Ink-jet printer and method for printing seamless can using same

A printing device, inkjet printing technology, applied in the directions of printing device, printing, printing machine, etc., can solve the problem of lack of freedom, and achieve the effect of suppressing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

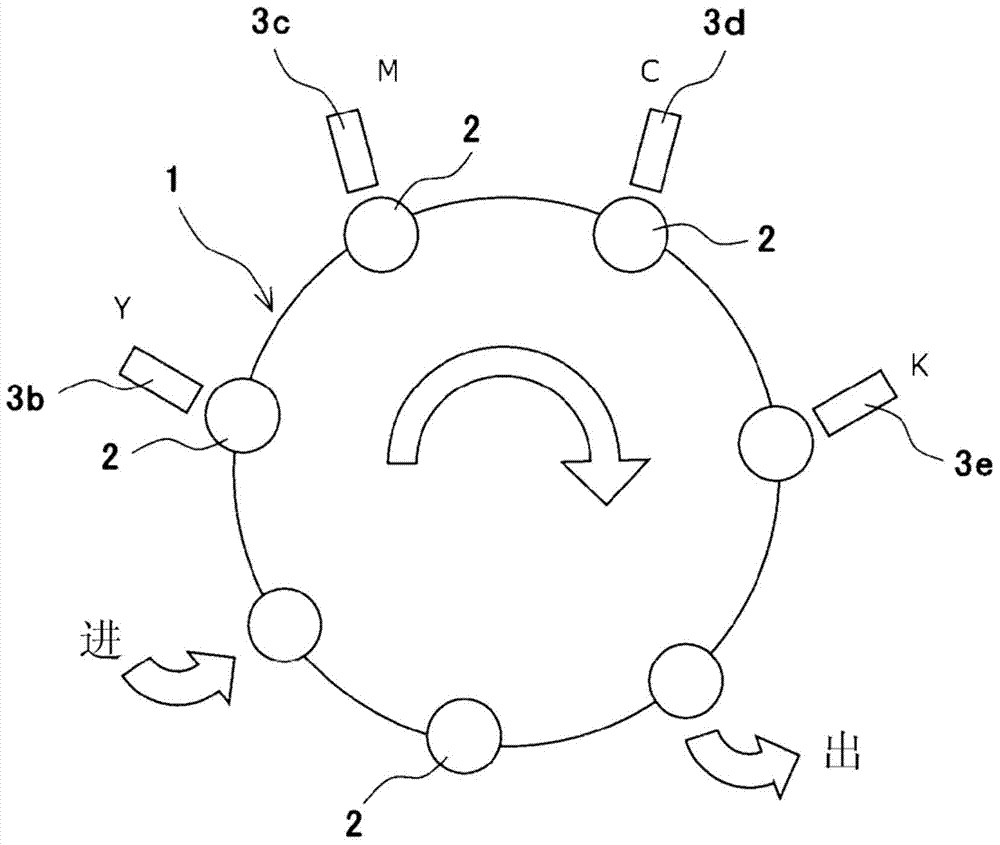

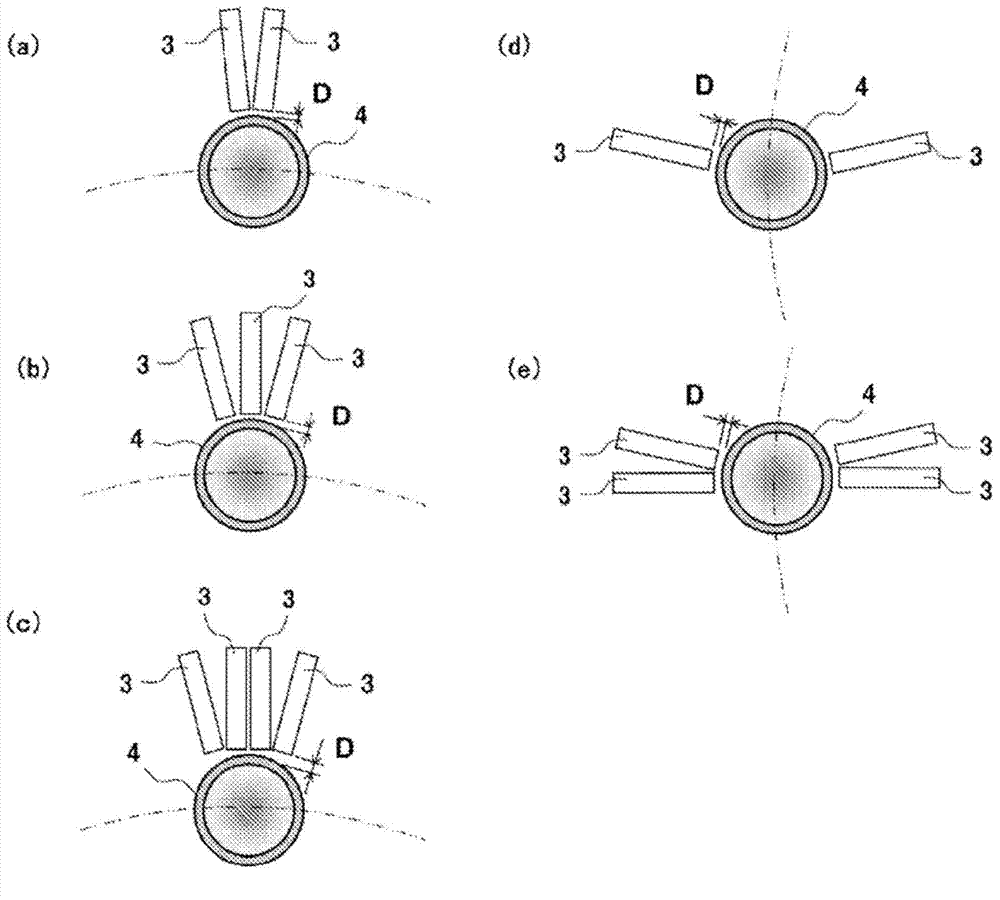

[0102] in such as Figure 7 In the inkjet printing apparatus of Example 1 shown in (a), two inkjet heads are arranged in each printing station. The printing stations were set up with a number of four, and the number of four, that is, with one in each printing station (in a way shared by two inkjet heads) was set Figure 4 The cleaning device shown in.

[0103] The printing station is arranged on the revolution track of the mandrel wheel ( Figure 7 outside of the dot-dash line in (a). The inkjet heads are arranged so as not to overlap with the orbital locus of the mandrel wheel, and are adjacent to each other above the orbital locus and face downward. The two inkjet heads in each printing station are of the same color. The inkjet heads in each printing station are arranged in the order of Y color, M color, C color and K color along the revolution of the mandrel wheel.

[0104] In inkjet printing devices, such as Figure 7 As shown in (b), the inkjet head is arranged alon...

Embodiment 2)

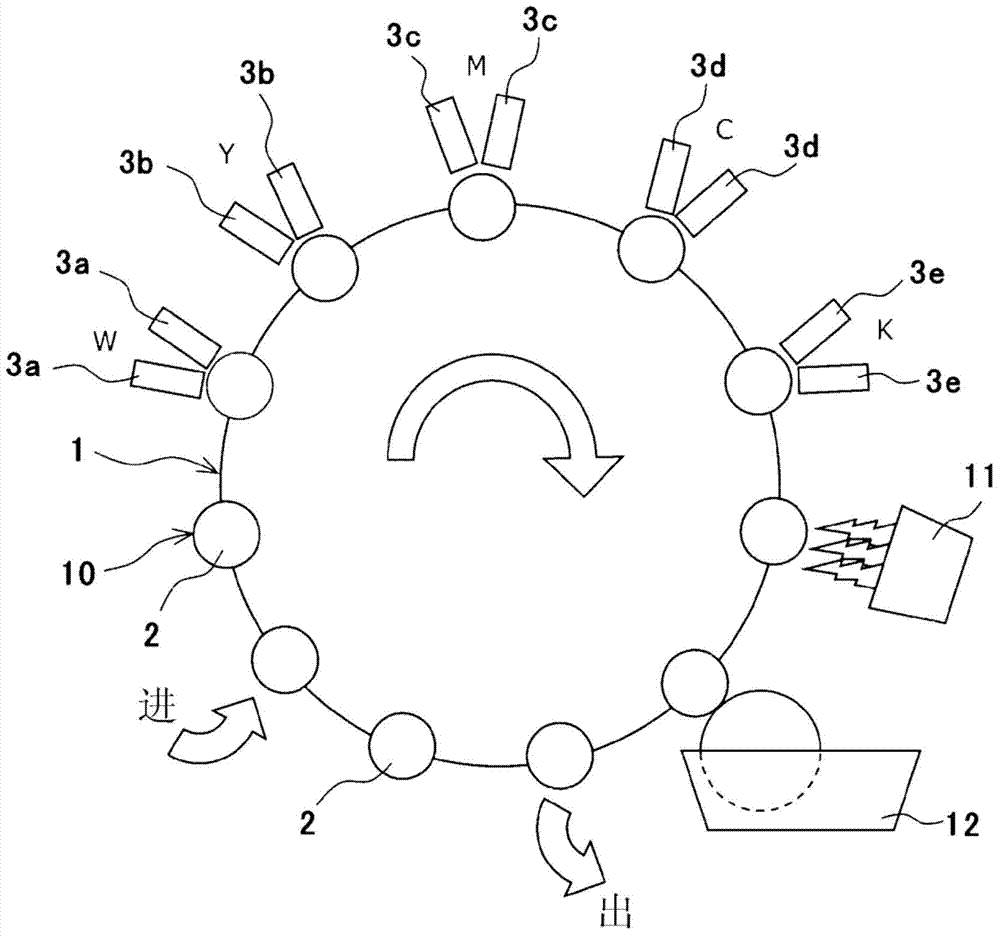

[0107] Such as Figure 8 As shown, the inkjet printing device according to Embodiment 2 has two heads in each printing station, that is, one inkjet head is on the orbit of the mandrel wheel ( Figure 8 The dotted line in (a)), the other inkjet head is on the inner side of the revolution track, and the mandrel is located between these two inkjet heads. Each printing station is arranged at a position movable in the up and down direction along the movement locus of the mandrel wheel. The inkjet head is arranged so as not to overlap the orbit of the mandrel wheel, and the inkjet head faces downward as much as possible while maintaining the minimum distance between the inkjet head and the tank. There are four printing stations and eight cleaning units (one for each inkjet head). Each printing station has two inkjet heads of the same color, and the two inkjet heads start from the lower side in the figure along the revolution track of the mandrel wheel and move upwards in Y color, ...

Embodiment 3)

[0110] Such as Figure 9 As shown, the inkjet printing apparatus according to Example 3 has four inkjet heads in each printing station, that is, two inkjet heads on the outside of the mandrel wheel, two inkjet heads on the inside of the mandrel wheel, and the core The shaft (seamless tank) is located between these inkjet heads. Each printing station is arranged at a position movable in the vertical direction along the revolution track of the mandrel wheel. The inkjet head is arranged so as not to overlap the orbit of the mandrel wheel, and the inkjet head faces downward as much as possible while maintaining the minimum distance between the inkjet head and the tank. There are two printing stations and four cleaning units (one for the two inkjet heads on each side). Each printing station has two inkjet heads of the same color on each side, and the two inkjet heads perform printing of Y color, M color, C color, and K color in a manner that follows the revolution of the mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com