Raw color matching yarn and preparation technology thereof

A color yarn and primary color technology, applied to spinneret assemblies, adding pigments to spinning liquid, textiles and papermaking, etc., can solve problems affecting costs, excessive transition materials or cleaning materials, and increased production of color spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0205] A preparation process for original color-matching yarns. Melts of different colors (black and white) are extruded from different spinneret holes on the same spinneret to obtain original color-matching yarns. The melts of different colors pass through different melts. The flow channel enters the distribution plate, and then is distributed to different spinneret holes by the distribution plate. The melts of different colors are directly polymerized. The melt materials of different colors are the same, which is PET melt. All the spinneret holes The cross section is the same, all are circular.

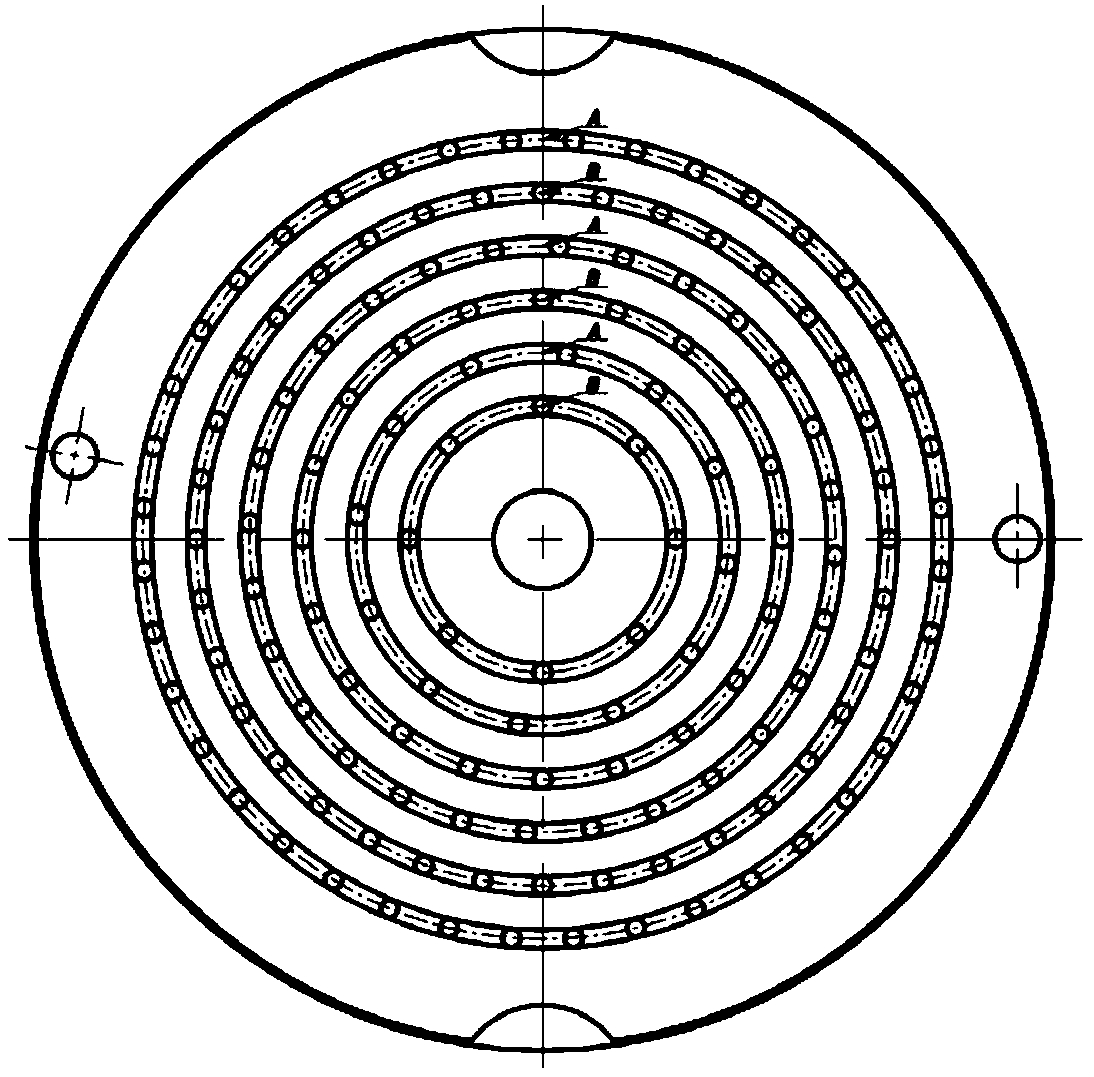

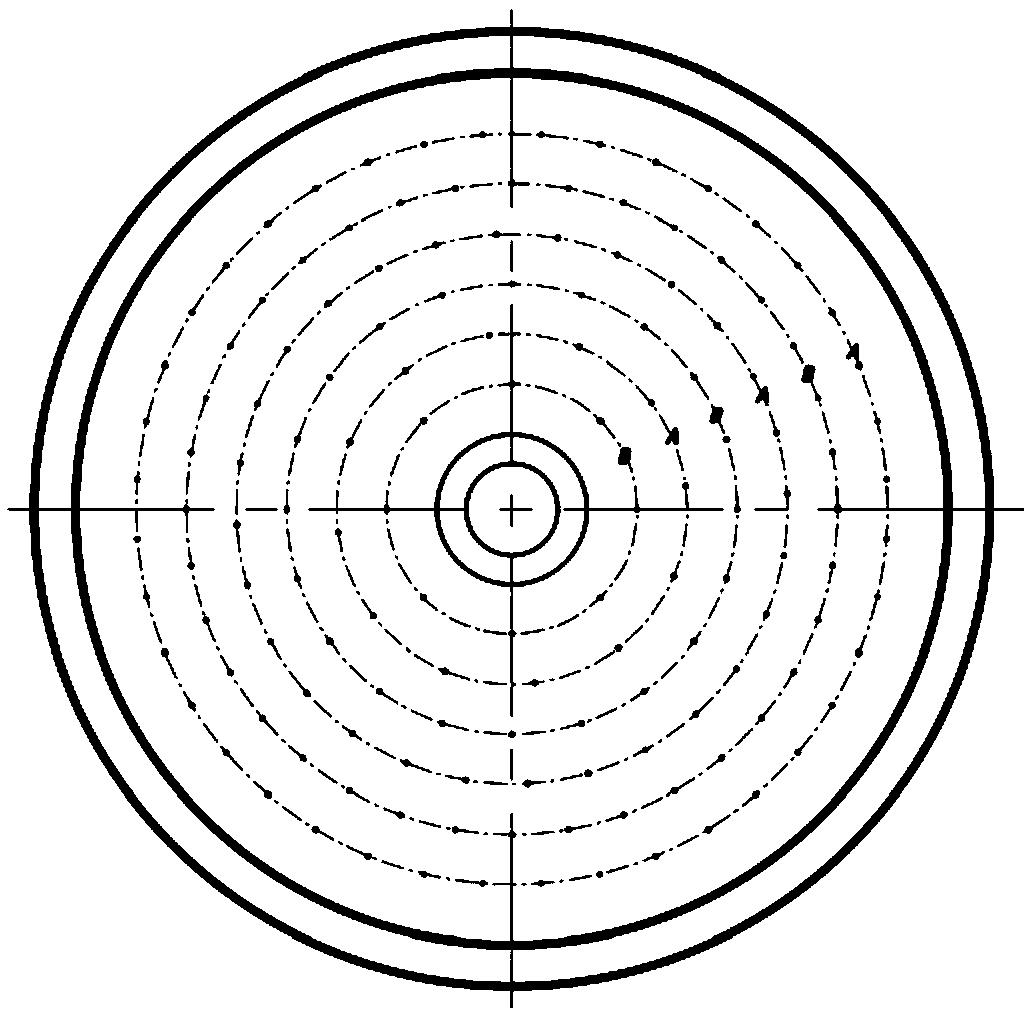

[0206] All the spinneret holes on the spinneret are arranged in concentric circles, and the arrangement of the spinneret holes corresponding to the spinning of two different colors of melts is as follows: figure 1 and 2 As shown, it is distributed in concentric circles, and melts of different colors pass through the spinneret holes on each circle arranged in concentric circles. One...

Embodiment 2

[0209]A preparation process for original color-matching yarns, in which melts of different colors (black and red) are extruded from different spinneret holes on the same spinneret to obtain original color-matching yarns, and the melts of different colors pass through different melts The flow channel enters the distribution plate, and then is distributed to different spinneret holes by the distribution plate. The melts of different colors are directly polymerized. The melts of different colors have the same material, which is PBT melt.

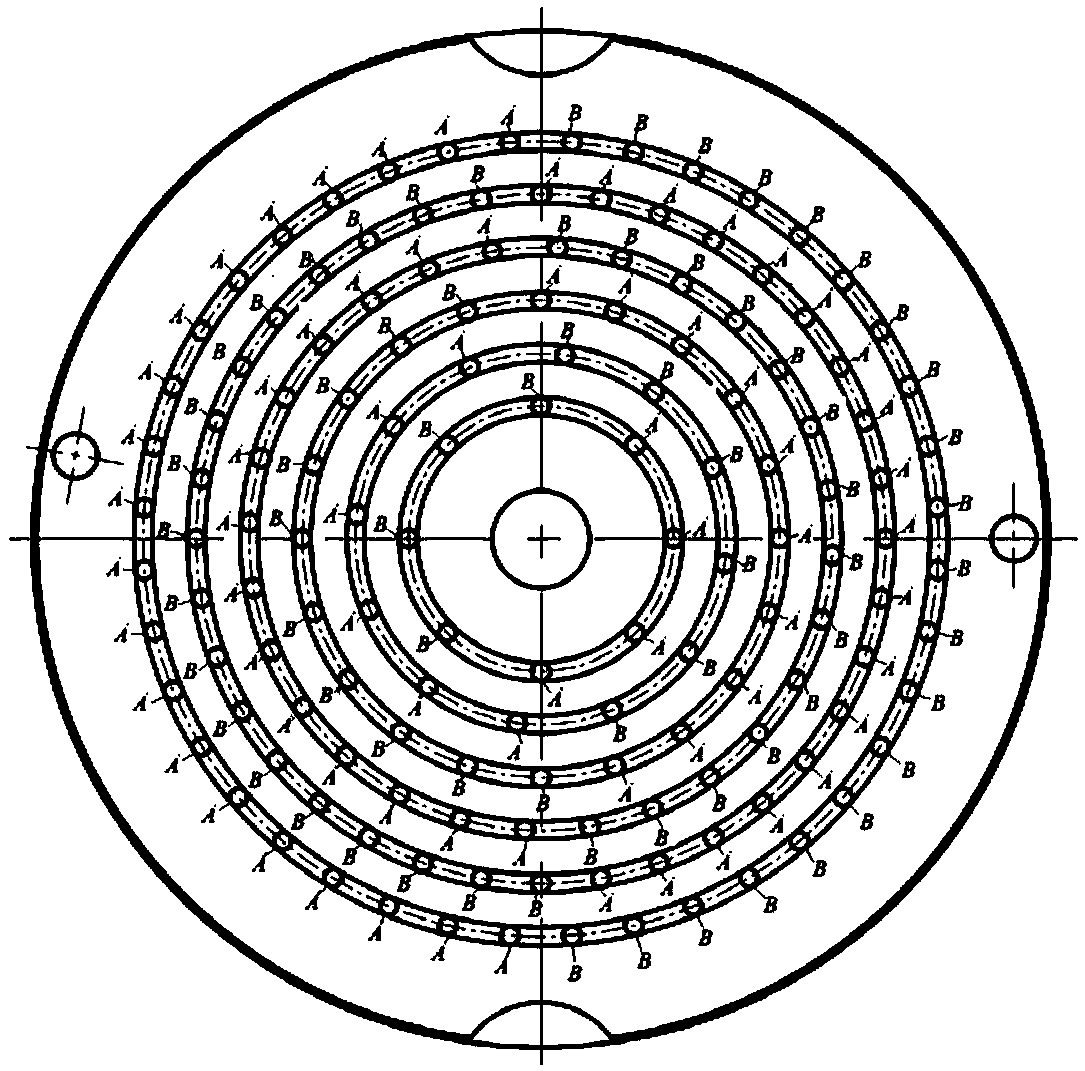

[0210] All the spinneret holes on the spinneret are arranged in concentric circles, and the arrangement of the spinneret holes corresponding to the spinning of two different colors of melts is as follows: image 3 and 4 As shown, they are distributed in concentric circles. Melts of different colors pass through the spinneret holes on each circle arranged in concentric circles respectively. One circle segment corresponds to different colors, and...

Embodiment 3

[0213] A preparation process for original color-matching yarns. Melts of different colors (black and white) are extruded from different spinneret holes on the same spinneret to obtain original color-matching yarns. The melts of different colors pass through different melts. The flow channel enters the distribution plate, and then is distributed to different spinneret holes by the distribution plate. The melts of different colors are directly polymerized. The melts of different colors have the same material and are PTT melts.

[0214] All the spinneret holes on the spinneret are arranged in concentric circles, and the arrangement of the spinneret holes corresponding to the spinning of two different colors of melts is as follows: Figure 5 and 6 As shown, it is in a radial distribution. The spinneret holes corresponding to the primary color fibers of each color are distributed on the radial lines. One line corresponds to one color, one color corresponds to twelve lines, and adja...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com