 and Table 4 respectively. The results of the iron phase analysis of the ore are shown in Table 5.

[0032] Table 1 Chemical multi-element analysis results of samples (%)

[0033]

[0034] Table 2 Chromium phase analysis results of samples (%)

[0035]

[0036] Table 3 Sample miner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com